Hello Chris, thanks for commenting and taking an interest.

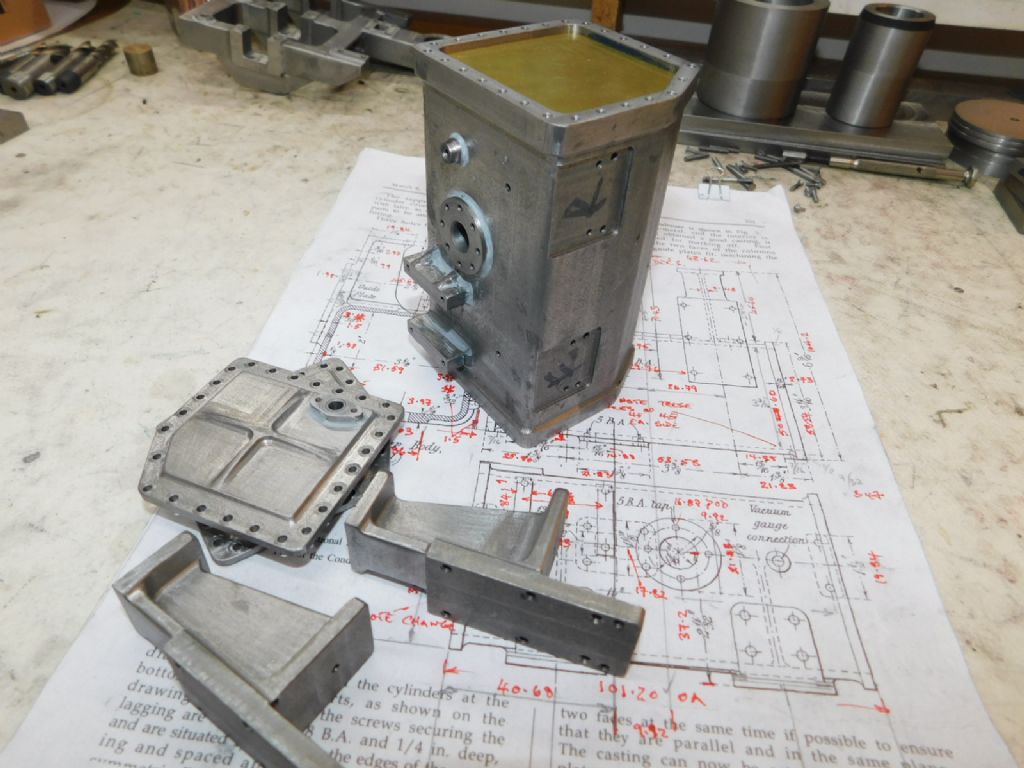

My very first model engineering project was the Stuart Compound Launch Engine !

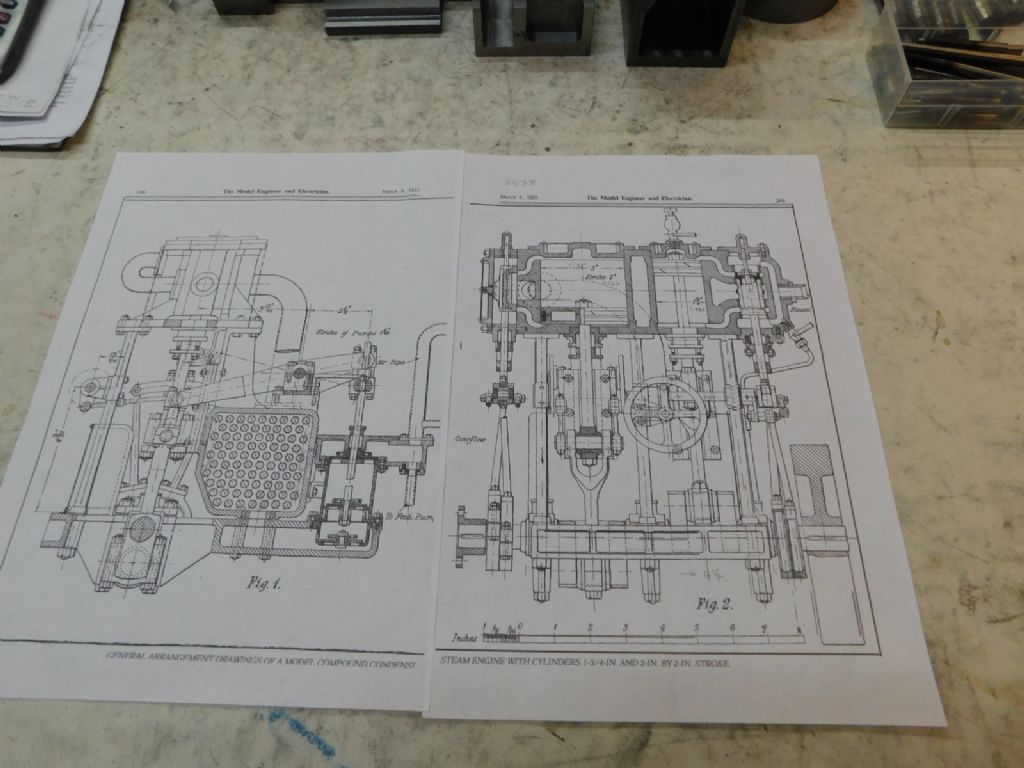

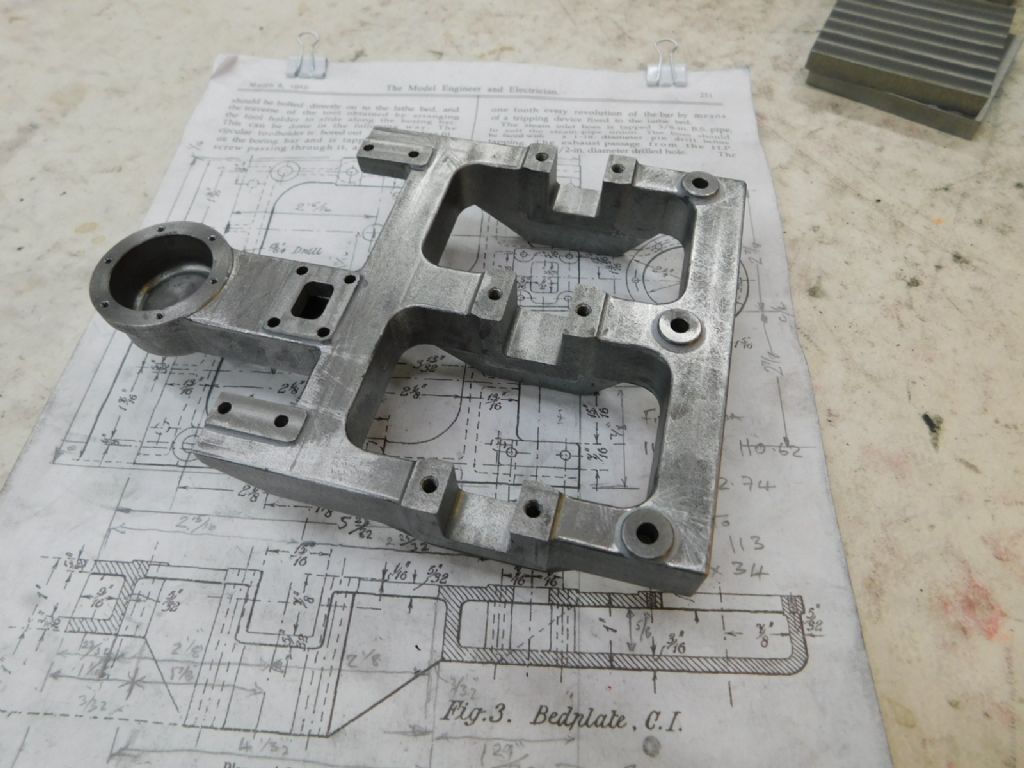

It was way, way beyond my knowledge and skill set at that time and doomed to failure from the outset – needless to say but it never made it beyond the shelf of doom. I've always wanted to have another go at one but never quite got round to it. After finishing my last engine I discovered this article and was very attracted to the quality of the drawing itself. I didn't check dimensions one to another but something said that there would be little to fault. As designed it was far to big to comtemplate but as said once printing to fill an A4 sheet the answer was in front of me – .625 fiting the bill nicely. I prefer to work in metric so converted all the dimensions first before making anything. No rounding up or down as such just working to the results eg 15/16ths x .625 x 25.4 = 14.88 mm – 14.9 at most

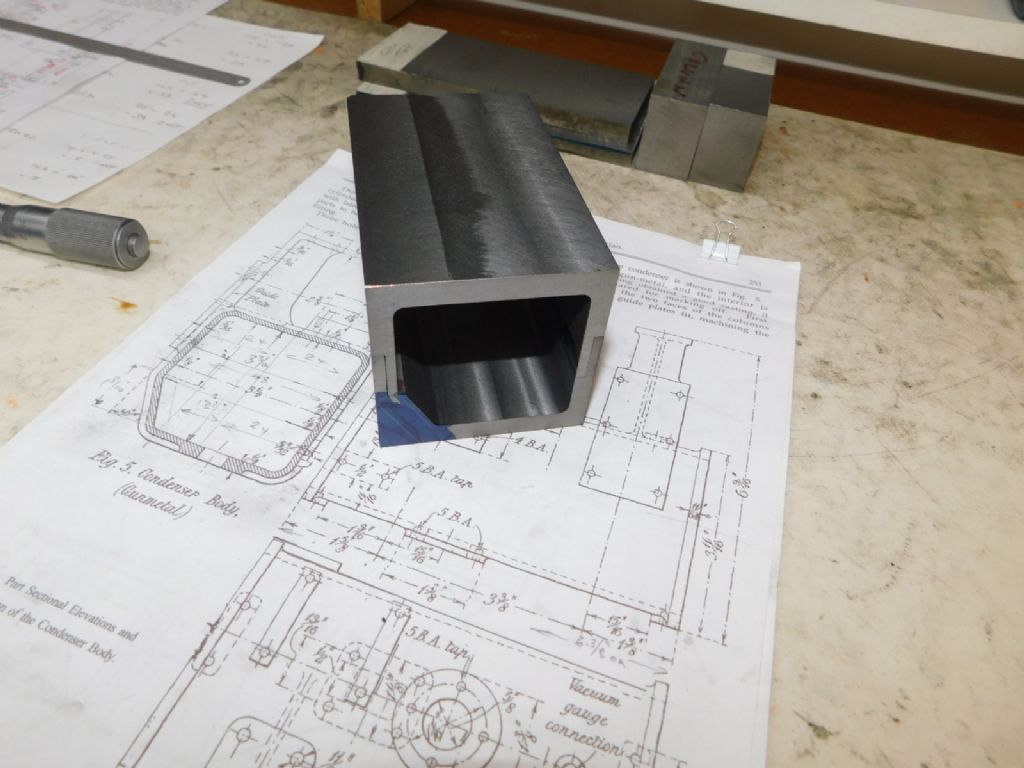

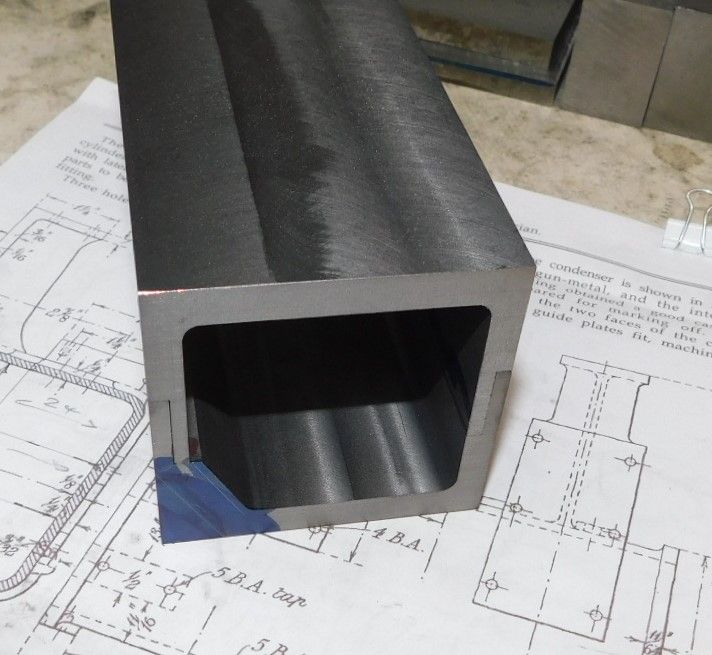

I think it would make a very good project if done at exactly half scale though and still make for an imposing model. It would probably ease the making of the condenser from one piece too as well as reducing the material cost.

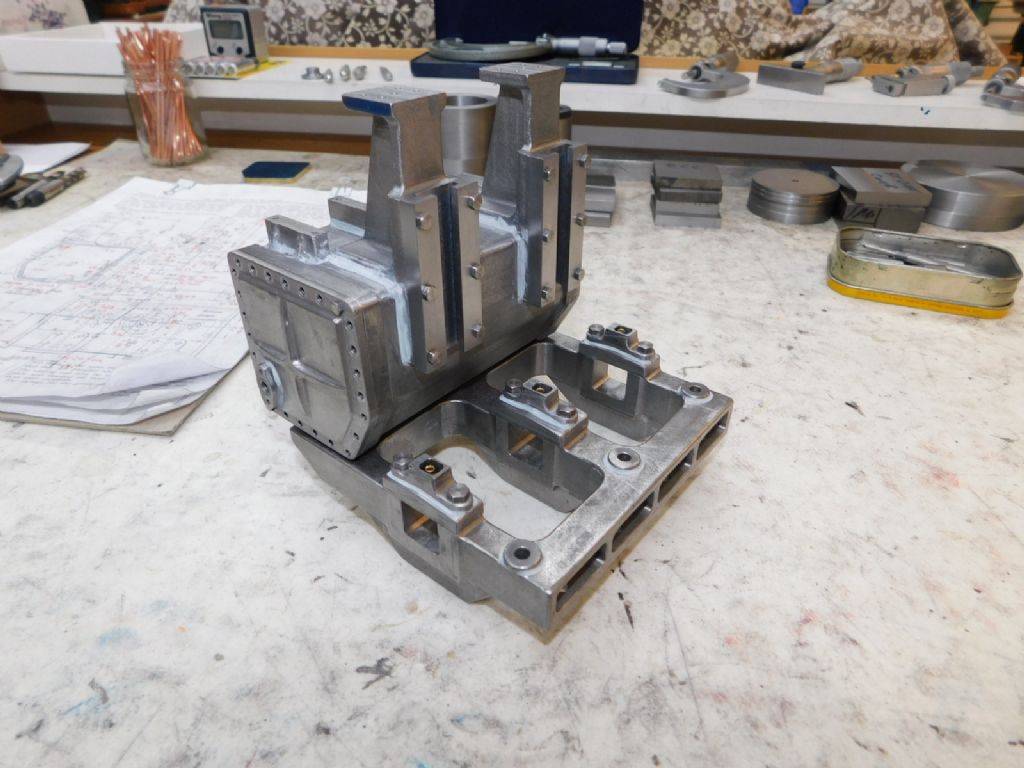

I've used (Standard) JB Weld for many years – well before using it to simulate castings and from the outset was impressed not only by it's strength but its ability to withstand heat to a fairly high degree – and still remain functional.

Though some may doubt it's usage I have every confidence in it for the type of application as on this build. This engine will only be run on air (for me) but it will certainly withstand steam temperatures of around 60psi with a considerable safety margin. The 'one piece' cylinder head on the modified Double Ten fitted to the Wide a Wake steam launch was made from seven individual parts JBW'd together with minimal fastening and runs on 60 psi dried, but not superheated steam without any issues.

There was very little to clean inside the condenser and was done as you say. I always place the bonded parts on an ali plate sat atop an oil filled radiator to cure overnight and fettle any fillets the next day. The longer it's left the better it is if it's going to be machined but filing fillets is best done as soon as cured.

It would be nice to think someone else was inspired enough to give it a go.

Any comments on JBW or anything else please ask

Regards – Tug

Edited By Ramon Wilson on 19/02/2021 15:32:30

Ramon Wilson.

Ramon Wilson.