Thanks everyone. Just to wrap the thread up, I got the 5” rotary table as suggested:

My thoughts, for what they’re worth as a relative beginner, are that it’s typical of the more inexpensive tooling commonly available: It does the job, but has its faults.

The first thing I did was strip it down to a) clean the anti-corrosion grease off it, and b) to see how it was put together (to inform myself of how any adjustments might work).

One thing I noticed was that the exploded diagram shows a roller thrust bearing in the worm shaft assembly (part 8):

This is not present – it’s just a plain threaded collar, which in my table wasn’t true to the shaft. This makes preload and play impossible to get right, since if you remove the bind, you get clearance 180 degrees round. I tried to clean it up in the lathe, but with limited success. If the roller bearing was fitted as listed, it would be way better. Further to this, there’s a grub screw which is a limit stop for worm gear engagement with the main gear. This is just loose in its thread, and would be free to vibrate either way, changing the critical engagement adjustment preset. I substituted a cap head screw and locknut which can be seen in the image below (just above the silver engagement lever). Anyway, once adjusted to the best of my ability, I got about 3 minutes of backlash on the handwheel, and about 0.0035” play at the edge of the table:

This adjustment gave smooth rotation for about 300 degrees, and a slight (but annoying) stiffness for the remainder. I assume this must be something to do with the main gear ring.

As Jason mentioned, the lack of zeroing on the main table is inconvenient, especially as you need an Allen key to zero the handwheel dial.

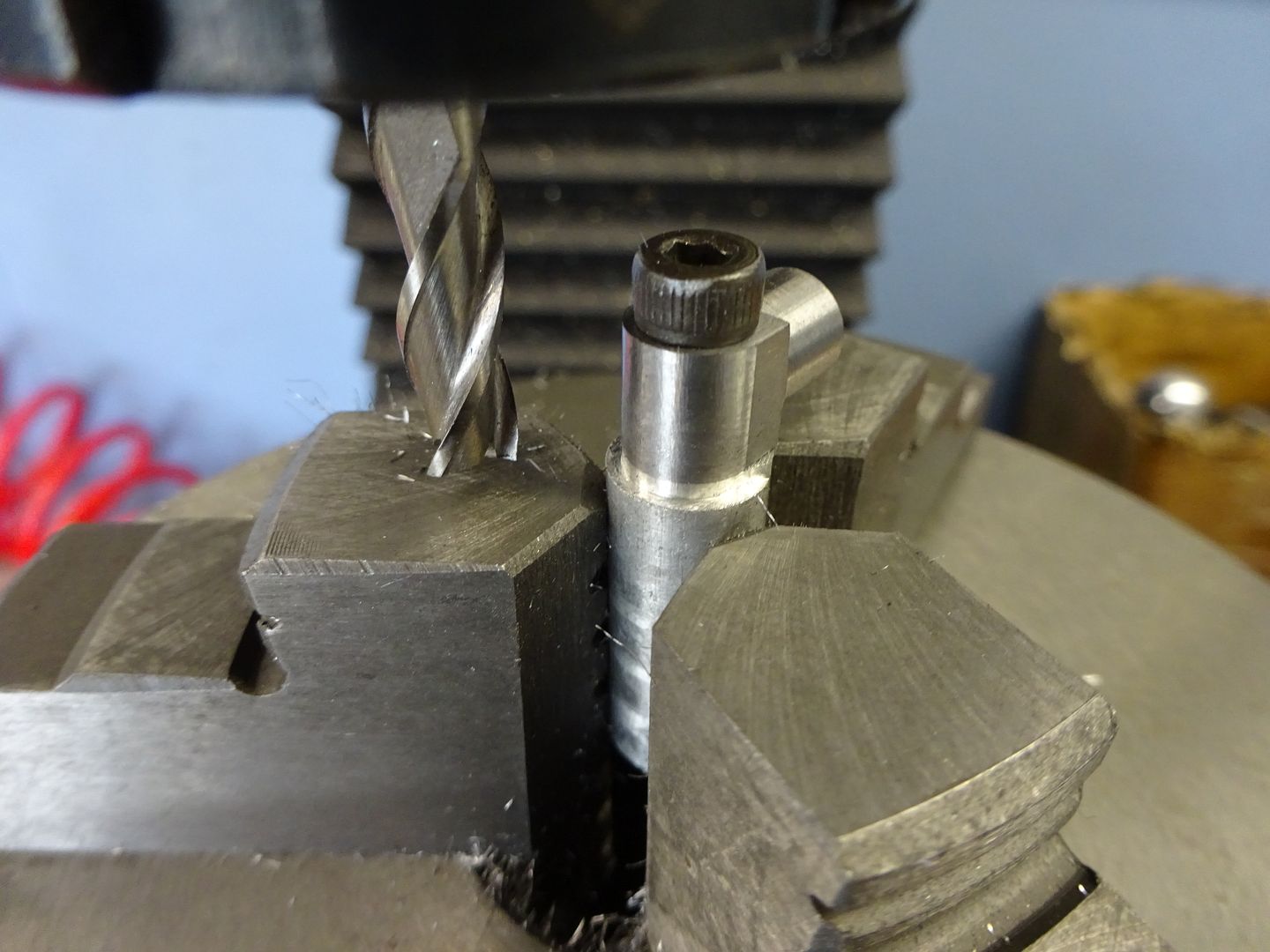

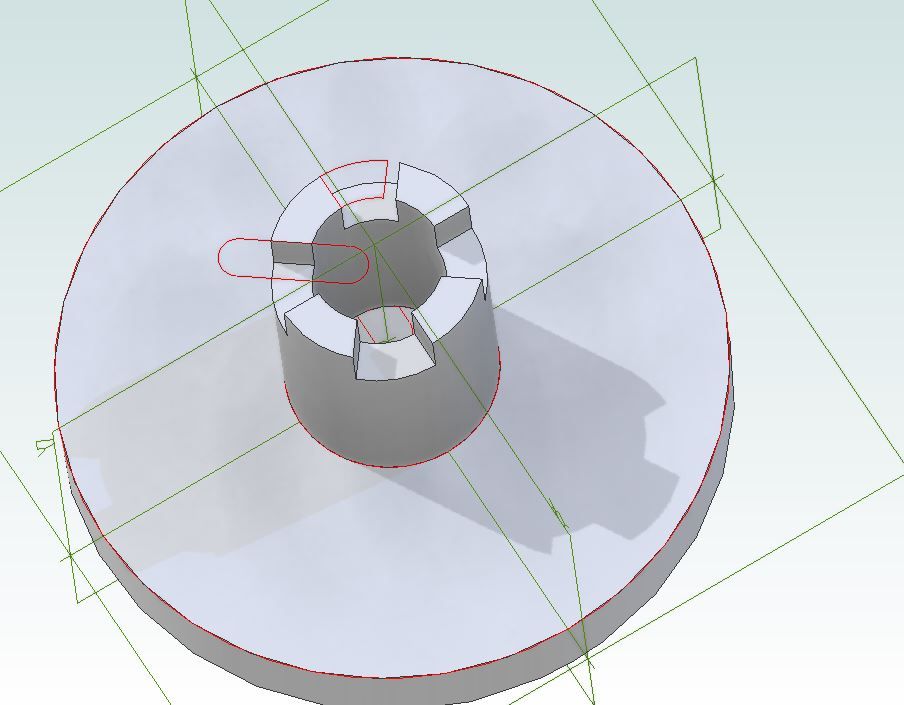

The chuck is OK, very stiff, but no big deal. The supplied t-nuts clashed with the lock plates, and needed thinning on the linisher. Contrary to some reviews, my supplied chuck key is a perfect fit. I tried the table/chuck out by helping my son making some differential parts for his r/c car. This involved milling sectors from a small diameter shaft:

And some lobed features on the reverse:

They work perfectly. Result:

Then, using my vice mounted to the table (made some clamps):

I profiled these packing gland castings:

I think they turned out pretty well.

After watching some Joe Pieczynski tutorials (as suggested on here). I initially centred the table using a dti rotated while in a collet:

Then, more accurately, by rotating the dti on the table with the lever in the spindle taper:

This showed an error of about 0.005”. The runout measured at the 2MT centre bore by rotating the table with a fixed dti was negligible.

I’ve not used the tailstock or dividing plates yet.

In summary: it’s fairly unrefined, frustrating to try and adjust perfectly (ie impossible), but despite the compromises, it does the job. Using it took some thought and calculation to avoid climb milling and backlash errors, but that would apply to an extent to any R/T I guess. Overall, I’m glad I got it and considering the hardware included, I think it’s good value. If it wasn’t for that slight bind on rotation, it would be pretty much perfect. Cheers!

Kevin D.