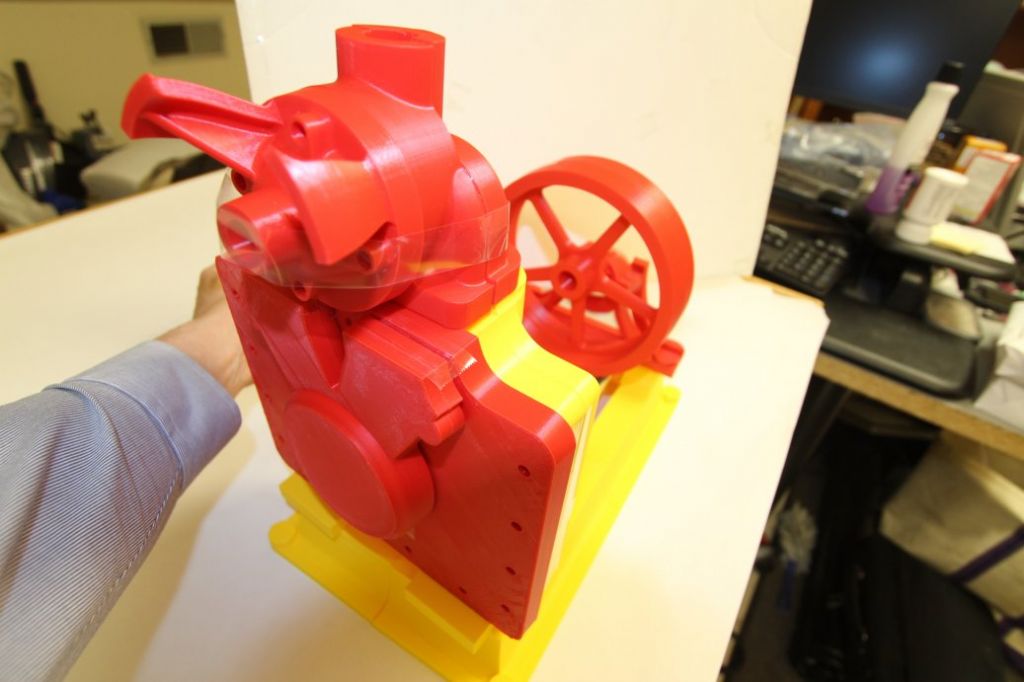

I have heard some describe this engine as a Wankel-type affair, but I think a Wankel had a single rotor, or perhaps a couple of rotors in line.

The Dake has a piston inside of another piston, but otherwise the pistons get pushed from the top and sides, similar to how a Wankel works, sort of.

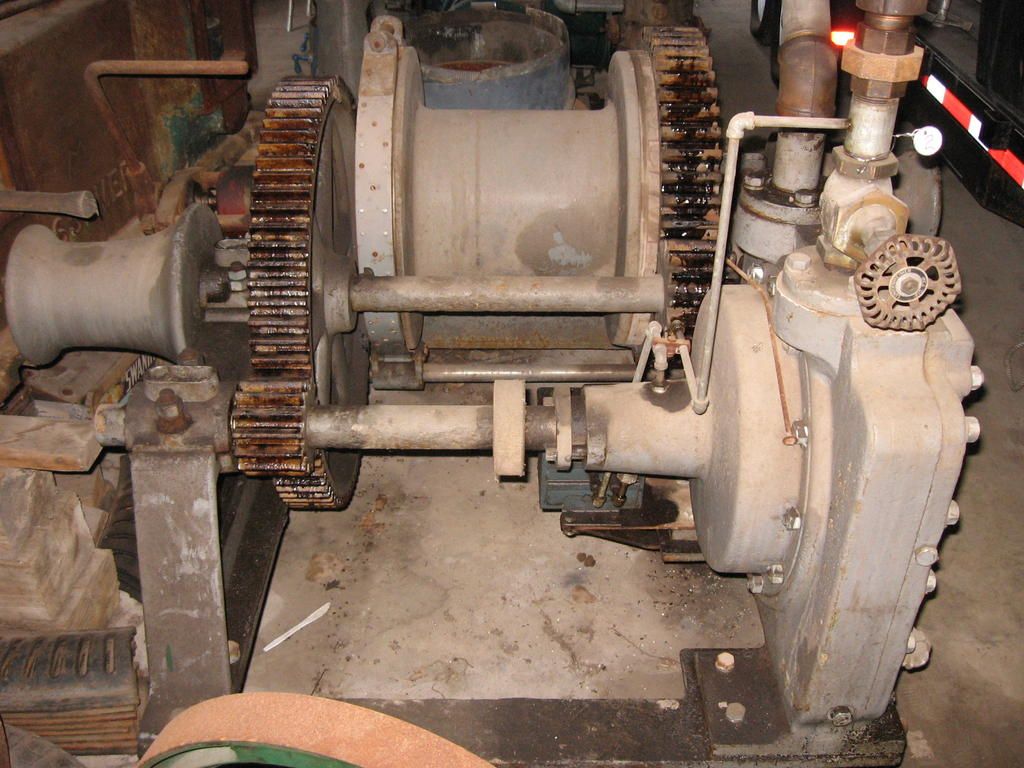

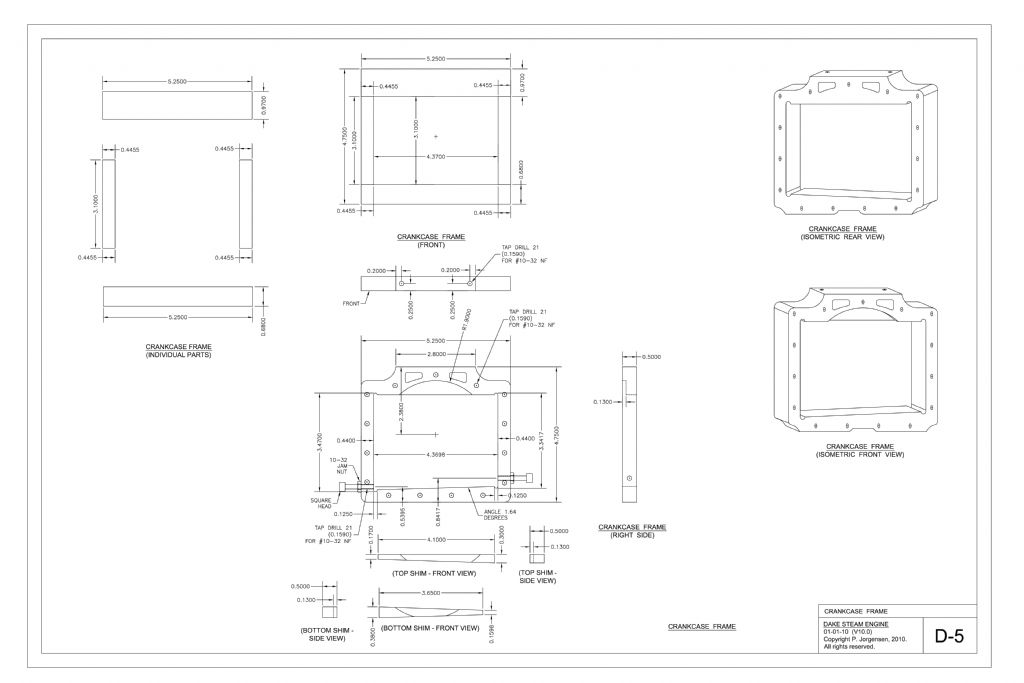

The clearance between the crankcase cover and the pistons was controlled by using stacked gaskets, perhaps each at 1/1000 thick.

I don't think leakage was a problem.

There was no adjustable cutoff, and so this would not necessarily be an economical engine to run at full speed continuously, but as a specially adapted engine that required quick reverse and no dead centers, it is an exceptional design.

These engines run extremly smoothly, and make an odd slushing sound when they run.

No doubt they make perhaps a constant torque as they revolve, similar to a 3-phase electric motor.

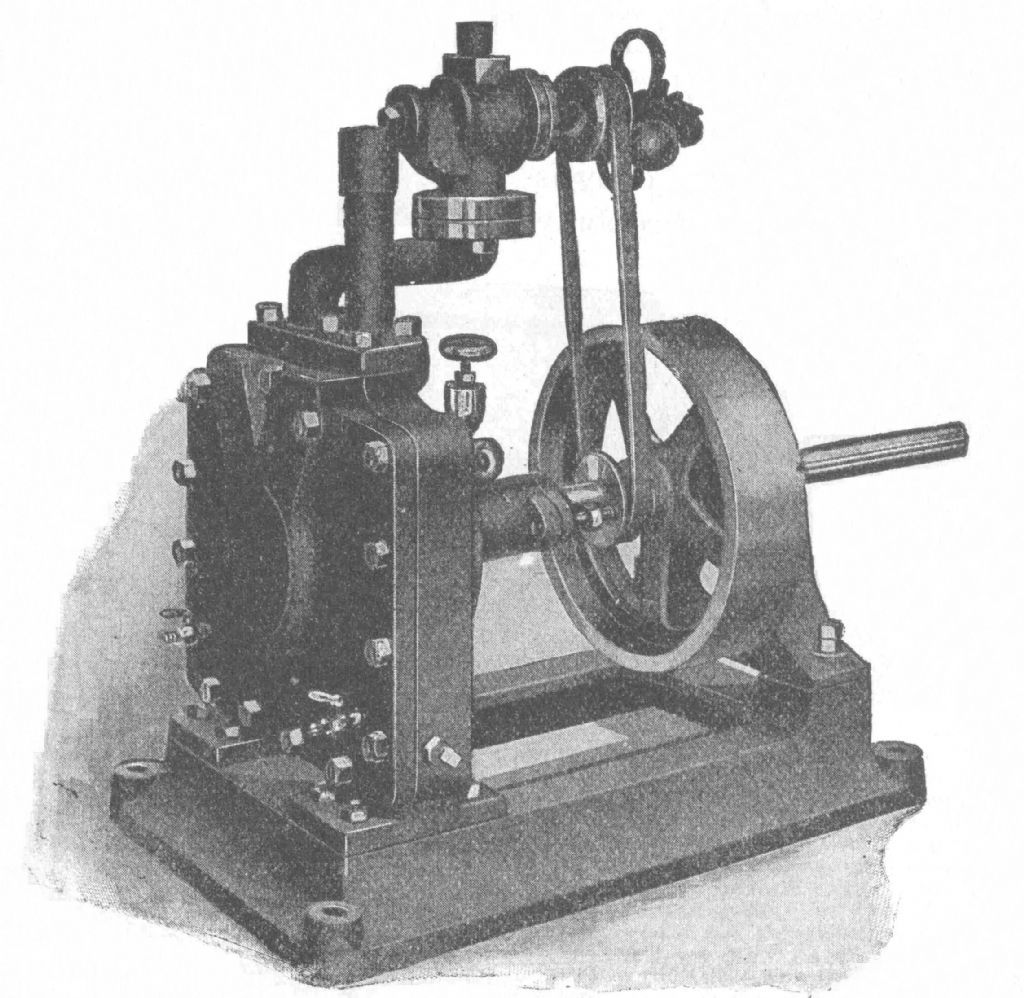

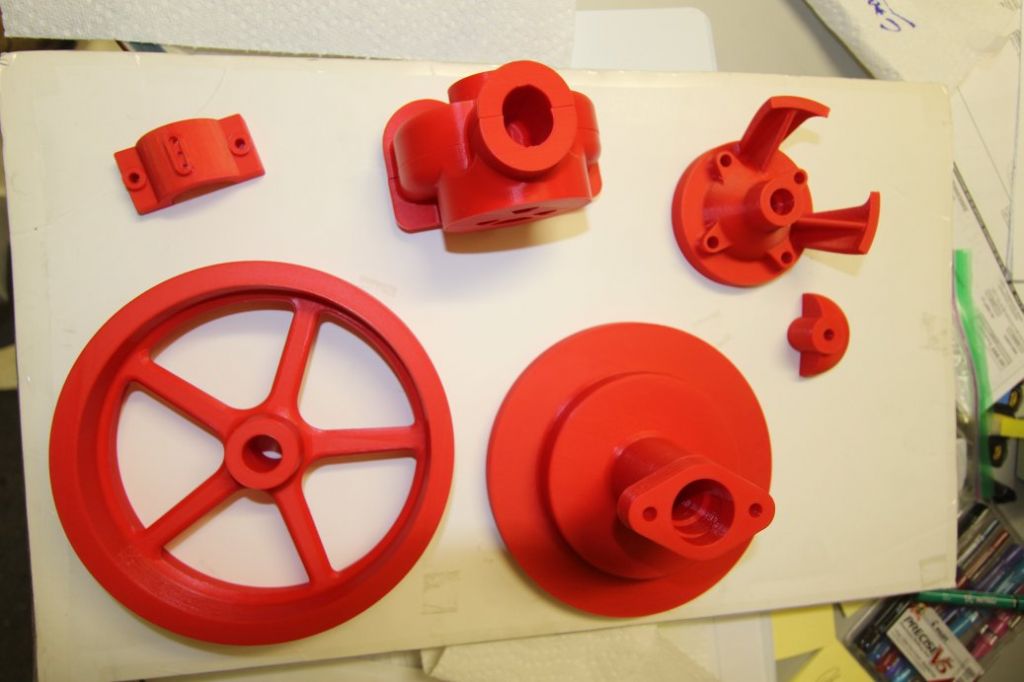

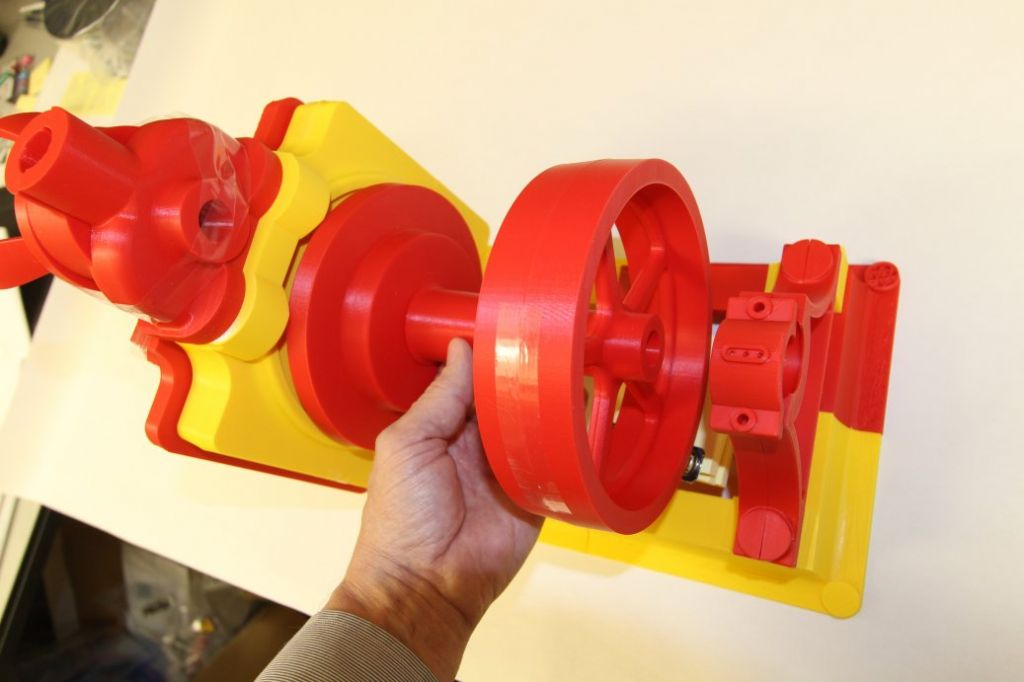

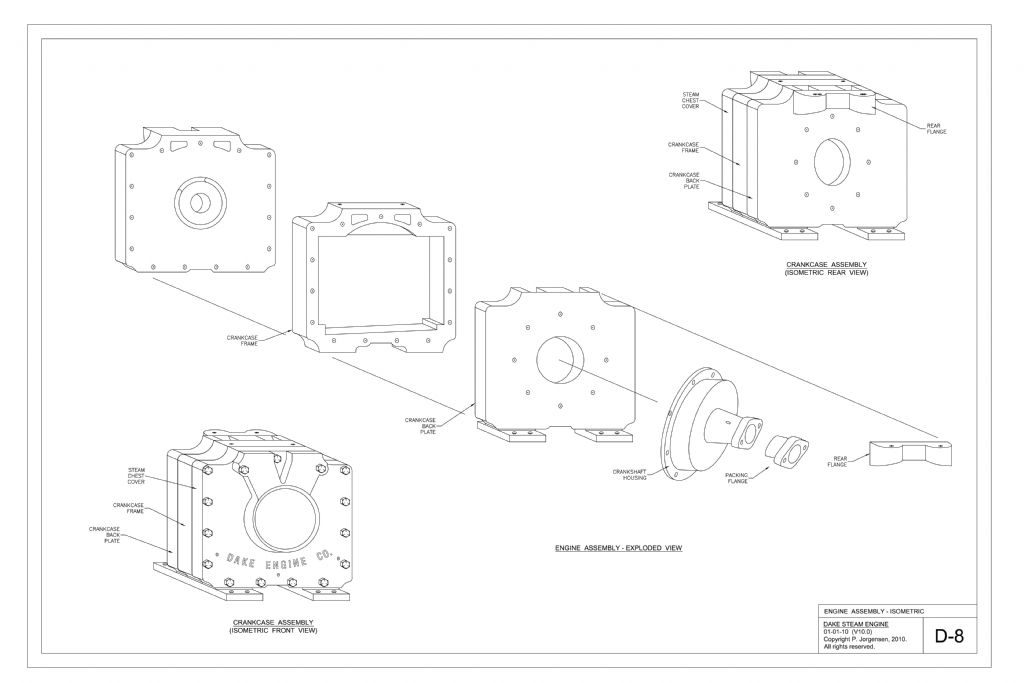

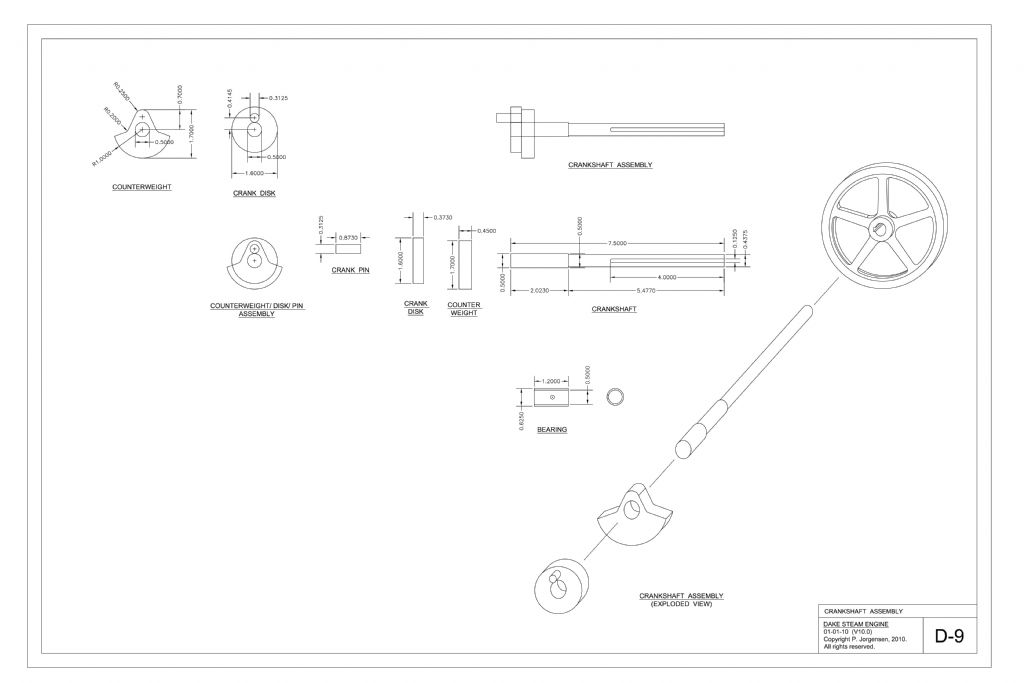

They were advertised as having only three moving parts, which is almost true.

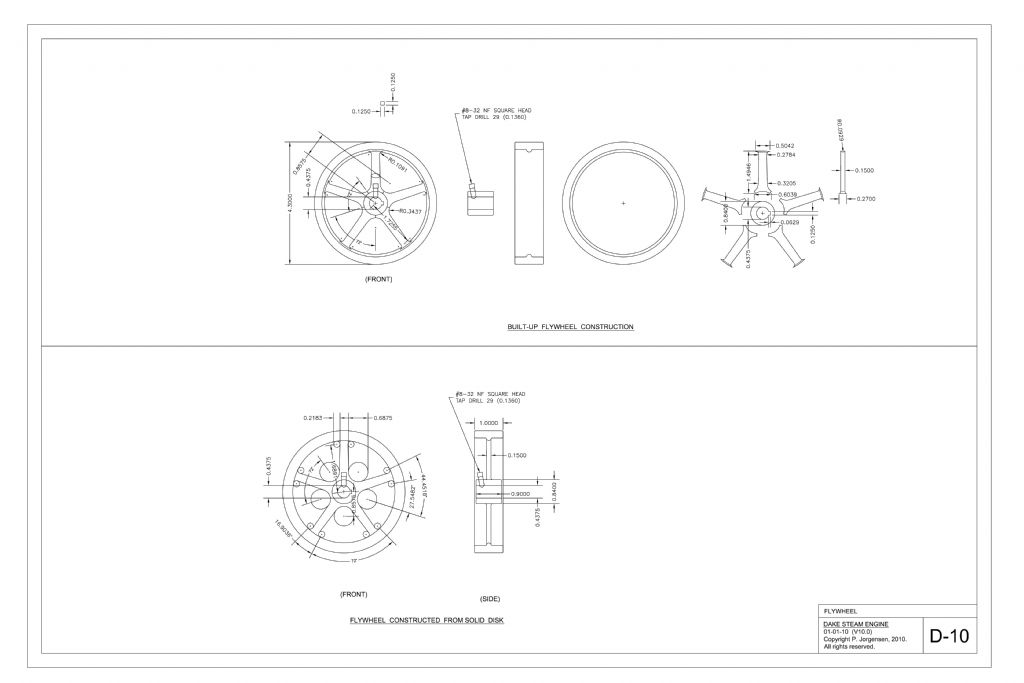

The flywheel, crankshaft, crank disk, and crank pin are considered on part (assembly).

The inner piston is the second part, and the outer piston and its two shoes are the third part (assembly).

From a parts count, it is an absurdly simple design.

From a theoretical functional standpoint, the engine is pure genius (the genius of Roots originally, modified a bit by Dake).

The inner piston is also a rotating multi-port slide valve.

I find this a fascinating engine, and for me to find one on ebay is sort of like finding the Hope diamond laying out in the front yard. I have never seen one of these engines for sale.

The totally enclosed design is a turn-off for some, who like to see the moving internal parts of an old engine.

.

PatJ.

PatJ.

It would be an education to see those squares moving about.

It would be an education to see those squares moving about.