Dear Forum Members,

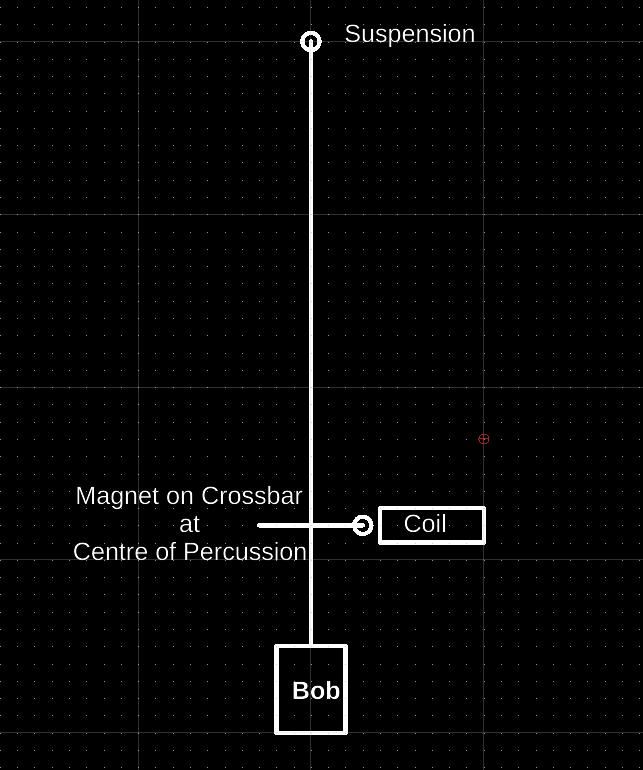

I've started work on an "Arduinome"-type hybrid mechanical / electronic pendulum clock. I'd like it to be simple, practical, and hopefully imbued with a touch of artistry. So far, I've completed the pendulum's hinge assembly.

The hinge itself consists of two 0.004" thick by 0.25" wide strips of beryllium copper. Cutting this using scissors did not work particularly well, as they leave a curled and uneven edge. Thankfully, John Haine (in this forum) made a creative suggestion, which I used: I clamped the cut strips between two 0.25" tool-steel blanks and used an old chisel, laid flat along the steel, to hammer-cut a sliver from the edges. After turning it around, I hammered off the other edge. This worked brilliantly, leaving very clean and straight cuts and a uniform width.

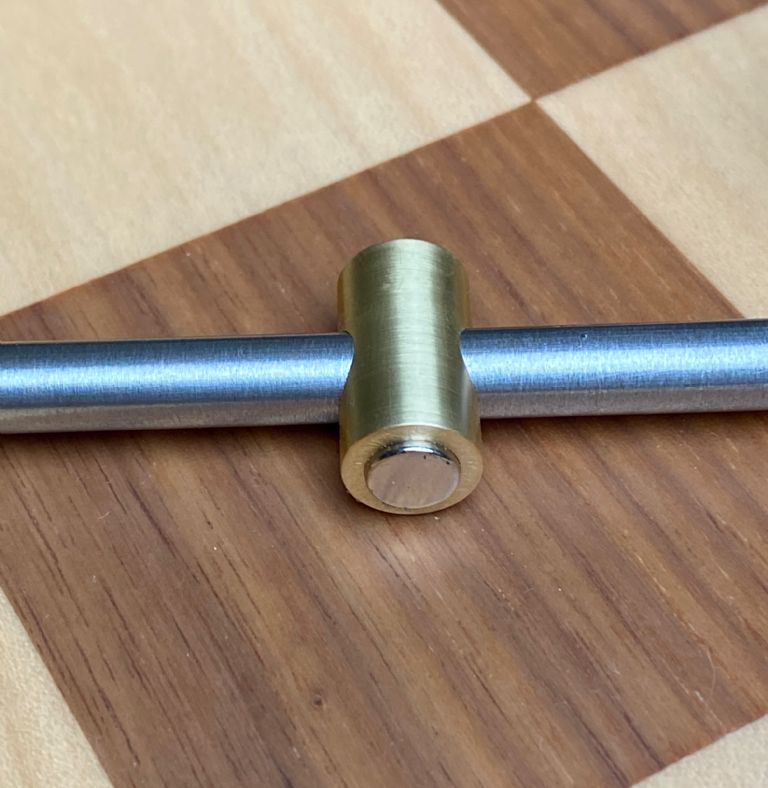

These strips are held by 0.25" thick two-piece "chops" for stiffness and stability. The upper chops were drilled and reamed for a 3" by 0.25" stainless steel rod. This will sit in a cradle that holds the pendulum.

The lower part consisted of two pieces: an "L" shaped main body, and a smaller piece that fits into the L. The "L" was used so that I could drill and ream the lower solid part to accept the main pendulum shaft. This was also drilled and tapped to accept two brass-tipped set-screws to fix the shaft in place.

Cyanoacrylate adhesive was used to join the chops. I'm a little uncertain if this will be sufficient in the long term, but I experimented with it, and it seems very strong. I suppose I could (and probably should) try to insert pins to further fix the strips in the chops. But for now, I'm more worried about ruining the hinge via mishandling!

The pendulum's shaft is a 0.25" by 36" rod of Invar, a low temperature-coefficient metal that is sometimes used in high-quality clock pendulums. It's quoted as having a 1.2 ppm TC. I may add further temperature compensation, or I may not, as this material should provide decent temperature stability on its own.

Next steps: I have a 1" by 3" brass disk which I will likely use as the pendulum's bob. This should weigh about 2 lbs, which is rather light for a bob, but the 0.25" shaft is too thin for the usual ~14 lb weight anyway. I also mocked up a cradle for the pendulum in 3D printed form, and will build it in brass, too.

Here's a picture of the hinge in its chops, the stainless support shaft and the Invar pendulum shaft:

It should be a fun and interesting project. 🙂

S K.