Gentlemen,

I'm back with a (sort of) conclusion.

How much nicer it would look with a chain drive – but not for me.

However, following the failure of the fishing line which transfers the oomph from the main-spring barrel to the fusee, and with the gift of hindsight I decided to check a few facts.

And, I still have egg on my face over the aspects of creep.

With great respect for the late Mr Stevens, the following details may also offer reasons (in my situation), why I had a fixation on fishing line, and why any serious modifications (to my fusee) are now prohibitive.

It is worth noting here that I machined the fusee back in the early 70’s, not long after Mr Stevens’ article was published, and (as I’ve mentioned too many times already), I no longer have a workshop.

In his article commencing in February 1972, especially (Vol 138 Issues 3334 and 3435, Pages 139, 140, 168, and 169 of Model Engineer), Mr Stevens provided information (and dimensions) of:-

- The fusee and the barrel – [page 139];

- A recess in the edge of the barrel for the knot of a Nylon fishing line – [page 140];

- An improvised fusee cutter – [page 168];

- The 0.035” wide bull-nosed cutter for machining the fusee groove – [page 168];

- A recess in the fusee for the knot in a Nylon washing line – [page 169].

Incidentally, the space in the fusee recess is swept by the fusee ratchet mechanism during winding, so anything protruding (eg. a knot) is likely to interfere with the winding process.

It wasn’t necessary for me to build the fusee cutter. I simply set up my Myford ML7 to machine the spiral groove using the same template I had used to `swing’ the basic profile (a 2” radius). Using a cam follower principle between the cross-slide and the machine bed, the depth of cut was adjusted through the top slide. I’m no stranger to the intricacies of screw cutting, so this exercise was hardly challenging.

On page 140, Mr Stevens then goes on to say;

A key-hole slot is made near the front edge of the barrel tube and a crescent filed on the cover immediately beneath. This is to take a Nylon fishing line which serves admirably in place of the traditional gut.

On page 169 Mr Stevens then goes on to say;

“A hole about 3/64 in. dia. [about 1.2 mm], is next drilled from the outside [of the fusee] into this recess which is to secure the nylon line, and a space for the knot milled out. (The nylon cord is obtained in the guise of a domestic washing line from any hardware shop!).”

So I now realise that as an amateur clock-maker, that’s where my fixation for fishing line came from.

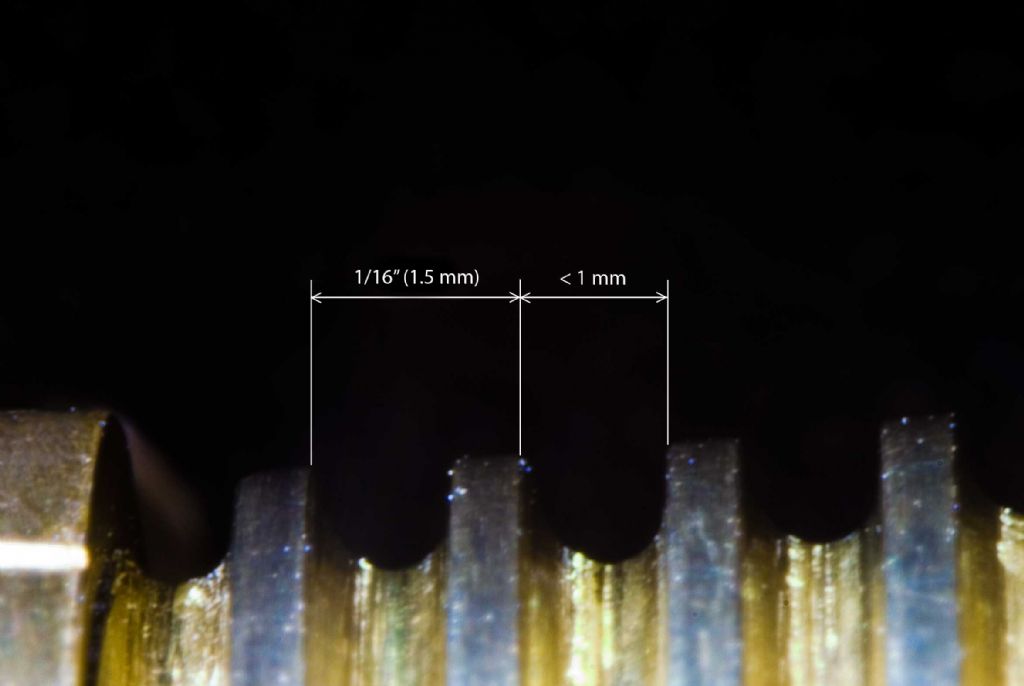

This photograph taken at the small end, is a rather `fuzzy fusee’ profile of the spiral groove as it currently appears. A 1 mm drill doesn’t quite fit, so it looks like I was fairly close to drawing.

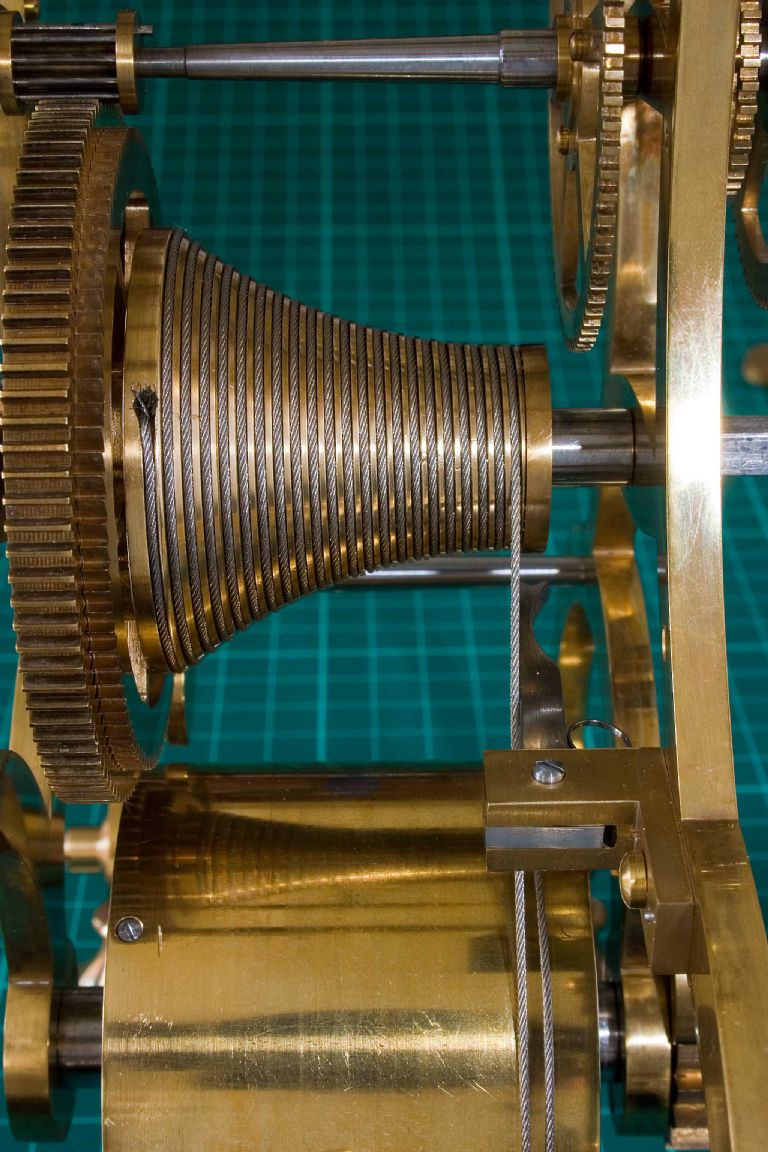

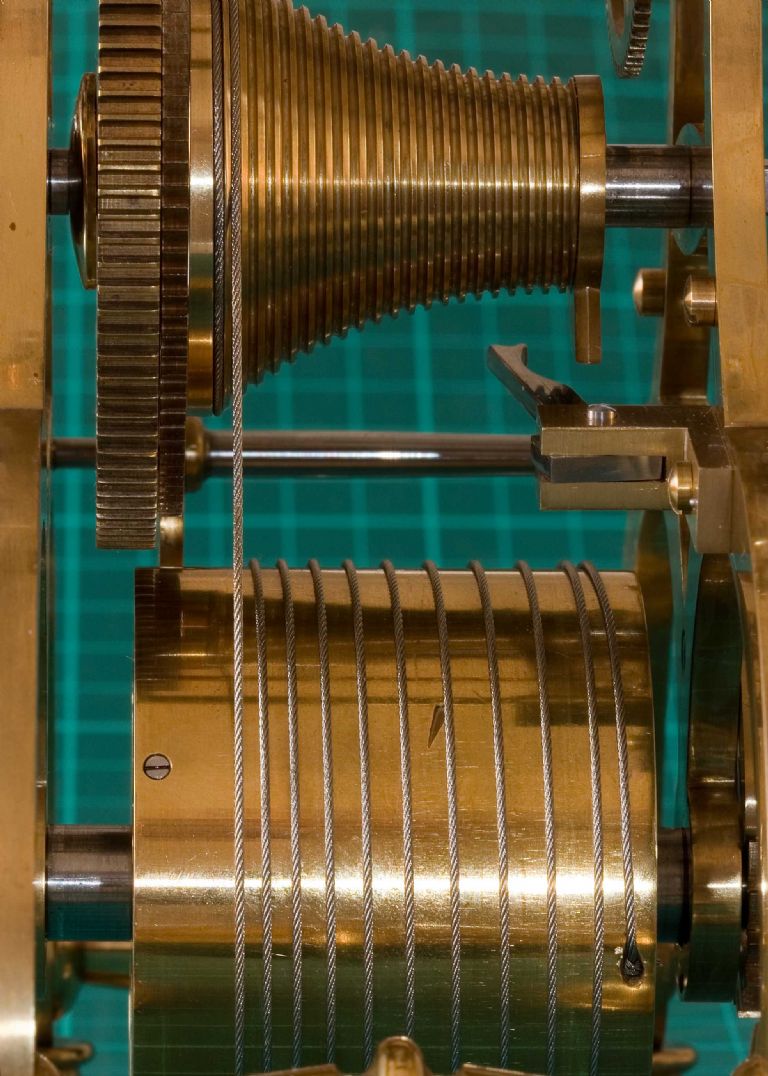

In conclusion, despite a fixation on using a synthetic cord (fishing line), I eventually accepted the advice of a professional clock-maker and used multi strand steel.

See this second picture.

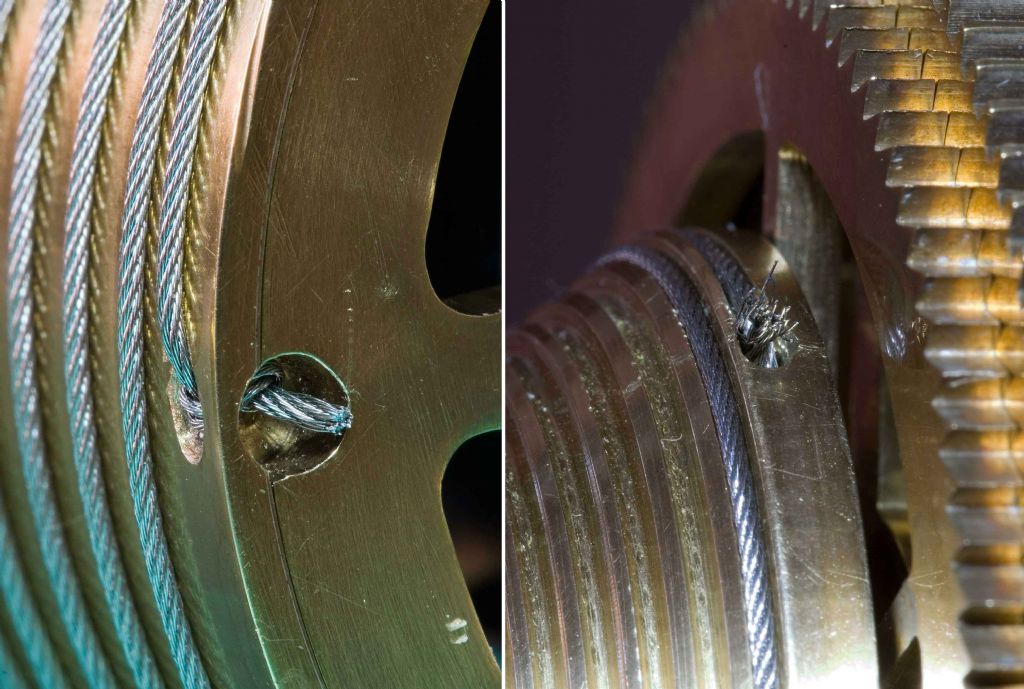

I’m not too impressed with the tail ends of the knots. My original method hid the line terminations.

As if all this wasn’t enough, I suddenly noticed in the very top LH corner of this picture that one of the pins in the first lantern pinion had worked loose. Oh dear! Or words to that effect.

Edited By Sam Stones on 10/07/2014 02:30:17

Sam Stones.