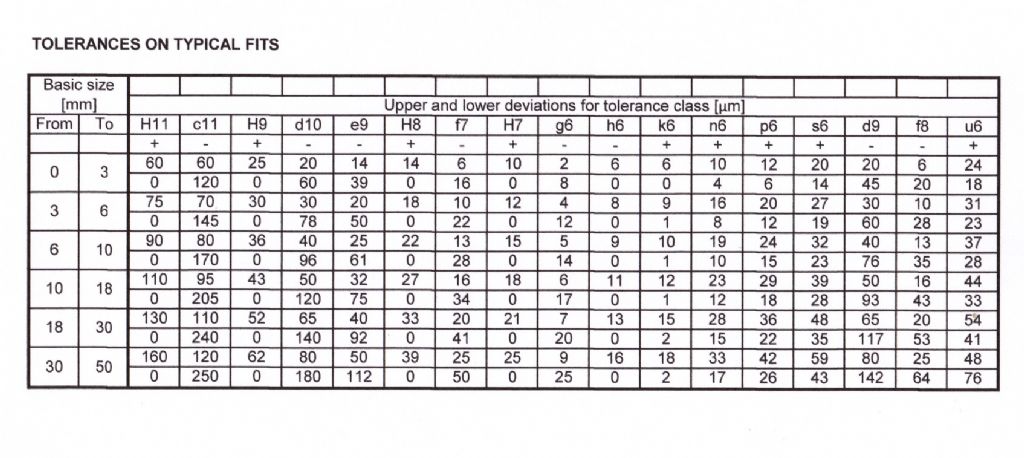

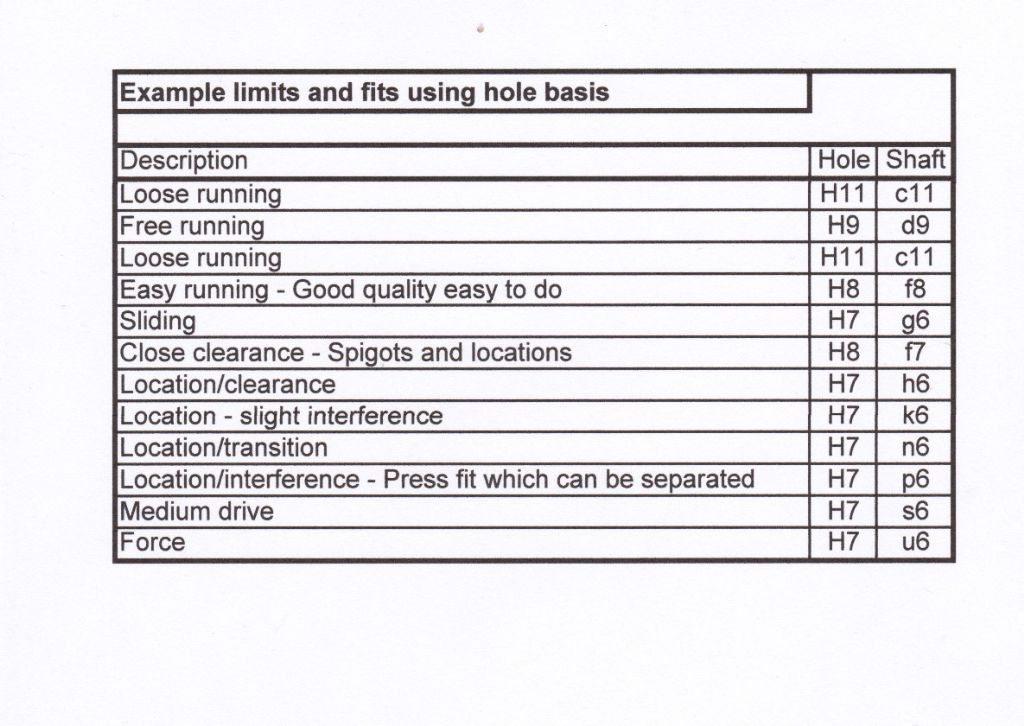

After a bit more research I think I can confirm that D tolerances primarily refer to the pitch diameter of metric taps. Presumably to avoid confusion with H tolerances which, strictly, were intended for holes.

I gather American practice is supposed to be to use GH rather than H for tap pitch diameter tolerance but this seems to be honoured more in the breach than observance.

For practical purposes it appears that D tolerances pretty much follow H tolerances with the same number.

I was unable to find a simple, straightforward explanation on the internet. the more detailed and potentially useful the presentation the more [deliberately?] confusing the explanation.

This link from Guhring **LINK**

https://www.guhring.com/media/InteractiveCatalog/jkko1oebbiy/files/basic-html/page32.html

has one of the less confusing presentations on the second page! I advise having headache pills, or at least a wet towel, handy before reading.

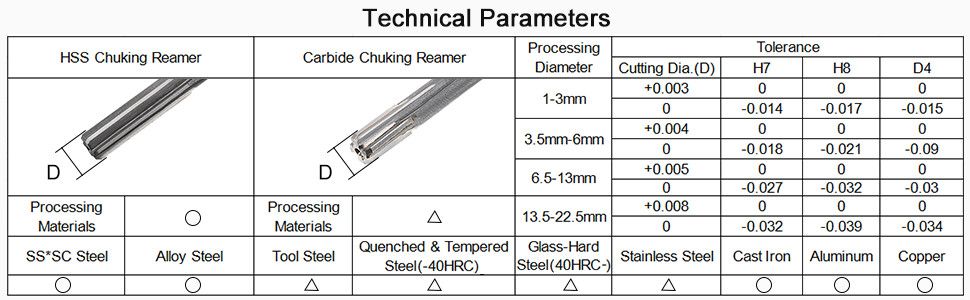

It all begs the question as to what a D4 tolerance has to do with reamers.

The Guhring reference above states that each D limit = 0.013 mm followed by a couple of examples that seem to make no mathematical sense at all.

Clive

Michael Gilligan.

Michael Gilligan.