MODEL BOILER DESIGN and MANUFACTURE

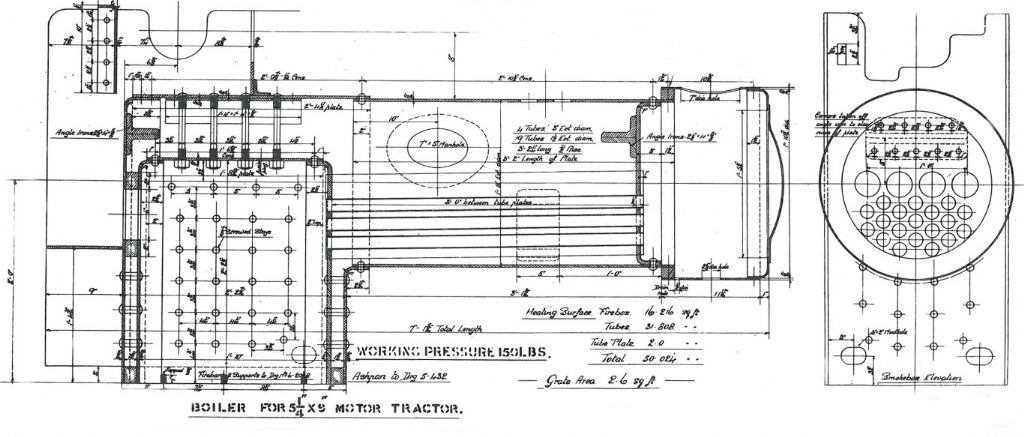

Boiler design for the original traction engine

The boiler on the original full size traction engine was 20” OD x 85” (508 OD x 2160mm) overall length.

Boiler wall thickness: ½”

Distance between tube plates: 36”

Fire tubes: 4 x 3” dia and 19 x 1.5” dia.

Boiler for 6” scale model boiler

The drawing for the model boiler specified a 10” OD x ¼” thick steel plate but 10” OD (254mm) is not a standard pipe size and the Australian Miniature Boiler Safety Code specifies that I use ASTM A 106 grade with a wall thickness of not less than 6mm.

I chose to use 10” NB schedule 40 pipe which is the standard commercial size and is 273.1mm OD x 9.27mm wall thickness. Flat boiler plates are 10mm thick.

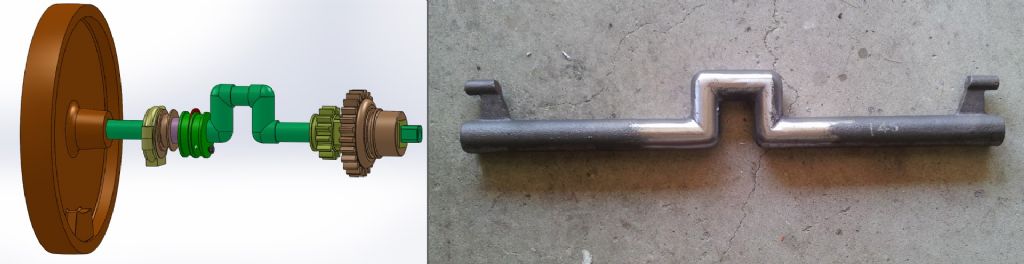

Because the barrel diameter is bigger than that shown on the model drawings, everything else had to be made wider. The crankshaft has to be made slightly longer and because the hornplates are further apart, the rear axle is also longer.

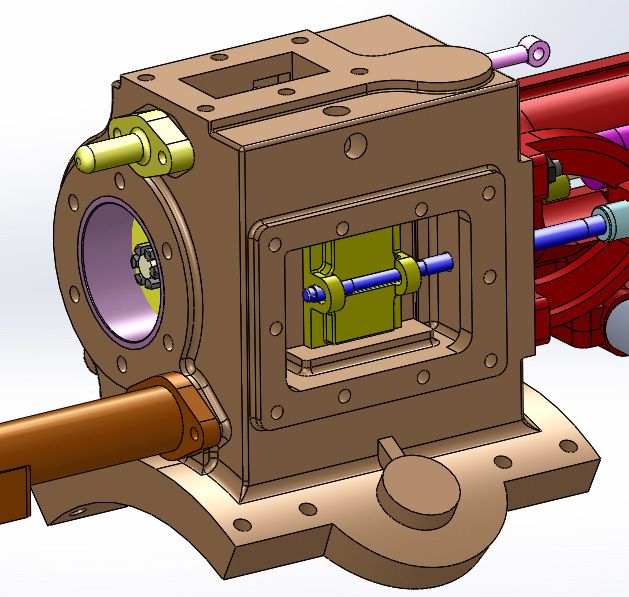

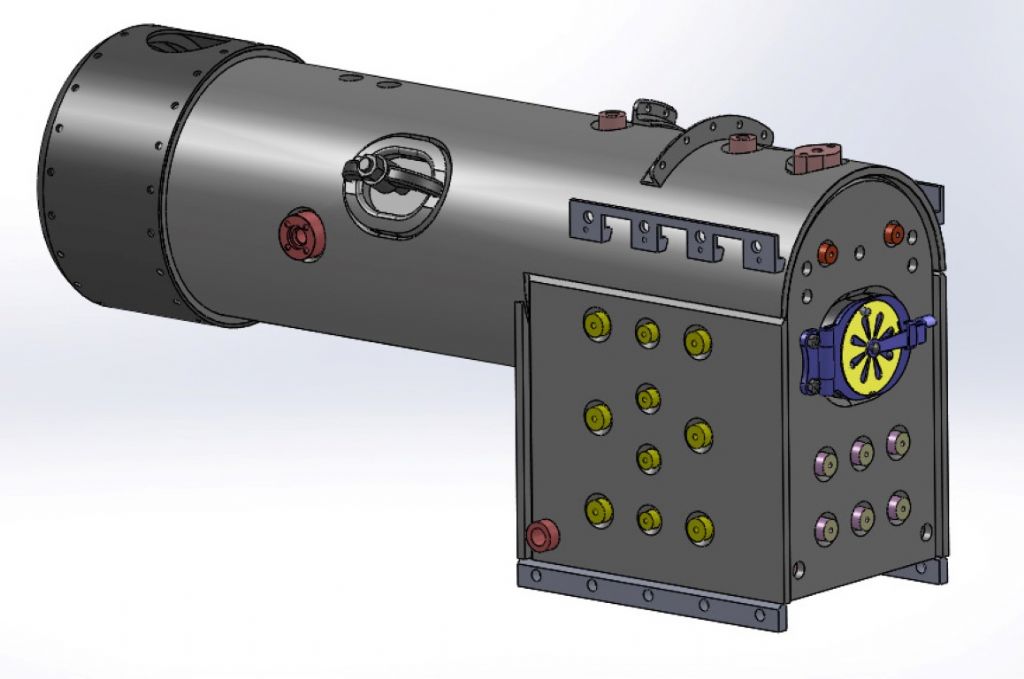

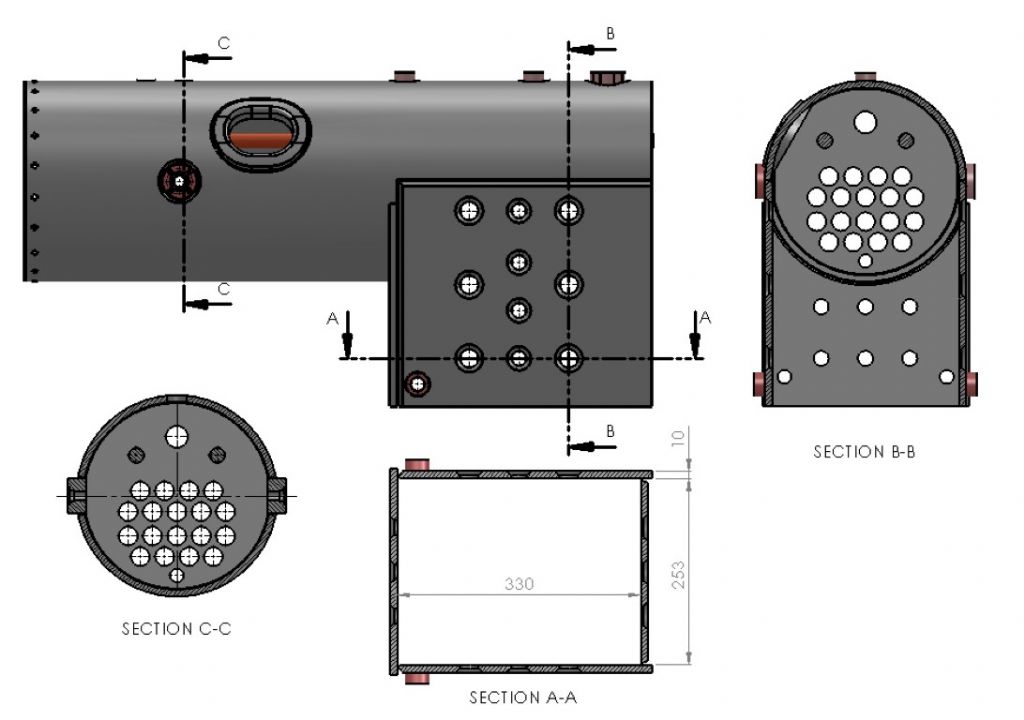

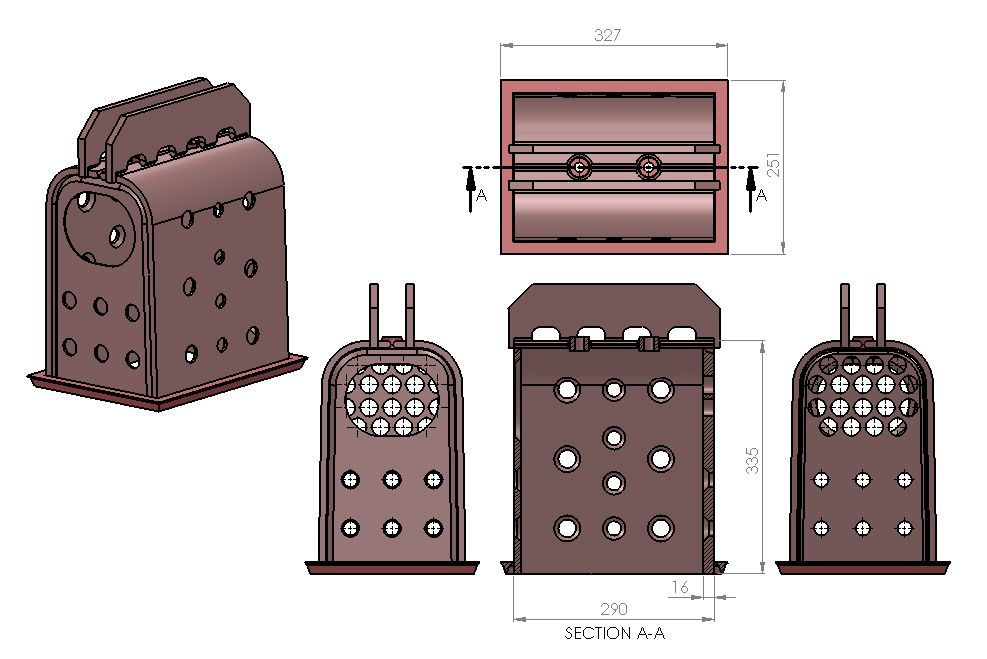

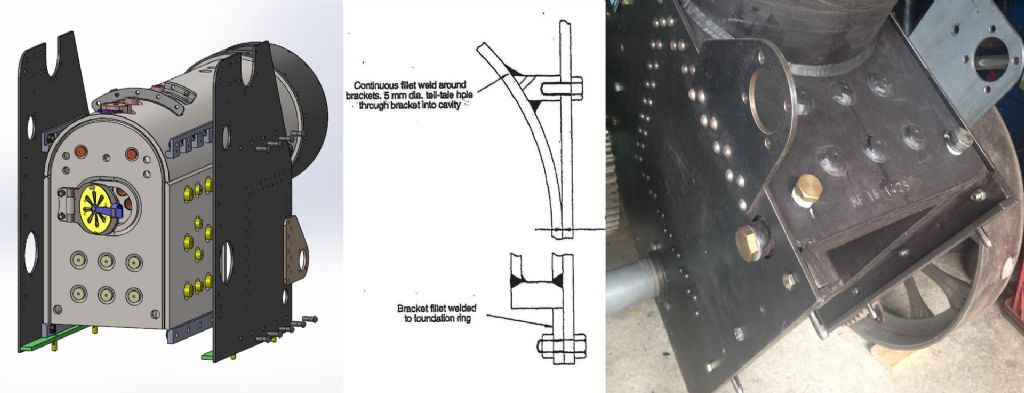

3D Models of 6” Scale Boiler created with Solidworks

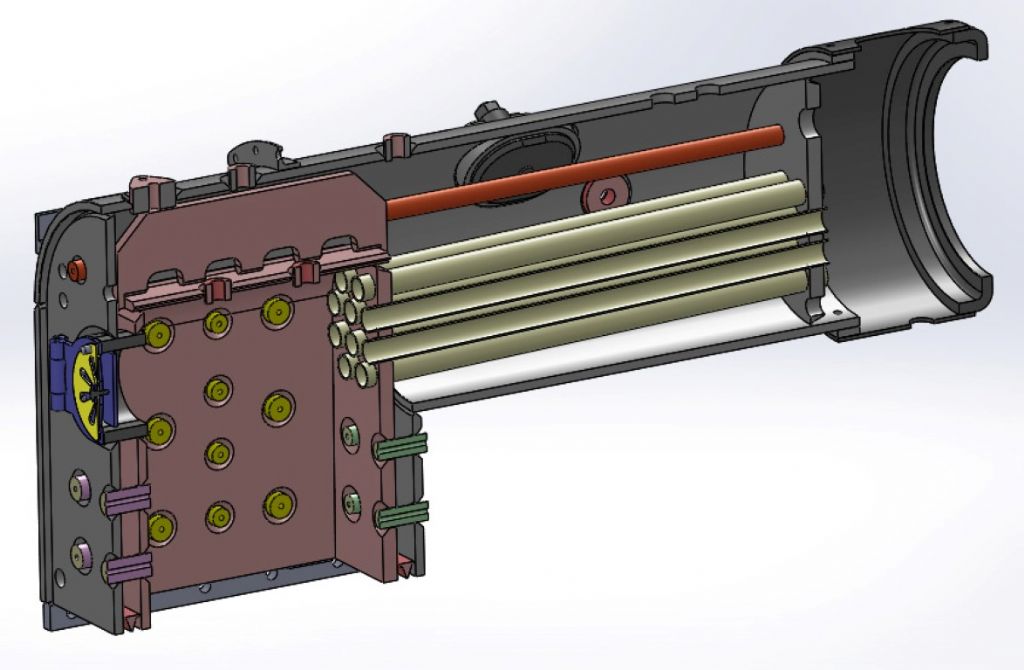

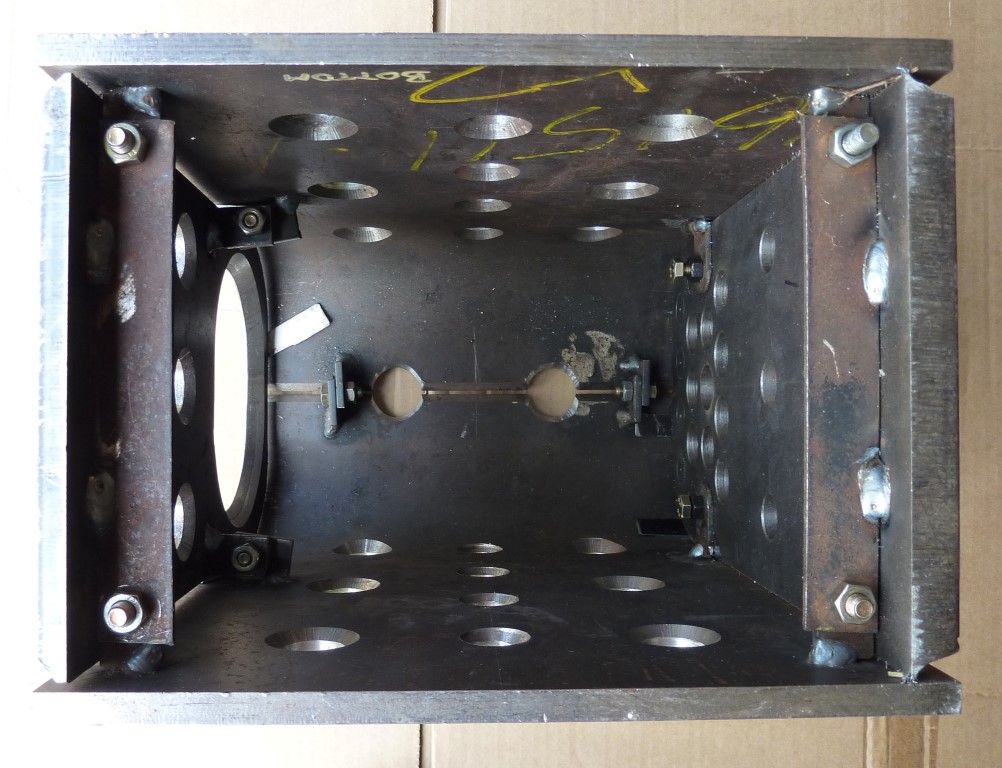

Sectional View of Boiler

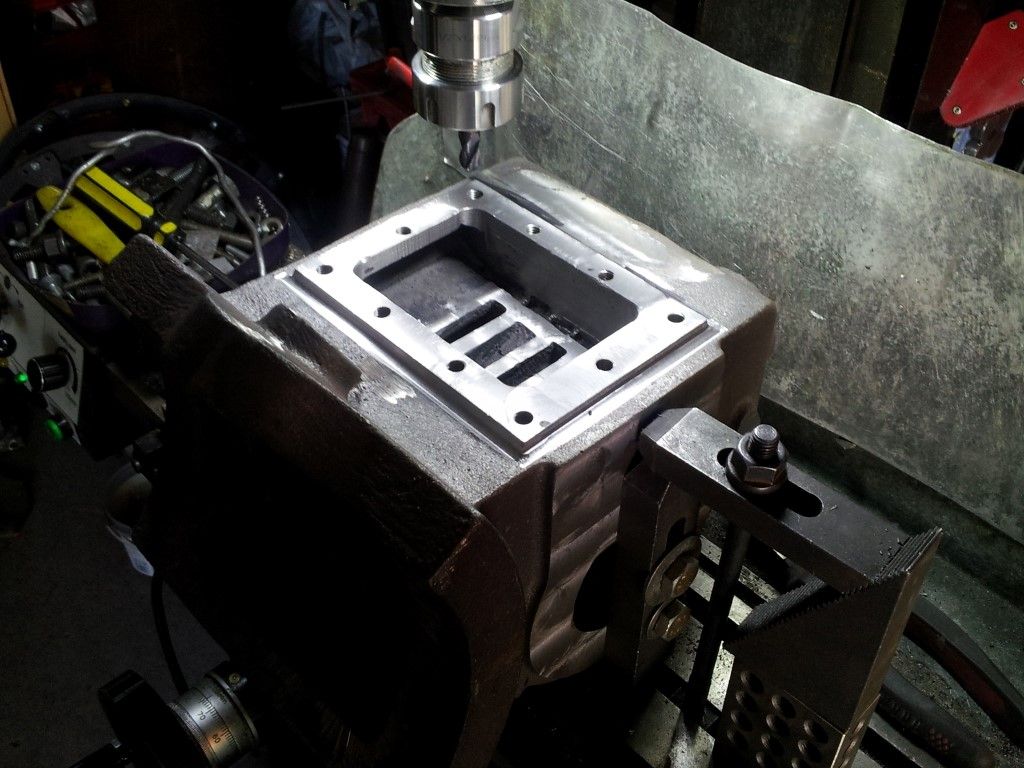

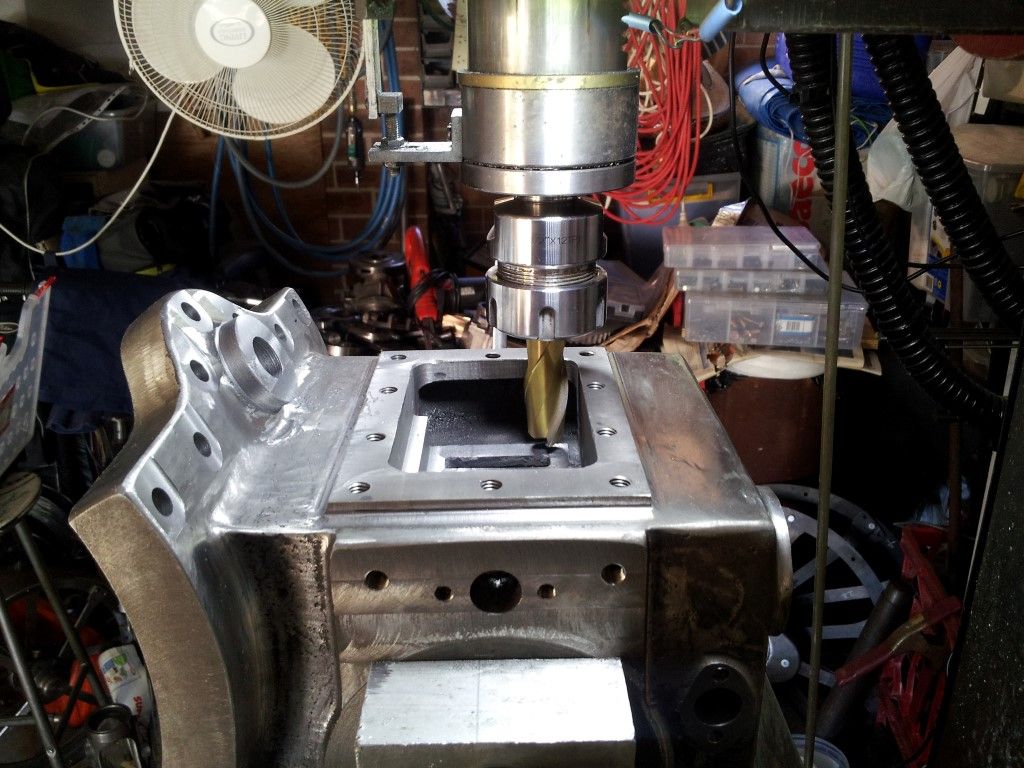

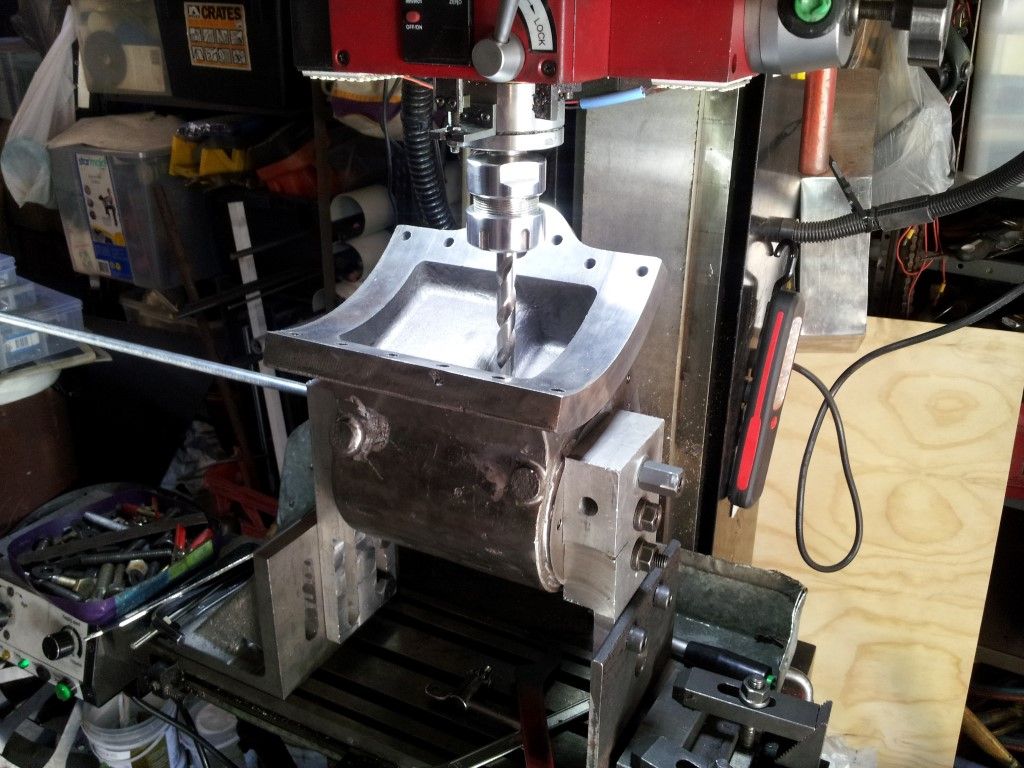

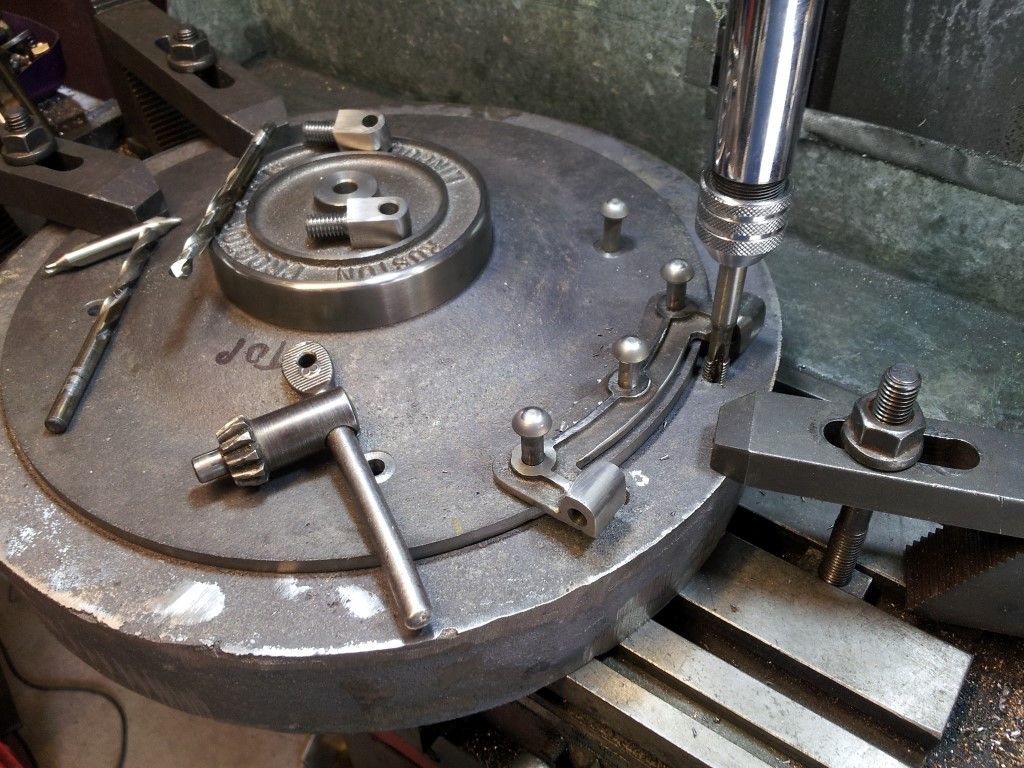

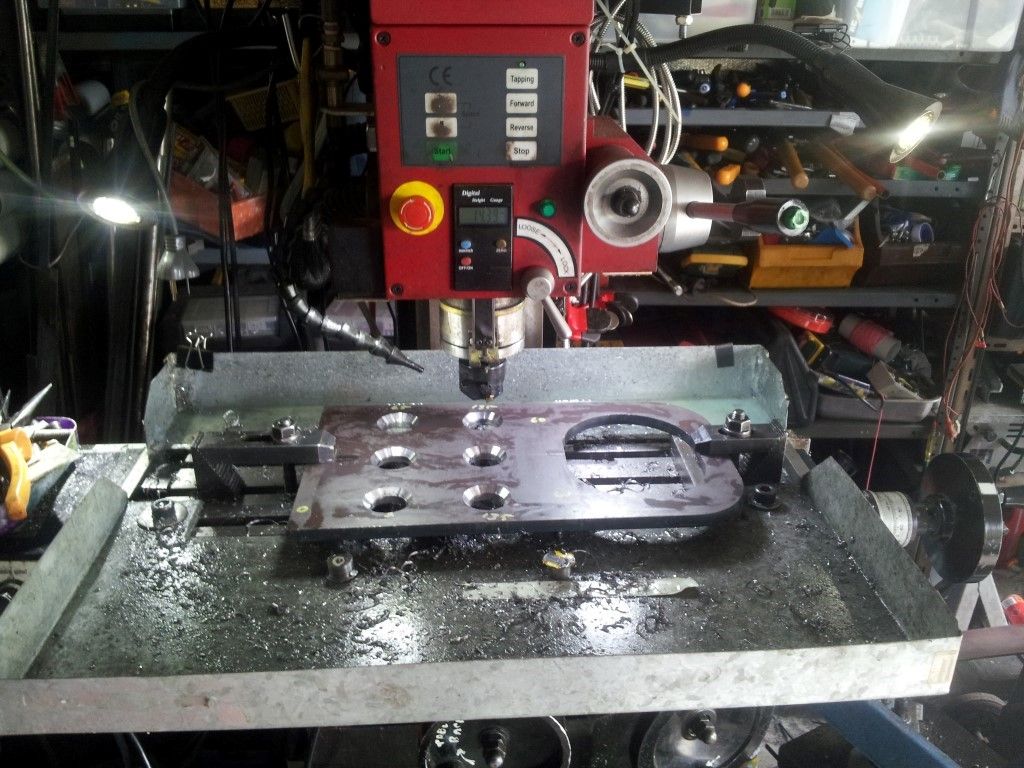

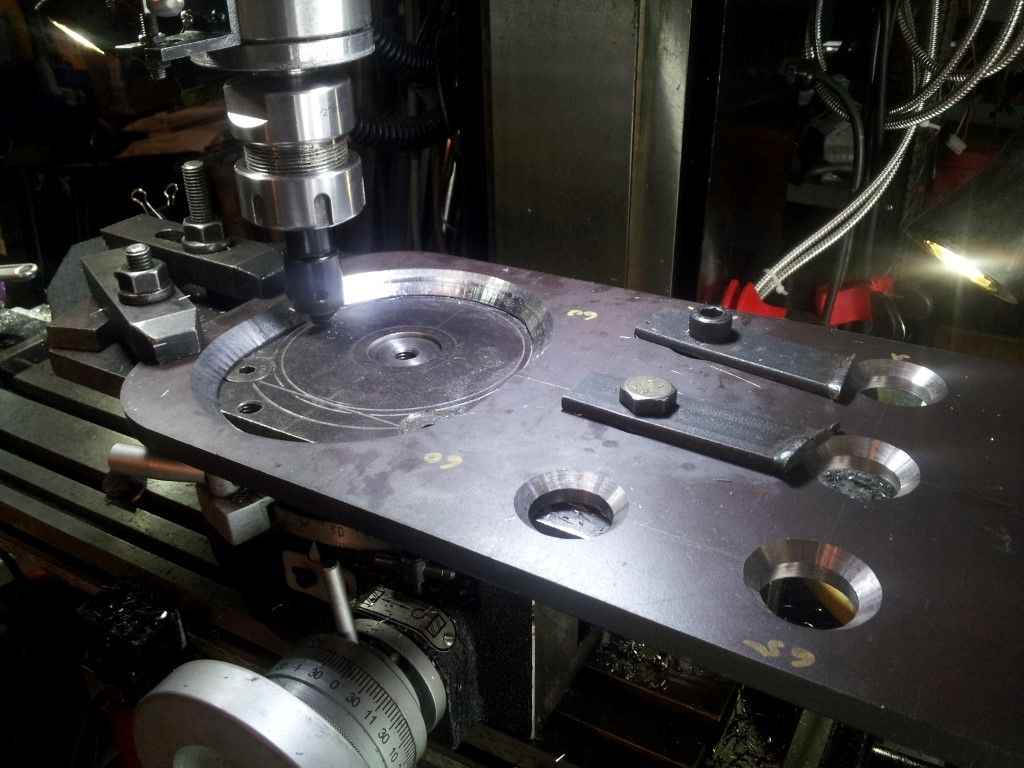

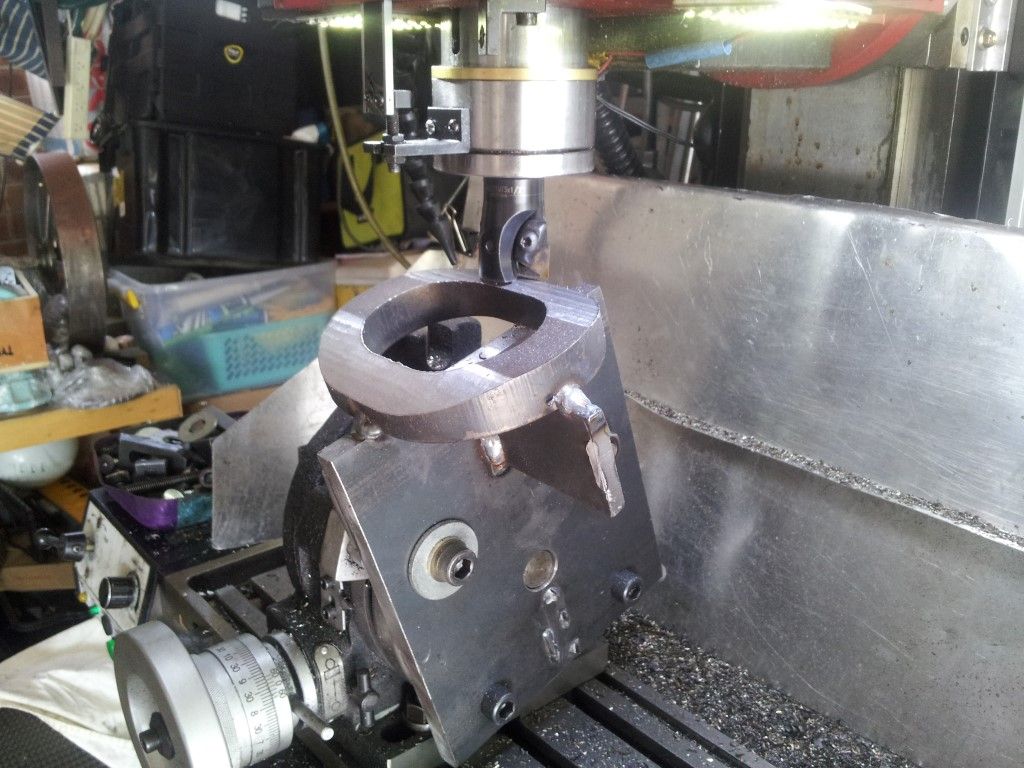

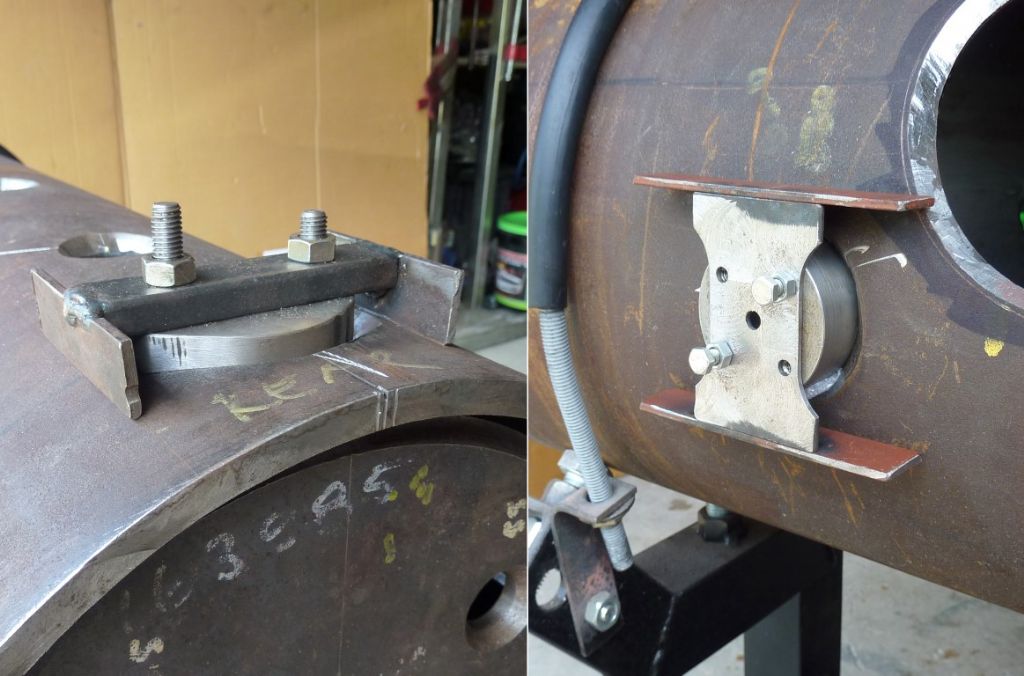

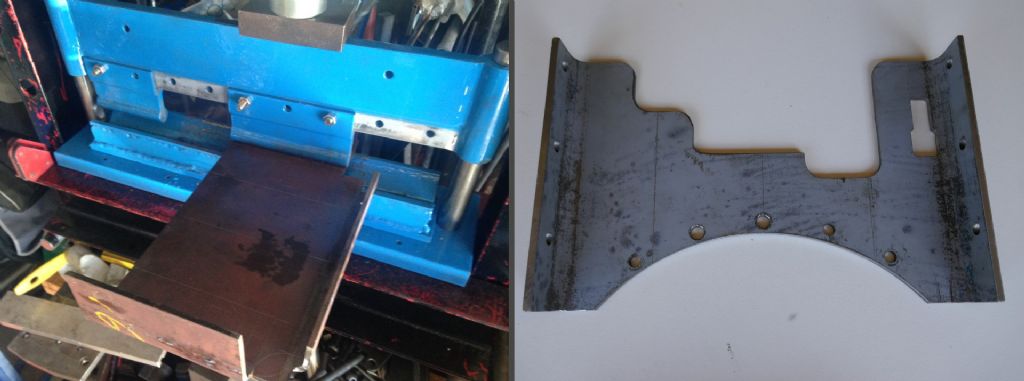

The boiler barrel was supported by a piece of pipe and held at both ends to take the load off the table of my SX3 mill while I machined holes for steam & water ports and for the manhole opening.

There was just enough space under the milling head for this operation and the sliding table is too small to carry such a big load.

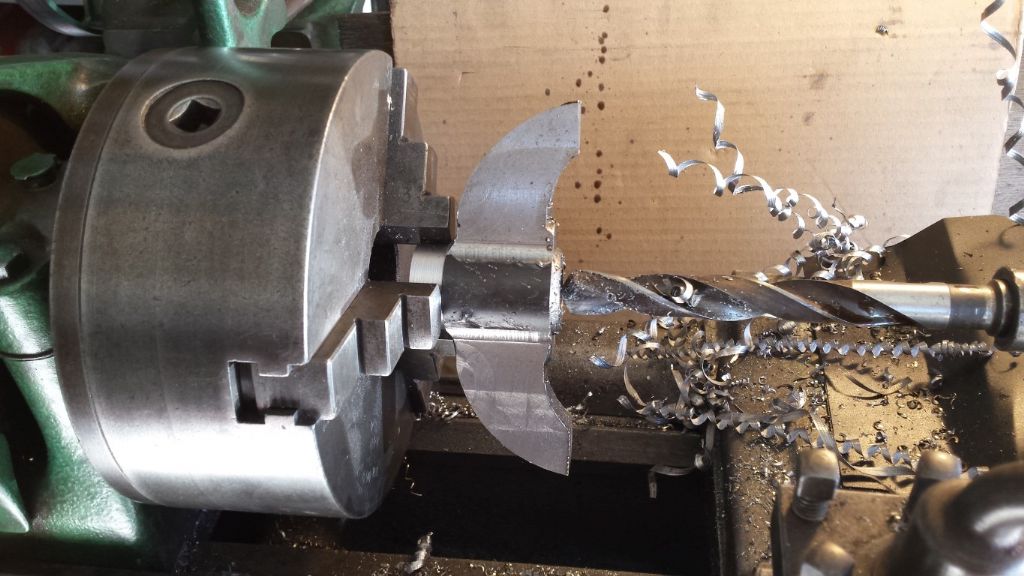

Each hole was roughly cut to shape with a rotary broach cutter.

Holes in boiler being bored to their finished size.

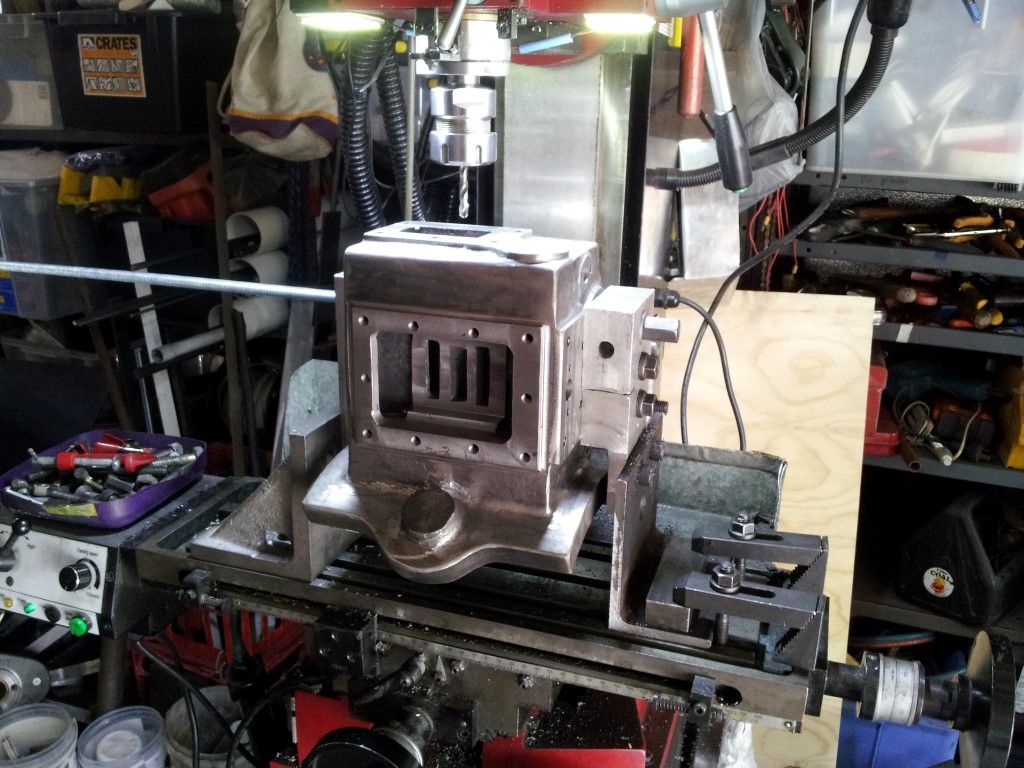

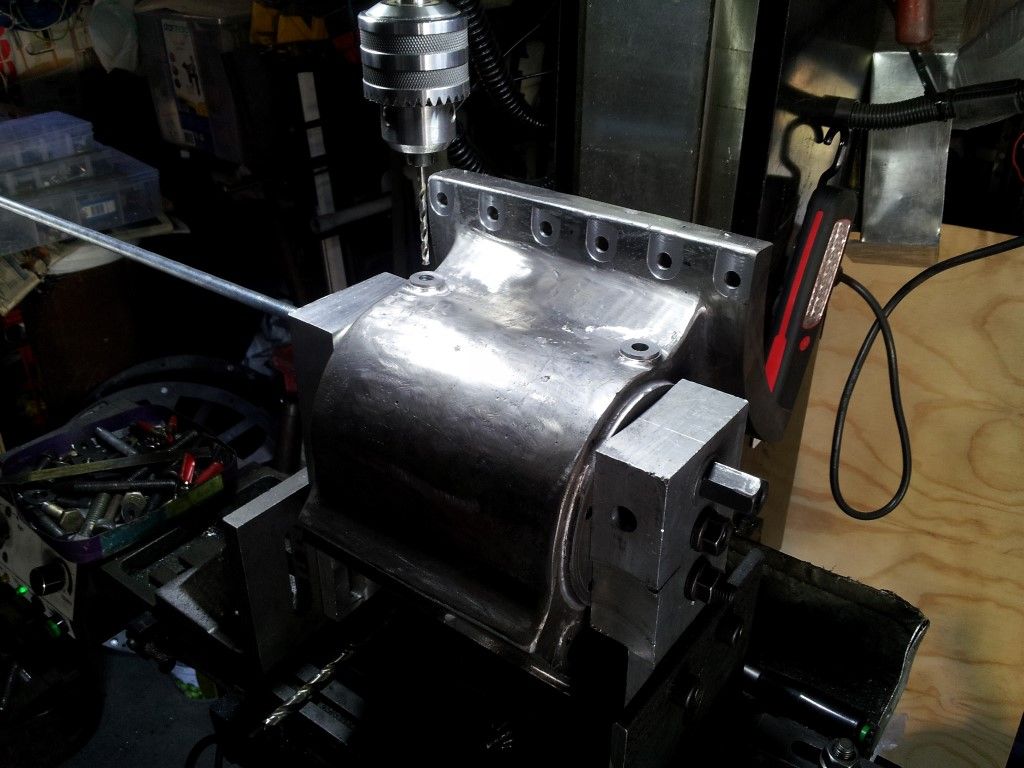

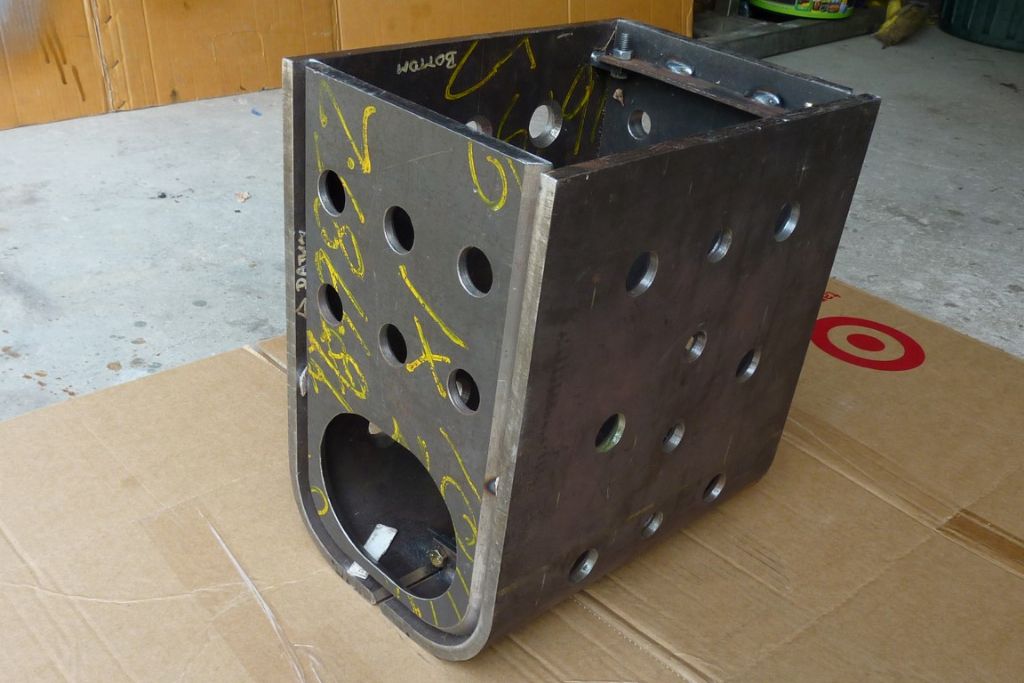

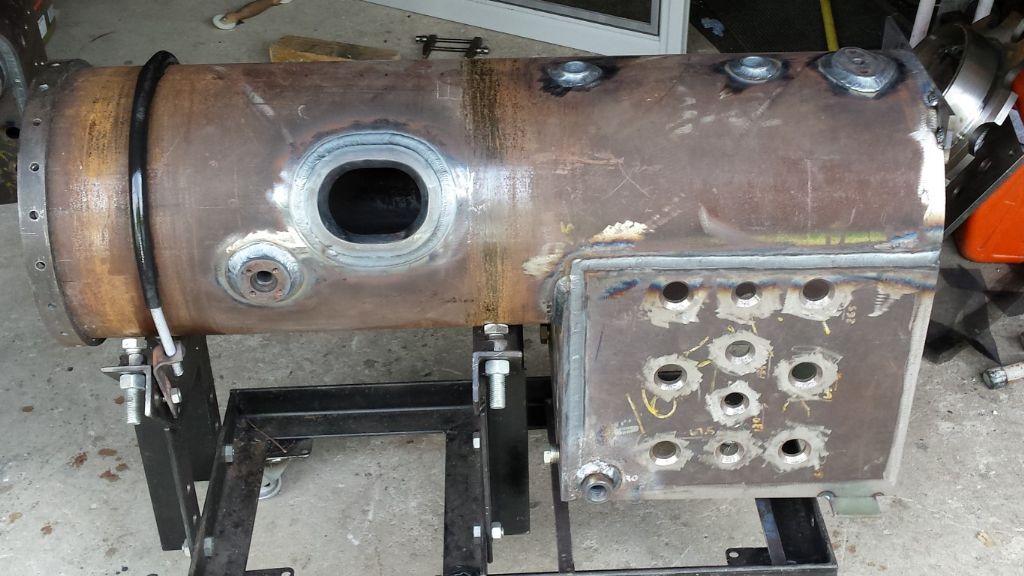

Boiler barrel mounted on a specially made trolley which is used for the assembly of the boiler.

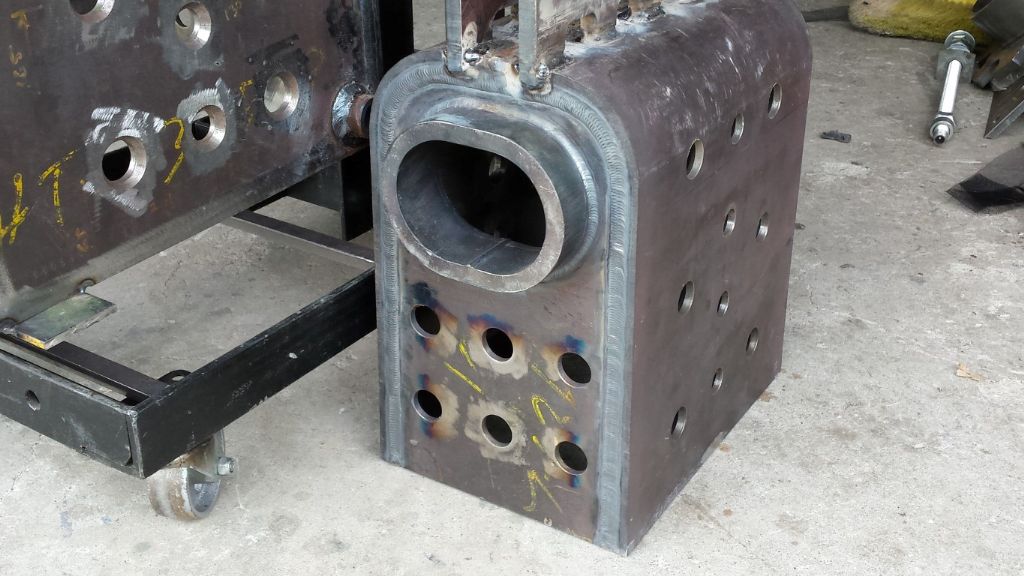

The barrel is at the height of the finished engine and can be rotated on the trolley for different assembly operations. It is shown in this view after being trimmed for the firebox plates. The cuts were made with a 1mm blade in an angle grinder.

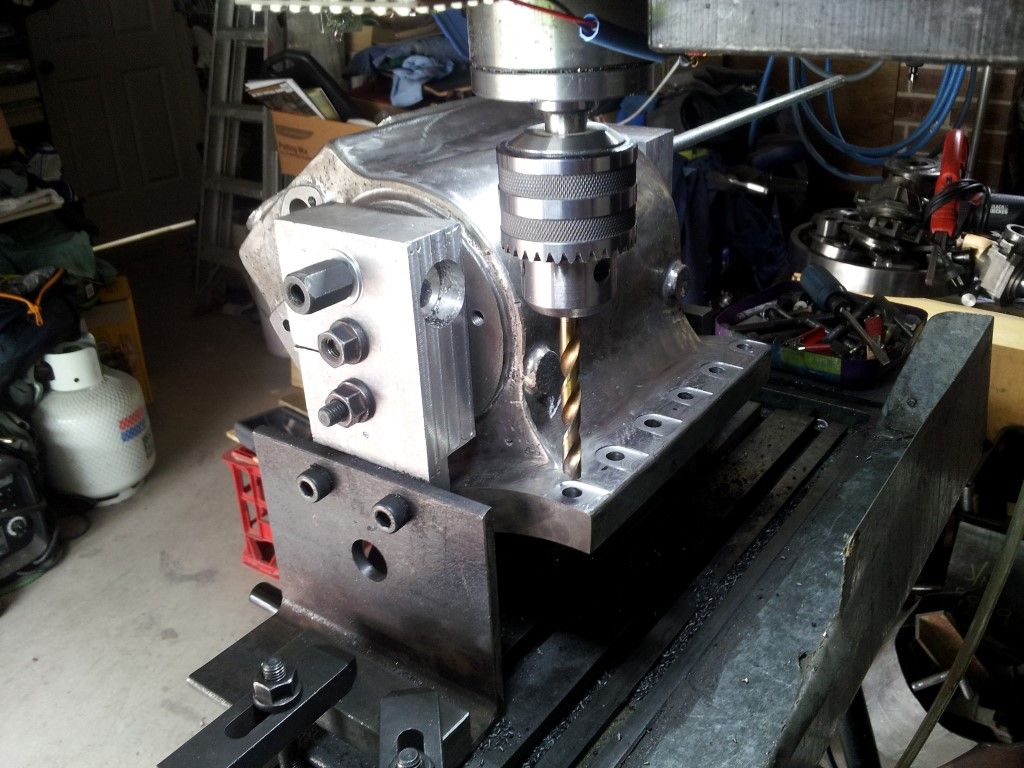

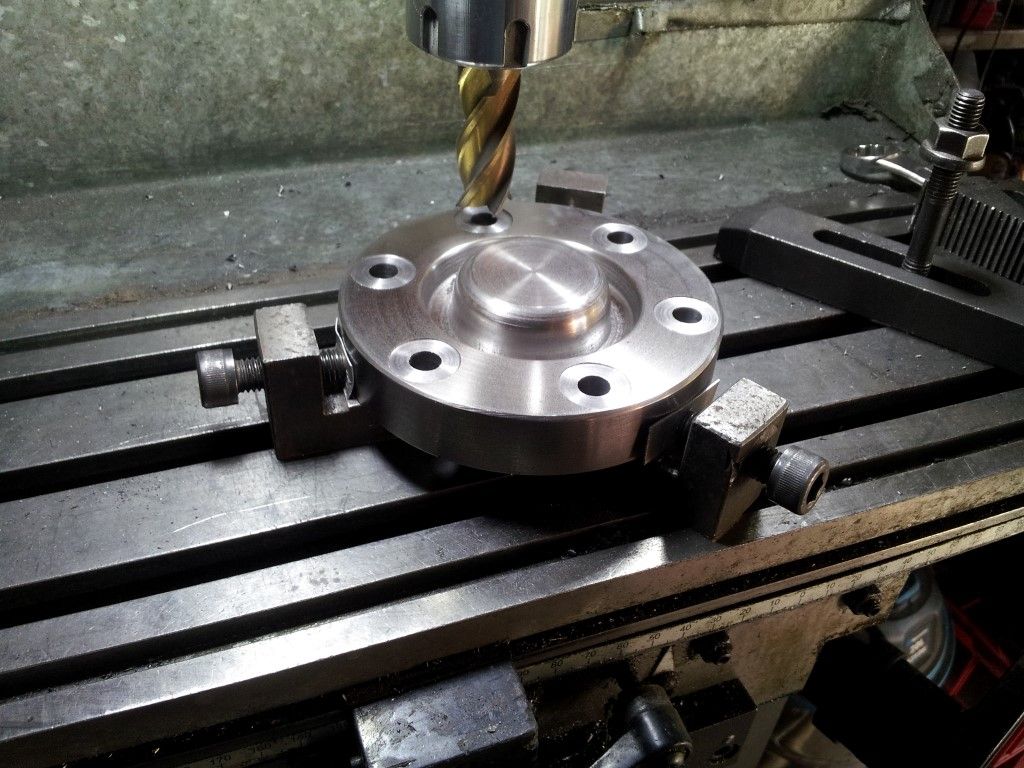

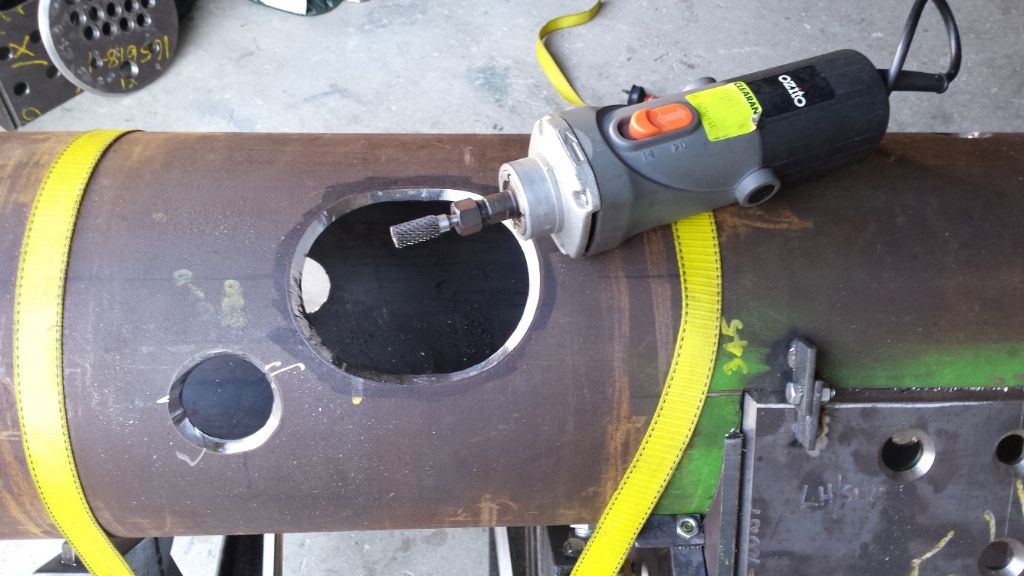

Weld preparations cut by hand with a carbide rotary burr in the chuck of wood router.

I found the router in the bargain bin of my local hardware store, less its accessories for $15. It has an 800 watt, variable speed motor that spins up to 22,000 rpm and easily cuts thru steel plate.

Edited By Paul Lousick on 23/11/2015 08:44:22

Jon Cameron.

Jon Cameron.