Some progress with the fence.

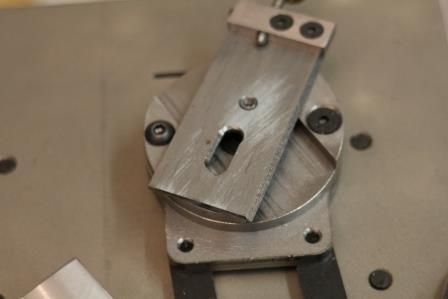

This shows the fence parts so far, the stop block, the fence itself (which is supplied cut out and slotted, just needs one hole drilling), the tee nut and the locking screw/lever.

The assembled fence. The drawings show the block with chamfers on the edges, but actually I think it looks better all square. (Well, that's my excuse!)

No pictures, but the tee not was a simple turning & milling job from a bit of 12mm bar (supplied). I popped in my dividing head (with Ward controller) and machined the flats to fit the wider part of the slot, then turned and parted off the final piece on th lathe.

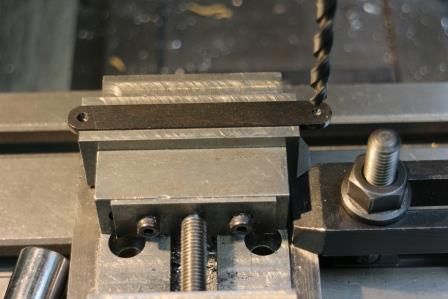

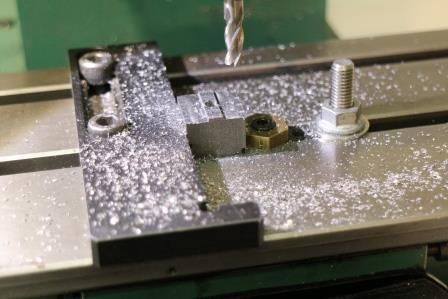

The block is supplied as a lump a bit over 16mm long sliced from a 20mm sq. bar. The ends need facing to thickness (15 mm) then there are tenons to be milled in the base to slide in the slot and 3 screw holes, one for the clamp screw, one for the adjuster, and one for a pad screw that applies some friction through a nylon pad to the adjuster. As shown the block has been faced, drilled centrally for the clamp screw, and had the tenons milled.

For little jobs like this where neither end is square it's often convenient to clamp it in a 4-jaw on the mill table. This is an old, hardly used but much abused Burnerd chuck I picked up for very little from a market stall. I finally got round to cleaning it up and making a key for it for this job. The advantage of a 4-J for this is that it acts as a vice which constrains the workpiece around two axes so the other axis has to be vertical. Here it's shown drilling the clamp screw hole but I used a similar setup to face the ends.

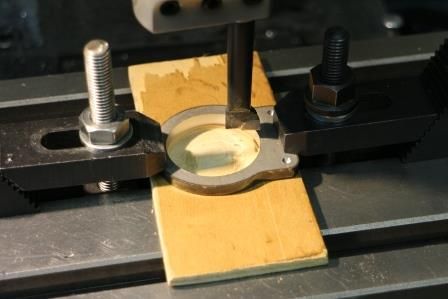

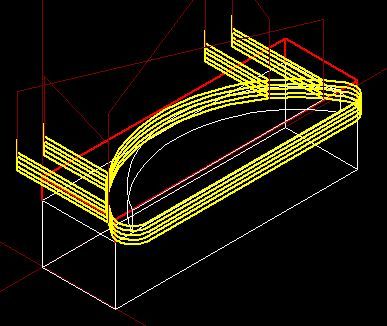

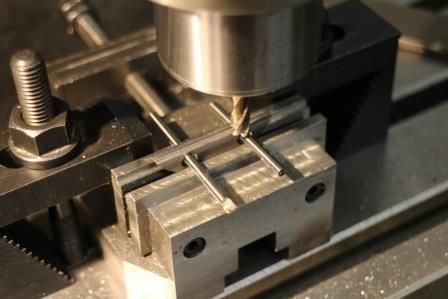

I made the tenon on one end using the Novamill. Clamped the block to the table, used G-simple to generate code for a "rectangular bulge", and set it off. Note the use of a Mitee-Bite clamp, I've never had one of these slip when doing a milling job. They came with the machine, an ex-school unit I scored on eBay, though I had to make my own drive system.

Next, need to drill the remaining holes in the block, and make the clamps that fit the fence to the table. Then the basic unit is done and I can get on to the toolholders!

Edited By John Haine on 24/11/2015 15:16:30

Dave Cee.