I've got, or have had, all varieties and would agree with Jason that the adjustable work table is most likely to be satisfactory for a wide range of work. Often slowest to set up and, out of the box, tilt angle is frequently limited to 45° or less. If I had one like that in Jasons picture as my one and only and had regularly used angles I'd seriously consider making a new support arm with plain drilled holes suitably positioned to get the angle instantly. Unless fitted for a gauge block stack, sine bar style, getting an angle dead nuts can be a pain. Pretty darn close with a protractor is easy tho'.

Bearing in mind that my mill is a Bridgeport and work is frequently 12" to the ft scale, so my rigidity requirements are perhaps somewhat more exacting than those of folk with smaller machines my personal assessment is :-

1) Inexpensive type angle vice with two pivoting side plates. OK as a drilling vice but may well be iffy as a milling vice unless only using very light cuts. Time was that the machining, manufacture and alignment standards were poor. Fair few articles written on how to measure and correct errors. One of the import products that cemented the early reputation of "kit of parts supplied assembled to save printing instructions". Consensus seems to be that once reworked you had a very decent device for a very modest outlay. I wouldn't know, mine hit the scrap bin so hard that it nearly bounced out! I'd hope that, in line with much of the other imported equipment, quality standards have risen since so that they can be used out of the box. However the precision needed to be really good is deceptive and I suspect the market won't accept a commensurate price.

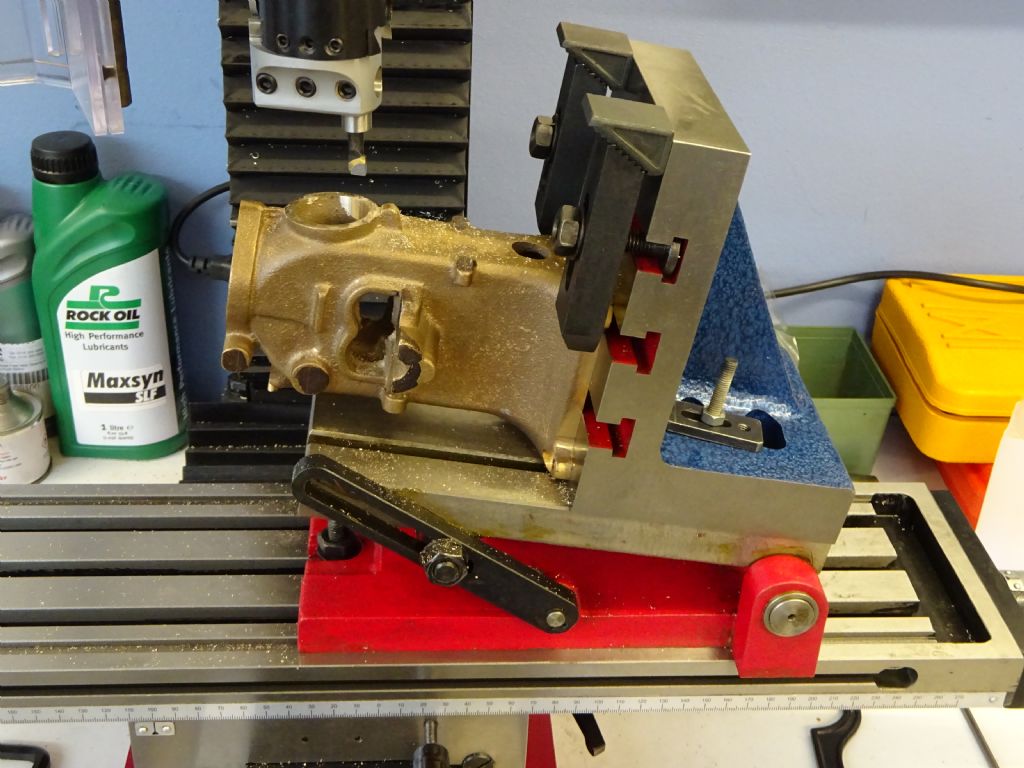

2) Inexpensive angle vice with part circle pivot runners each side and locking screw one side to hold the setting. Drilling only. Which was what mine was got for. Seriously chancing your arm if you expect it to stay in place when milling. Mine came from Northern Tools (remember them) at a very attractive price and is quite accurate with negligible twist between vice jaws and pivot axis. Better than I expected actually. Still comes out for appropriate jobs.

3) Proper pivoting vice with part circle recesses in base and matching runners in under the vice body with two bolts to hold the setting. Mine is a 6" Abwood on a rotating base. Very heavy, crane onto table, and rock solid. Needs a screw jack underneath to adjust it. Lord knows what it cost new. Can't see that quality at import prices but the design is inherently solid. Be advisable to check the alignment of the vice jaws and pivot axes to quantify any variation with movement. Unlikely to be anything that can't be worked around or fettled out.

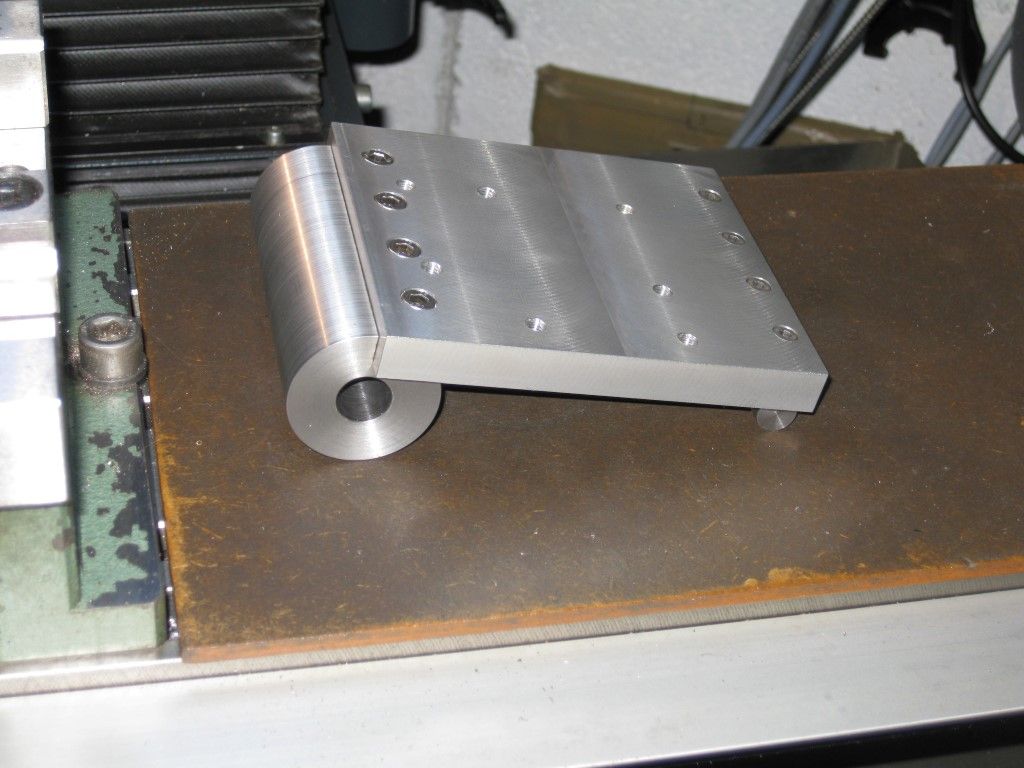

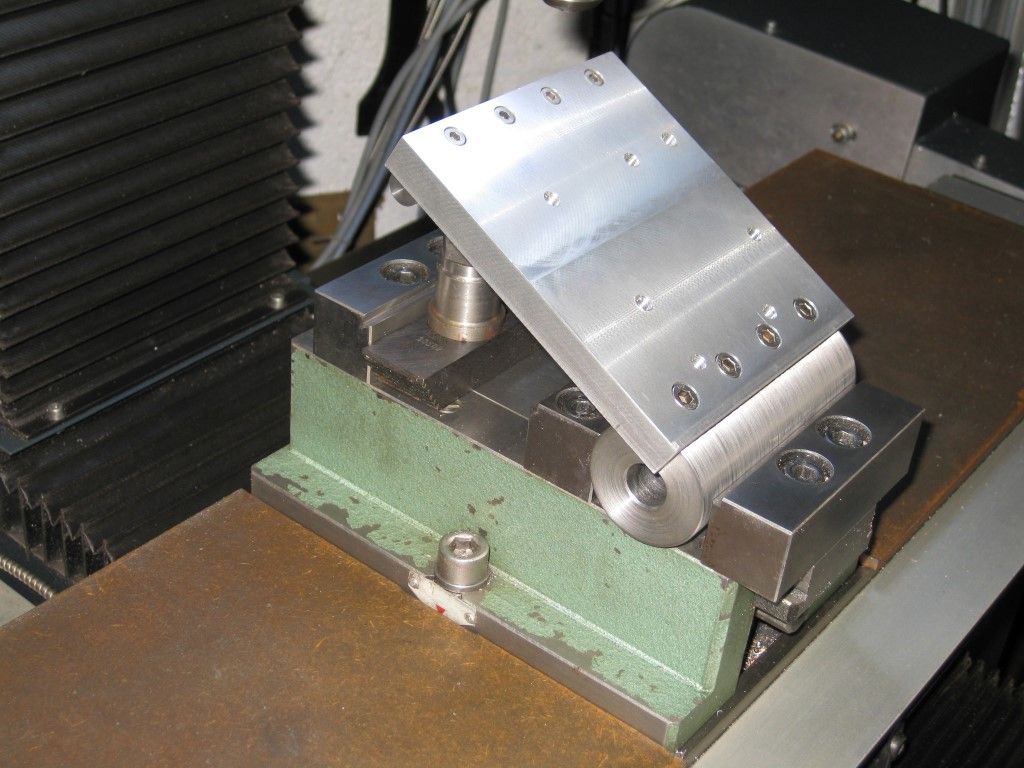

4) Adjustable angle plate. Mine is a British made one of the style having a more or less semi-circular base with the plate running round it. For my money the most solid type of angle adjustable work support likely to be a accurate at a modest price. Often advisable to bolt a handle on to the plate to help with adjustment.

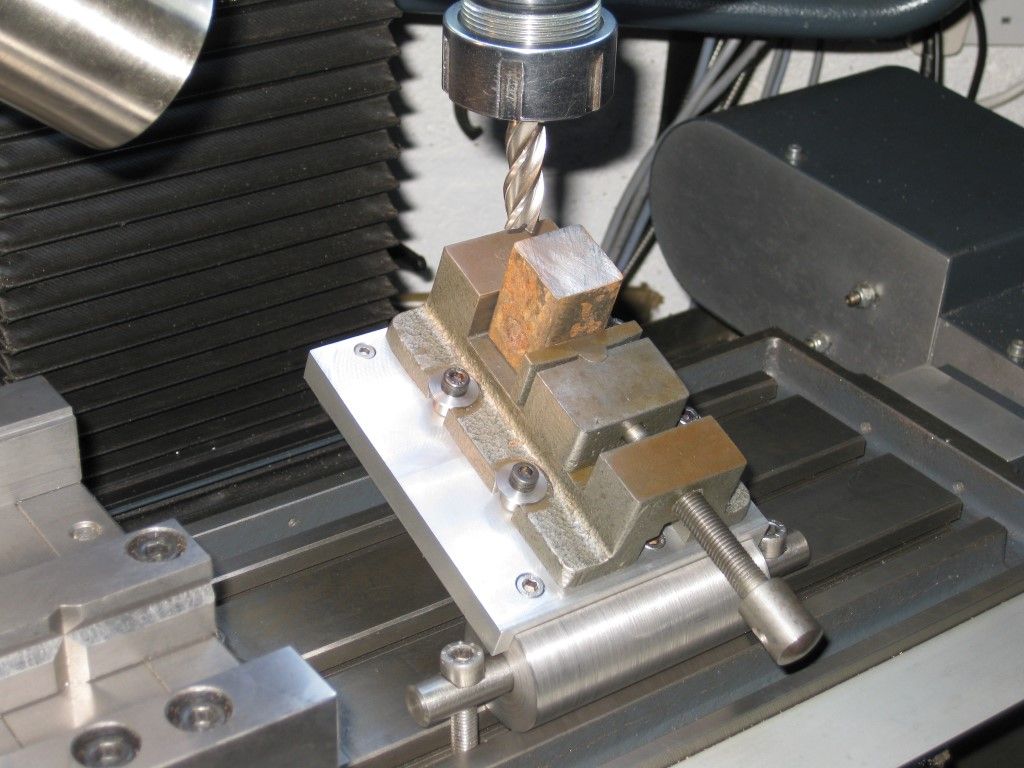

5) Adjustable work table. Best ratio of carrying capacity to weight. Not something to be overlooked when lifting onto the machine. Simple design means its easily made to decent accuracy at modest price. Not as inherently stiff as no 4 but up for all rational cuts. Major disadvantage is that its not a complete solution out of the box. Need other devices, like Jasons angle plate, to do the actual holding. But you should have such things anyway and, even if you need to get them, they will find plenty of other uses. Although vices are convenient they can be dreadfully limiting. Mine is a double one that tilts in both directions with fittings for gauge block stacks. When you need it there is no substitute but jobs really needing it are best avoided unless well paying.

Clive.

Neil Lickfold.