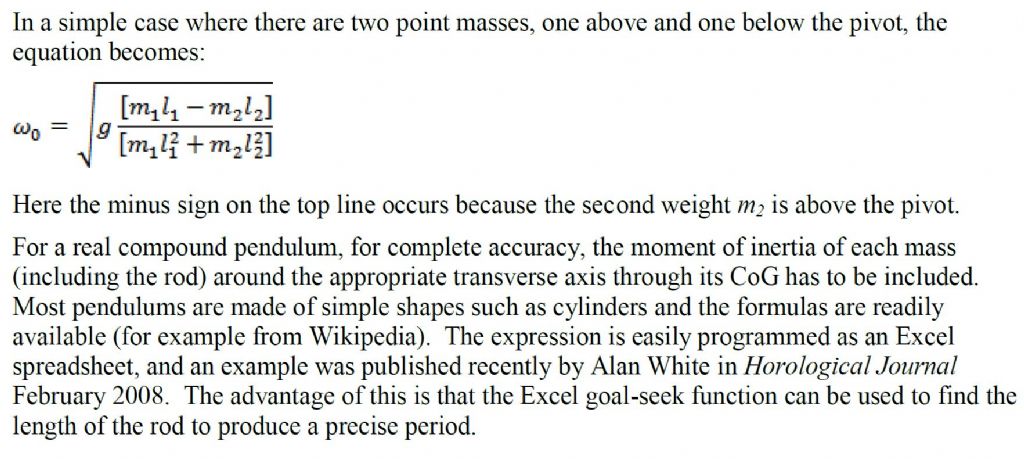

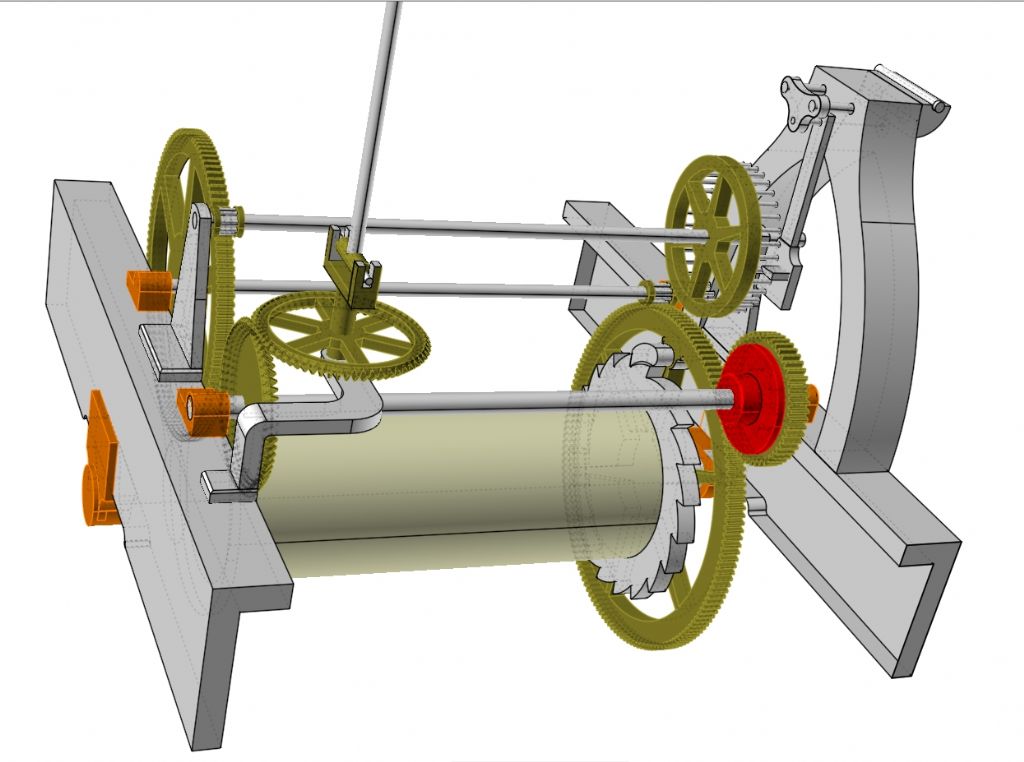

In case anyone is interested!. It has been a bit cold in the workshop for progress on the "other projects", so I have amused myself by developing the design for the church clock model. Rather than the original idea of having the chime triggered twice (rather than the four times of the original), I did some spread sheeting to develop an alternative time train that gives a once per hour minute shaft, and for which the wheels are fairly close to scale – I chose 6mm = 1" as I prefer to work in metric, but the clock is clearly imperial dimensions. So far only the time train is close to a finished design, the chime & strike trains will be closer to the original as the gear ratios can be retained.

The model so far is

Time Train

Church Clock Model

Great wheel Teeth 120 150

Rotates Every 3 Hours 3 Hours

Ratchet Teeth 20 20

1st Pinion Pins 10 8

2nd Wheel Teeth 90 116

Rotates Every min 15 9.60

2nd Pinion Pins 8 8

Escape Wheel Pins 35 35

Rotates Seconds 80 39.7

Pendulum Period secs 2.29 1.13

BPH 3150 6343

Minute Wheel Teeth 40 50

Rotates Once per hour Once per hour

Bevel Gear Teeth 76 60

Dimensions 1" = 6mm

inches mm Scale

Great Wheel 11.75 76 1.08

2nd Wheel 8.5 59 1.16

Escape Wheel 5.5 32 0.97

Minute Wheel 4.0 26 1.08

Bevel Gears 7.5 28 0.62

Drum 6.0 36 1.00

Pendulum Length 51.20 320 1.04

Using MOD 0.5 for the gears, the second wheel is a fair bit (16%) bigger than scale which required the escape arbour to move to one side, at which point it clashed with the minute arbour drive wheel, so the bearing mounts needed lengthening to raise it up to maintain depthing. The output bevel gears also needed to be made a bit smaller to avoid a clash with the second wheel, but otherwise things are fairly close to scale.

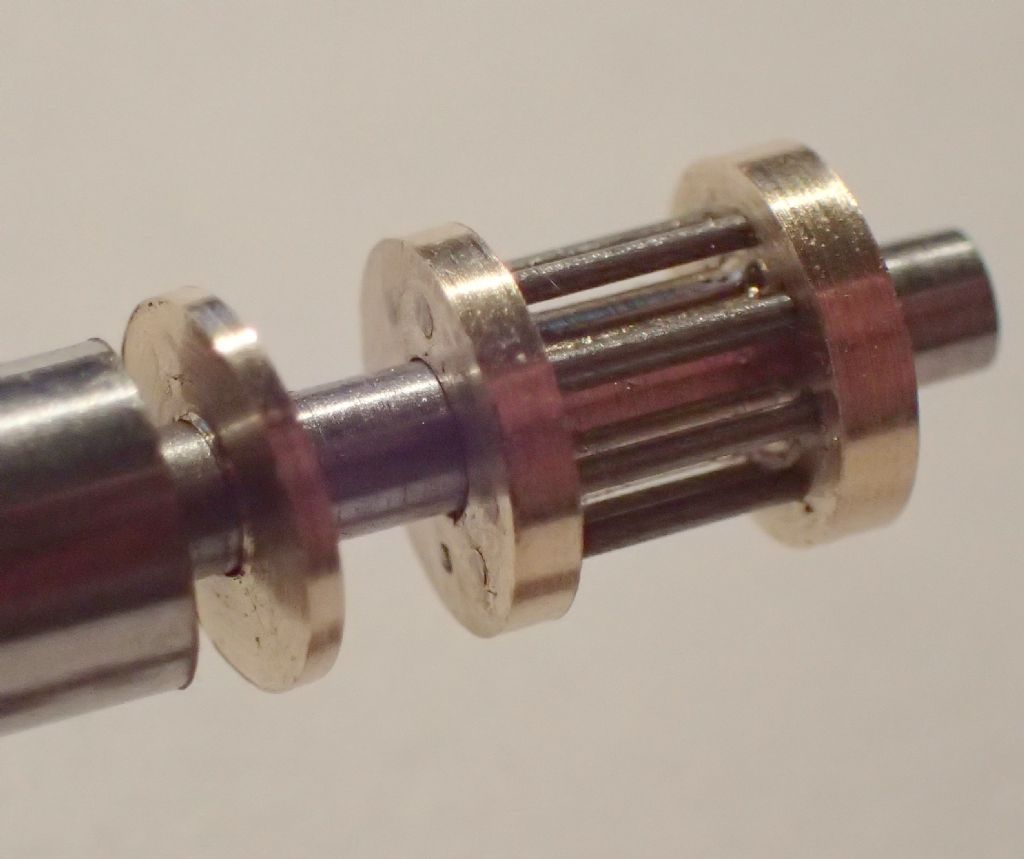

The escape wheel teeth on the original are flattened and about 1/8" thick. To scale they look rather fragile at 0.75mm, so I have used 1mm pins and modified the pallet spacings to suit (I hope!). The plan is to make the arbours from silver steel and harden the pivots. All bearings are brass. Several parts (the frame, the escape arbour, bevel wheel bearing supports and the pendulum support are clearly cast iron. They will be fabricated from steel ( silver soldering is a skill I will need to acquire). The winding ratchet also looks to be cast and that together with the similar parts for chime and strike, plus the strike cam have some complex curves that I will need to work out how to make. I might see if I can find a local laser cutting organisation willing to make small one-off parts for a reasonable cost (unless anyone has a cheap desktop laser cutter capable of cutting 4mm steel plate going spare).

As always, comments and suggestions gratefully received.

Edited to correct tabulation of table ( I hope)

Edited By Peter Cook 6 on 20/01/2022 17:50:07

Edited By Peter Cook 6 on 20/01/2022 17:52:38

Peter Cook 6.