I have access to (OK I have wound it twice a week for 20+ years) a flat bed tower clock in the local church. It occurred to me recently that creating a model of it it might make a good build project (once I get the current list out of the way in a year or so!).

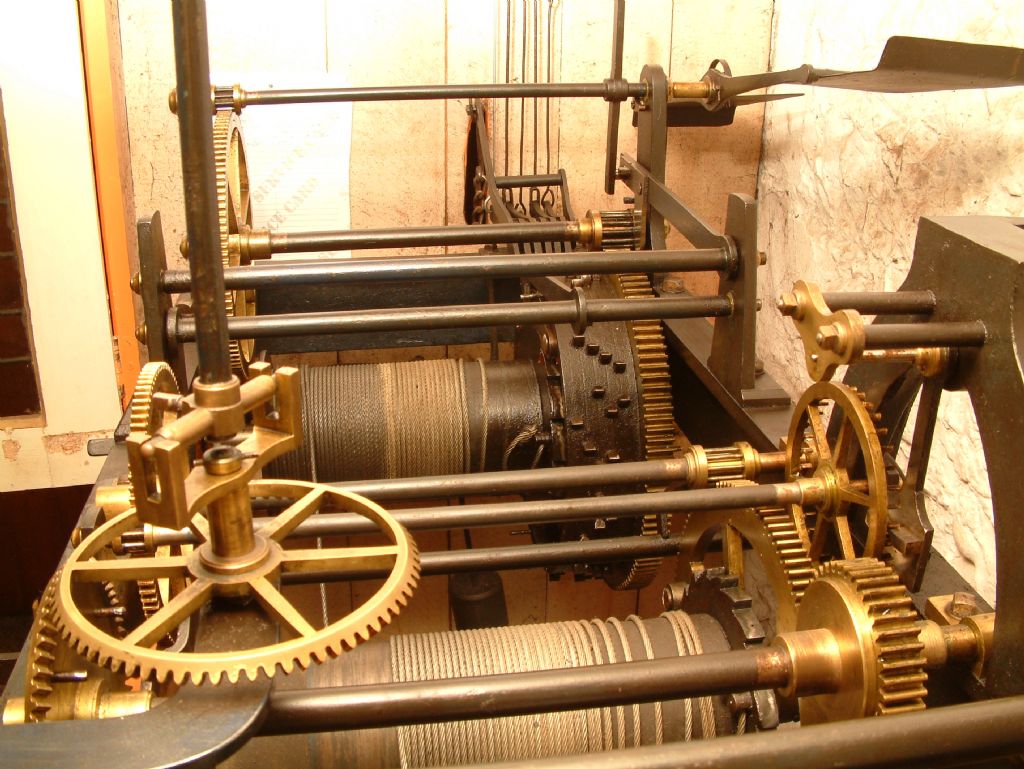

It is a three train flat bed clock made in 1889 by Smiths of Derby, and still maintained by them.

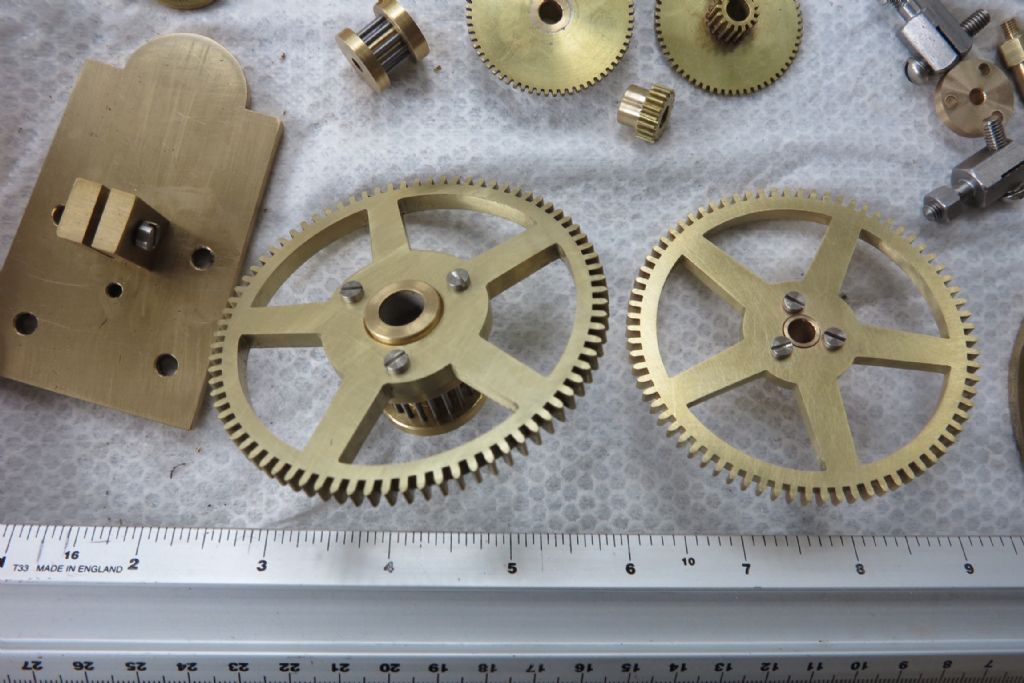

The movement is fairly simple, pinwheel escapement, count wheel chime and strike. Each train has a limited number of wheels. All the pinions are lantern, and the bearings are brass bushes, some in iron castings individually mounted on the top and bottom of the bed so depthing should be fairly easy. The bed is one piece cast iron – but I would probably fabricate it from steel.

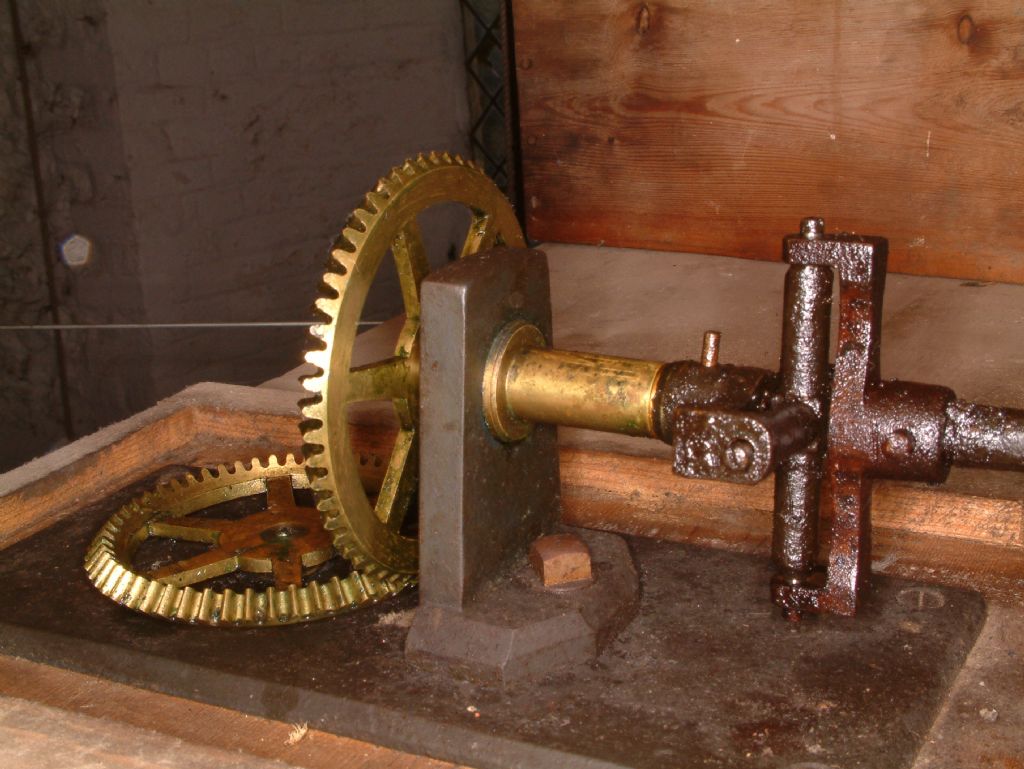

The real thing is about six feet wide. It beats 3150/hour, and trips the chime train four times for each revolution of the output shaft (closest to the camera on the image above) . Thinking it through I t seems to me that if I made a 1/4 scale version it would beat twice as fast, and if I tripped the chime train twice per rev I would get a clock that looked OK, and kept to time. The motion work behind the dial ( about 20ft above the clock) is driven by a pair of bevel gears.

By halving the ratio of these gears I should be able to get the hands to turn at the right speed.

I can't see anything too difficult (apart from having to learn how to cut wheels!!) except possibly the pair of bevel gears that send the output up to the dial and those on the motion work, and the latter could probably use a standard commercial set as they will be non scale and hidden behind the dial.

The chime barrel will be fairly fiddly to get right, but in principle should be doable.

Before I set to measuring the real thing, counting teeth and planning a bit harder, I thought I would ask on here to see if anyone has done something similar – or if anyone can think of any major gotcha's I might run into.

Edited By Peter Cook 6 on 30/10/2021 16:23:31

Peter Cook 6.