ACME is quite doable if you have a Myford 7, but there are a couple of things to think about.

Smaller than 1/2" you need to use a tap, but larger you can use a boring bar. I made a boring bar from essentially a tube and a rod. The rod is threaded on the end, and when you tighten a nut against the tube the rod is pulled through.

If you cross drill both the tube and the rod somewhere near the far end, then you can poke a bit of round HSS through both – sticking out sideways. By tightening the nut, the HSS round is clamped in place. You might make a couple of these with the hole drilled at different angles. A 45 degree angle is good for boring to a deep shoulder. 90 degrees is good for threading.

It saves a whole load of relief grinding.

The smallest easily available HSS round is 1/8" and this suits a boring bar of perhaps 3/8" in diameter. As you can imagine a 1/2" ACME tapping hole is pushing things quite a lot.

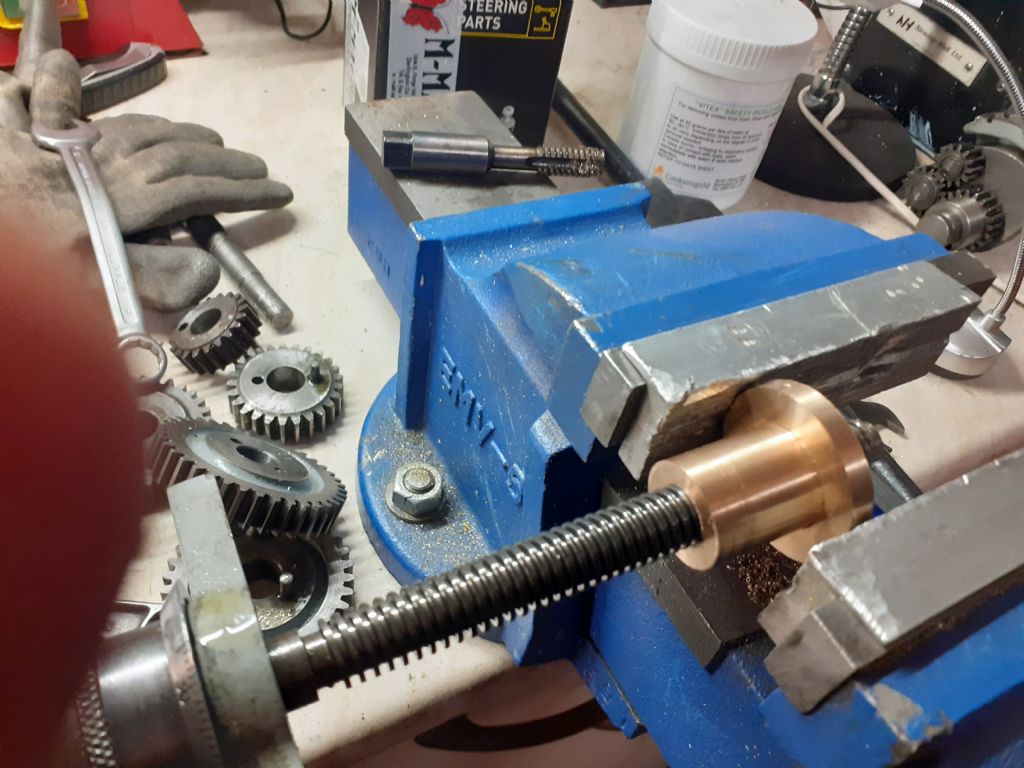

You can get ACME left and right hand taps from Tracy. I have found it is quite useless to try and drive them by hand with a wrench. They just act like reamers. Your really have to push them through.

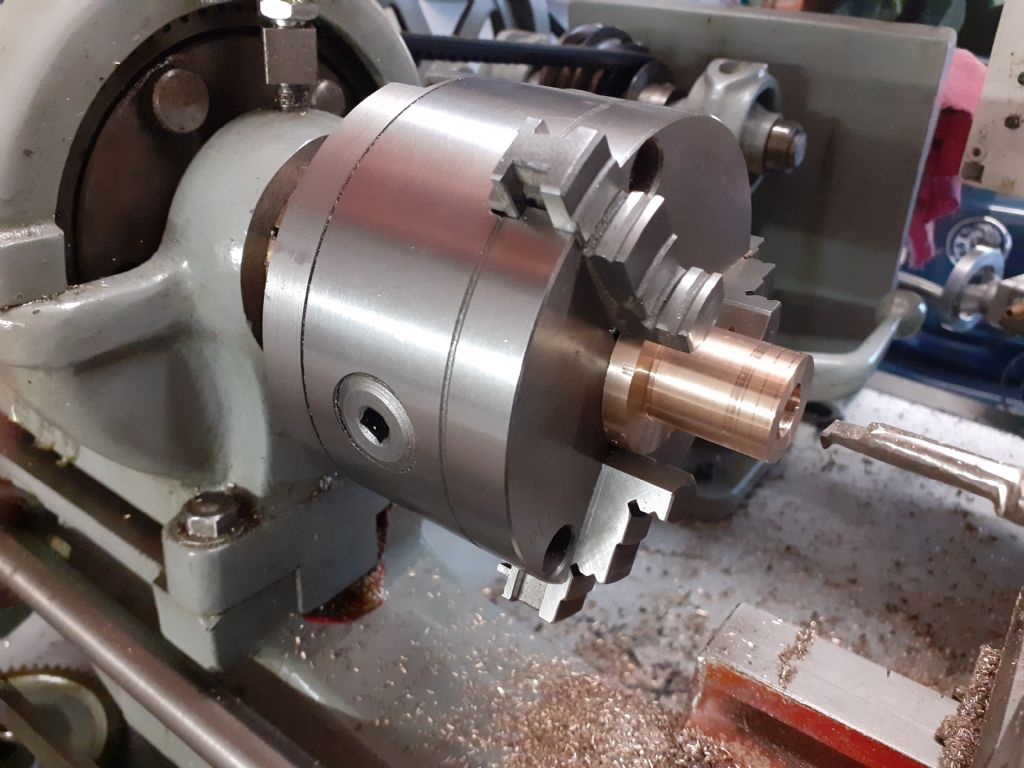

It is much better to put the prepared nut in the vertical slide and have the hole central on the lathe axis. Then set up for screwcutting with a pitch the same as that of the tap. Put the tap in a collet chuck in the headstock so it cant slip. Drive the nut to be, onto the rotating tap using the lathe leadscrew.

The ACME taps I use are quite long. They won't go through in one go. You will have to back up and clear the chips. As long as the pitch of the tap is imperial, you will be fine on a Myford 7. The rules are the same with respect to disengagement of the leadscrew as they would be for screwcutting.

If the pitch is metric, then you will have more trouble. The lash is too great to simply back up by reversal, leaving the half-nut engaged. It will destroy your new thread as you back out and clear the chips. Instead, you will need to release the tap from the collet chuck. You can then wind it out by hand. To pick up again, set the tap to position manually. Take up the lash and then clamp the collet chuck before proceeding under power.

For a 3/4" thick nut and a 1/2" ACME tap you will need to clear the chips four or five times. The tap for this operation will be be 8 – 9" inches long. It will taper from nothing (core diameter) to full depth over a length of perhaps 6".

I get a really nice nut this way. Very little play – like a bought one.

Hope it helps.

Edited By Andy Ash on 17/04/2022 02:43:42

bricky.