Posted by Steve355 on 23/01/2022 13:15:45:

…

More expensive but easier and more flexible is a motor/VFD package. …

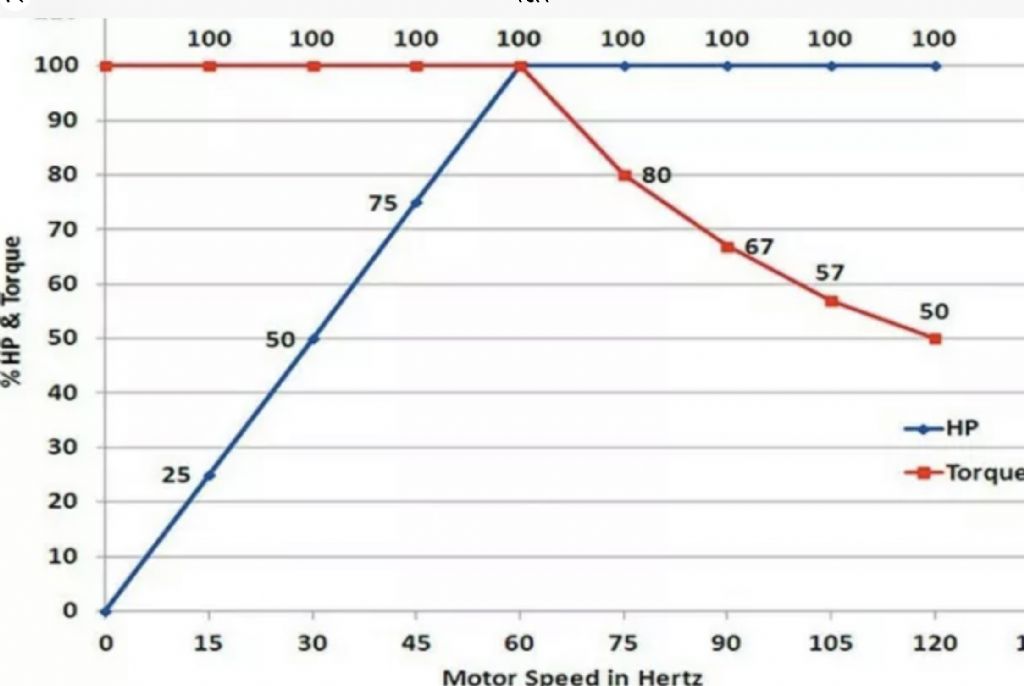

The thing is I don’t understand the hp rating of these setups at low rpm. They have linearly lower hp, but high torque – see diagram. My question is, does this matter? Or is it torque I need rather than hp?

I have seen lots of geared motors for sale but they all have very low hp. Again, does this matter? Or are they high torque?

thanks

Steve

First, you might try fitting a 6-pole 750rpm motor. This example from Bearing Boys is 0.75kW, other powers available.

Second, control it with a VFD. The 6-pole/750rpm motor is better placed to deliver lower RPM whilst maintaining power output than a 1500rpm motor.

Torque and Power make my head hurt, but I'll have a go at explaining it/

- Power is the rate at which work can be done, note time and a unit of work are both involved. An example might help to put the two in perspective. 1HP (746W) allows approximately 1 cubic inch of steel to be removed in one minute. Therefore a ½HP motor will take twice as long (2 minutes) to remove a cubic inch of steel, and a 2HP motor will remove one in 30 seconds. As about 1 cubic inch per minute is a rate of work that suits most ordinary workshops, 'our' machines typically come with motors in the ¼HP to 2HP range. I guess Model Engineering tools average about 1HP, which is always a good guestimate – not too weedy and not over the top bonkers.

- Torque is twisting force, measured in Newton Metres. Imagine a stopped motor at the moment it's switched on. As RPM is zero, the motor cannot be doing any work – it's power output is also zero. Torque is the force that accelerates the motor up to speed. When the motor is delivering power, applying a braking force greater than the Torque will stall the motor.

The amount of Torque produced depends much on the design of the motor. Single-phase motors and petrol engines both suffer low torque at low RPM, and need to be up to speed before the load is applied. Three-phase motors have much higher starting torque, and stepper motors deliver maximum torque when stopped. All motors lose torque when over sped.

Even though it's vital I tend not to worry about torque much. Machine tools aren't heavily loaded from the get go. Therefore, provided the motor is of reasonable power, it should have enough torque to start and accelerate up to operating speed. If the operator stalls a machine running at design speed, he's working it too hard. Bad driver: back off. Unfortunately, overheating, mangled brushes, sheared gears and other damage are likely before a stall finally issues a Red Card.

The graph means the motor delivers best power and torque at 60Hz. No surprise in a motor designed to run at US mains frequency. The motor maintains Torque as the VFD frequency and hence RPM drop – it won't stall. But the rate at which the motor can do work does fall with frequency. It's power output is halved at 30Hz, so it would take twice as long to finish the same work done at 60Hz. The graph also shows that speeding the motor up maintains the power output (it doesn't increase), but the torque falls. It's twice as easy to stall the motor at 120Hz than at 60Hz. (A VFD is likely to reduce this effect electronically.)

Loss of torque and power might make the VFD sound a dicey proposition, but speed control is a major advantage that usually outweighs the disadvantages. For example, surface speed is arguably more important when cutting metal than power or torque. Certainly true of my lathe which I measured with a Wattmeter: even though the motor is good for 1.5kW out, I never use anything like that during normal work. Usually power input is between 200W and 1000W, with most cuts taking about 800W. The VFD, helped by a simple two speed belt runs the spindle at the RPM I want without any practical effect on power or torque.

When speed is changed with a gearbox or belt drive the ratio effects speed and torque inversely. The relationship is simple: decreasing speed increases torque, whilst increasing speed decreases torque, both pro-rata.

Dave

Steve355.