Hello Members

It has been a long time since posting regularly on here about a project – not for any untoward reason but simply that of time – a lot of posting has been done elsewhere, mainly on the Model Engine Maker site, and doing it twice or more as some amazingly seem to be able to do has simply not been an option.

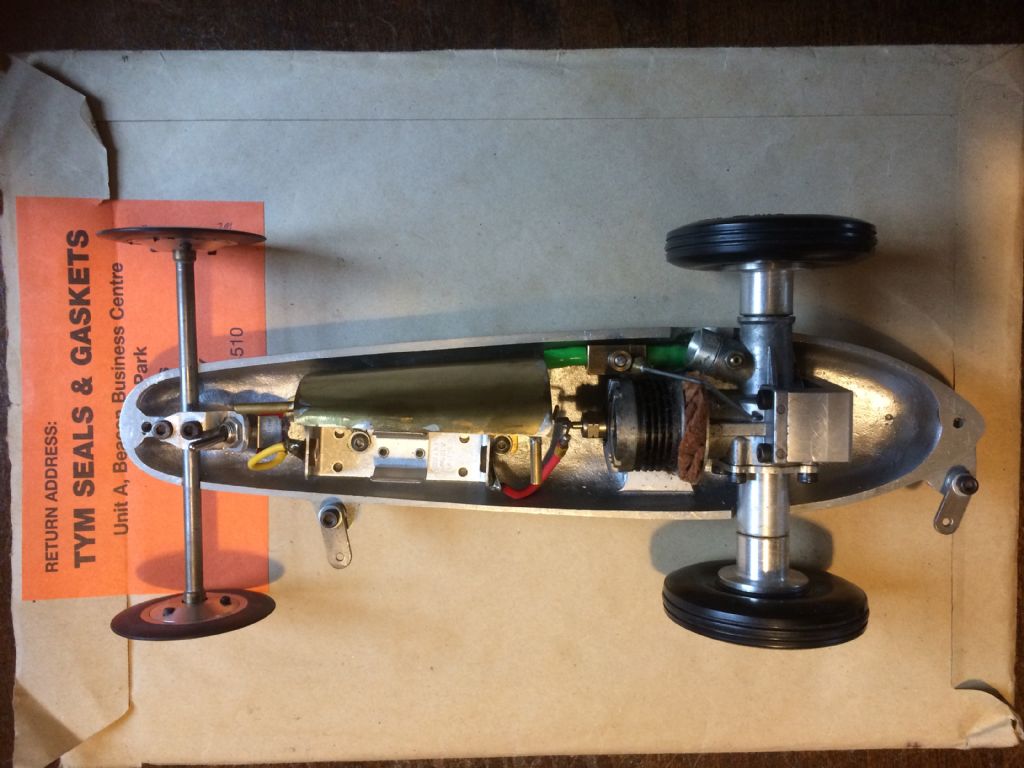

The recent discussion on the Nalon Viper thread however has resurected a fairly long held desire to make a 5cc diesel engine with twin shafts suitable for a tethered car so I thought it was time to make amends!

Whilst reasonable experience has been gained over years with model aircraft engines and to a much lesser with model boats the world of tethered cars – indeed any car modelling – is a totally and utterly alien environment.

Some will be aware that several 5cc versions of smaller commercial model aircraft engines have been scaled and successfully made over the last few years but whilst this will no doubt be similar in vein the specific (if there are any of course) requirements for a twin shaft engine are unknown. Hopefully this thread will entice some comment to ensure the right direction is taken.

The first intention is to build the power plant – if successful then it can be taken further. It has to be said from the outset this will not in any way be a quest for outright power nor highest potential speed. Hopefully it will be seen at all times as a model engineering project that will prove of interest and even more hopefully will encourage others to participate in the thread – all input no matter from what skill level will be very much appreciated and help keep momentum.

So, today a start has begun on drawing an engine based on a previously machined crankcase for a 5cc version of the Nalon Viper and already questions have arisen .

Although a lot of engine 'info' has been collected over years there is virtually none on car engines – about the only thing to hand giving any referrence to design layout being the Oliver Story book by John Goodall.

So first my question is – What kind of wheel spacing at the drive end would be considered for a 5cc diesel powered car of the vintage kind. I am thinking about 120mm or so

Second is Tires – that may be a long way off but knowing the width of average tires would assist greatly in establishing the wheel hub width and subsequently crankshaft length.

Thirdly – does the centrifugal action on the car place differing forces on the crankshaft bearings on either side of the engine and if so how would this usually be dealt with – the engine will be fitted with four ball bearings.

There are lots more (questions) but this should get me past the current small hiatus.

So, that's my intent, once designed I'll get to making it and post pics and cover the build – hope this will be of interest to some of you

Regards – Tug

Edited By Ramon Wilson on 30/12/2019 14:48:59

Ramon Wilson.