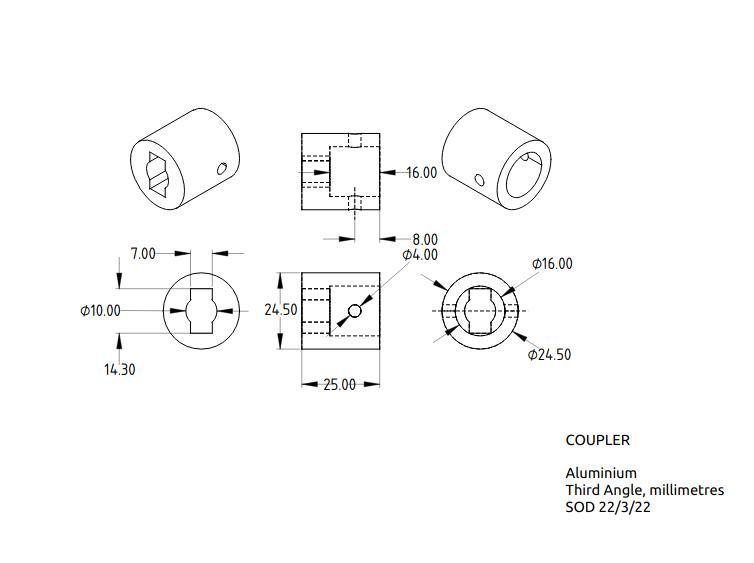

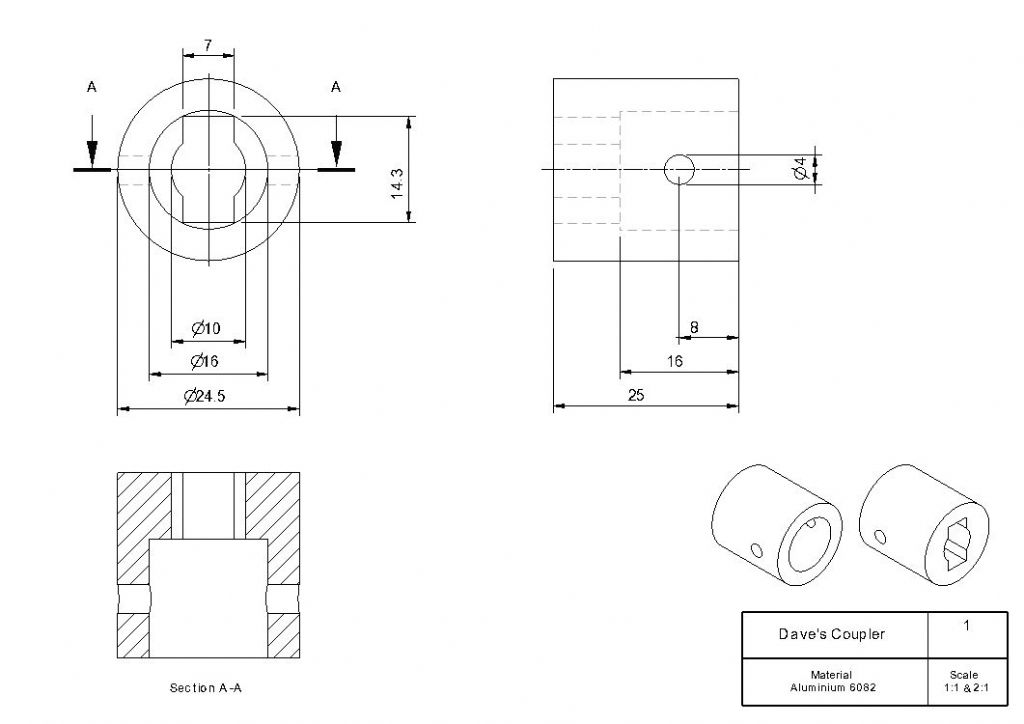

Special Mention in Despatches for Nicholas. His version gets the prize for maximum information in the smallest spacer without clutter:

Unfortunately, it's a little unexpected, and as Nicholas says: 'Doing that simple part was tedious, it isn't practical for a complicated one.' One oddity, when I first looked at it I saw an Einstein's Head inversion! Despite the brief optical illusion I like it. I believe FreeCAD/TechDraw could create most of the drawing automatically, so it may be more practical than Nick believes. I'll try it later.

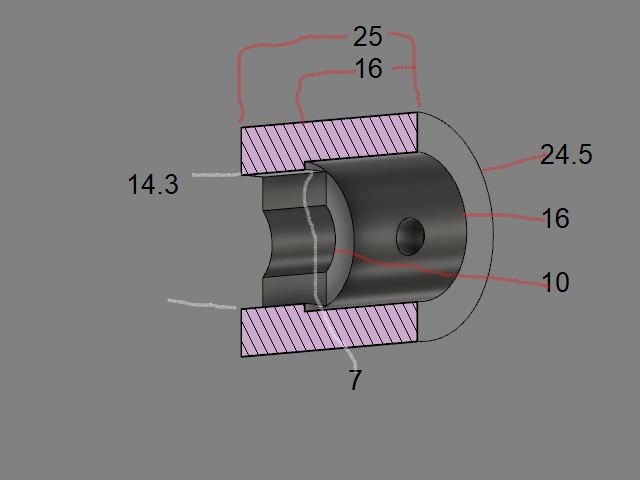

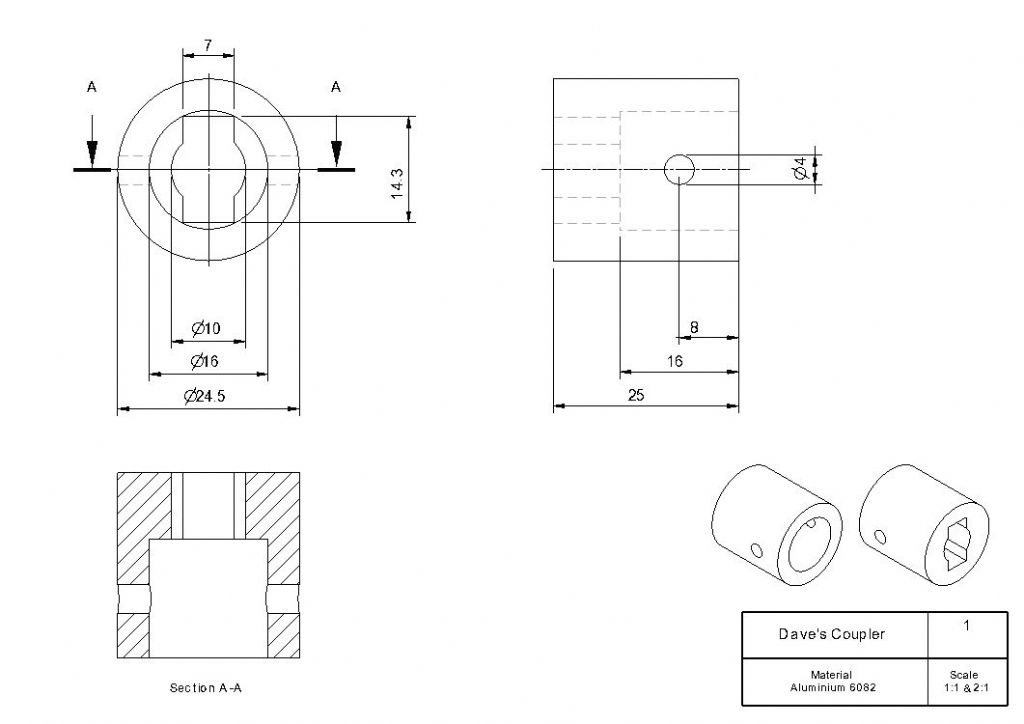

First prize goes to Jason.

It's cleaner than my attempt and I'm sure TechDraw can do the same. Watch this space.

Been reading what my 1947 Newnes Engineer's Reference Book has to say about Drawing Office Practice. It's based on B.S.S 308(1943) and how it differs from B.S.S 308(1927). Nothing is ever simple – two BS308s.

Much good advice in Newnes, but BS308 can be verbose too, as in 'Hole letter G drill (0.261" dia)'. And hard to see how clutter is avoided if BS302 surface finish, tolerance and other production information is added. Fortunately not needed on most home workshop drawings.

Newnes casts an interesting light on who actually produced the old Technical Drawings I admire so much. Good chance it wasn't a Draughtsman!

Newnes advises draughtsmen to concentrate on design, leaving most of the actual finish drawing to Tracers. Tracers specialised in producing the clean fully populated drawings needed for production from the Draughtman's drawings and notes. The tracer decided how the drawing looked and how it was completed: line thicknesses, dimension placements, titles, version numbers, reference numbers, colour, hatching, sections, and tables etc. He drew the nice arrow heads and other posh features.

Another specialist, the Checker, reviewed drawings independently before they were submitting them to the Chief Draughtsman/Drawing Office Manager for final approval. Big Drawing Offices were a team effort, with many opportunities to spot mistakes before anything got to a machinist. As I have to combine all these roles, and am untrained in all of them, I don't feel so bad about my mistakes now!

Dave

SillyOldDuffer.

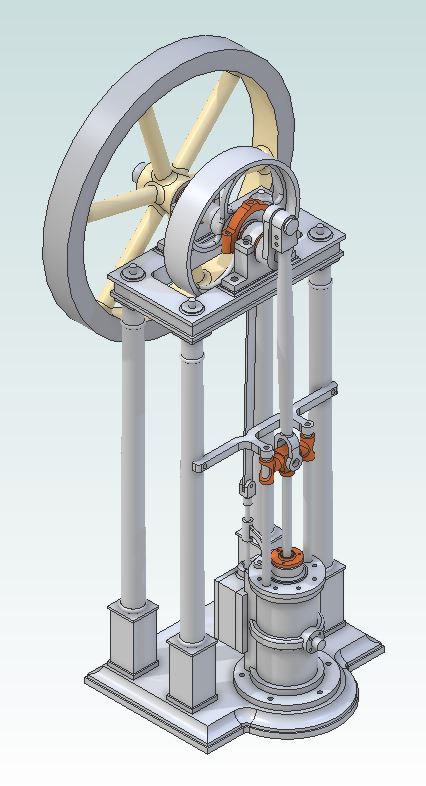

![20220321_155413[1].jpg 20220321_155413[1].jpg](/wp-content/uploads/sites/4/images/member_albums/44290/905830.jpg)