Posted by SillyOldDuffer on 20/08/2017 18:26:11:

Perhaps someone who owns a horizontal mill could comment on their pros and cons?

I have both vertical and horizontal mills. The vertical has a horizontal adaptor and the horizontal has a vertical adaptor. In both cases it is time consuming to swap from one mode to the other, not least because the vertical attachment for the horizontal mill weighs more than I can lift without requiring a visit to A&E.

If there is only room for one mill, then I'd lean towards vertical. A quill is essential, I do 99.99% of my drilling on the vertical mill. The quill is also useful for reaming and power tapping with self-reversing tapping heads. Personally I think that power feed on X, at least, is essential. If nothing else on the higher feedrates I couldn't move the handle fast enough manually.

My horizontal mill was a cheap impulse buy. Once it was cleaned up and settled in a final position it has proved to be rather useful. It knocks the vertical mill (Bridgeport) into a cocked hat in terms of rigidity and metal removal rates. Table X and Y travels are similar to a Warco WM16, but my mill weighs 3500lbs. Horizontal milling cutters are cheap on Ebay, provided you avoid the fantasists; I generally pay less than a fiver per cutter. A horizontal mill is good for cleaning up hot rolled steel:

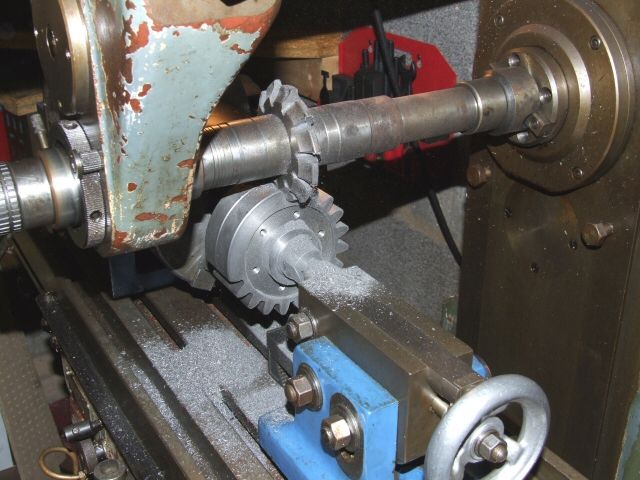

And for cutting gears small,:

and large, in one pass:

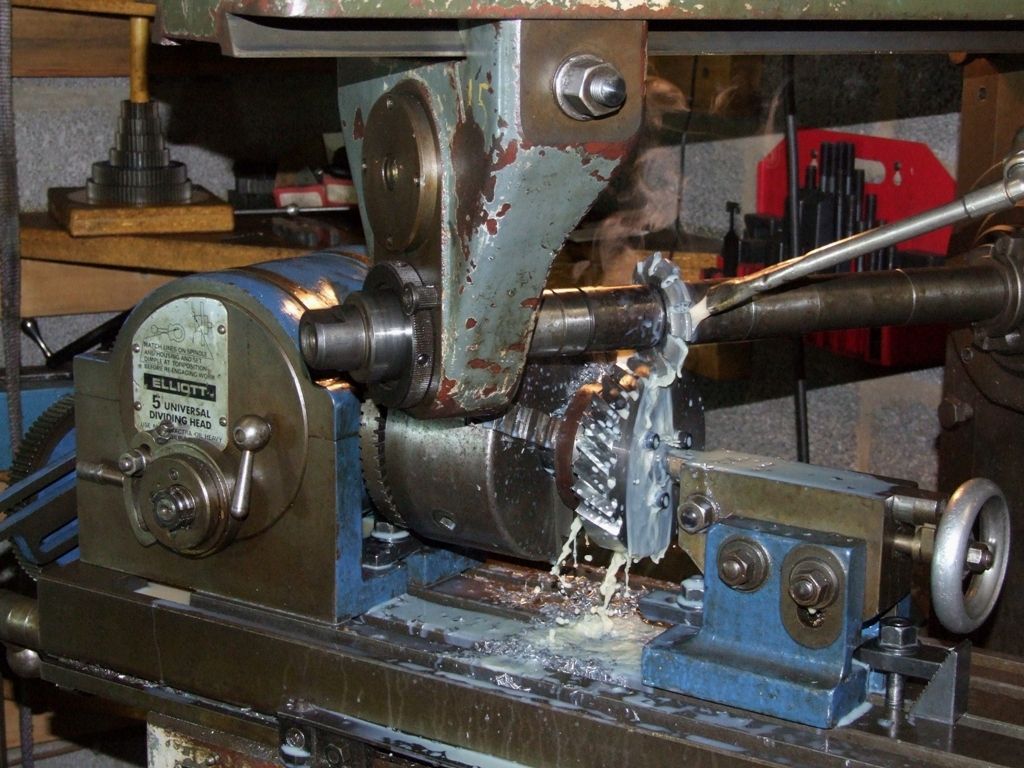

With a swivelling table they can also be used for gashing and hobbing worm wheels as well as cutting helical gears:

Total cost of the setup above was less than £600.

I will be using the horizontal mill to do the majority of the heavy machining on the cylinder blocks and smokebox castings for my traction engines.

While horizontal mills are possibly in second place to vertical mills they are a useful addition to the workshop.

Andrew

SillyOldDuffer.