Hi Michael,

Thanks for the kind words, in an ideal world the part should have gone back.

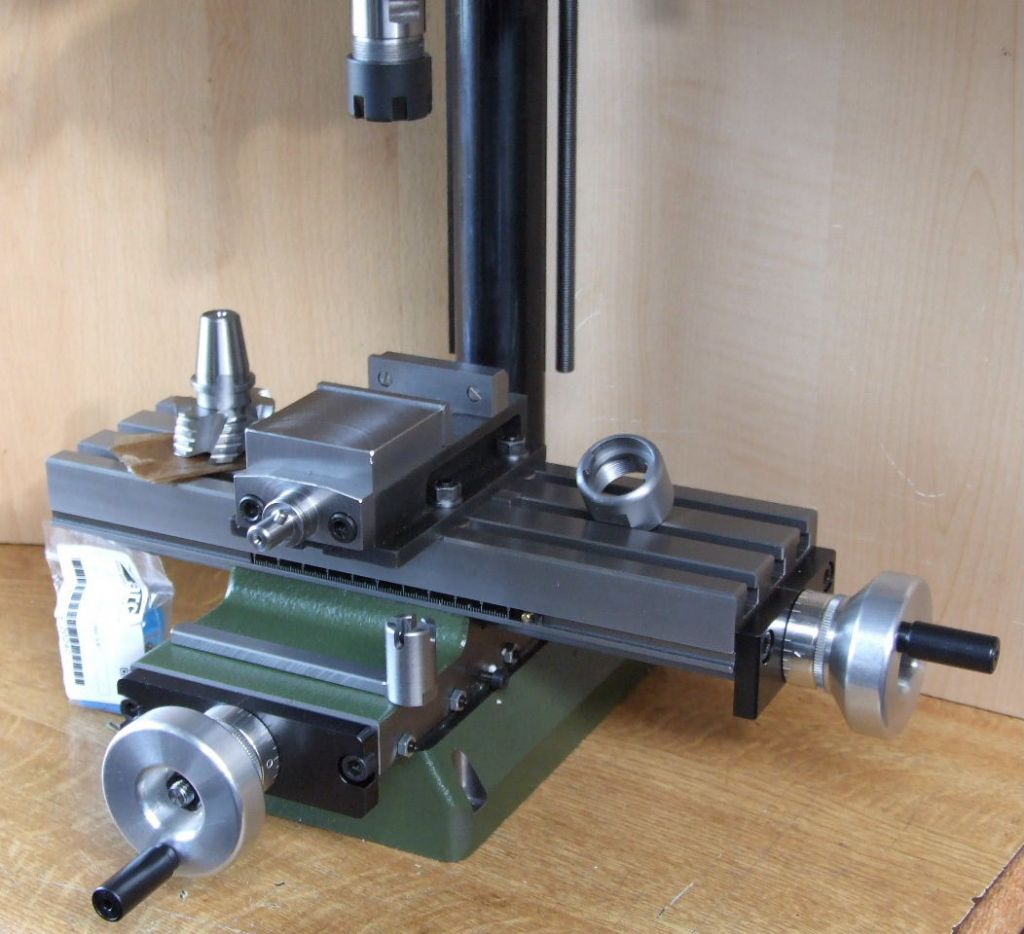

Unfortunately post Brexit things from the continent now take months instead of days. I had waited 3 months for the milling table base to go with the vertical attachment I already had. In the end I purchased a complete machine.

Thus getting a part replaced under warranty would just take too long in my book. There is also the chance that the replacement will be no better.

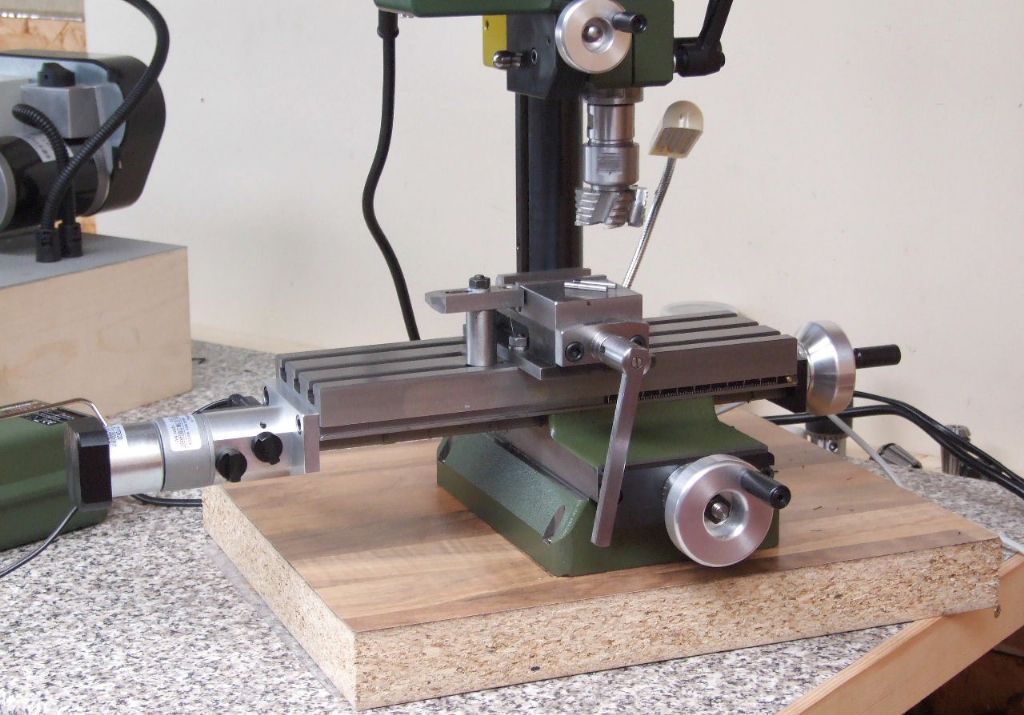

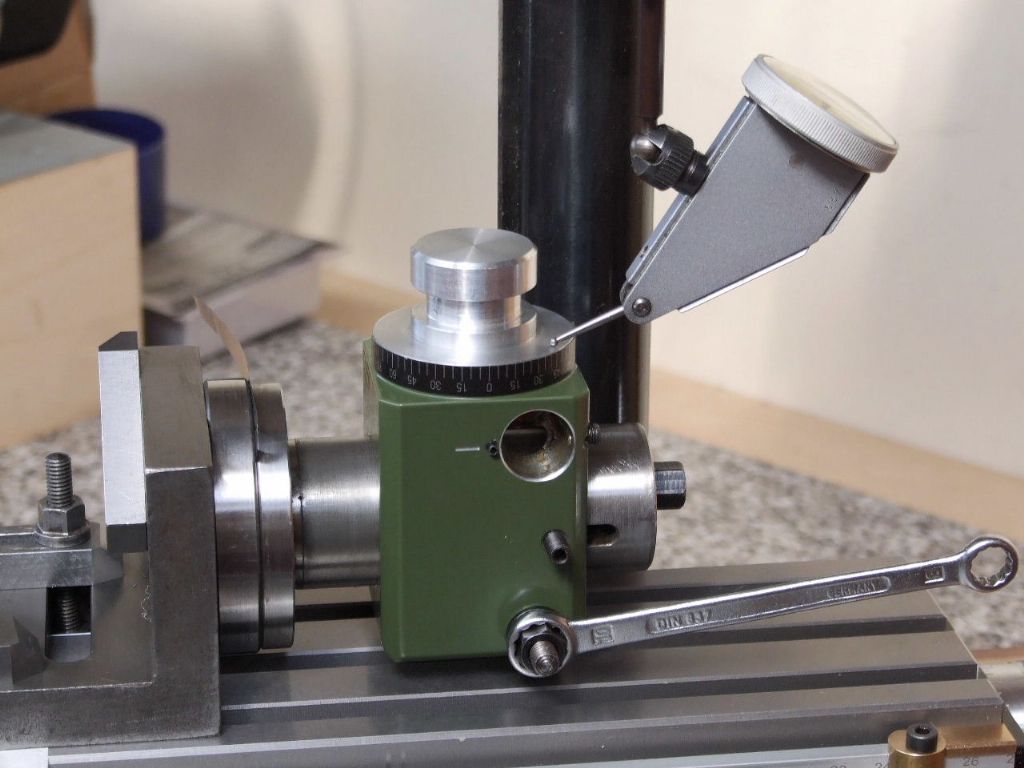

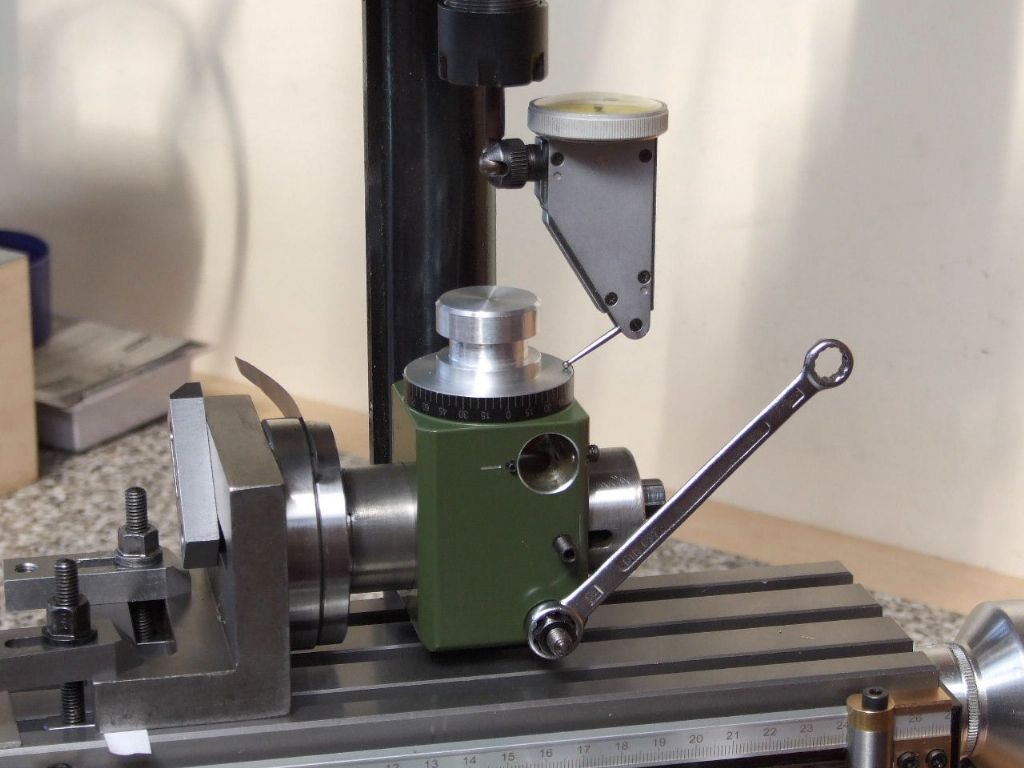

The actual amount of material removed was miniscule to correct the part, but I am not impressed with my set-up. It was hoped to machine the offending face of the component using my homemade boring & facing head. While the head had sufficient travel to do the job in hand, the head would not extend far enough.

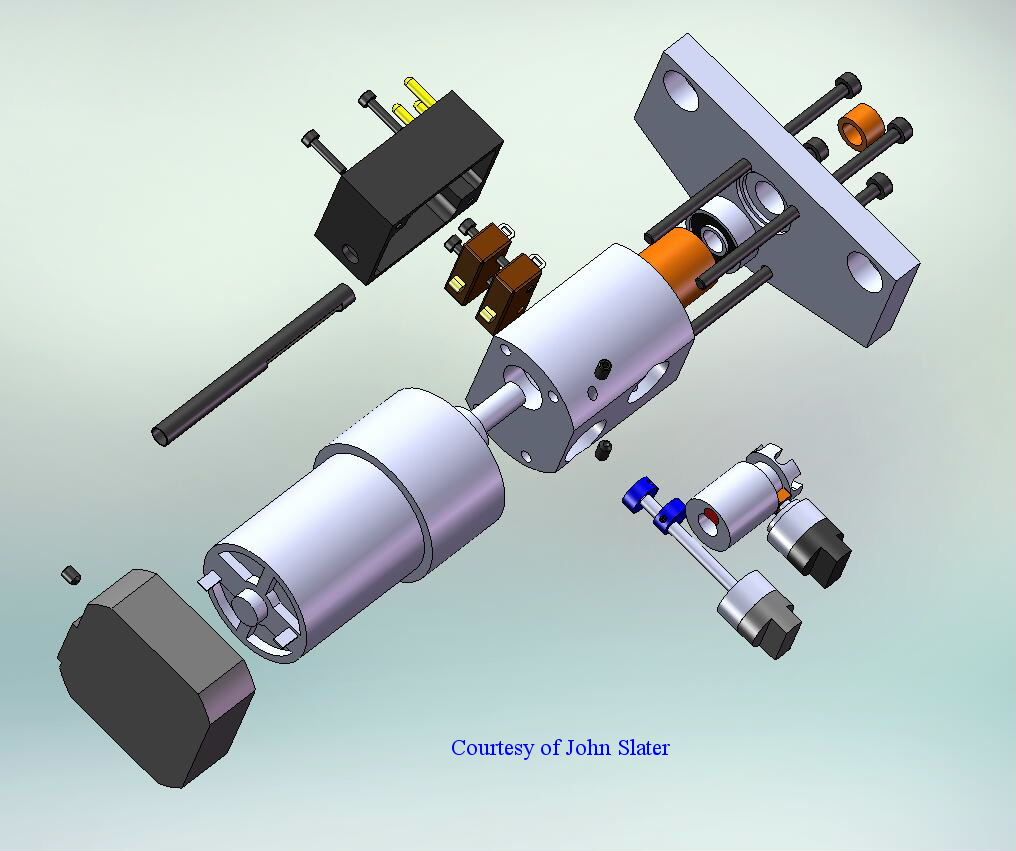

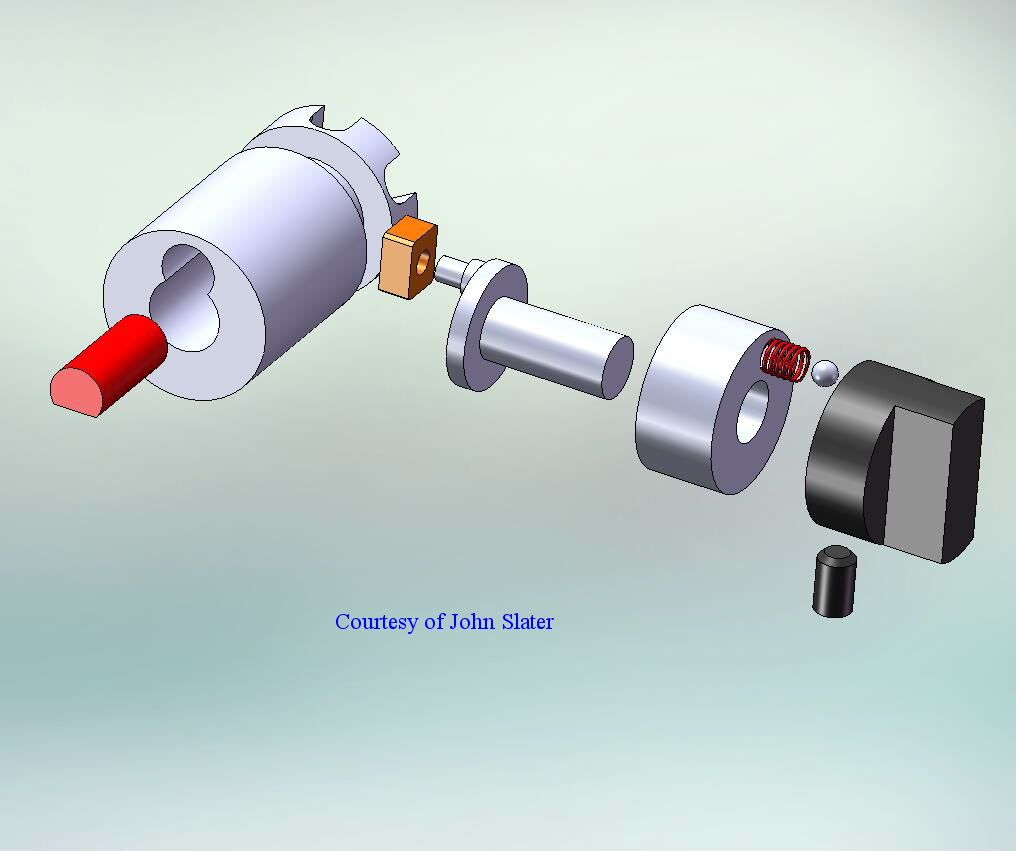

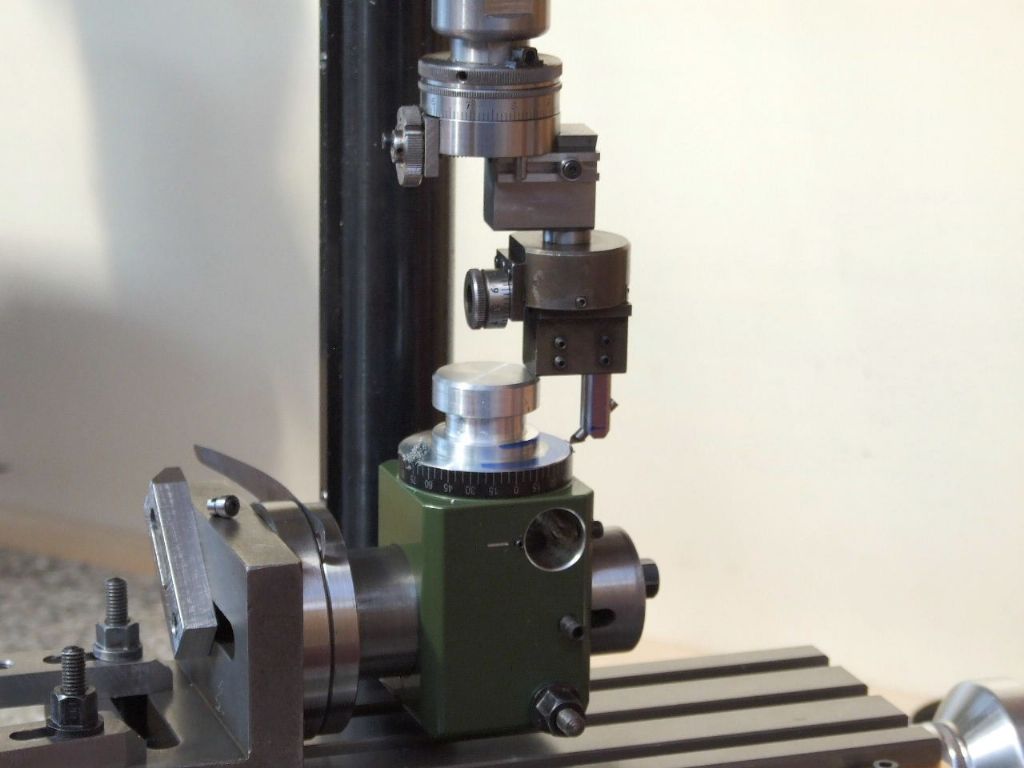

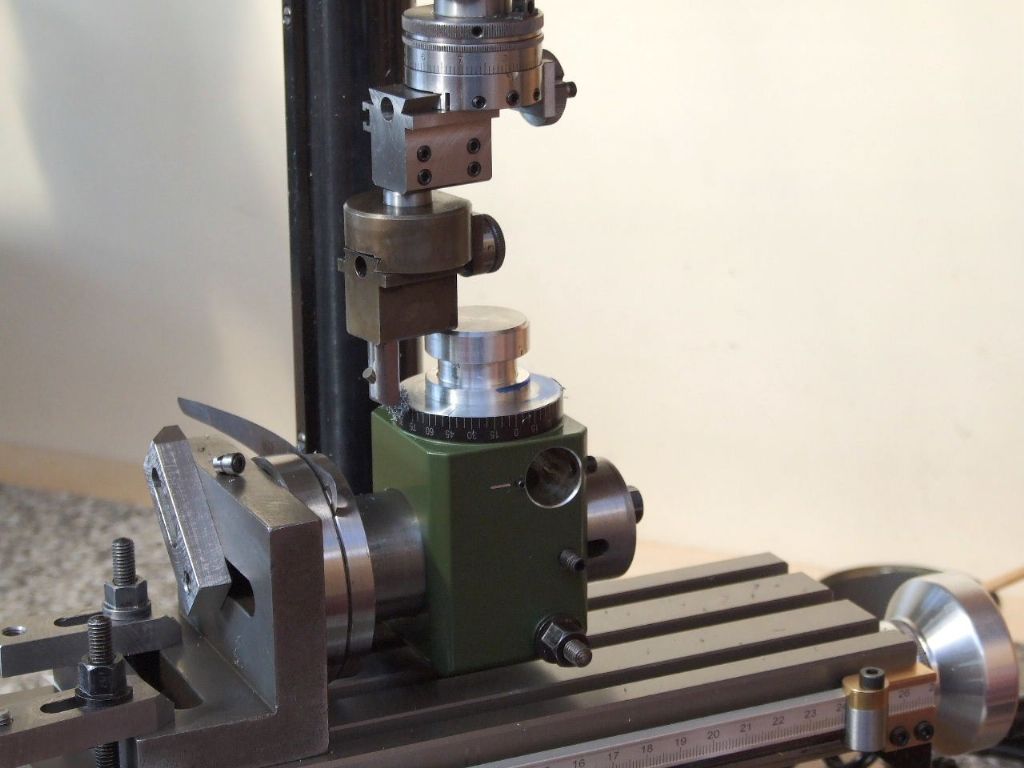

As the Proxxon is now my only working source of milling machine, (The Unimat 3 is still waiting for attachments), it was either strip the set-up down and make an extension holder for the boring bar, something that is now underway. Or adapt something to extend the range of the existing boring head.

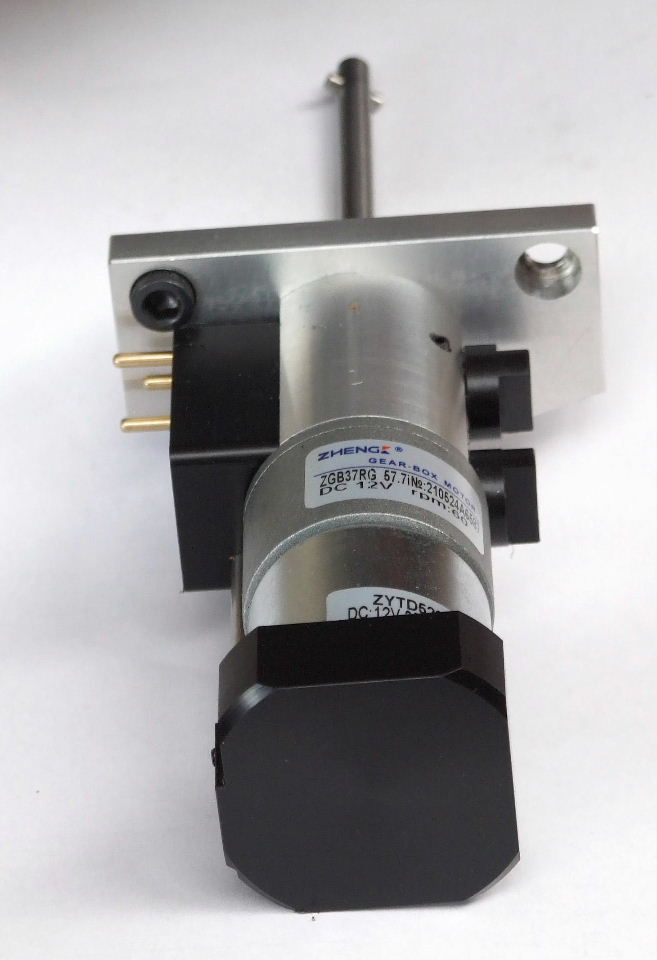

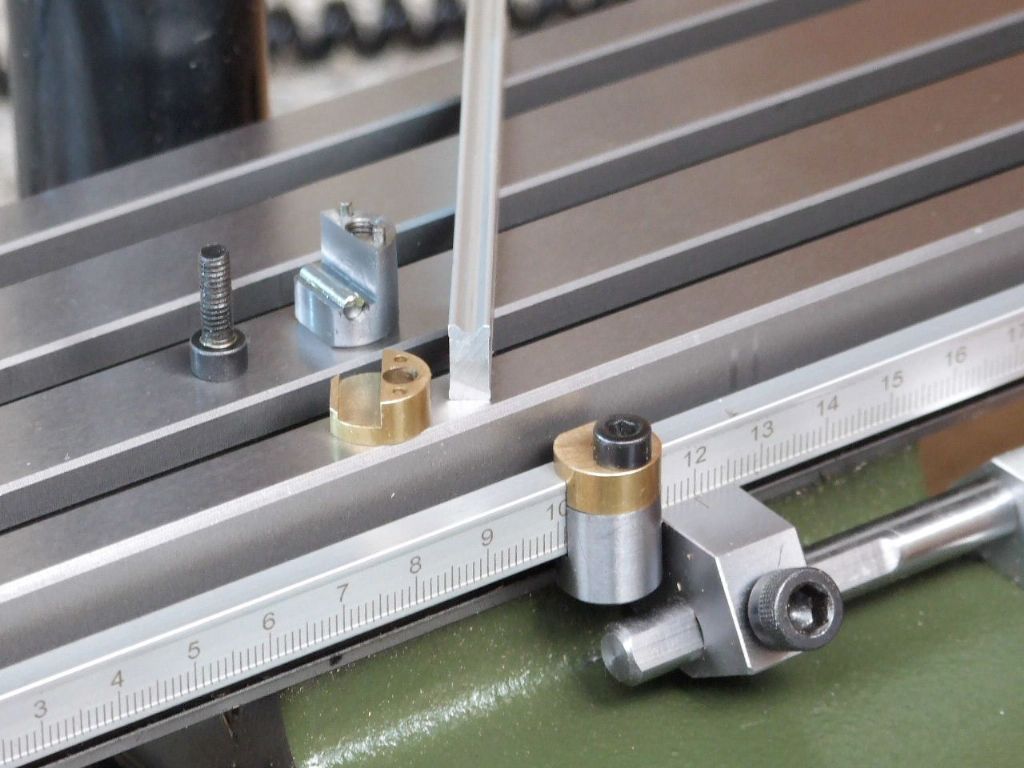

I have had for some time a small manual boring head. This has a detachable 12 mm shank, so a new 8mm one was made and the additional boring head offered up. At the bottom speed of 280 RPM I was expecting the machine to throw a wobbly, but it did not show any signs of complaint.

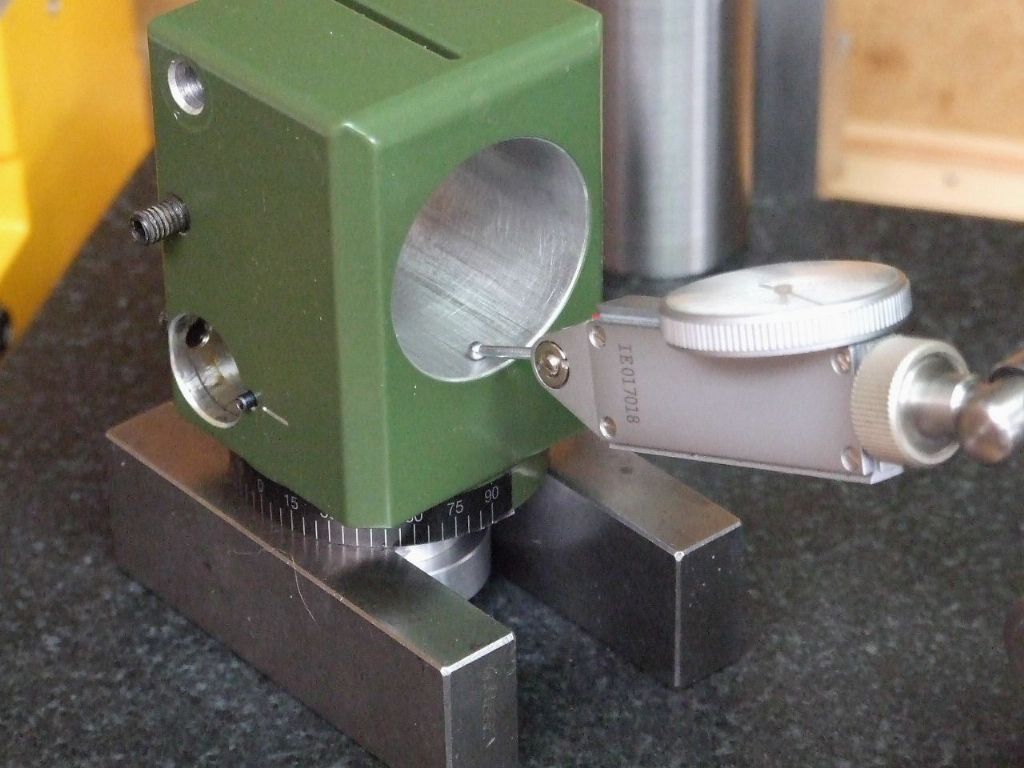

Whilst the set-up had more overhang than I would like it performed the job in hand to my satisfaction and produced an excellent finish. The swarf can be seen on the boring bar.

Re-assembling the milling machine it would be nice to say it was perfect upon re-checking. I had decided I would accept a total run-out of 0.05 mm. Luckily it was less than this at max error of 0.01 mm, thus a mornings work including the photo session was well worth the effort.

After all I had a result the same day. Despite the poor engineering of the machine it is still a good design and works well given its diminutive size. The Proxxon School Report would read "could have done better"

Regards

Gray,

All the right letters but not in the right order!

Edited By Graham Meek on 15/10/2022 13:04:29

Graham Meek.