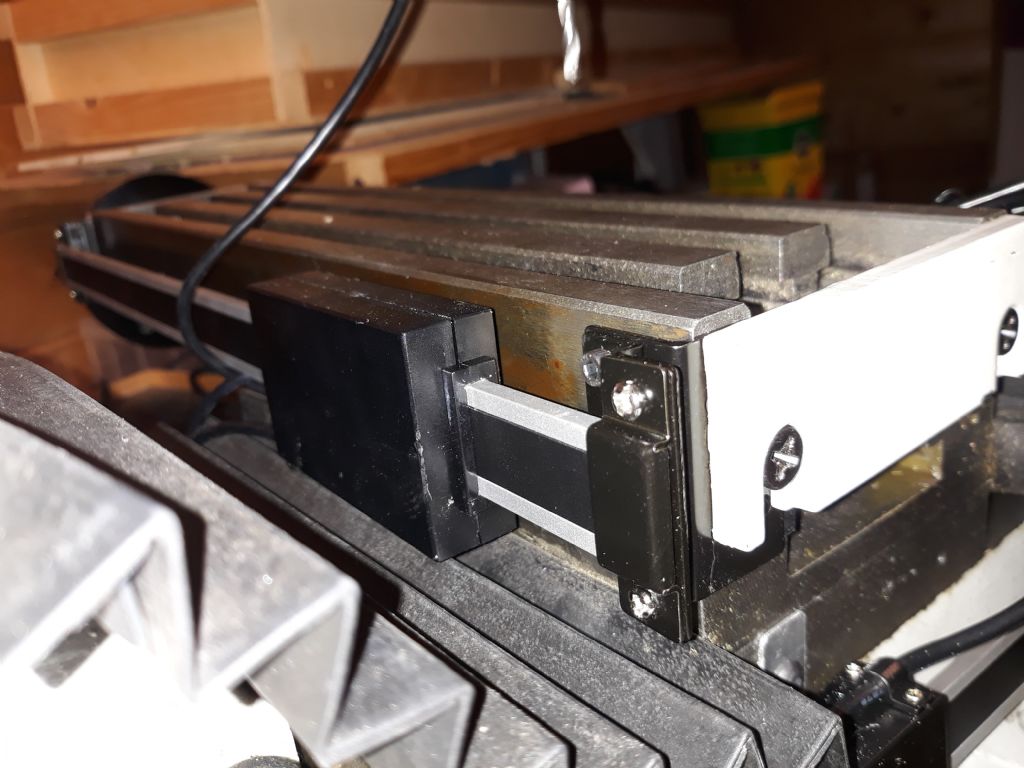

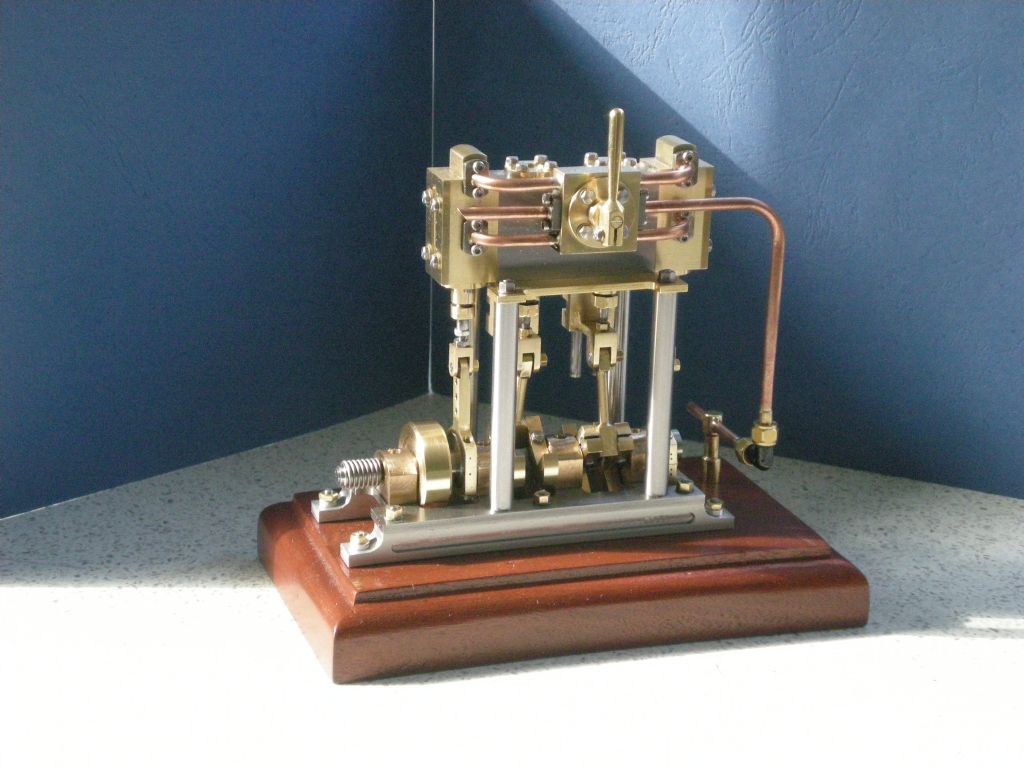

Years ago (and I mean many years) I started work on a twin engine, where the cylinders are made from one block of brass stock. The machine is rather small, bore 12mm, stroke 13mm. Unfortunately I lost my drawings (probably threw them away during some miserable phase). The cylinderblock was moved from Austria to Italy, and from Italy to the UK. It has probably survived 8 house-moves. Now, just finishing my late fathers Stuart 10v which I found in a rather rusty condition, I decided to do something with this old cylinder block.

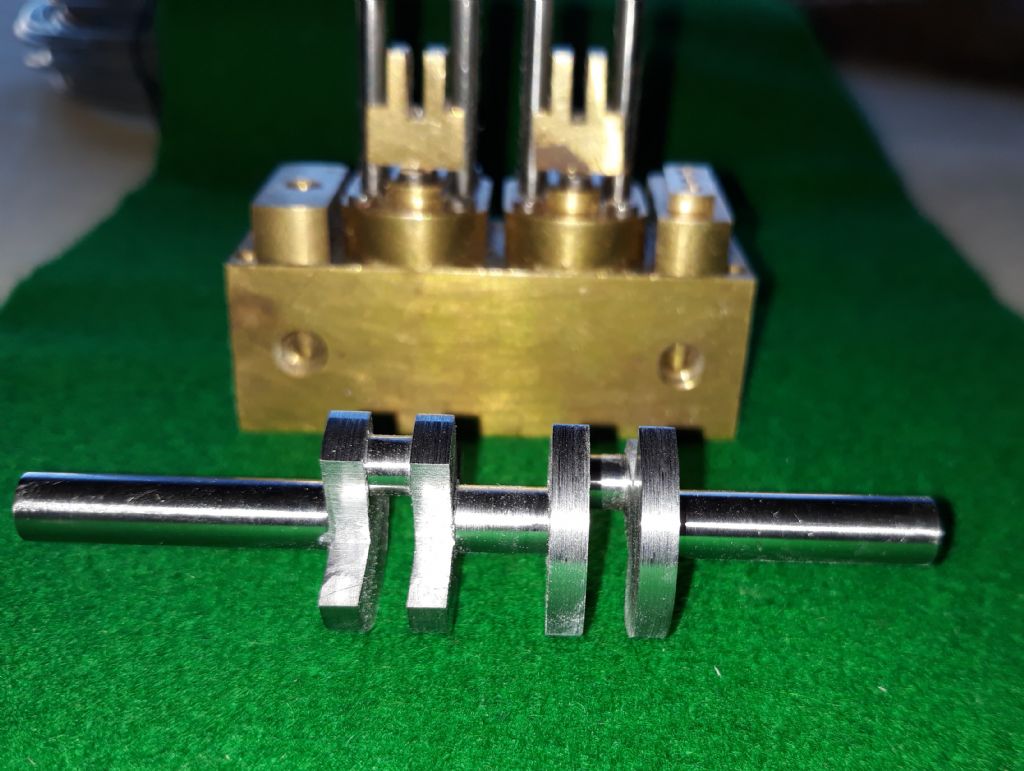

There were no pistons in the machine – so I made some, just to see how bad it has been machined. And – I am surprised – after some playing around I could make them to move quite free inside their block.

So this brought me to the decision not to throw the thing into the scrap metal box at the New Bradwell dump – sorry – MK waste disposal and recycling centre – but to start re-doing the drawing.

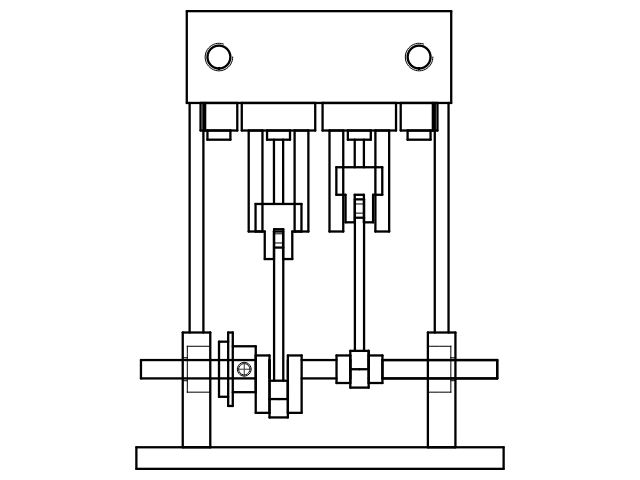

Well, I am an engineer, I have some past (25 years ago…) experience with autocad – so on we go. Autocad is too expensive for an almost retired part time worker so I use QCAD, where I have a little bit of experience in.

Pretty time consuming, and I am far away from where I want to be, but I can say it should be possible, if I can machine a crankshaft which is neat enough for this machine. I had my doubts if there is enough space for the valve excenter between bearing block and crank. Just measured 10.9mm on my drawing, so it should be doable.

If you want to see if it ends up in the dump finally – watch this space….

Gerhard Novak.