It has been a while since I last posted anything on this thread. I have just completed a couple of items. The first is an adjustable lever that fits inside the belt cover and thus saves me looking for an Allen key. Having to search for an Allen key is one of my pet hates when it comes to using my machines.

The Lever above is shown in the locked position and is so designed that the guard will only close in this position.

This image shows the lever released. One thing that no longer happens is the Pulley tilting over as it did when using a capscrew to lock the assembly. That is because an M6 stud now replaces that capscrew and thus keeps everything vertical.

Changing speeds is no longer a hassle of trying to get a belt over a constantly moving pulley.

The next item is something that came about after a suggestion and a PDF from John Slater. The PDF was a set of drawings by Stefan Gotteswinter for a Low Level Clocking attachment. I am beginning to think John is clairvoyant as this is something I had been thinking about for sometime for the Proxxon.

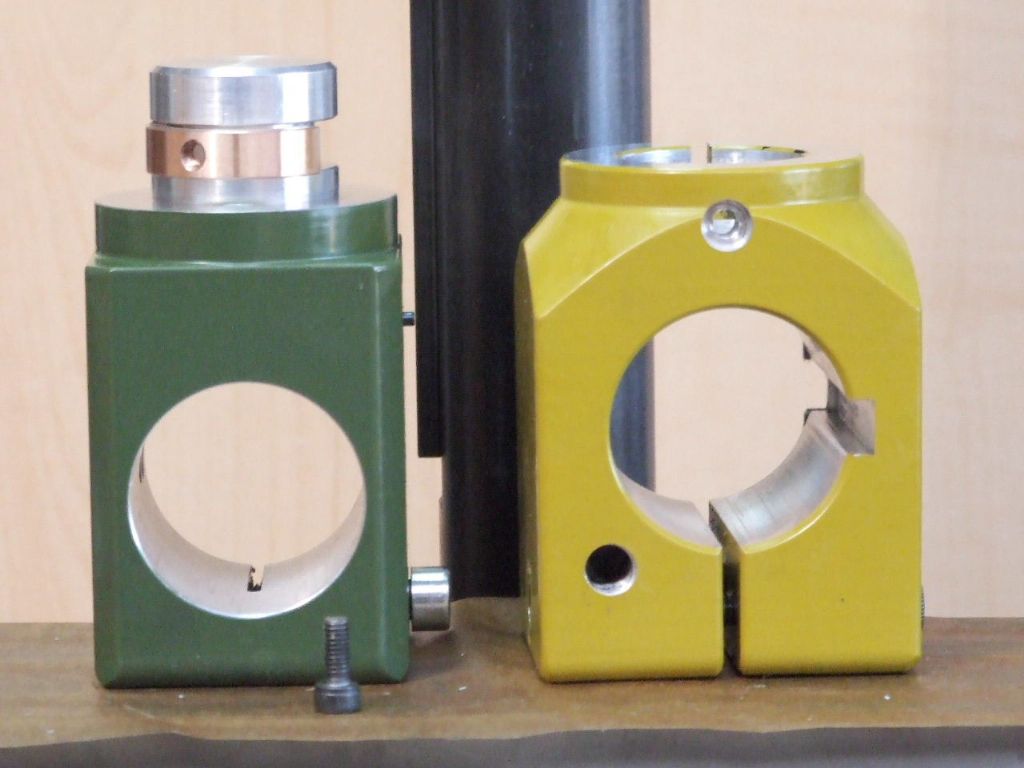

Whilst Stefan’s design was for a simpler sliding mechanism. A rabbit hole was introduced with regards to “it would be a good idea if the attachment had a fine adjustment”. While I disappeared down one rabbit hole John came up with a different design.

However I wanted something specific to the Proxxon, and as such had a restricted swing before the attachment hit the Column of the machine. John having the larger Sieg mill needed a greater swing and had the luxury of more room under the spindle.

Not fancying having to screw the clock from one end to the other. There is a spring loaded quick acting nut fitted. Which allows rapid adjustments without the need for the fine adjustment. In Stefan’s original design he incorporated an eccentric arbor to mount the unit on. This allows the stylus of the clock to be set on the machine centreline. His design needed the clock to moved out of the way for each adjustment. My design has a split clamp to allow adjustment and a shoulder which stops the whole unit dropping off the end of the arbor during adjustment. As such the clock is much easier to set-up on centreline.

This shows the unit in the machine.

As can be seen from the proximity of the clock dial to the slide bar this is a very compact design.

This last view shows the quick acting nut button. Pressing this disengages the feedscrew and allows rapid adjustments. The clock fitted is one of the shortest on the market that I could find, without spending a fortune. As this clock will remain fitted to this unit.

If the Moderators think this last item warrants a new thread then I am good with that.

Regards

Gray,

Graham Meek.