Posted by David Heskin on 17/06/2022 22:34:51:

I'm following the electronic free pendulum clock articles in ME Workshop, but need to secure details of successful motion work before committing to the project.

To be honest and with respect, I'd much prefer a solid state digital LED display. I'm hoping that'd be easier and more reliable. Quiet, too. Can anyone advise how to go about it, please?

Well, Tony Jeffree is using BBC Micro:bit microcontroller, for which LCD and LED modules are available. Examples picked randomly off the web from the Kitronics Web Shop:

Kitronik :VIEW text32 LCD Screen for the BBC micro bit

Monk Makes – 7-Segment for micro:bit

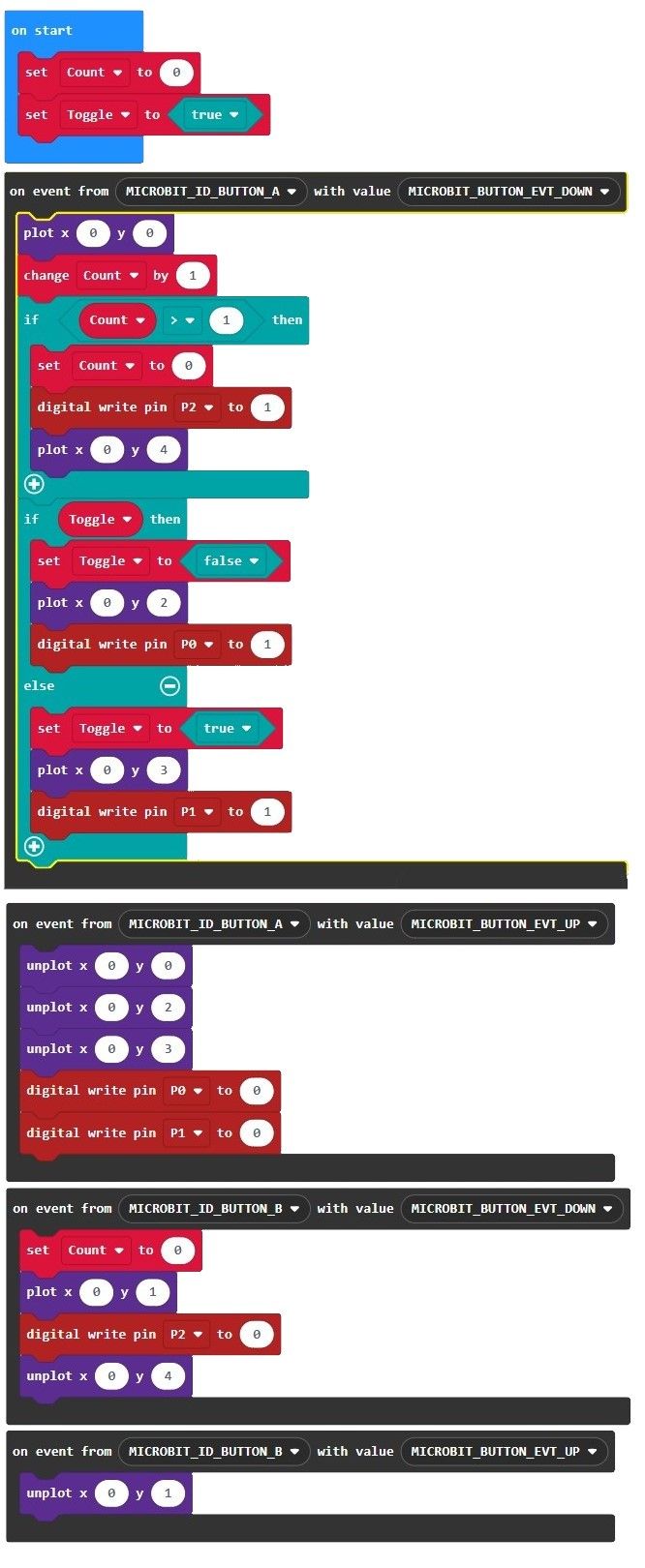

This chap documents a Micro:bit and LCD display coded to be a stopwatch, not complicated and a reasonable start point. The software part is done with a graphical Blocks language called 'MakeCode', lots more examples and tutorials here.

Tony hasn't shared his code yet, but in principle, however he's done it, it will be possible to add digital clock functionality. Basically a clock display just counts pendulum pulses, and, knowing how long they each take in seconds, uses them to increment a counter working in HH:MM. The main complication is the code needed to set HH:MM to local time in the first place.

Also possible to program another microcontroller as a separate HH:MM clock ticked by the pendulum. The advantage is avoiding the need to understand and modify Tony's code, which might be time critical or otherwise tricky to modify. (Probably won't be.)

I'd use an Arduino for this, but only because I'm familiar with programming them and have never seen a Micro:bit in the flesh!

Dave

Brian Smith 1.