Hi John,

As a first step you don’t need anything fancy to check if the chuck jaws and tailstock are worn. For the chuck, put a longish bar in the chuck and tighten moderately. Then see if you can move the bar by pushing and pulling by hand. The most likely error is that the jaws no longer grip parallel. If this is case the outer end of the bar should move.

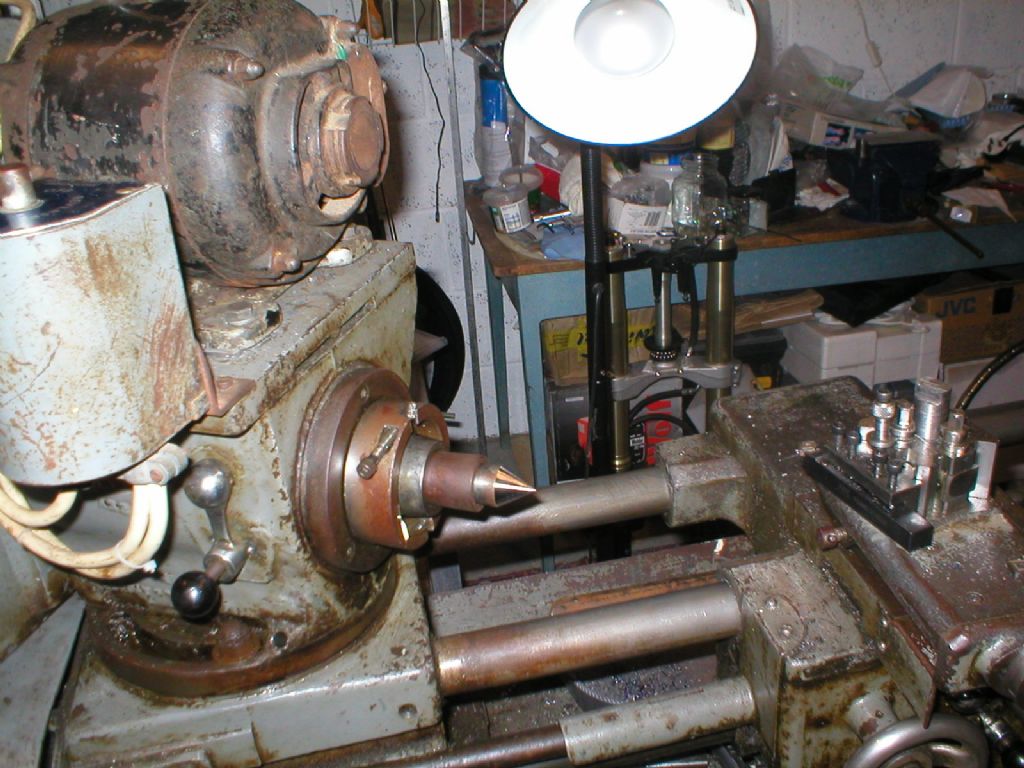

I assume that you have a Barker lathe, with the round bar bed? Interesting design concept. The tailstock looks a little short, so this may be where the play is. Wind the barrel out, apply clamps and see if you can move the barrel by pushing and pulling on the end. The most likely fault is some wear in the barrel housing, and this will be most apparent when the barrel is fully extended.

I wouldn’t even think about swivelling the headstock to turn a taper. Once it is set up to turn parallel, leave well alone. Apart from anything else, I don’t think it will be that easy to set. Much easier to move the topslide. It’s a right royal pain in the posterior adjusting a cylindrical grinder for Morse tapers, where it is relatively easy to adjust the table the odd thou at a time with a fine pitch screw. It’ll be more difficult on the headstock. According to my calculations 1 thou over 3″ gives an included angle of about 1 minute of arc. That’s the sort of accuracy you will need to achieve.

Best Regards,

Andrew

John Coates.