Hi Guys

This will be my final post on this project this year and I'm afraid it will be quite a while before the next. Quite a bit of progress has been made this month though not as much as hoped but I now need to set it aside for a while whilst I deal with something else.

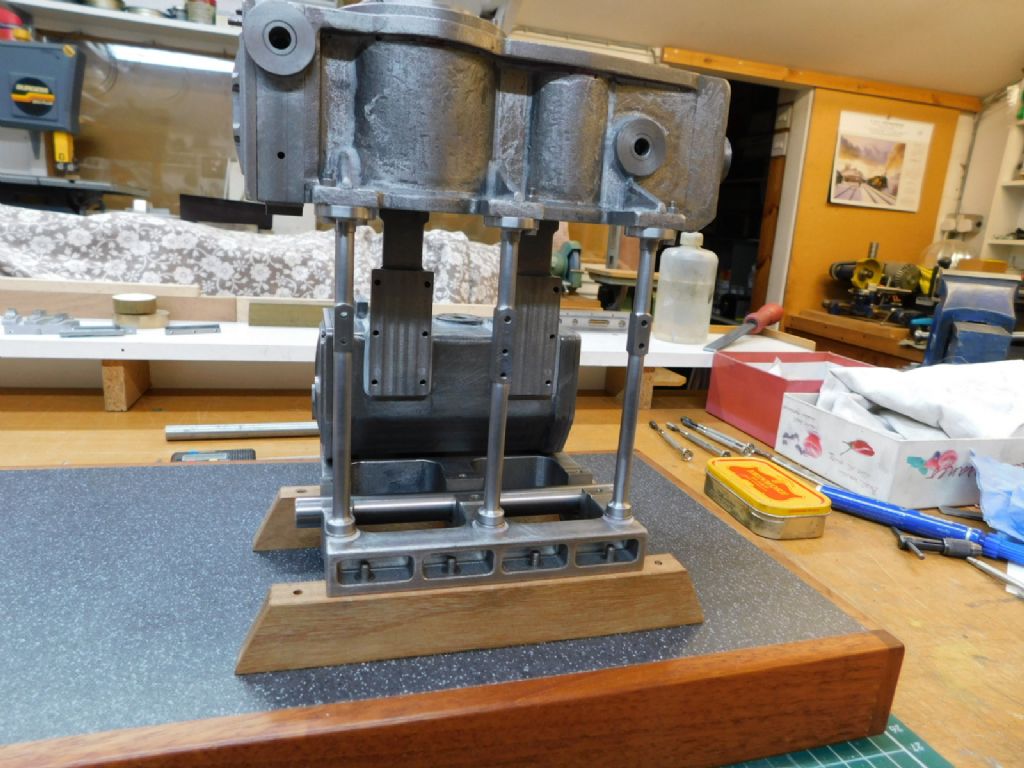

I did remove the engine with the intention of doing as you suggested Derek but having cut some wood for cross bearers decided against it due to the potential of not ending up with a flat structure and potential wringing of the bed plate. So the bearers were squared off and I carried on. I have shortened the base and glued a new end piece on which now looks a bit more in keeping.

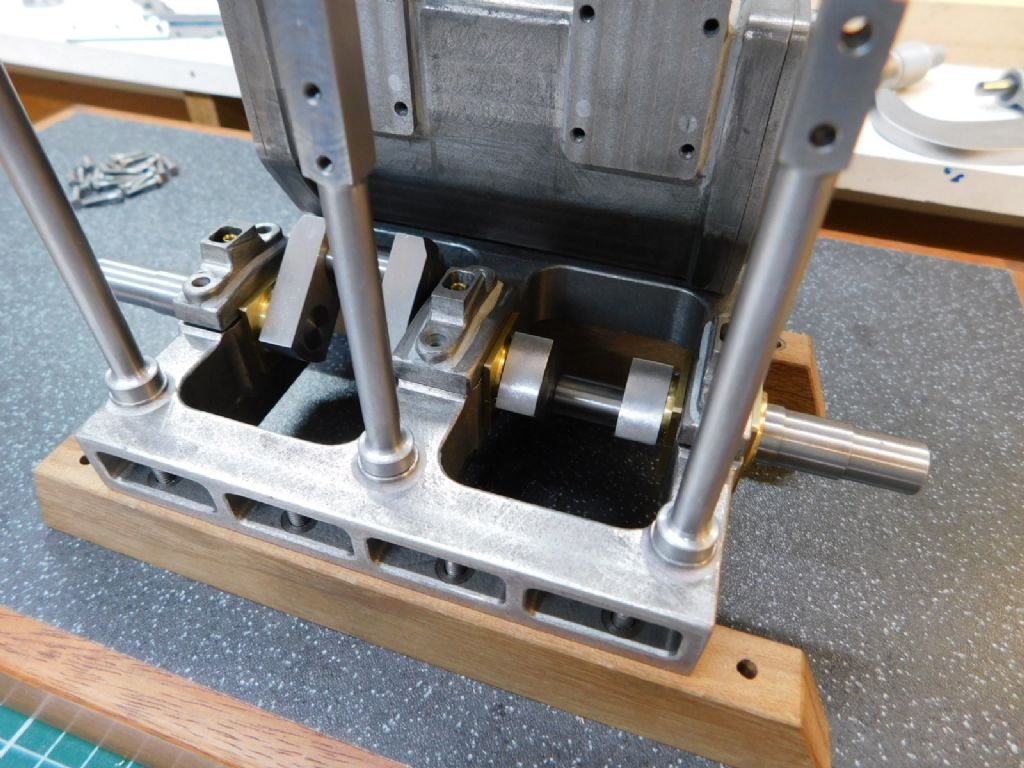

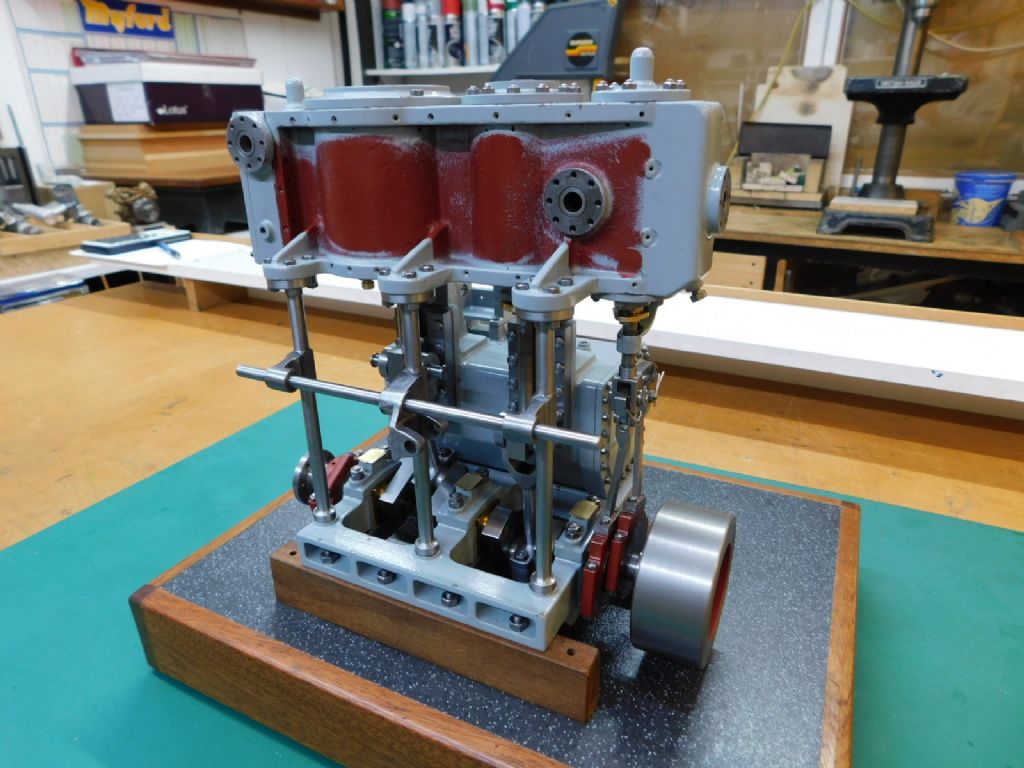

With the conrods made it and the gudgeon pins to suit it could at last be turned over – slight draggy friction but no specific tight spots so well pleased with the overall alignment considering all the potential for error.

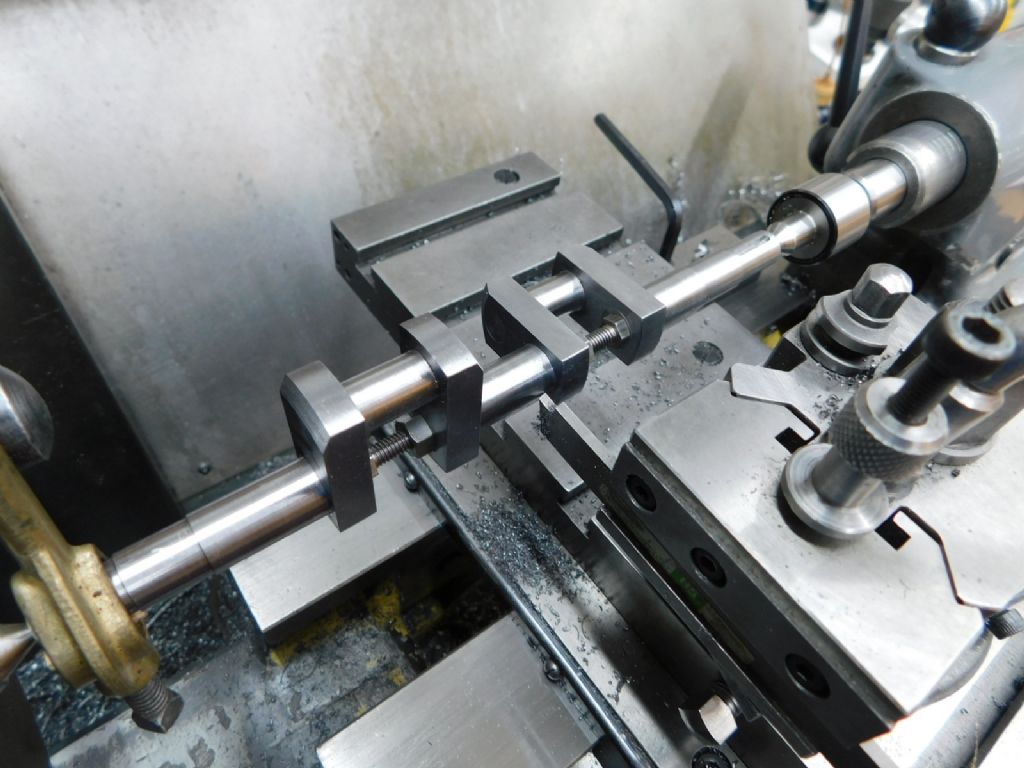

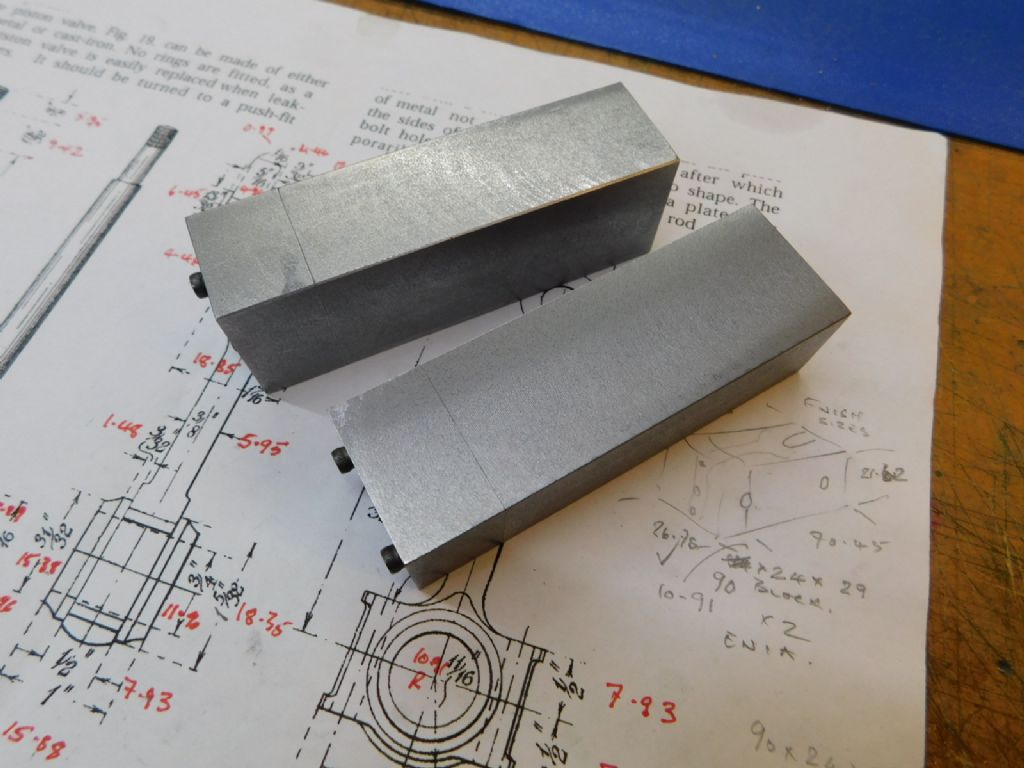

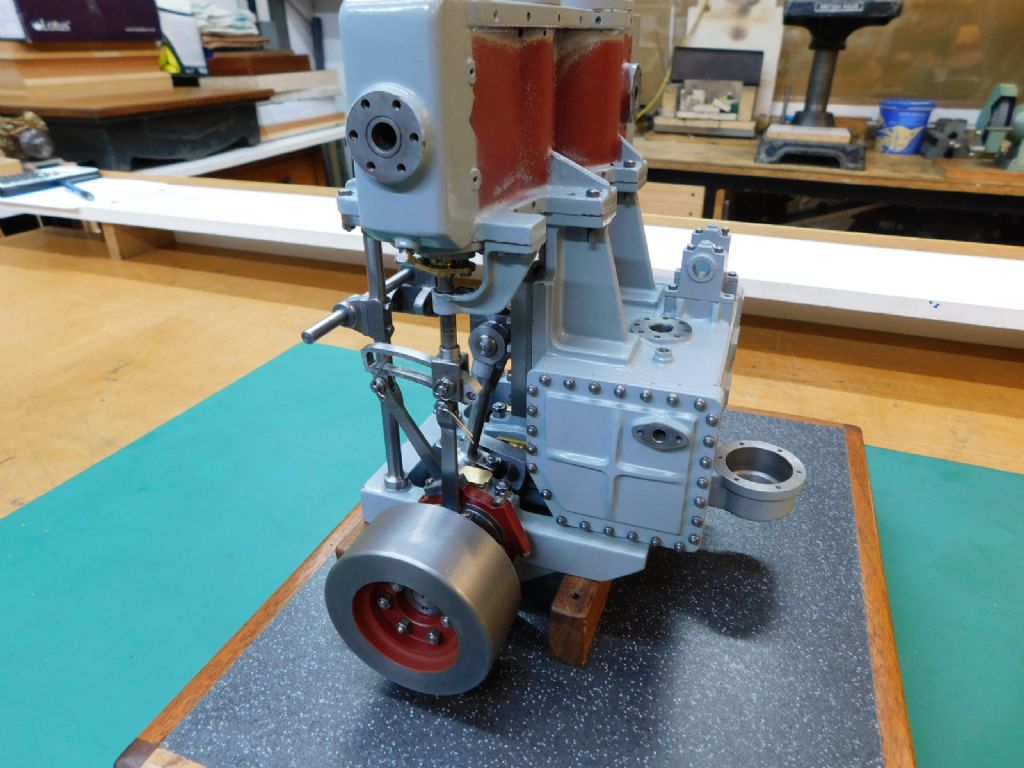

The original drawing calls for two, spaced apart, radial plates to form the expansion link but I decided to change it to the more usual slotted link and the straps milled rather than turned which made things easier when bending the offset.

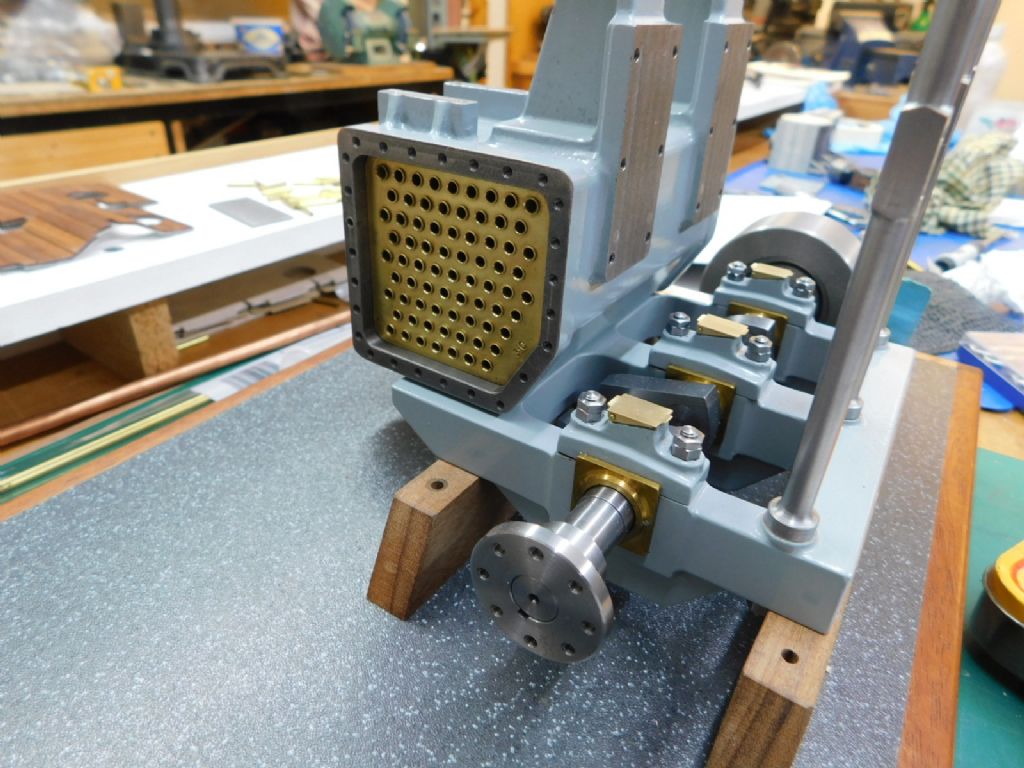

Pleased to tell that with a jury rigged air line pushed in the inlet it ran quite readily on the HP cylinder only – the only tweak a slightly thicker washer under the piston valve to even things out. Even with the short running time the slight friction soon eased and the engine turns over reasonably smoothly with just a slight resistance

Still a long way to go of course but it bodes well for the LP side.

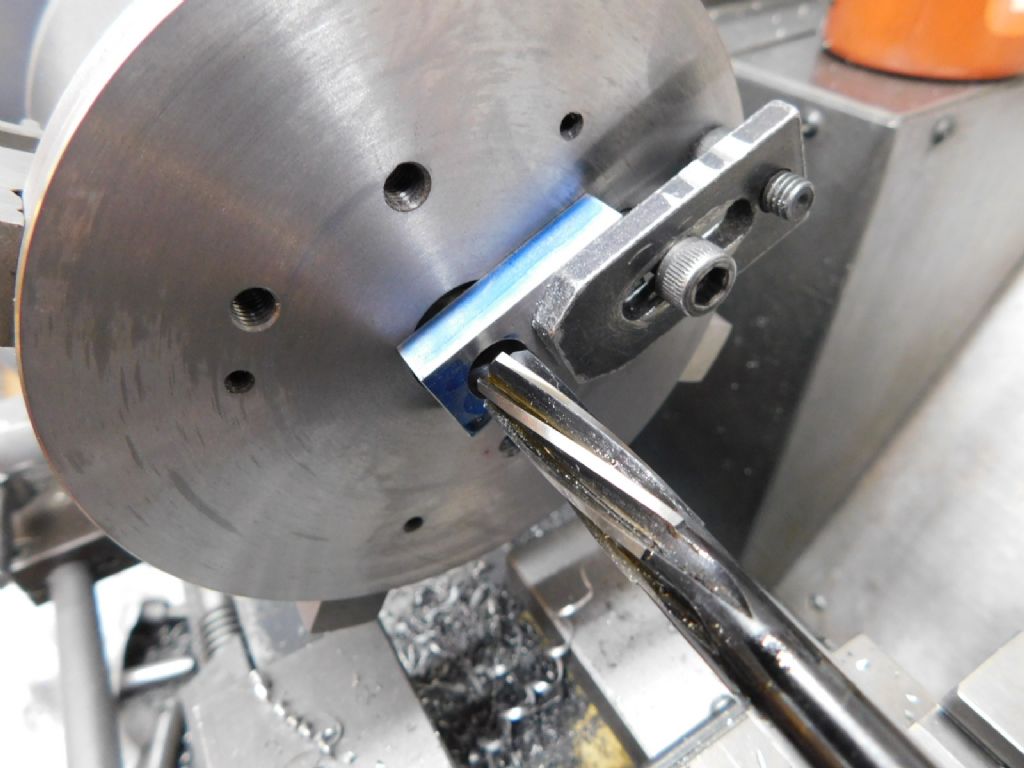

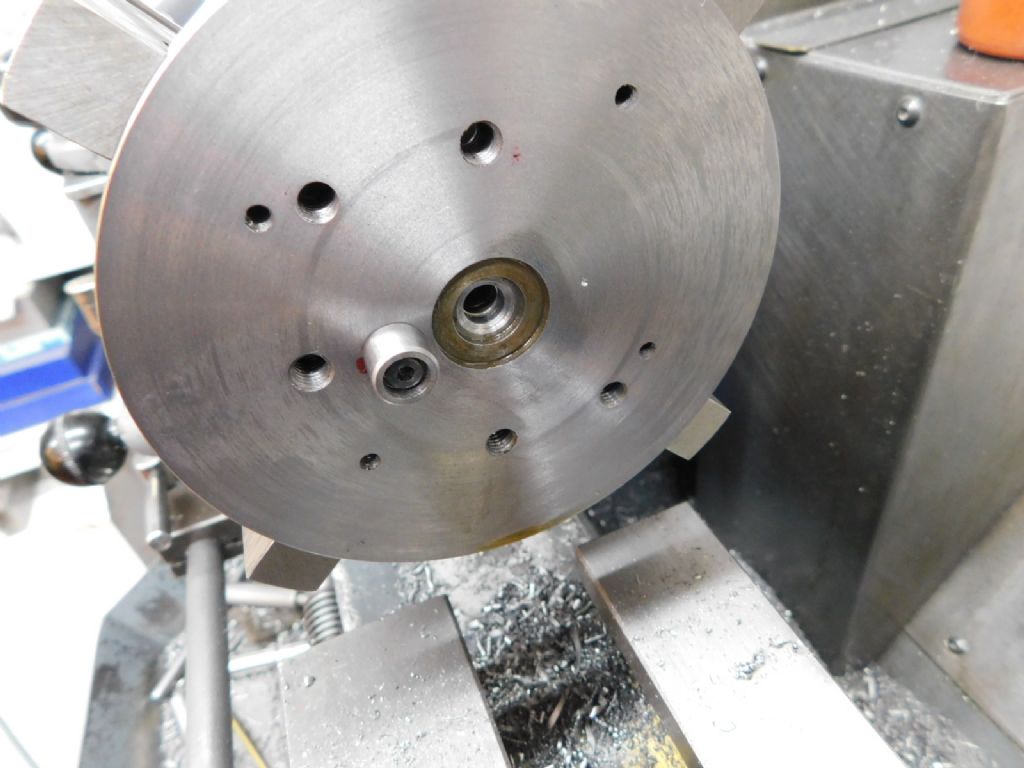

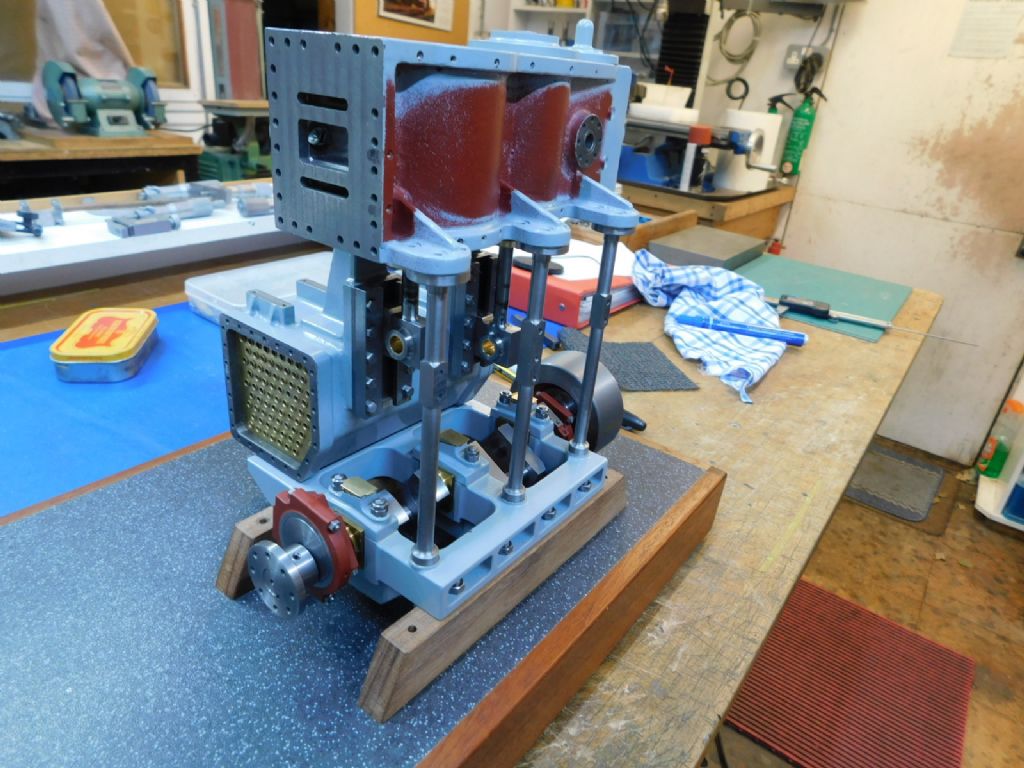

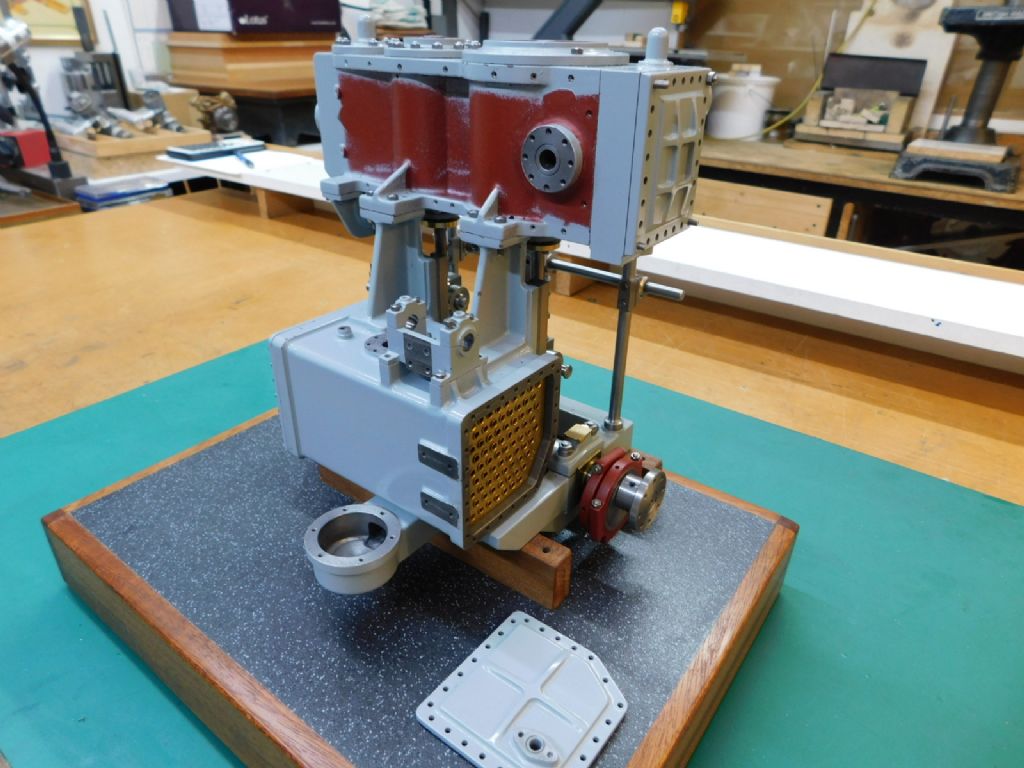

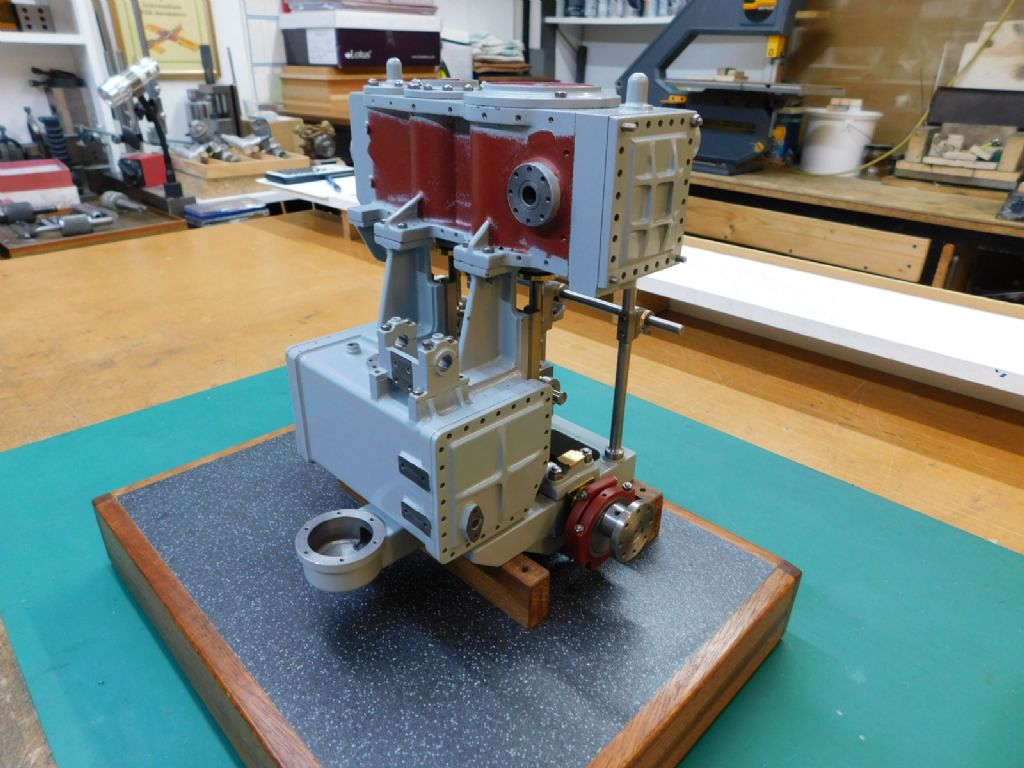

Here are some pics of the current state of play as of today

Well that's it for a while – I have a plastic project that needs to be worked on for my clubs annual comp in March that will take the weeks before then to finish.

A Happy New Year to all who look in – see you next year – sometime

Best – Tug

Edited By Ramon Wilson on 29/12/2022 22:16:57

Ramon Wilson.

Ramon Wilson.