Posted by Malcolm Timmis on 02/04/2020 17:25:52:

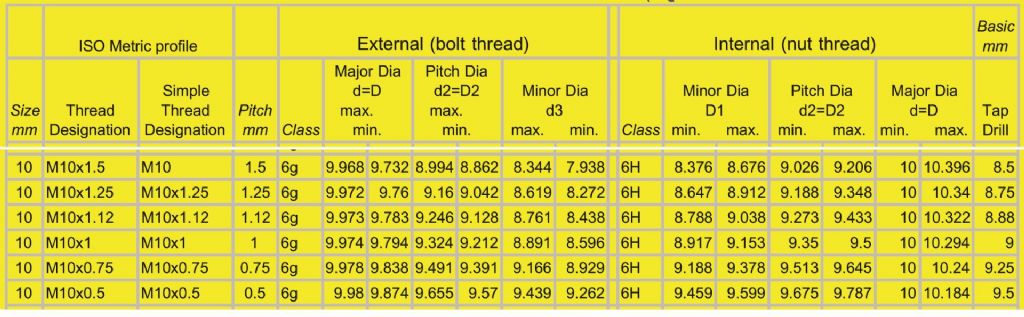

I have had to make a number of new parts for motor bikes, bicycles, and other items, which require me to turn down a diameter to die cut a thread. Not knowing any better I usually start with … I have read most of the books at least twice hoping to find the definitive formula that will tell me what the exact diameter should be for any given thread.

…

I can live with my mistakes, but I am frustrated by the time that is wasted, so any advise will be very much appreciated.

Thanks

The other answers, and the books mentioned, all concentrate on threads from a home-workshop perspective, which is exactly appropriate to me, where I usually reduce diameters slightly before cutting threads to make the job easier. The advice may not be appropriate to Malcolm. It's right for non-critical threads, which most are. They only have to be 'good enough' for less demanding situations and are made relatively loose of relatively inexpensive metal. They're not as strong or vibration resistant as close-fitting threads made of a strong alloy.

Some bike threads are critical. Strength and resistance to heat or corrosion may all be required. Not good to have steering or brakes fail because of a weak thread failure, or for the engine of a performance bike to come off at speed!

The quality of thread needed can often be guessed from context: number plate fasteners are bog standard ordinary, whilst pedal bolts are special. Bolt heads are often marked to indicate their class, but I'm not sure if this applies to old bikes, especially pre-WW2. In the modern system no marking on a bolt head means ordinary. On US steel bolts the number of radial lines increases with increasing specification. Metric steel bolts are numbered 8.8, 10.9 and 12.9 as they go up. Otherwise, the maker's original specification or plans may be needed to identify thread quality.

How much this matters depends entirely on the purpose of the repair. Simply made threads on a classic motorbike restored for undemanding display purposes are probably acceptable. The same threads on a superbike taking part in the Isle of Man TT would need to be done properly, whatever the specification calls for.

Lastly, it may be impossible to produce a high-specification thread with a lathe or die. It's because cut threads are weak compared with rolled threads and inaccurate compared with ground threads.

Dave

Howard Lewis.