I've started a Leeuwenhoek microscope project. There have been many replicas made by others, but this one will be mine. 🙂

Leeuwenhoek did not exactly invent the microscope, but he is famous for the many original findings made via his instruments, enabled by his secret method of making superior lenses – a secret he took to the grave.

His instruments contained a single lens element of high power. They were originally thought to be tiny glass beads (spherical lenses), but some recent examinations suggests some or all were bi-convex in shape.

Instead of blowing or grinding a lens, I simply purchased one. It's a tiny 2-element optically-coated achromatic lens that is 3mm in diameter by 3mm thick, and with a 4.5mm focal length. This makes it very high powered at 222 diopters (a typical magnifying glass is 4 diopters), and is in the neighborhood of Leeuwenhoek's various iterations.

An achromatic lens is typically made from two different glasses (classically, "crown" and "flint" glass), usually cemented together, such that the two glasses partially cancel out chromatic aberration. This lens also has a magnesium-flouride anti-reflective coating. (It was not cheap!)

Using a 2-element coated achromatic lens is an unfair advantage, since achromats and optical coatings were hundreds of years into the future for Leeuwenhoek. But if he had these technologies available, he certainly would have used them!

Here's a picture of the lens. You can see where the two elements join.

I temporarily mounted it and managed to view things through it, and I have to say it's quite difficult to use, especially due to the very shallow eye relief. In retrospect, perhaps I should have bought a larger-diameter and longer focal length lens. But once you get it right, it provides a surprisingly high quality and highly-magnified image that I'm sure Leeuwenhoek would have enjoyed.

Leeuwenhoek mounted his lens sandwiched between two thin sheets of metal that were then riveted together. I chose to use a solid piece of brass, into which I drilled and reamed a 3mm hole as an exact fit for the lens. This avoids obscuring the lens' periphery. I'm a bit terrified with the idea of using a retaining adhesive on it, though!

As the brass was slightly thicker than the lens, I added a countersink on one side so the lens can sit a tiny bit proud on both sides. That way, the lens can hopefully be kept clean a little easier.

The body of the microscope is paddle shaped, about an inch by two inches. It fits comfortably pressed against your cheek and nose. This is essential, since with such a shallow eye relief you need to brace it steadily lest you poke your eye.

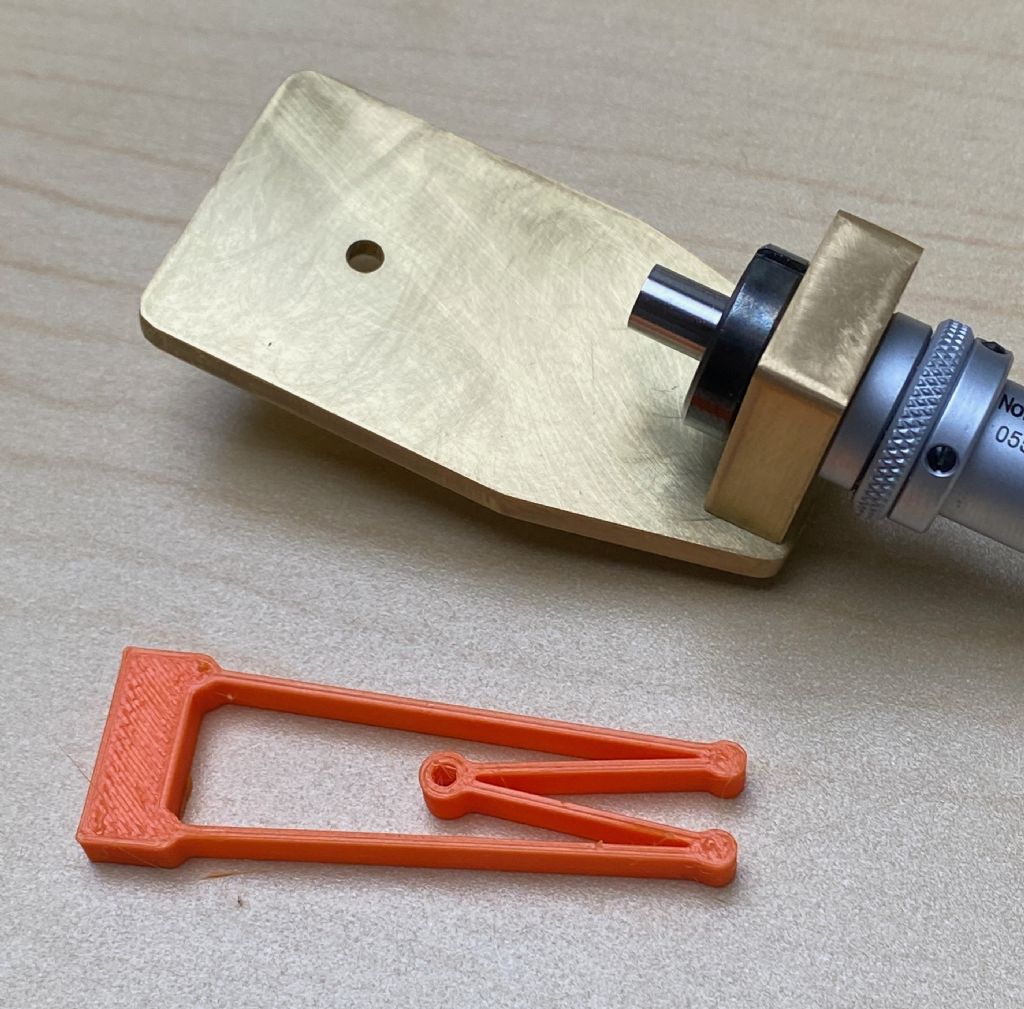

Here's the body in its final shape, with the reamed and countersunk hole for the lens. The lens is sitting on it.

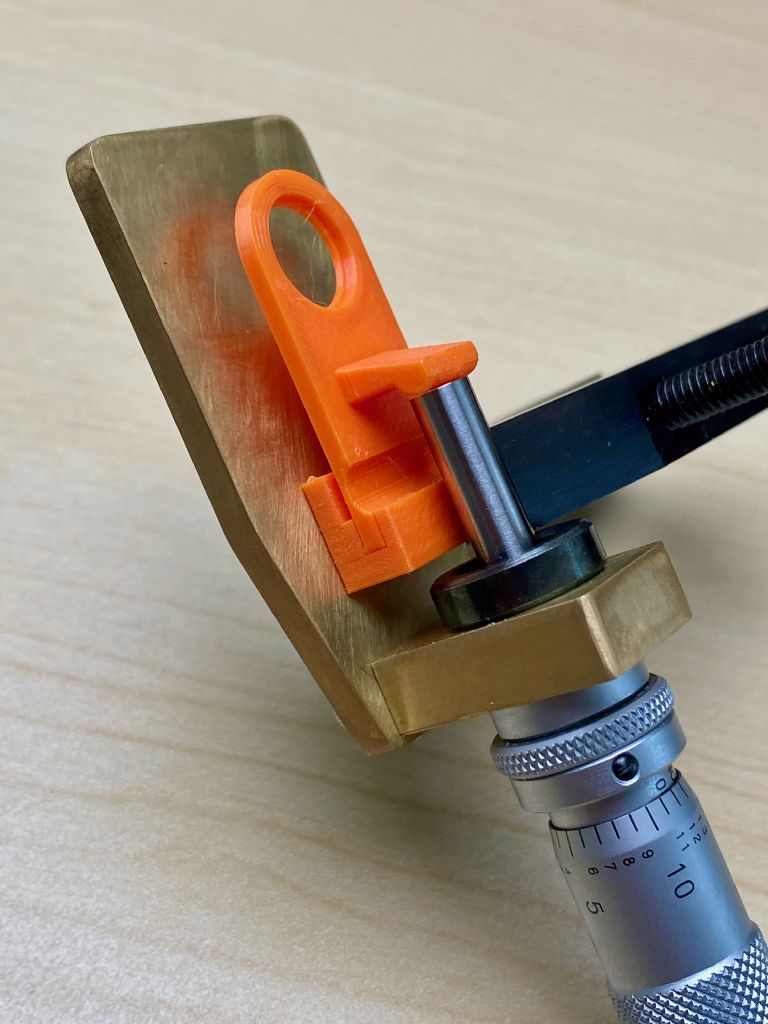

So just a little progress so far in a relatively simple project. Still to be done are to add a translation and focusing mechanism, a clip of some sort for holding the subject, and a handle.

His microscopes used a point to hold the subject. Instead, I'd like to make a holder for microscope cover-slips. I'd also like to improve on his focusing and translation mechanism while retaining the spirit of his approach. If I fail at that, I'll just do it Leeuwenhoek's original way. After all, he reportedly made well over 400 microscopes(!), so he likely went through many ideas.

Thanks for reading.

Edited By S K on 14/05/2023 02:25:56

S K.