I'm calling this one finished. It's a Leeuwenhoek homage microscope rather than a replica.

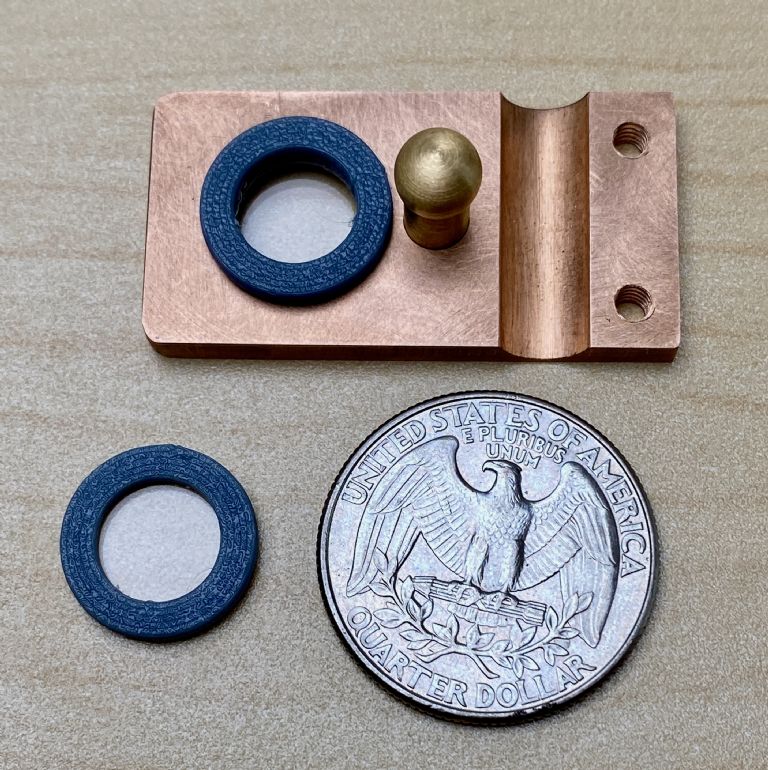

The lens is a 3mm diameter coated achromatic doublet with a 4.5mm effective focal length and a numerical aperture of 0.3. This gives it about a 55-56x magnification, which is on the low end of Leeuwenhoek's surviving microscopes.

Mine deviated quite a bit from his approach, though I tried to keep it recognizable as following in his footsteps. Some differences beyond the lens:

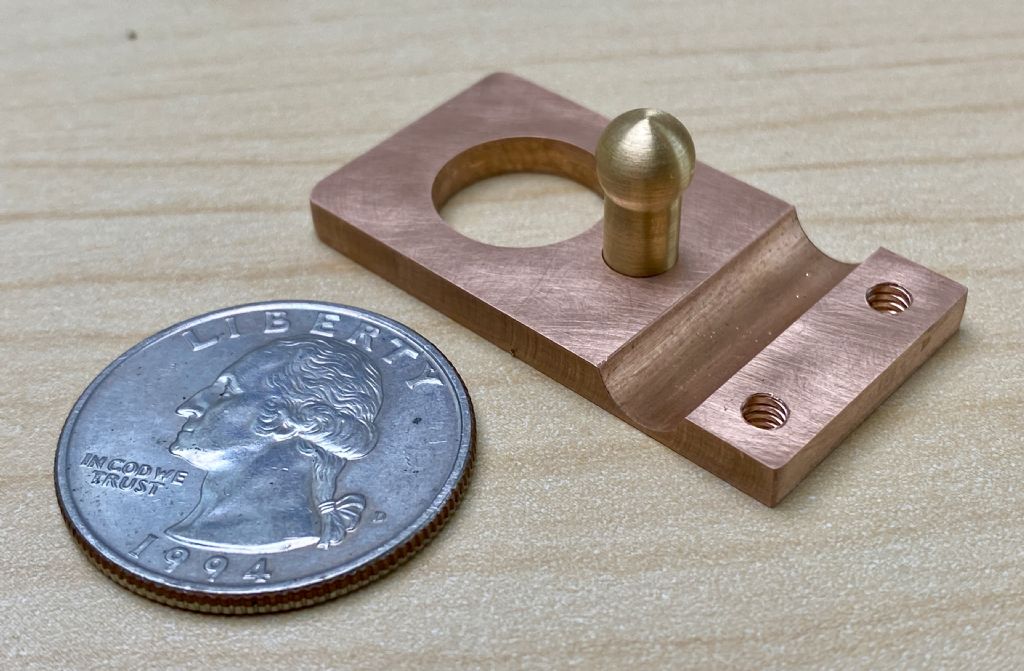

- The body of his microscopes were two thin metal plates sandwiching the lens, and then riveted together. Mine is a solid piece of brass into which the lens is held in a reamed hole.

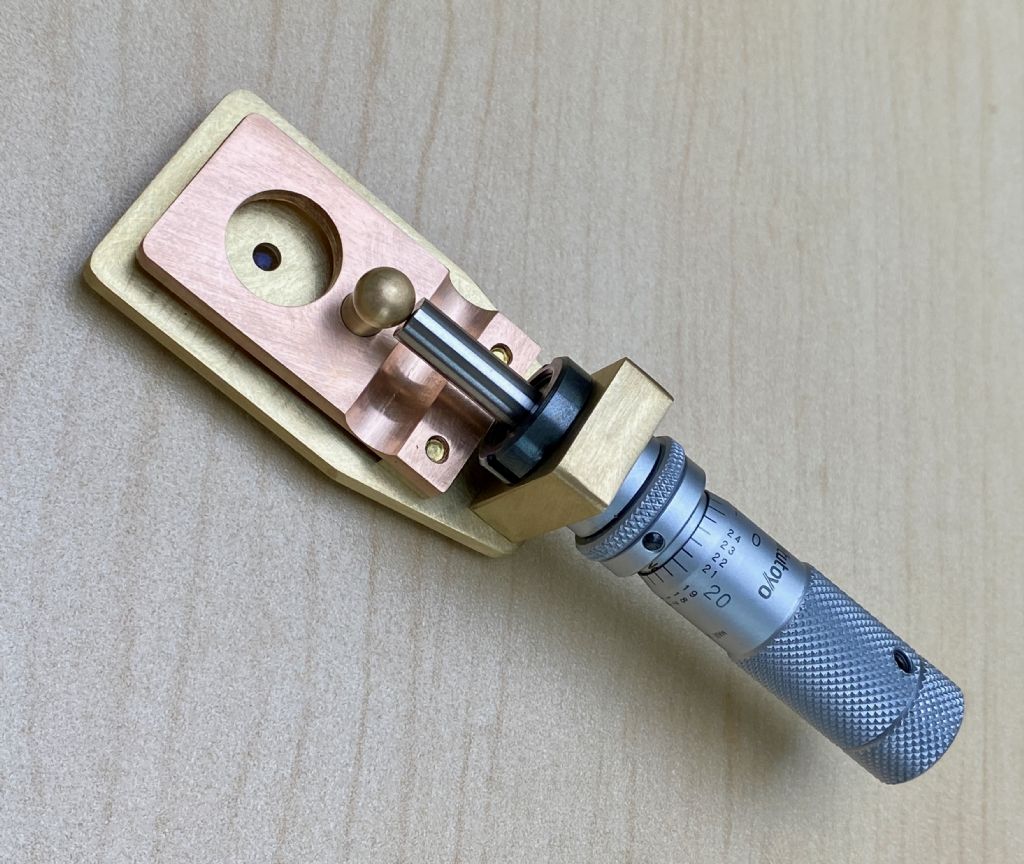

- His "handle" was a screw that adjusted the vertical position of the subject. Mine is the micrometer head, which adjusts the focus.

- His had a crude means of adjusting the subject's horizontal position, whereas mine has none.

- His used a needle-like point to hold the subject, whereas mine uses a stage with a 12mm hole, into which glass "slides" can be placed.

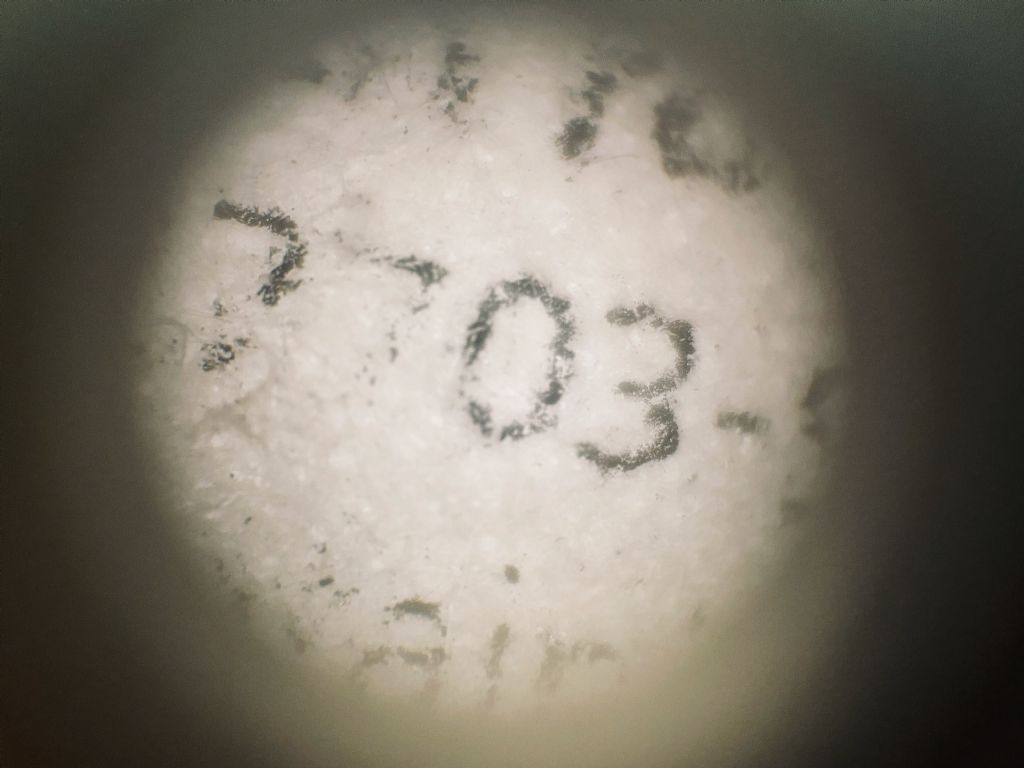

It's sharp, with quite little distortion or chromatic aberration except at the far edges. The contrast is seems lower than I expected, but that's probably because I haven't figured out how to properly illuminate the subject yet. The field of view is decent, and is wide enough that you can "look around" the image a little.

I looked at a slide of a tiny smear of my own blood. At about 55x, you can clearly see the red blood cells, but they are only pale tiny roundish dots. You can imagine that they have a particular shape, but it's not clear.

If I could go back in time and give this to Leeuwenhoek, what would he think? Certainly the achromatic lens would have amazed him. But otherwise, his microscopes revealed as much or more than mine could given their generally higher power.

It was a fun little project. I already have a lot of ideas for a Mark II version. 🙂

S K.