Thanks for advice. I had hoped that I might be able to get away with leaving the switch in position, but after reading exchanges between Nick, Martin and Noel:

Posted by Nicholas Farr on 08/05/2022 21:01:51:

Posted by Martin Kyte on 08/05/2022 13:07:23:

Posted by noel shelley on 08/05/2022 11:57:23:

The switch may be ON in all positions, to different functions so leaving in place may not be an option. Good Luck. Noel.

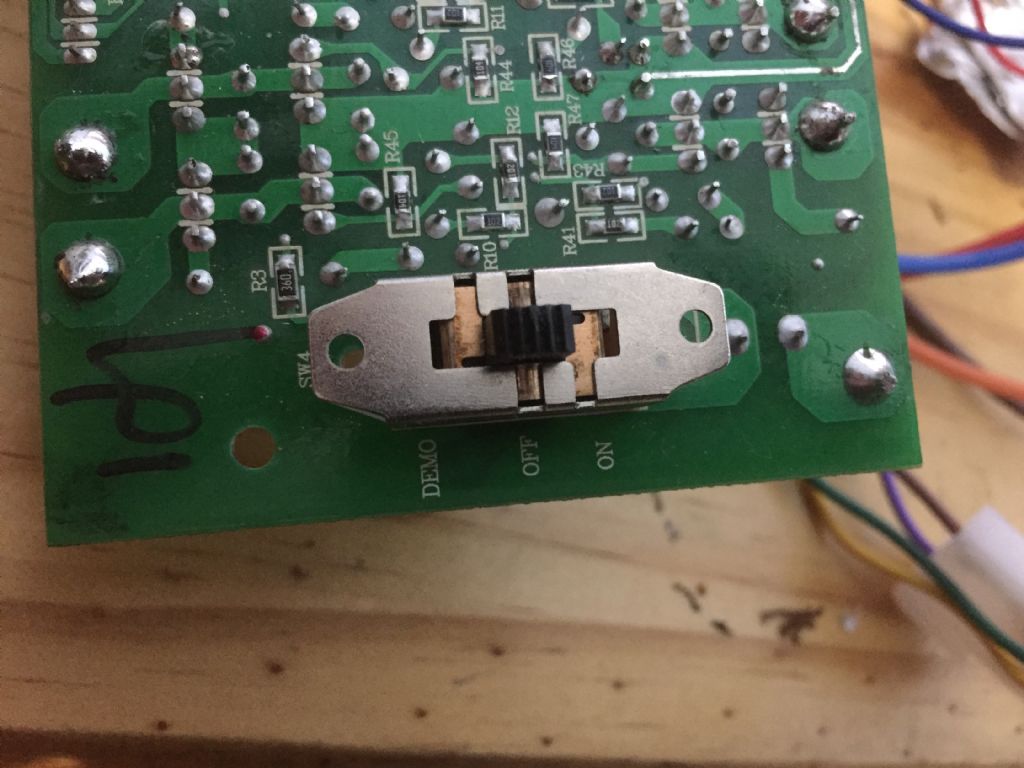

The info on the silk layer says 3 positions are ON OFF and DEMO with the centre marked off so it's pretty certain that the switch osolates all pads in the centre position. Easily checked with a meter.

regards Martin

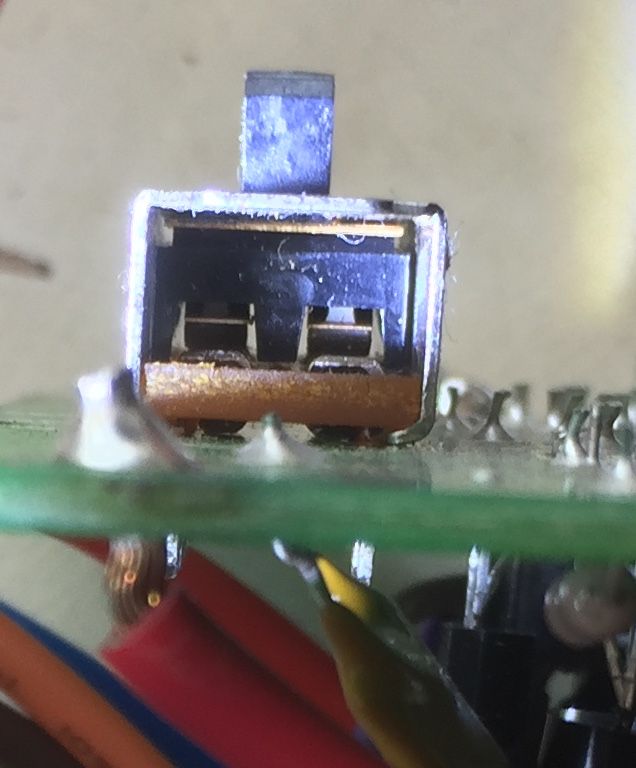

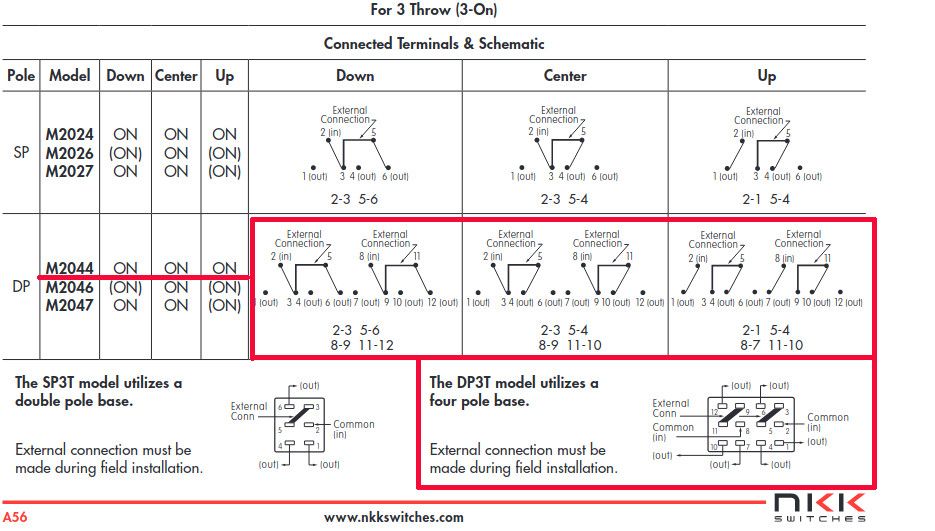

Hi, from my (non extensive but over many years) experience, you can't be certain about anything that looks like a switch is configured in such a way that it must be what you would expect. The switch in the photo is a three way, but it has eight pins, which could mean that in the off position, it may be holding up to four different aspects of the circuit off and just adding a new switch without removing the old one or it's contactor components, the circuit might not work or it may even short other parts out, so the circuit needs to be checked out before just adding another switch. More or less what Noel has said.

Regards Nick.

Edited By Nicholas Farr on 08/05/2022 21:03:10

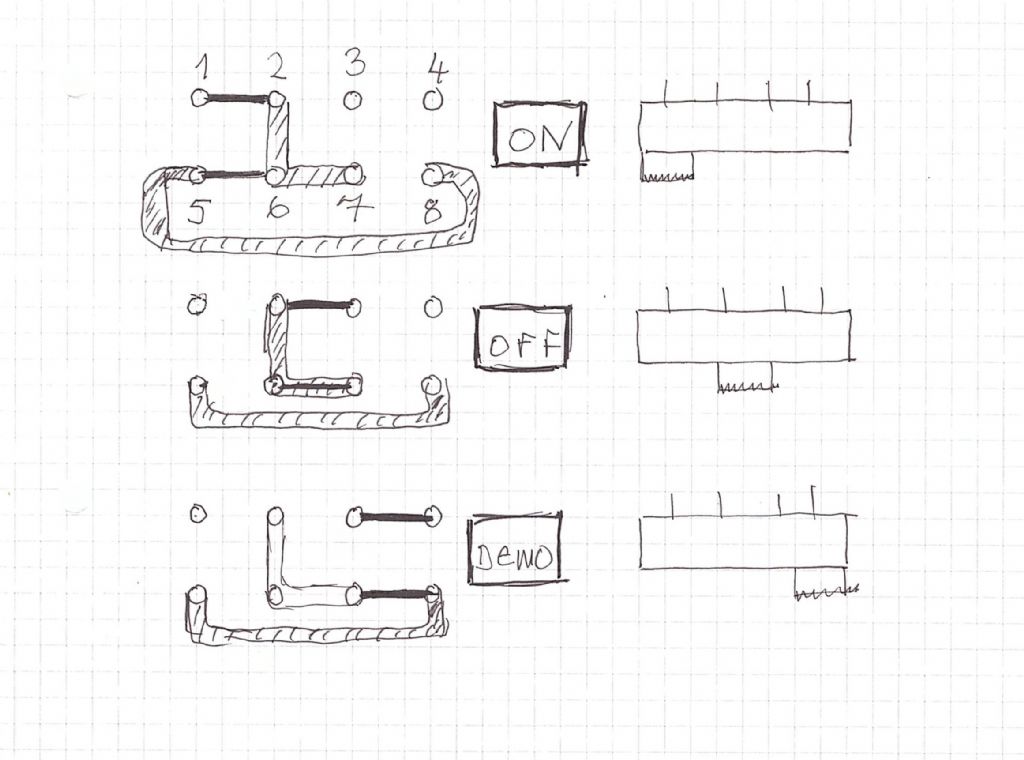

I took a multimeter to the switch and found:

The hatched things are pcb tracks – I can see the L – shaped track connecting 2,6,7 on the component side and infer the existence of one between pins 5 and 8 because they are connected at all switch positions. Presumably on the other side, obscured by the switch body. I have also inferred the switch connection between 6 and 7 in the 'off' position – symmetry seems to demand it!

The problem with leaving the existing switch in the 'off' position and wiring up another one seems to be that pins 2 and 3 will remain connected in 'on and 'demo' modes. Maybe that wouldn't matter but I can't be sure.

I'll have a go with the wick, but if it doesn't look like it'll work I'll resort to Nick's suggestion of destroying the switch – drastic as it seems it might actually be the least risky option.

If anyone's interested the board came from a (now obsolete) Hasbro FurReal toy pony. You can see it here. They cost over 1000 USD when launched I'm told!

Robin

Edited By Robin Graham on 09/05/2022 00:38:01

Robin Graham.