Compensating Centre

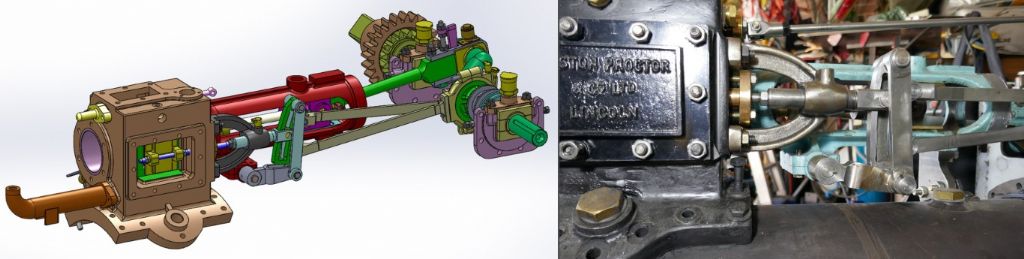

The compensating centre (differential) is normally made from a casting but this was missed when I ordered the other castings for my engine. The original order was sent to Australia by sea freight and the extra weight would not have increased the delivery by much. Sea freight cargo has to be sent in a large wooden box so it can be loaded by forklift. It also has to be fumigated making it expensive.

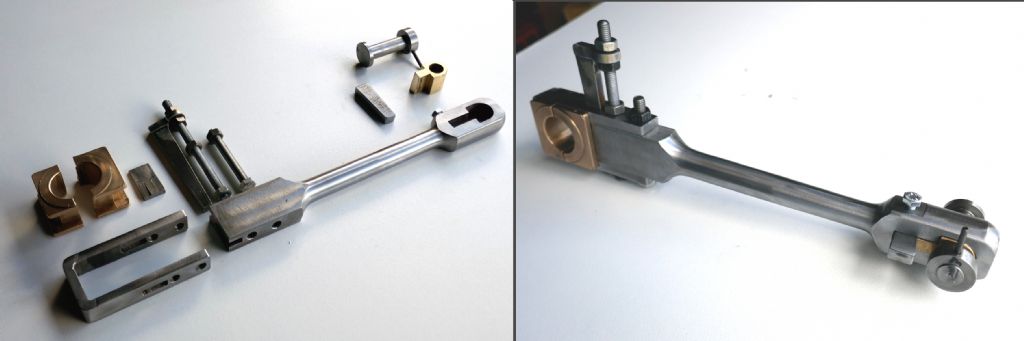

It is a large, heavy casting which sells for about £120 but would have cost another £160 for air freight. Too expensive, so I fabricated my own from plate and hollow bar.

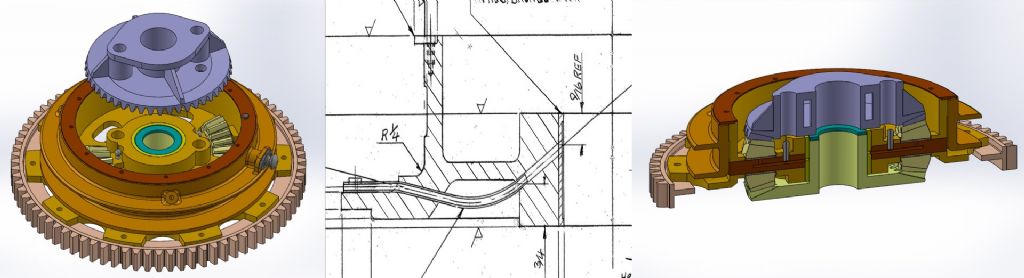

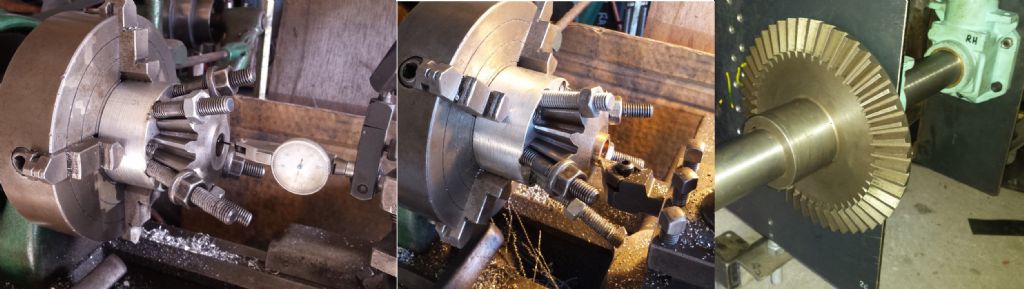

As well as designing a fabricated version of the hub, I modified the lubrication arrangement. In the original design, a pipe was used to carry oil to the drive gear bush and a hole in the casting to oil the pinion gear shaft. As the gears and bush rotate slowly, I prefer to use grease. Oil lubrication without shaft seals is messy and drips onto the ground. (and my driveway).

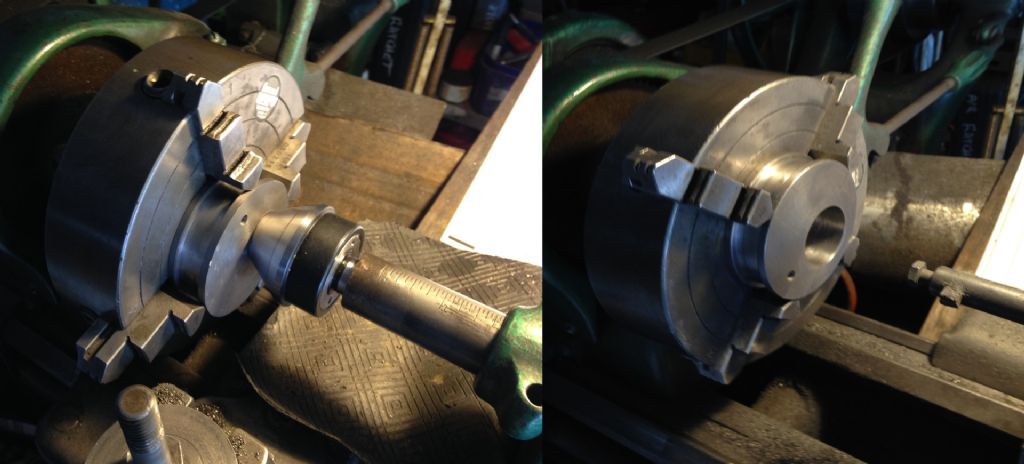

A hole in the centre of the pinion gear shaft carries grease to both bushes. Access to the grease nipple is thru the holes for the wheel locking pin. The pin is removed and outer gear rotated slightly to expose the grease nipple. The nipple also prevents the shaft from rotating.

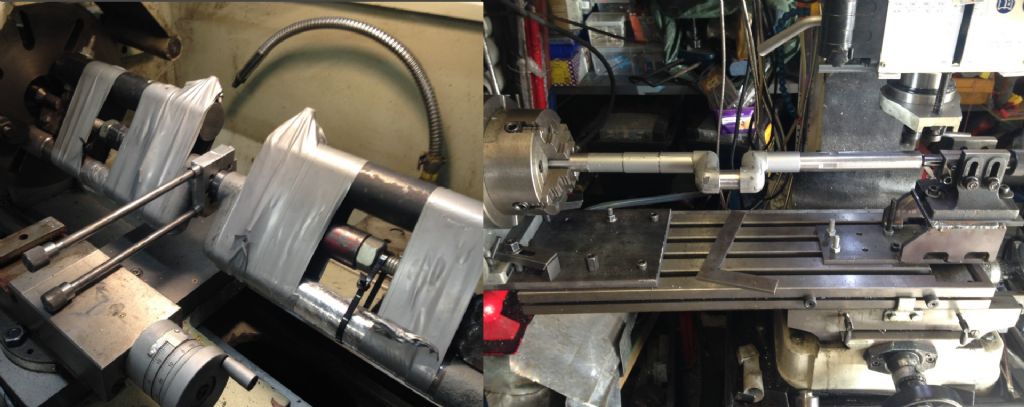

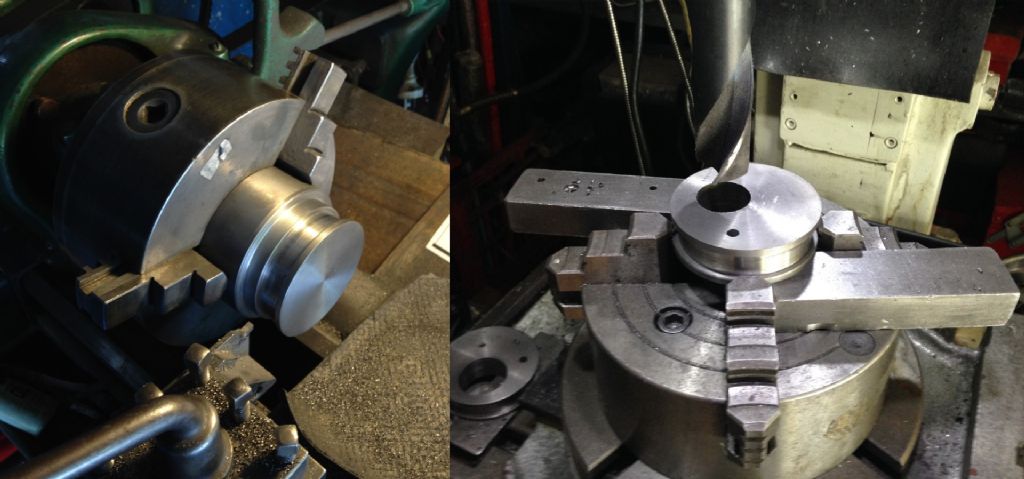

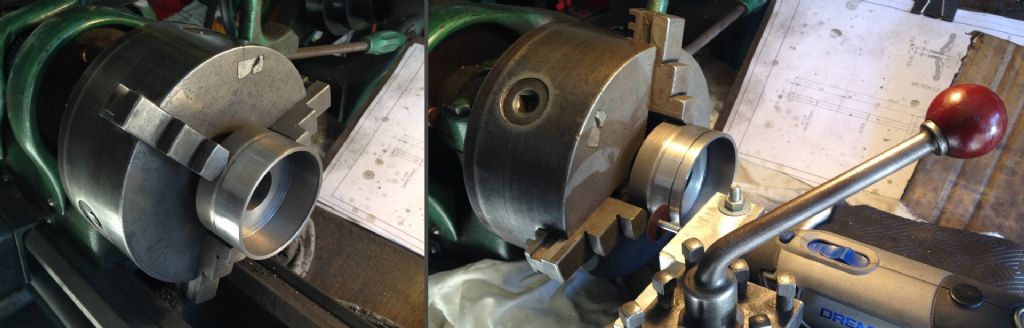

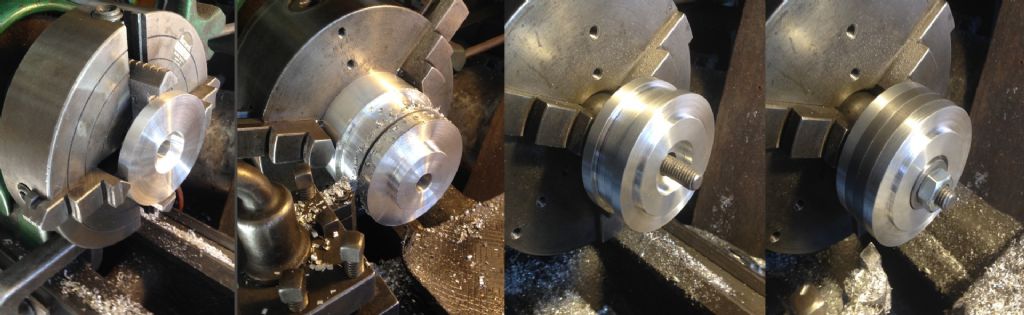

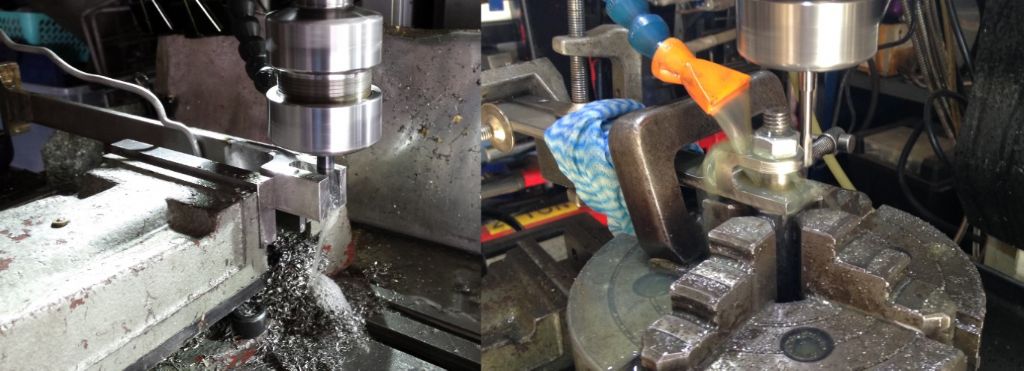

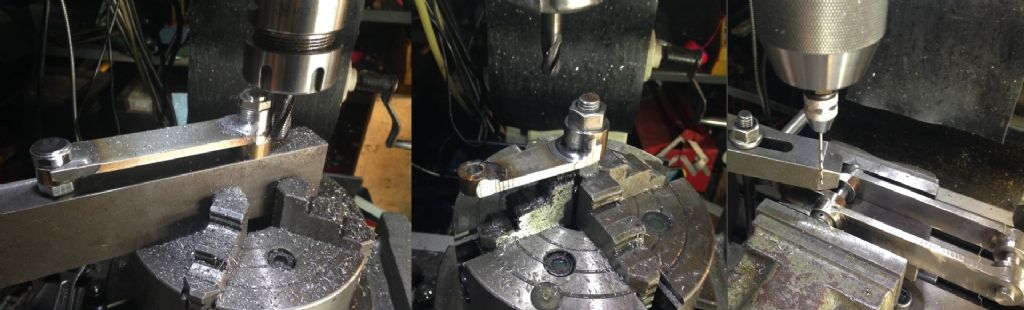

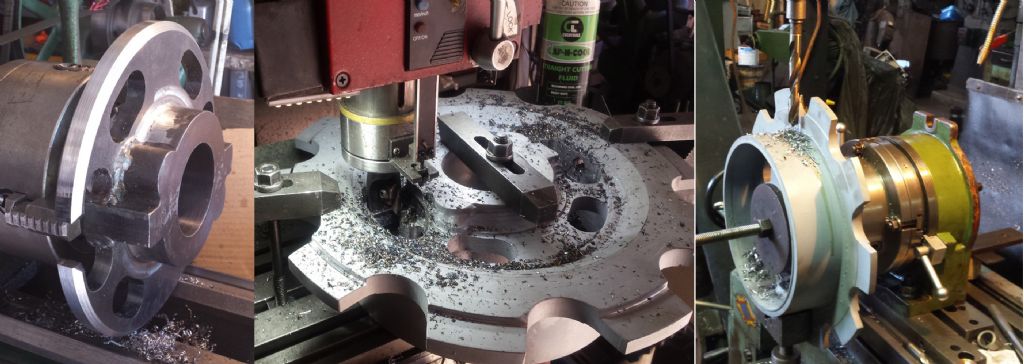

Left: Preliminary machining of hub prior to welding hollow bar, Middle: Final machining, Right: Drilling and reaming holes for bevel gear shaft

Jon Cameron.

Jon Cameron.