In Volume 100 of ME, on page 44-45, Duplex discusses the use of the Starrett Bench Block No. 129 as a useful tool for drilling cross-holes central in round bar. He shows a couple of sketches as to how to go about doing this.

To quote his text,

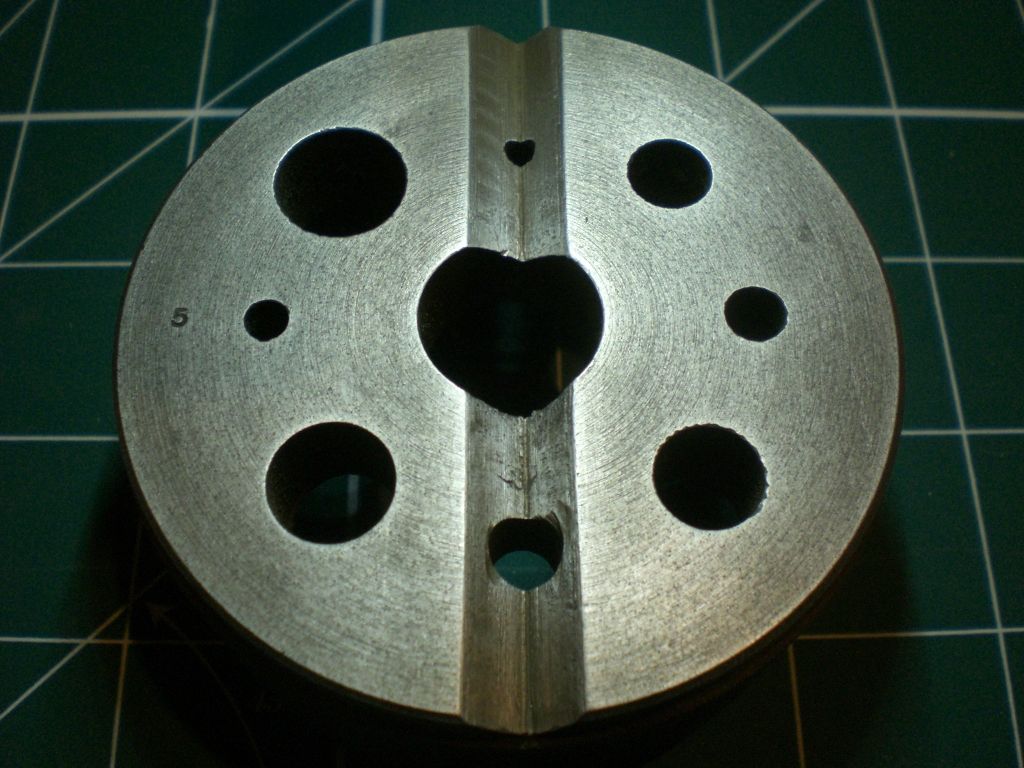

"The Starrett bench block No 129, illustrated in Fig 11, which is accurately machined and surface ground after hardening, could, without difficulty, be adapted to make a drilling jig of this pattern. The central hole is bored 5/8 in. in diameter and lies on the axis of the V-groove machined on the upper surface of the block. Moreover the recess in the underside of the base would provide ample space for housing the nut and washer fitted to the central clamp bolt".

Further, this was one of my last items to be made in the apprentice training school at Dowty Rotol Ltd. This was without doubt a copy of the Starrett item, as Starrett ones were in use in the Toolroom. I well remember the difficulty setting up to grind the Vee. Not only was it to be central with the central hole but also the other two holes in the Vee. If that was not hard enough the Vee had to be a certain depth as well, checked with a roller, slips and a clock.

The operation taking best part of a morning to achieve for an apprentice, but this put us in good stead for when we reached the shop floor.

While the larger holes on the flat surface could be used with a simple attachment to make shim washers, as on our blocks these holes are on a common radius. The two holes in the Vee were merely for drifting out pins in shaft assemblies. My block has served me well over the years, especially when I was a Toolmaker, and I would not be without it.

Regards

Gray,

Bazyle.

Bazyle.