Hi All,

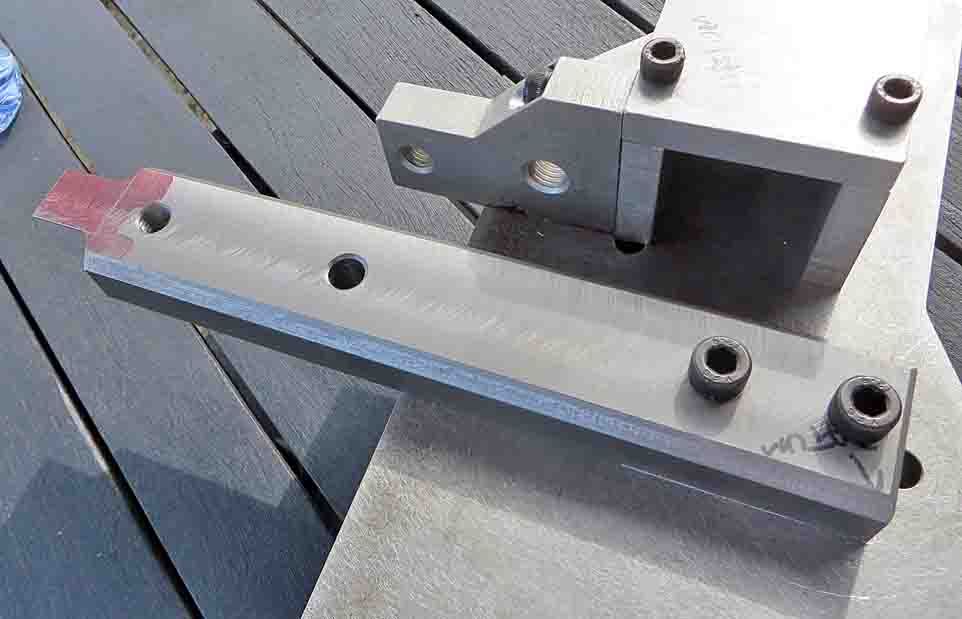

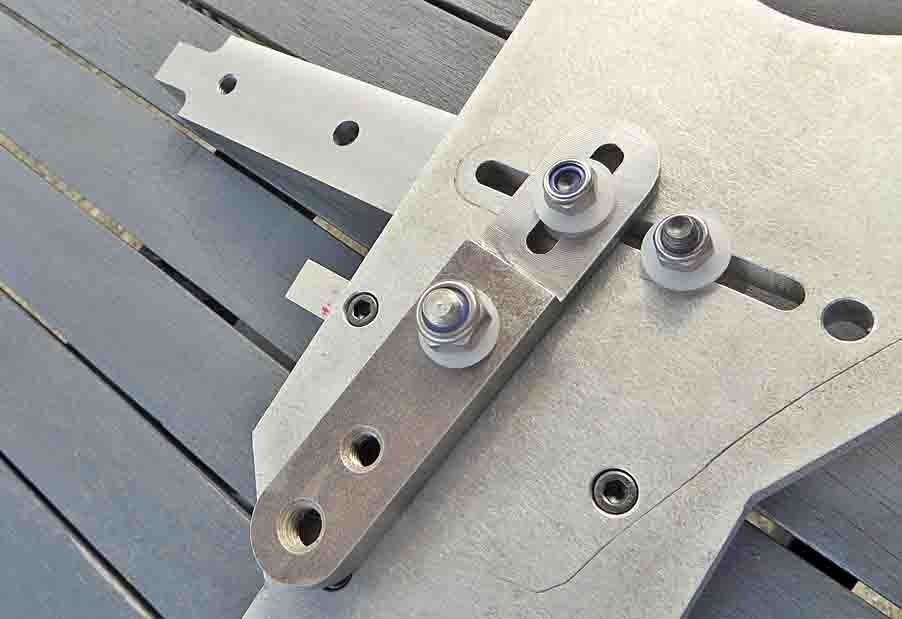

Some progress made, just received a very nice counterbore kit from Arc so have done the main frame part which allowed a trial fit of the box section already made. This went together well but the small buttress like parts needed some slight fitting with a file as there was not enough "wiggle room" for a couple of the bolts.

There appears to be a slight error in the plans which show an M10 bolt to go in an M12 hole that is already tapped so will cut down an M12 to fit, no big deal.

I had a length of UHMW plastic rod which is perfect for the plastic washers needed.

The very nice locking levers have arrived from WDS just waiting for the gas strut now. The nearest size fit I can find is a whopping 700N, (180N needed) but WDS assure me that the strut is adjustable via a valve. I presume that this will be a "suck it and see" type operation!

Knocked up a ribbed lever handle from some scrap alloy and cut up an old M10 screw for the thread.

Next job is to tackle the extension arm that carries the adjustable tracking pulley, quite a big chunk of 40×20 steel with heavy chamfers. I think it best to make that first and then do the slot it slides in to fit OR should I do it the other way round?

One irritation was that I tried to make the tiny 38mm long x 12mm axle that carries the extension lever. The piece I picked was stainless and machined OK but when I came to die cut the two ends for M10 there was no way I could hold it tight enough either in the 3 jaw or collet chuck. VERY hard work, kept stalling the Myford in back gear and made a right mess. I tried finishing it by hand but ended up binning it and remade in a bit of EN1A. Much easier!

I think in retrospect that I should have made a female thread in a larger bit of stock to hold the workpiece before attempting the second thread?

Onward and upward, Cheers, Martin

Raymond Pullen.