It strikes me that Margaret is largely blameless in all of this, and the info given out by ARC is partly responsible for her confusion.

I've got a Model 000 toolpost from ARC, which came, as the ARC website suggests, with an M10x1.5mm stud. The page in that link meant to me that the stud supplied was threaded M10x1.5 at both ends, as indeed it is. As expected, it also came with a matching M10x1.5 flange nut for the top end. It fits my lathe fine with no adaptations needed.

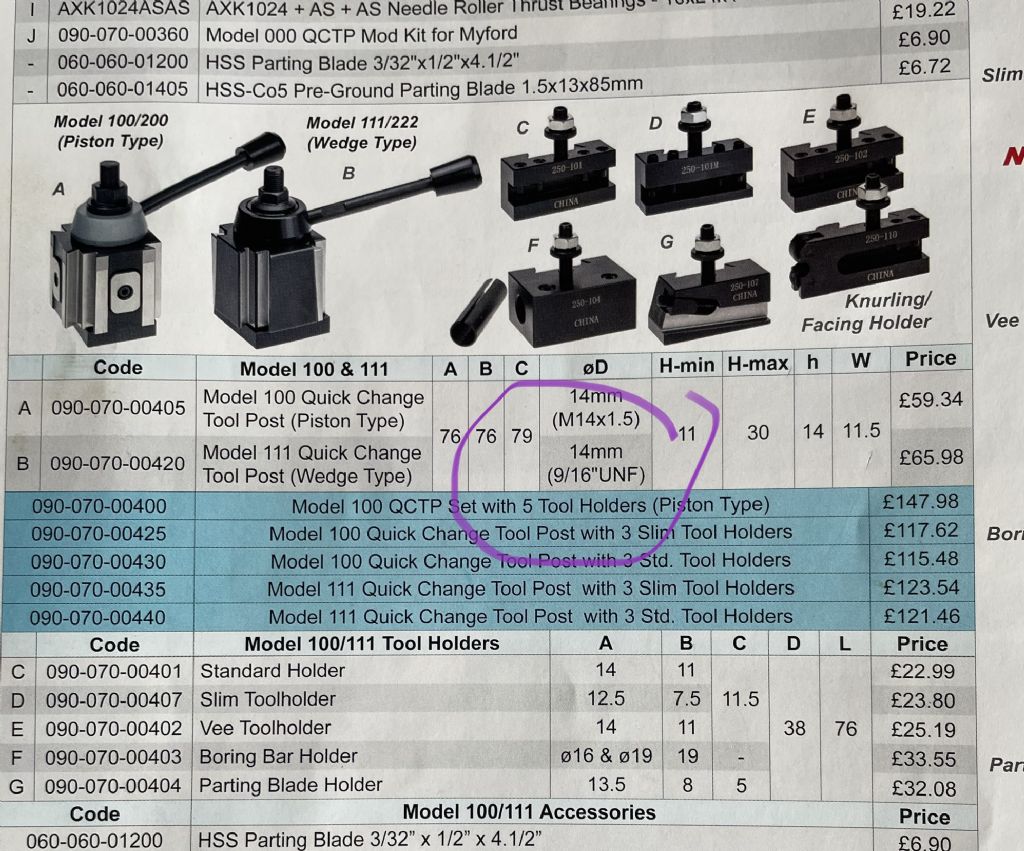

Based on this experience of ARC's website's descriptions, if I were buying a Model 100 toolpost I would expect it to come with an M14x1.5mm (both ends) stud and matching nut. Perhaps owners of that toolpost could clarify that this is the case.

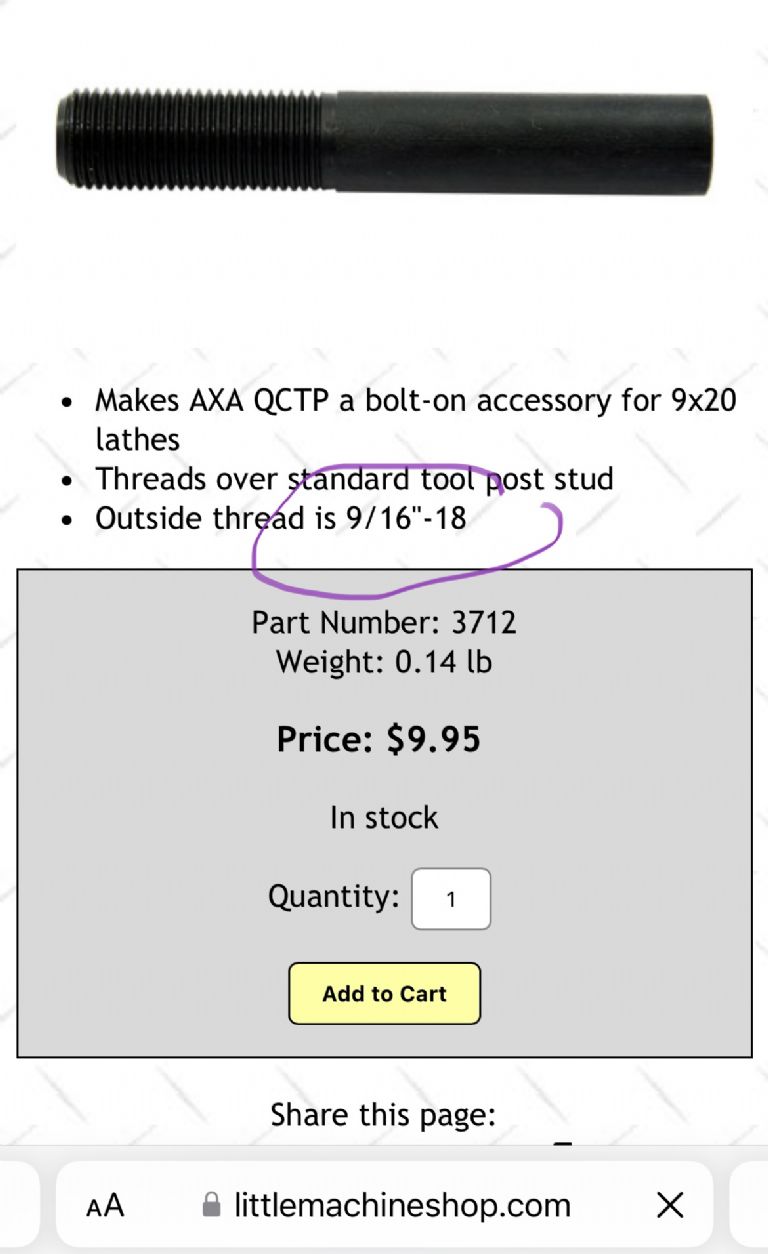

Finally, if I were buying a Model 111 toolpost, as Margaret apparently did, I would expect it to come with a 9/16" UNF (both ends) stud, as the link I posted earlier suggests. It seems, however that it too comes with an M14x1.5mm stud and nut, or at least something that is not 9/16" UNF. Perhaps an owner out there could again clarify this.

With the limited thread and diameter measuring capabilities Margaret has, she seems to have gone about things pretty logically. She knew firstly that she needed a stud with an M8 female end to thread on to her lathe's existing old toolpost stud. She then deduced, from Arc's description and the roughly 14mm diameter stud they supplied to her with the Model 111 toolpost, that the nut that came with ARC's toolpost would fit the stud she needed to buy (for its female 8mm thread on one end) from the LMS.

But it didn't, because the stud and the nut that are supplied with ARC's Model 111 toolpost are presumably M14 x 1.5, not 9/16" UNF, as stated, or at least strongly suggested (if my buying experience with the Model 000 is anything to go by) on ARC's site.

Have I got this right, everyone?

And is this a fair representation of how you got to where you are now, Margaret?

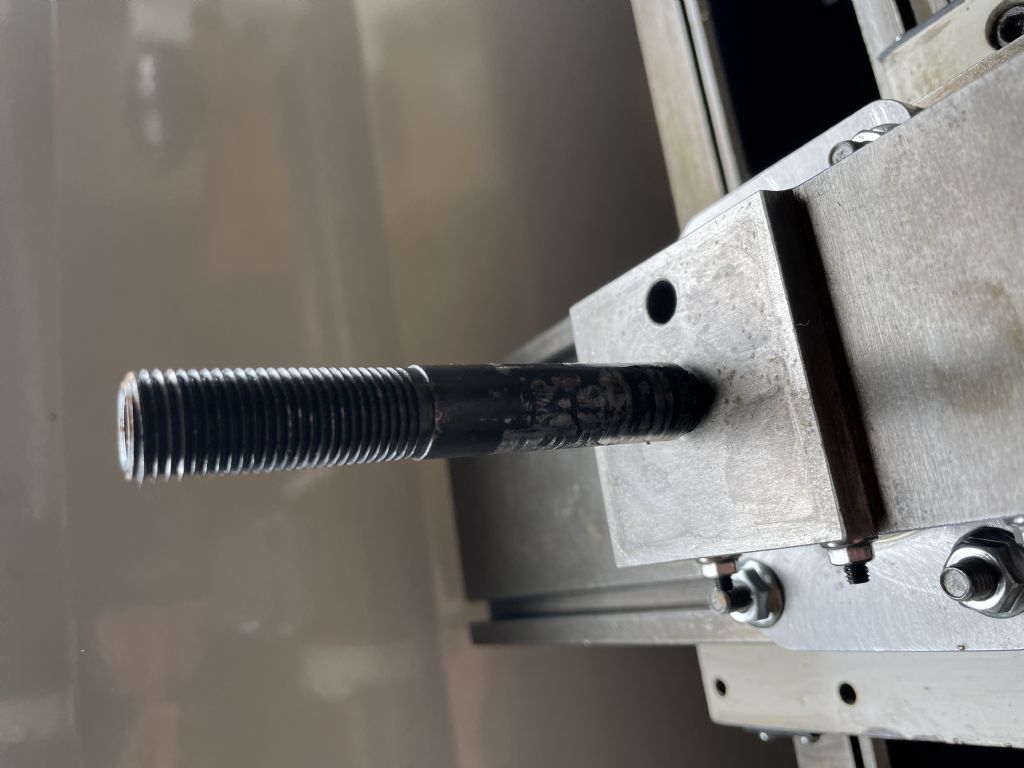

I should add that in one thing you are slightly to blame, Margaret: you have visibly marred the unthreaded surface of the LMS stud, presumably by tightening it into the hole with grips? Is this how you went about tightening down the LMS stud?

If so, when you buy your 9/16" UNF nut, buy at least two: you can then lock them together at the top of the stud and turn the top one to tighten the stud down and the bottom one to loosen it.

Howard Lewis.

)

)