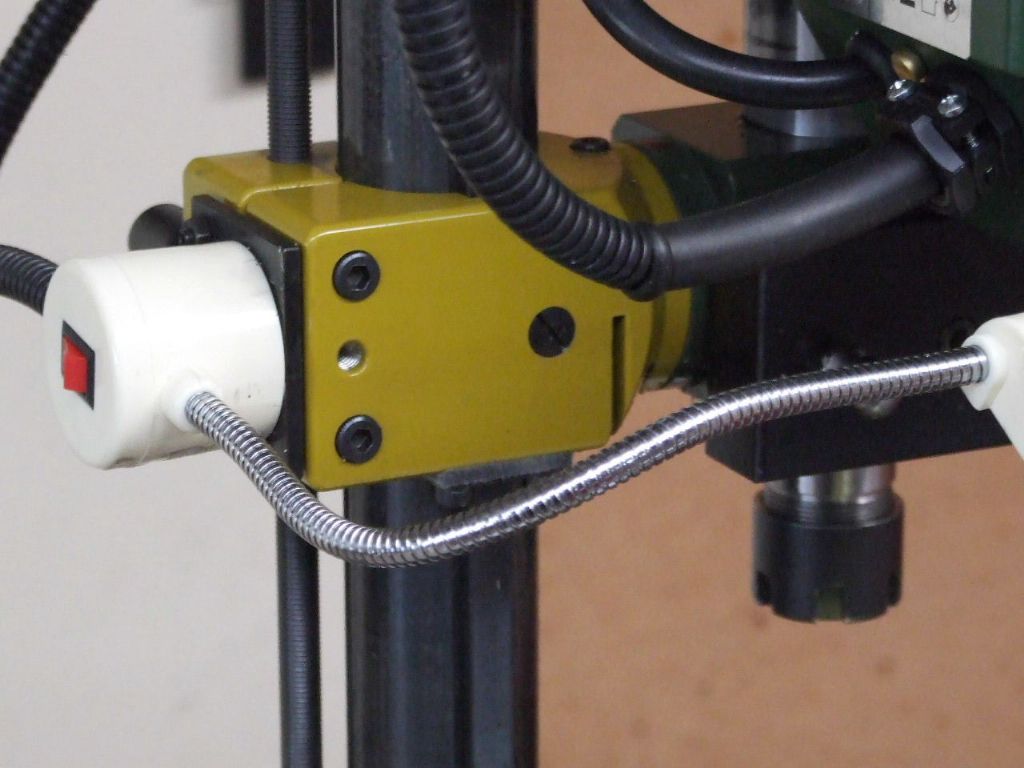

Posted by Kiwi Bloke on 20/02/2023 00:30:45:

Gray. Interesting mod, that can be applied to other machines, of course, and beautifully executed, as we've come to expect. Two questions…

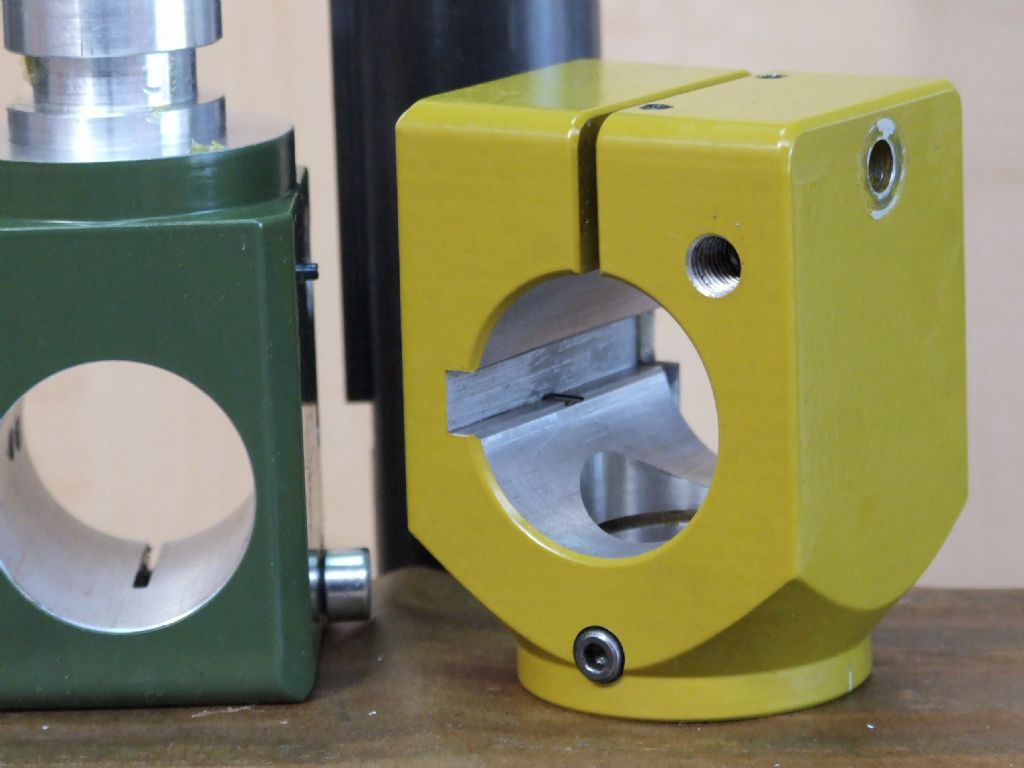

1. Why did you choose to use a roller (ball bearing set) to follow the guidance strip/key, rather than fit a gib strip?

2. (Apologies if I've overlooked the answer). Is the column's guide strip/key located in a groove in the column, or just planted on its surface, or on a flat?

Hi Kiwi Bloke,

I apologise for not responding before but I did not see this post.

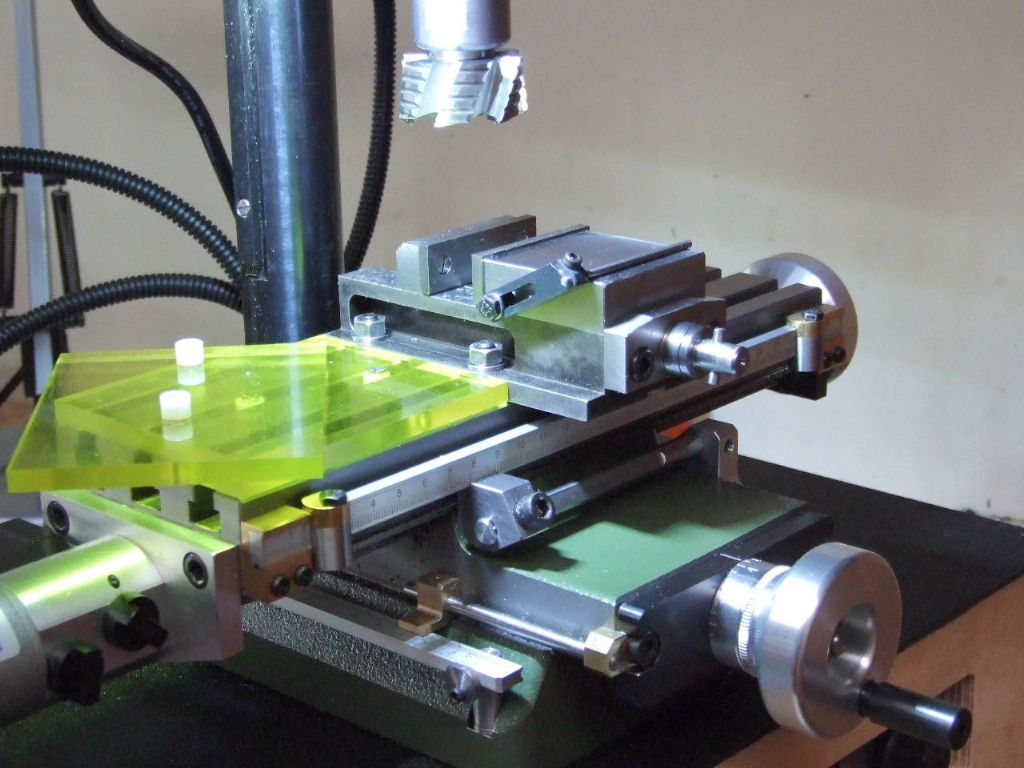

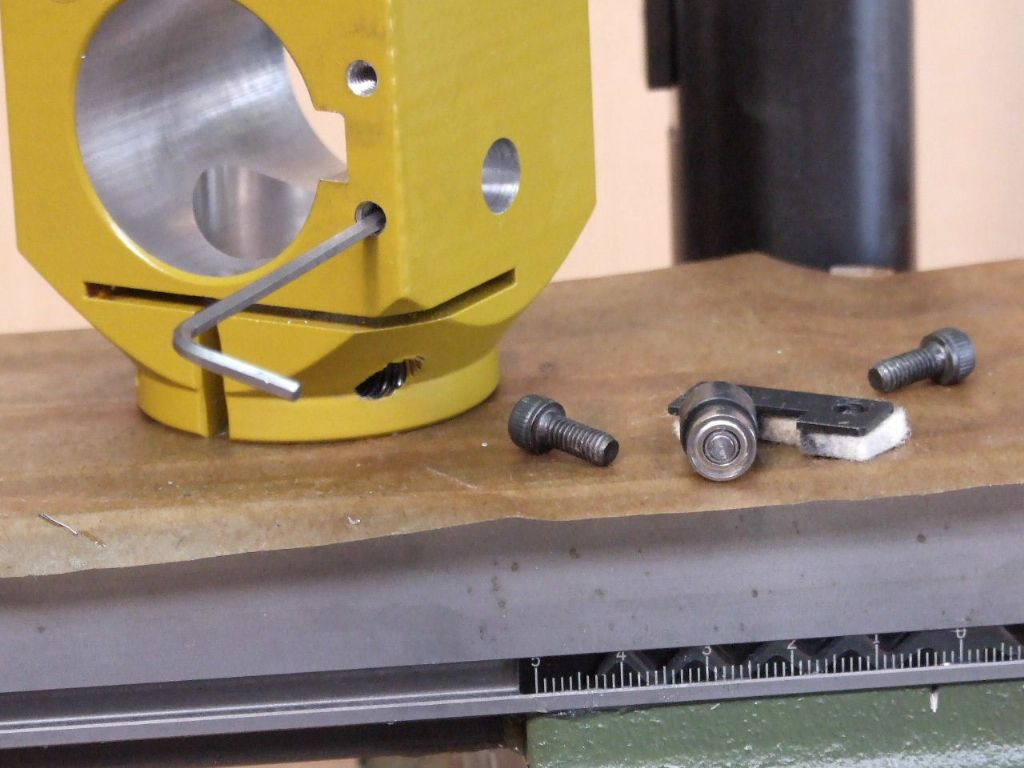

1. To fit a Gib adjustment strip would necessitate opening up the Keyway in the Slider. Twelve months ago when I had my other equipment this would not have been a problem. Today that would be impossible unless I subcontract the job, which is fraught with problems.

Fitting a Gib here would also mean putting the adjustment screws in from the back of the machine.

When the head is unlocked the turning couple due to the weight of the milling head. Tends to concentrate the force at the top of the rear face of the Keyway. This would be directly onto the Gib strip if it was situated here.

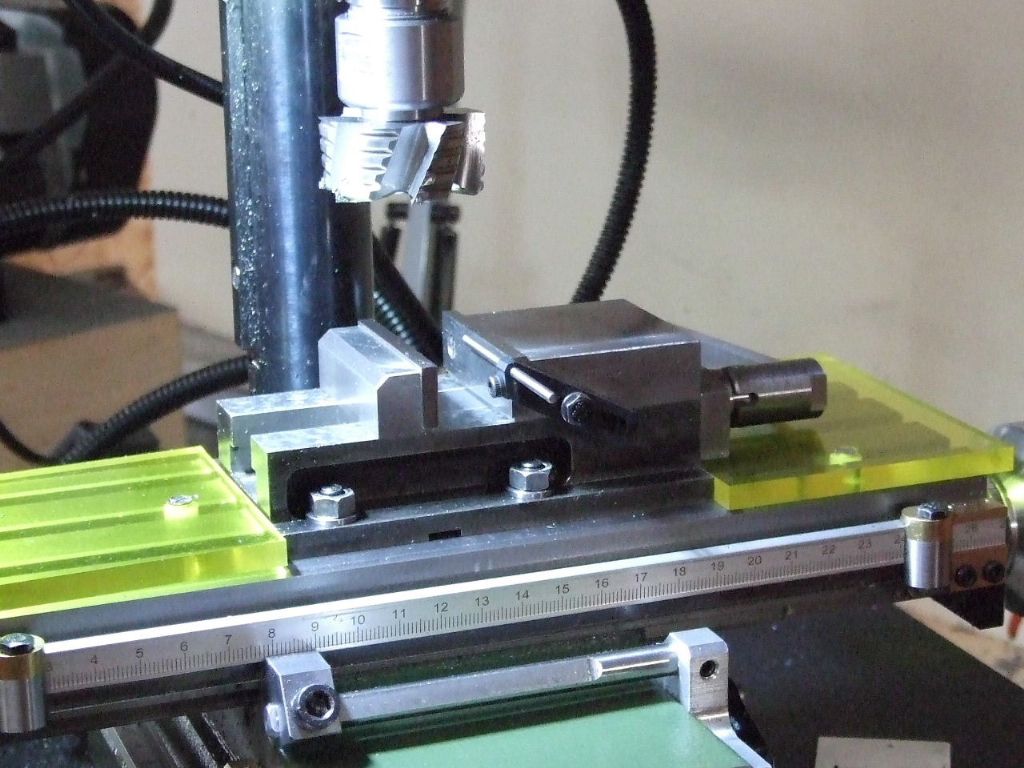

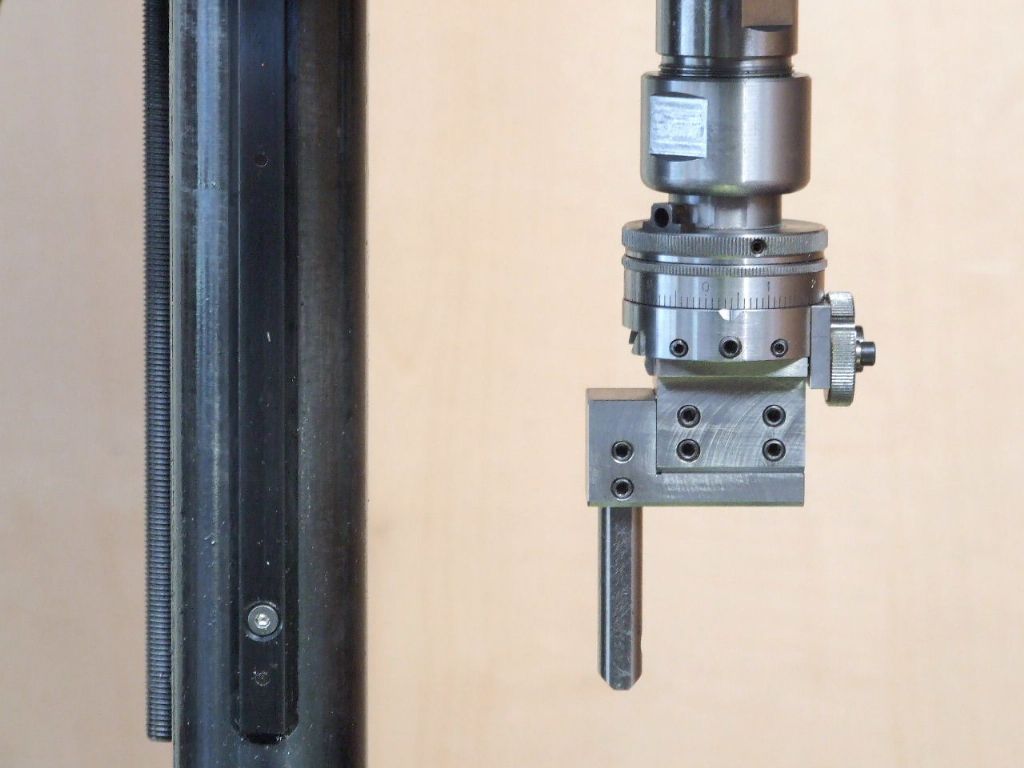

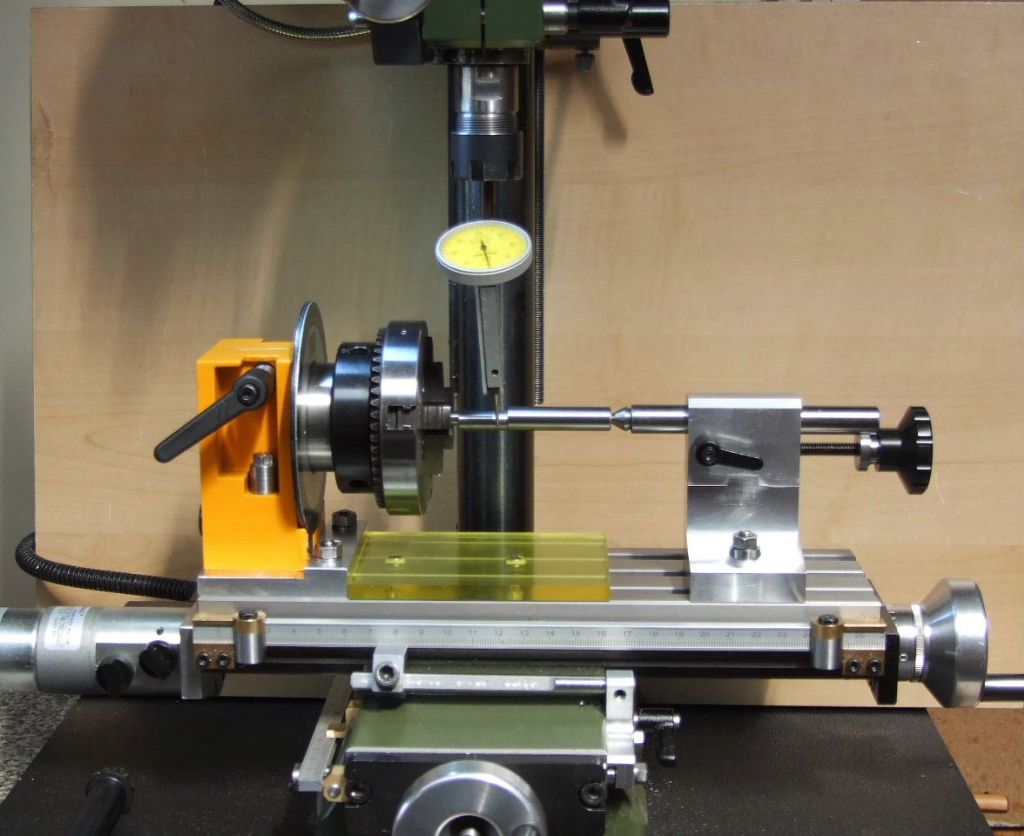

The ball race allows the adjustment to come from the opposite side and any droop from the turning couple is taken by a solid face. I also chose the ball race because this would reduce the drag. When compared to a full length Gib strip. It will also tolerates a slight deviation in the Key strip width, due to this being just drawn bar stock.

2. In an ideal world I would have fitted this key in a shallow groove. This does two functions in that it would take out any straightness issues from a bent Key strip. Secondly it is not going to move in use. Plus it would not matter if Countersunk screws are used.

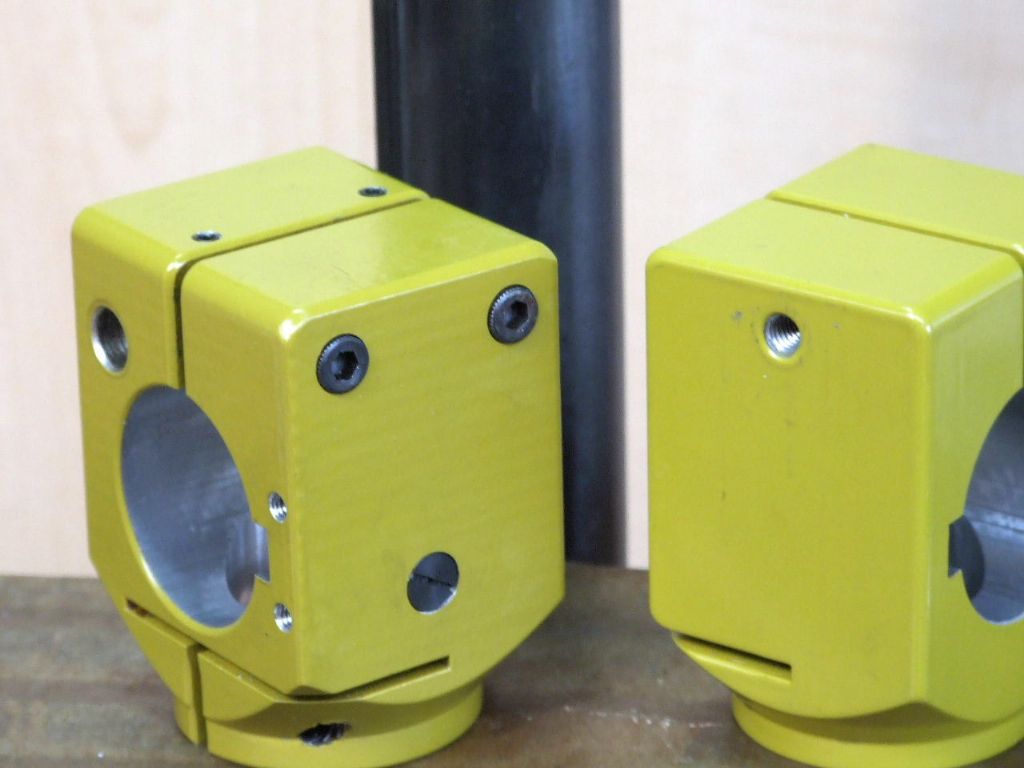

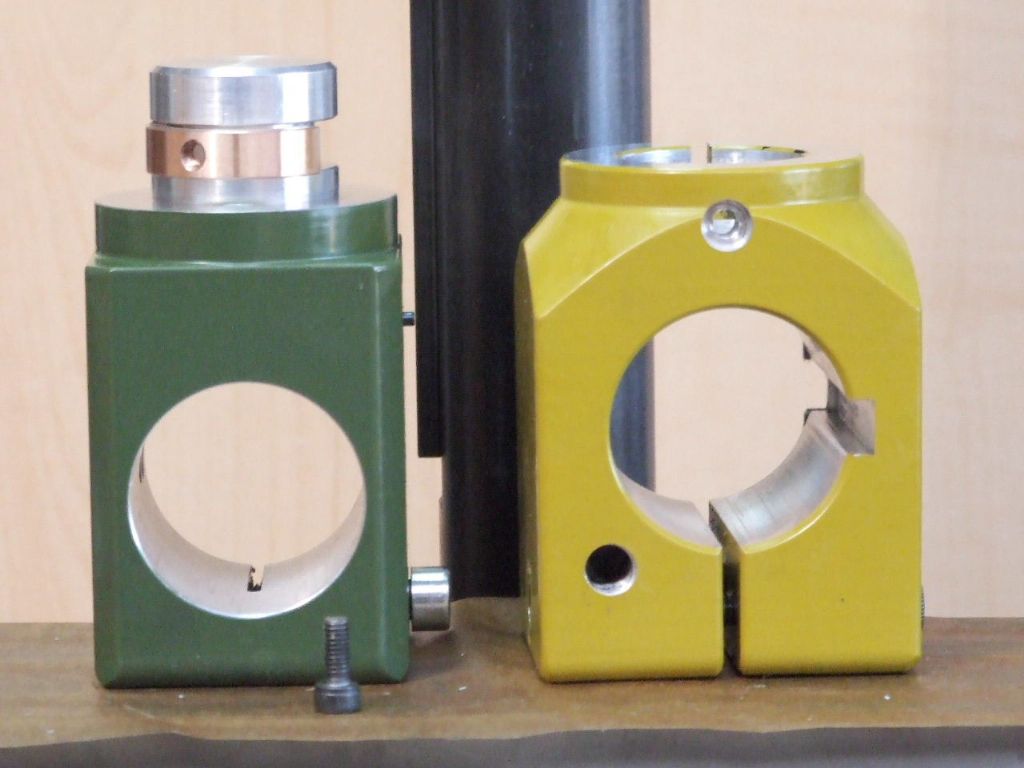

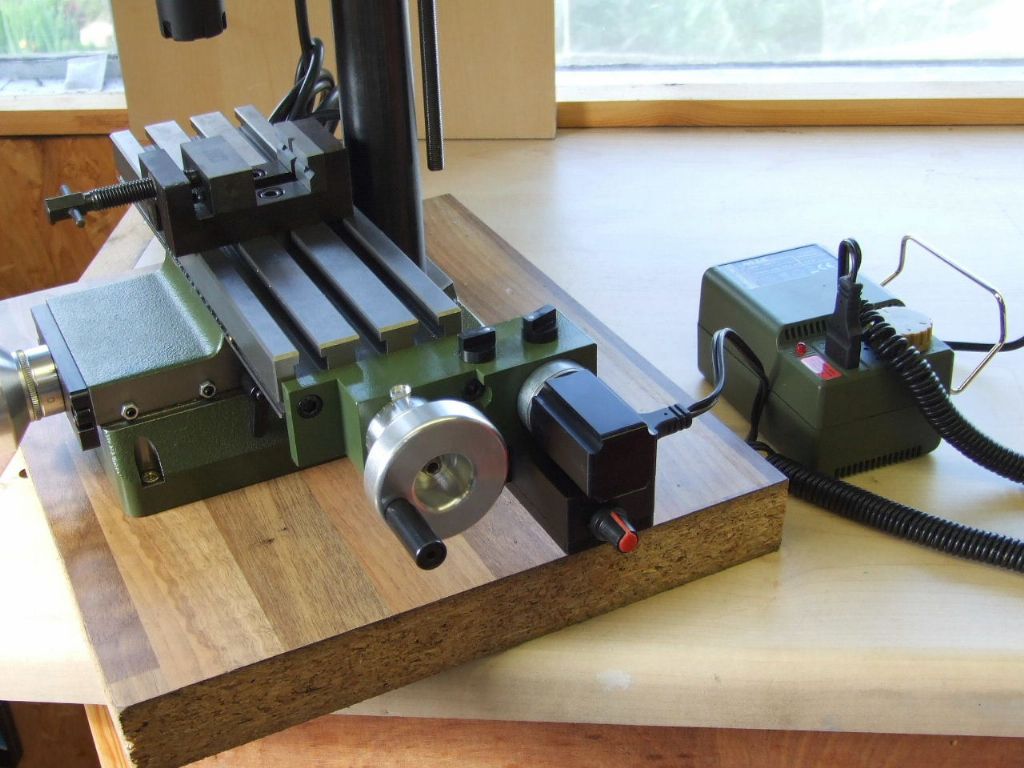

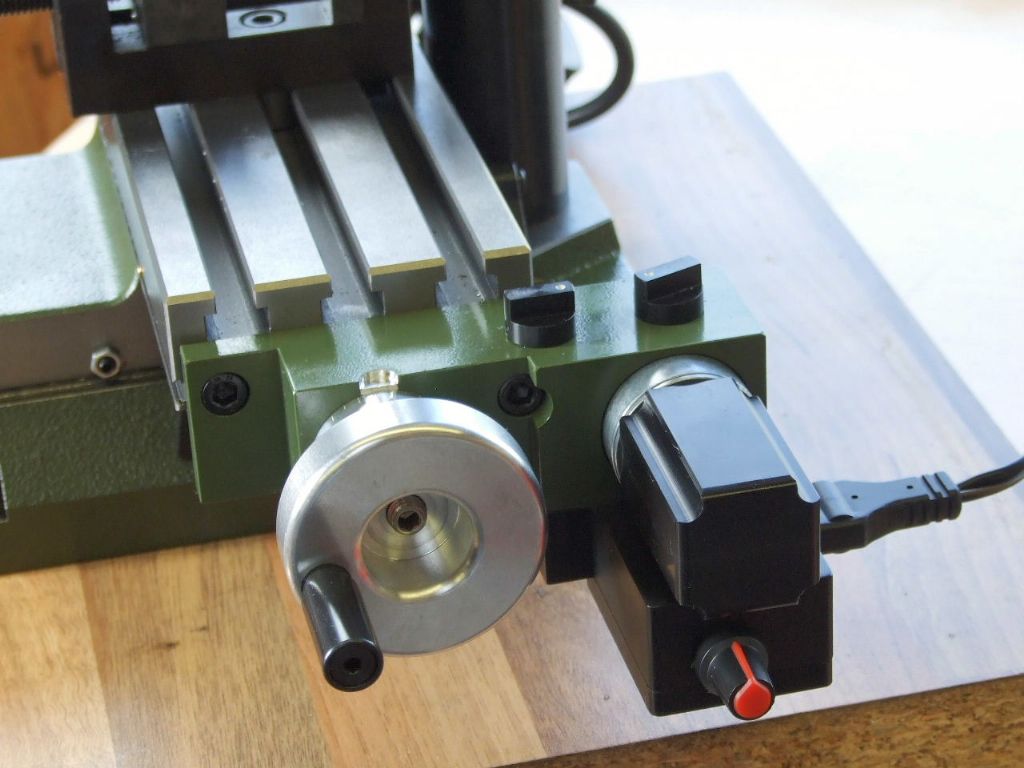

Proxxon have had two different types of Key strip attachment from the components I have in my workshop. Some years back they were attaching the Key strip with M4 Slotted Countersunk screws. This Key strip is planted directly on the Column diameter. The Column on this set-up is of "Drawn" appearance.

Currently there is a flat machined on the Column and the Key strip is held with 3 x M3 Countersunk screws onto this flat. Even here there is a second deviation in that some columns have been turned, while the two new ones I received from Proxxon recently have been "Ground". I have put Ground in inverted commas because I am of the opinion from the finish that this may have been done with a tube linisher. The new Columns do perform better than the old ones.

I hope this helps?

Regards

Gray,

Edited By Graham Meek on 21/02/2023 11:39:21

Colin Creed.