Part 2 – Options

Let’s run through the main options from which you may need to choose when buying your lathe:

As mentioned before, I would suggest going for as long a bed as you can obtain. Some suppliers may offer an induction hardened bed, this may appeal if you expect your lathe to enjoy a particularly long and hardworking life but should not be seen as a necessity for normal use.

Hardened bedways will extend the life of your lathe before the bed needs to be reground. The amount of hardening that can be applied to cast iron bed is limited, and mine has unhardened ways and has had a fairly typical sixteen years hobby use yet shows no signs of needing a regrind. I would suggest that this is a ‘nice to have’ but not essential.

The metric leadscrew/option is of greatest importance to those who wish to cut screw threads. It is possible to swap between metric and imperial leadscrews (and half-nuts) but as we will see metric threads can be cut on imperial machines, and vice versa.

Digital readouts are a point of debate. With the handle-type fitted to a mini-lathe they do not solve issues of backlash, but nonetheless some users find them invaluable. They can be retrofitted. A built in tachometer (speed readout) is useful at the beginning, but as you get more confident you will ignore the tacho and listen to the ‘cut’ instead.

A lever locking tailstock is a very convenient accessory, though it is not essential and can be fitted as an aftermarket upgrade.

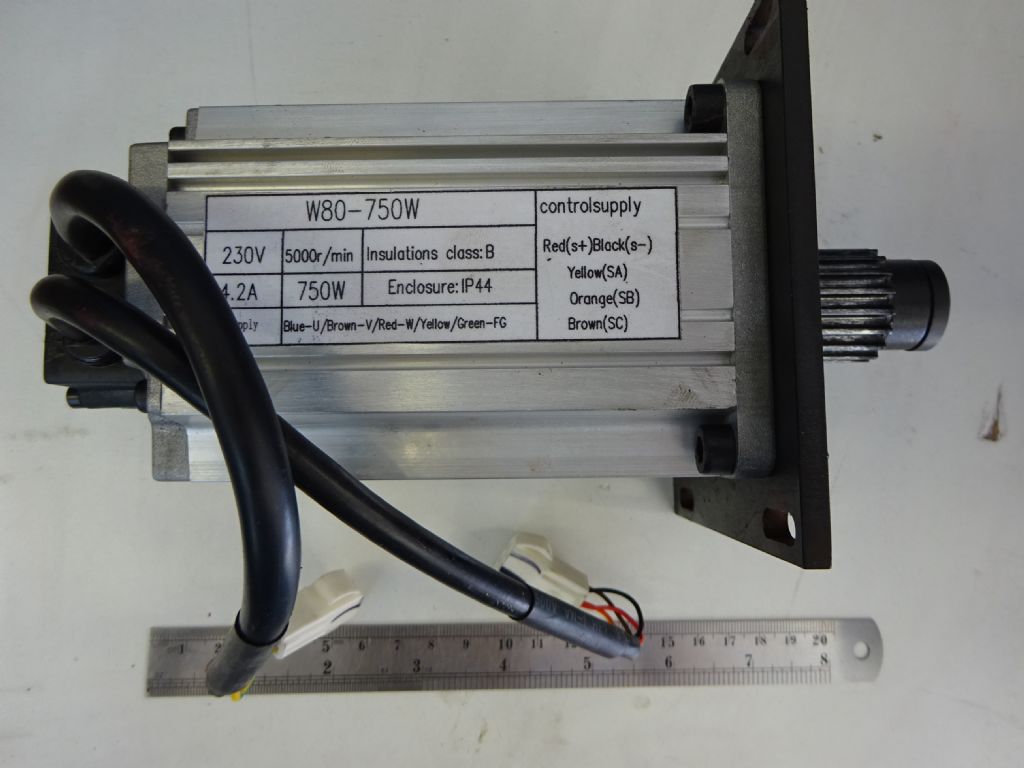

The option of a brushless motor is a good idea, especially if you hope to work the lathe quite hard. But unlike a locking tailstock it is not an easy retro-fit. This is not just as a new controller board is needed as well, but because the bed castings are different to accommodate the larger motor. That said, nothing is impossible.

None of these facilities are essential. A hundred years ago many model engineers did not even possess a three-jaw chuck and drove their lathes with a foot-motor (treadle). This did not prevent some achieving work of a standard far higher than I can attain with all my accessories! If you can afford just one of these options, you may wish to choose the lever-operated tailstock, not the high technology readouts. It is the one extra that you will use all the time, and it will make many repetitive tasks far quicker. Even so, this is an accessory you can add yourself later, either buying a lever tailstock, or modifying a bolt-on version.

A final piece of advice, increasing numbers of cheap mini lathes are appearing on sites like Amazon and eBay. Because both established sellers and 'fly by nights' use these selling routes it is hard for a beginner to know which of these machine are a good deal and which should be avoided!

If a lathe is not being sold by a company with a track record in selling to model engineers, then you may not get the after-sales support and service you would like, including access to spares or difficulty in returning a poor or broken machine.

Some distributors appear to import one container of machines, sell them, and disappear for ever. If you buy a lemon from such a source , you may have no recourse.

There are lathes out there which are QC rejects or 'bitsas'' assembled from scrap bins, spare parts or returns from different sources. If a price looks too good to be true, it probably is.

I hope this helps some beginners make a better informed choice.

Neil

old mart.