George, Nick, thank you for the nice comments

John, thank you very much!

Neil, I've spent most of this evening sorting issues out in the headstock – nothings damaged, I suspect its purely bad design (I have an early version, these issues would be easily resolved)- maybe this is why they didn't take off initially – I wonder if they picked up a bit of bad reputation?? I was certainly surprised, and studied over the litrature and sectional drawings, all the parts are present and correct, its all in the right order, no washers, spacers, etc etc have been assembled in the wrong order – its all there, its just not very good sadly.

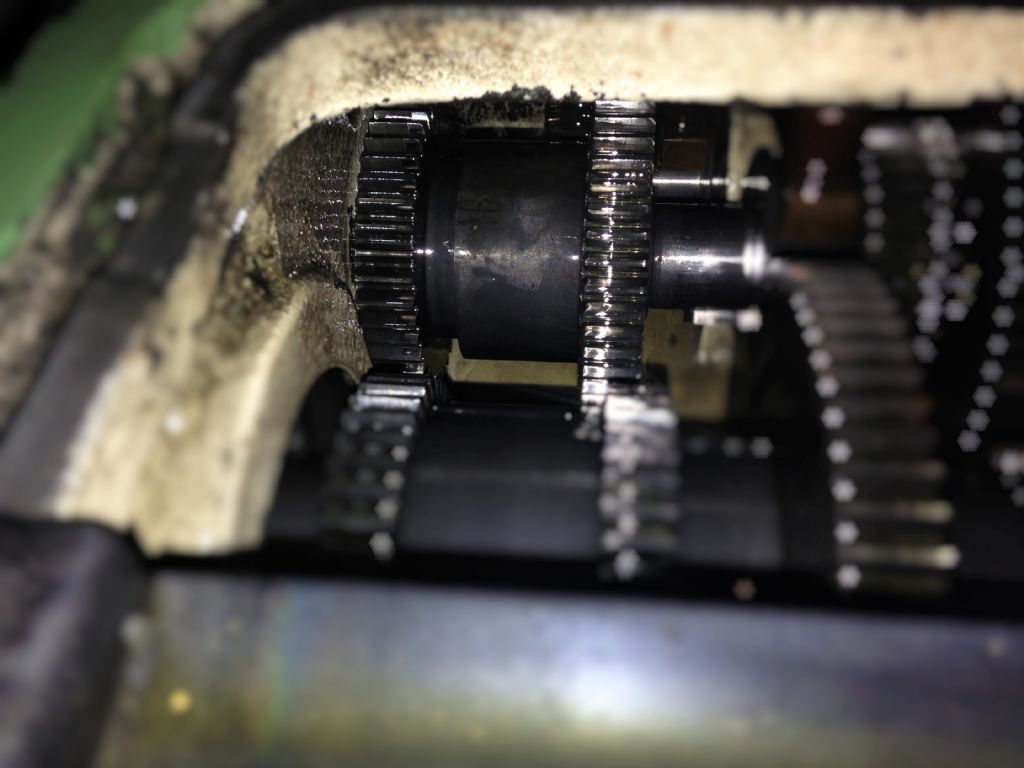

The main issue has been on the first 2 pairs of gears which can be selected, the sliding pair are fine, but the static pair are keyed and press fitted onto a hub which transmits power to the shaft it is sat on. In the photo (the in focus gears) I have gently tapped the right gear back upto the shoulder, it had slid off just as far as the one on the left which is almost touching the casting, it should be right up to that shoulder. There are no securing screws, no circlips, no grub screws in the end of the shaft. What happens is, when moving the sliding gears, if they don't mesh as they slide towards the left/right, they lightly "tap" and naturally, you rock the spindle a little by hand – unfortunately just that little tap, is enough to knock the gear off its hub!

So, I'm not wildly impressed with that design. but it does look easily resolved (IF, and this is HUGE if, I can get the gears, and that hub, out of the box, without taking the spindle out which looks very, very unlikely) – so, I'm surprised it even made production, I can only assume my gears are not quite tight enough on the shaft, of someone forgot to apply so sort of adhesive (can you even bond a gear to shaft in an oil bath?)

The near end of this shaft is supported by a roller bearing with an oil seal etc -.no problems there. The far end is supported by an oilite bush which acts as a thrust against (again) only the tapping created by gently shifting the sliding gears into it – again a miss match would create a gentle knock, and again, this is enough to just gently tap the bush out of position I can easily resolve this without stripping the gearbox by tapping the bore through the casting (or fitting a threaded plate to save damaging the bore if the shaft needs to come out that way) and then fitting a threaded thingimajig to just sit against the bush and hold it in place.

Fixing the pressed gears is a bit more difficult. The only access is the large cover over the spindle, and the spindle blocks it in as the shaft those troublesome gears are sitting on are behind it.I could possibly try to extract the shaft far enough for those gears to become free, but getting fingers back in to reasseble, or even remove that lot…… unlikely….

Apart from the dooooooooom and gloom, I'm really pleased with it. It's all there, none of it is damaged and bar that one pair of gears and the bush, it is very, very well made.

Edited By Russ B on 16/03/2016 23:19:23

Russ B.