The Precision Gravity Pendulum

The pendulum’s shaft is made from 0.25” diameter Invar, an alloy of iron and nickel (generally 64% iron and 36% nickel). This material has an unusually-low coefficient of thermal expansion of about 1.2 ppm per degree C. This substantially reduces temperature effects on the precision of the measurements. The shaft is about 2’ long.

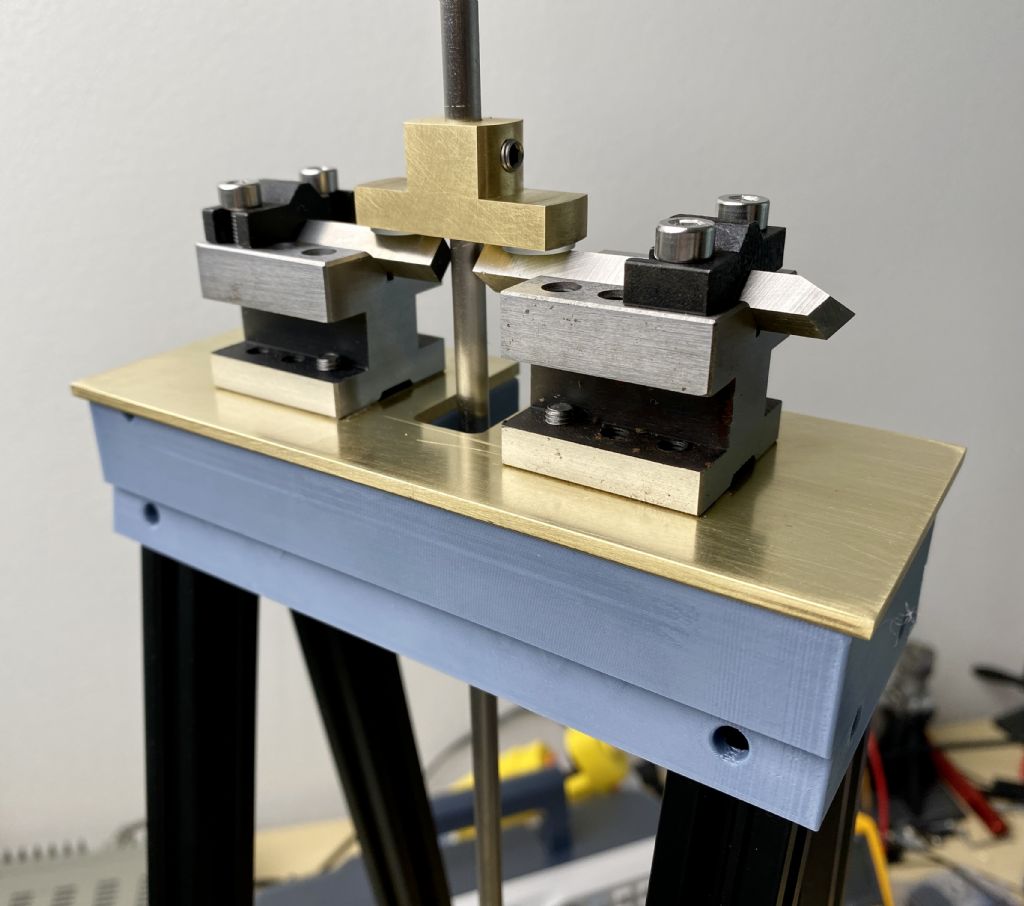

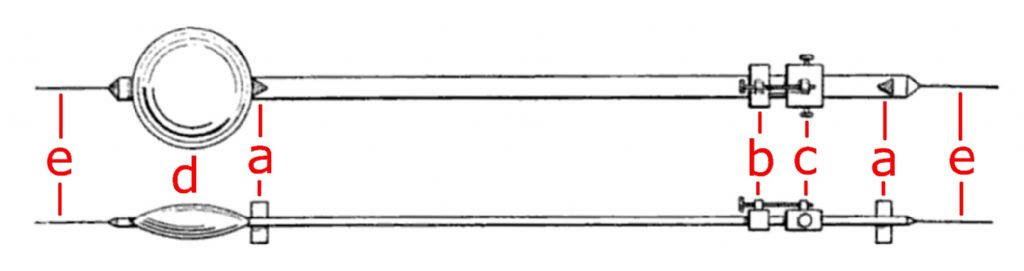

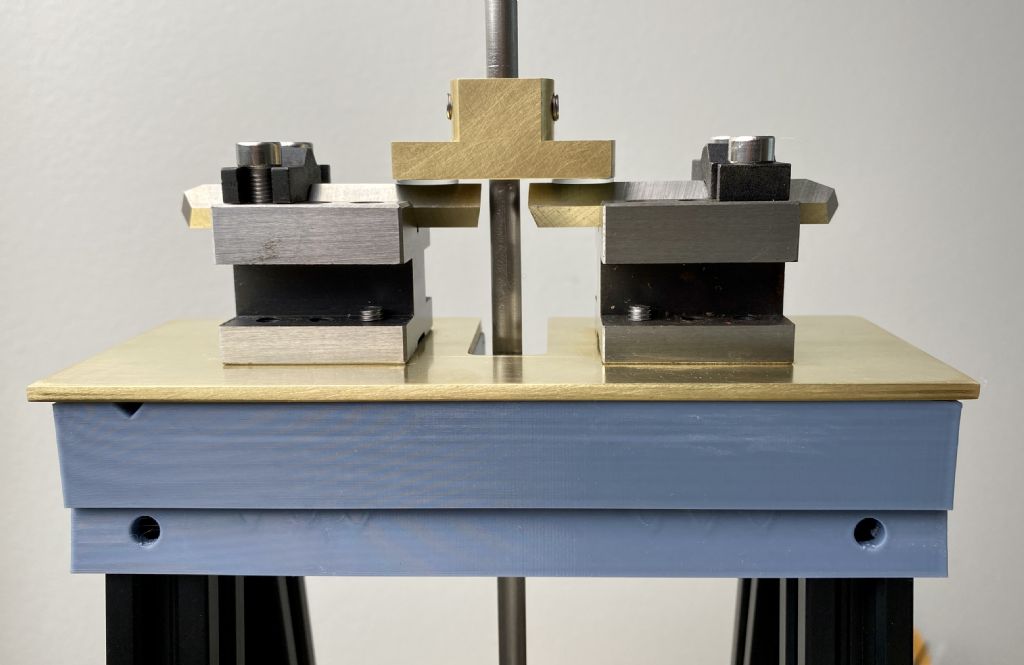

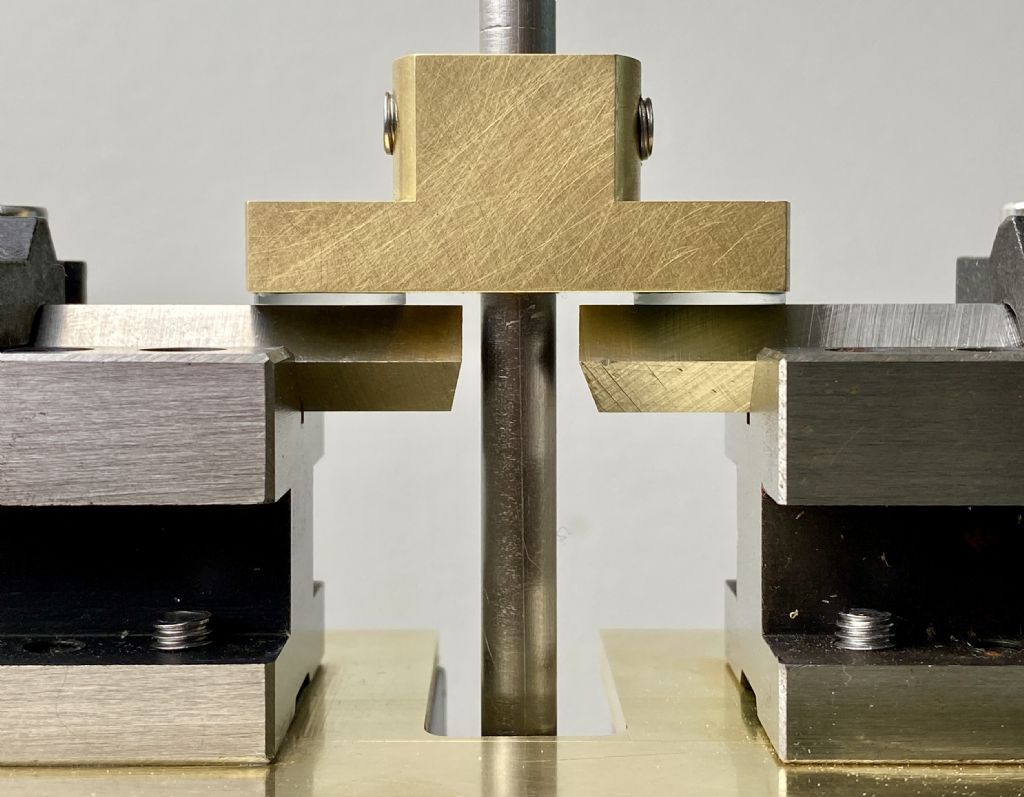

Kater placed the knives on the pendulum, which rode on agate plates on the pendulum’s platform. I reversed this, putting small sapphire disks on the pendulum and the knives on the platform. This means that the same set of knives is used either way the pendulum hangs, eliminating one source of error.

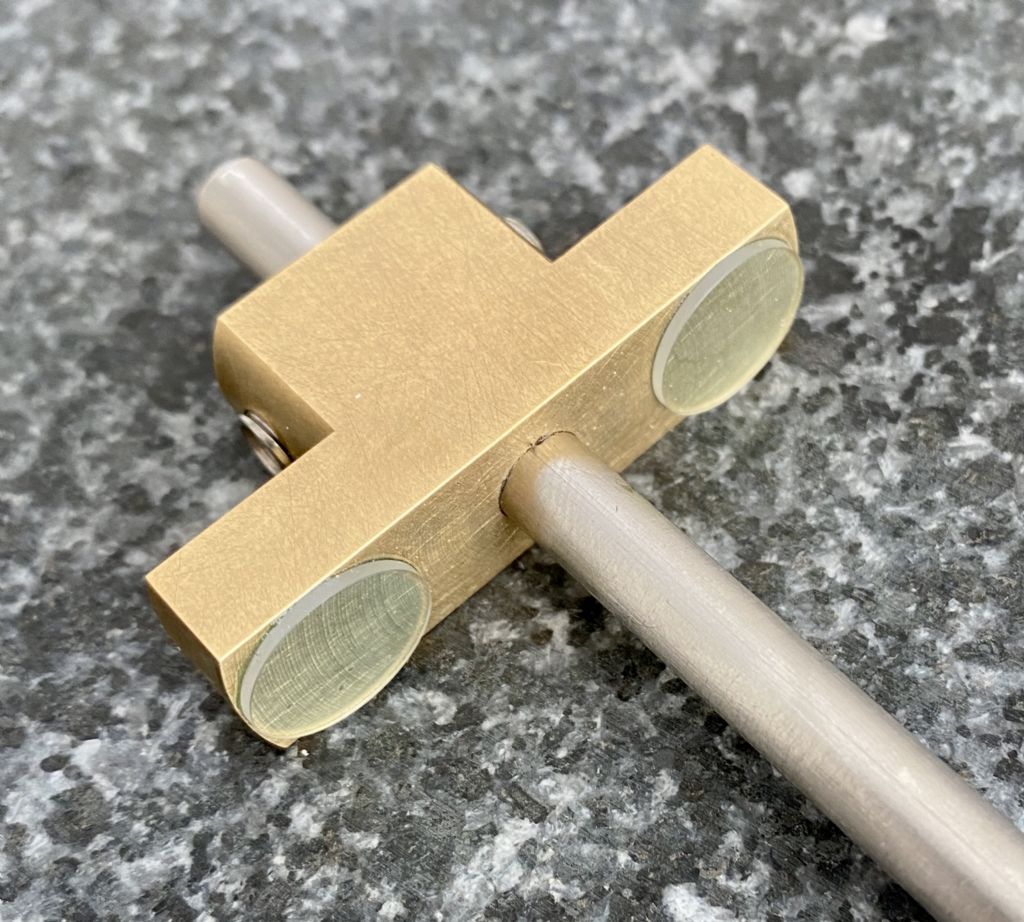

On the light side of the pendulum (the normal “up” side) is a small bar of brass that acts as the anvil on that side, resting on knife edges. It can be moved along the shaft and fixed in position using two brass-tipped set-screws. Moving its position is the primary way to adjust the period of the pendulum, i.e. by lengthening or shortening it.

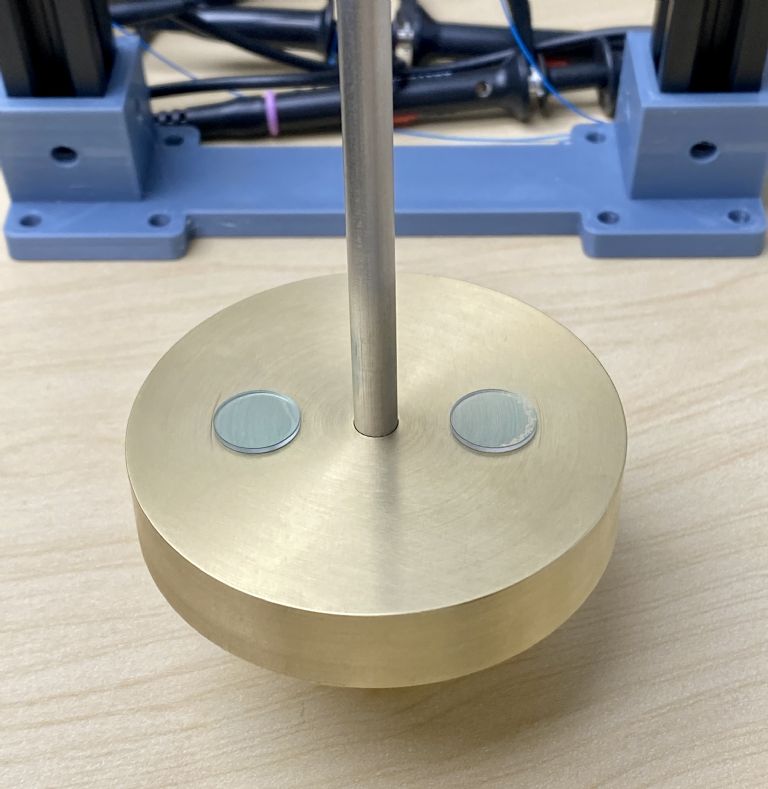

Two 0.5” by 0.0394” sapphire windows were applied to the brass bar to act as “anvils.” Sapphire is far harder than steel, and can rest on steel knife blades without being marked. Pure sapphire is extremely clear, and the blue tinge seen is from the adhesive. The windows were selected to be the same thickness to well under 1 thousandth of an inch.

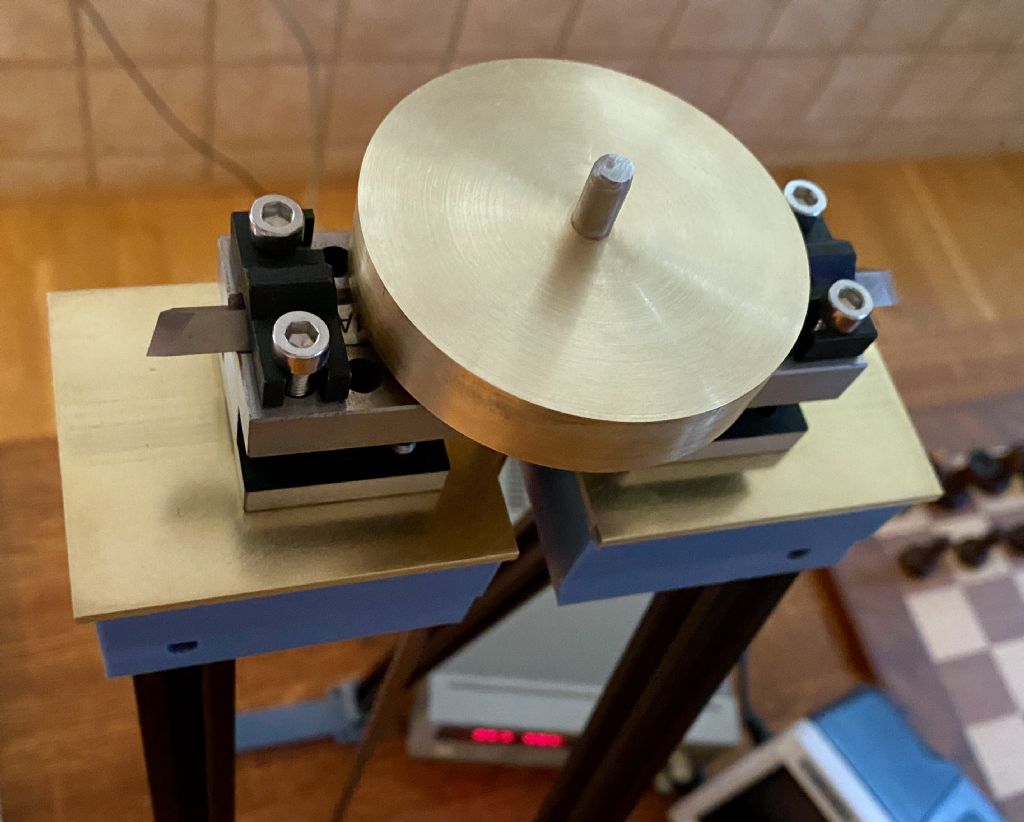

The bob is a brass disk of about 0.5 by 2.75 inches, and weighing about 1.5 lbs, fixed to the Invar shaft by a penetrating adhesive. The bob is hung with the disk parallel to the horizon rather than hanging vertically as normally seen in clock pendulums. This position centralizes and minimizes the spread of the weight over the length of the Invar rod that it’s attached to.

Having the mass close to the pivots is also important. If all mass was right at the pivots, the length of the pendulum would not need any adjustment – any length should have equal periods when hung either way. But if the heavy mass (especially) is at all distant from the heavy-side knives, then the light side’s mass and/or position has to be adjusted to compensate. So an orientation of the heavy bob as close to the knives as possible, as this configuration allows, has advantages. Having the bob oriented this way also provides a convenient platform – the bob itself – for balancing on knife-edges (again, as close to the mass as possible).

I noted that the adhesive was not quite applied as evenly on the bob side as I'd hoped (I only had one shot at it), but so far it doesn't seem to be an issue.

Being cut with square edges, this bob is not as aerodynamic as clock pendulums usually strive to be, but it allows an easy and accurate measurement of its dimensions. The Repsold/Bessel pendulum (an improvement over Kater’s design) also included a same-sized bob on the light end, e.g. made of aluminum instead of brass. Having equalized shapes on both sides of the pendulum nullifies differences in air friction when the pendulum is reversed. It’s my intention to eventually 3D print a light shell that can be fitted over the light-side anvils for this equalization.

S K.