Posted by Ron Laden on 23/05/2018 07:39:15:

Just out of interest I located my digital tacho and did a non loaded check on the 4 motors.

The motors are rated at 5167 rpm, the readings came out at 5988, 5997, 6040 and the highest at 6235 rpm.

The motors are running a fair bit faster than the speed quoted in the spec but then I dont know how they test or arrive at that figure.

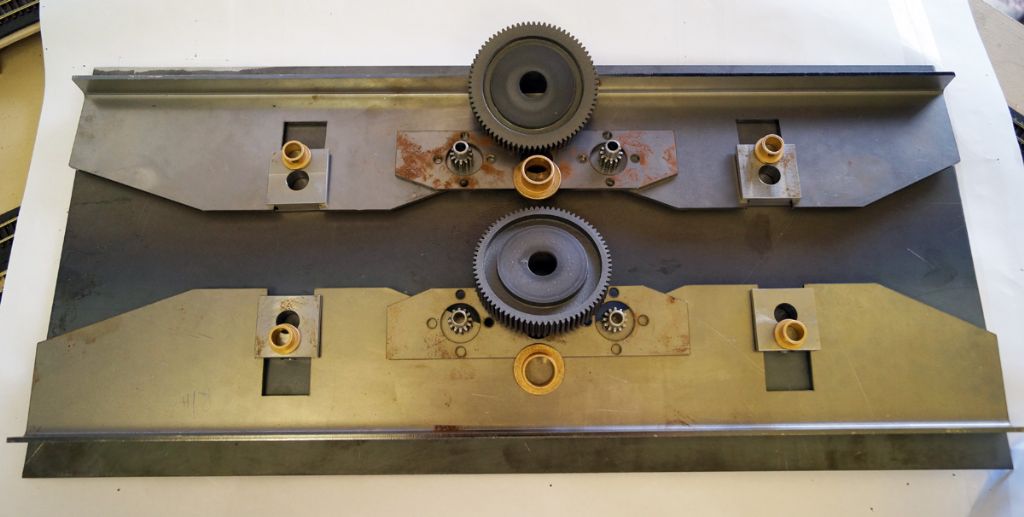

Three of the motors are very close considering they are just can motors with the fourth one a little higher. They will be running through a 6.25/1 reduction so they should be fine as a set.

Ron

Edited By Ron Laden on 23/05/2018 07:42:46

As already said four similar motors should would work together as a set without problems.

It's not particularly useful to measure no-load rpm as this is an unusual condition in practice. (It might happen if the shunter derailed!)

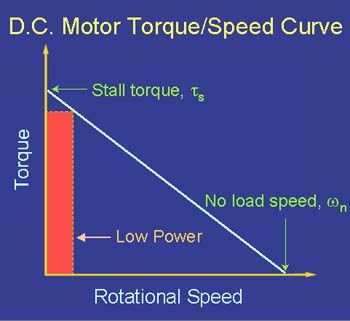

DC Motors operate under a range of conditions between trying to start from stopped (or stalled) and no load. The characteristics of a motor – torque, power and rpm – vary across it's operating range and are best expressed as a graph. It's more common, but less helpful, for makers to give figures for torque and power at one particular speed, usually the one at which the motor is most efficient. They may also indicate that the motor only meets those figures intermittently – don't run motors like that continuously, they need time to cool off between bursts of work.

Torque, power and rpm aren't related intuitively. You might expect maximum torque and power to occur at maximum speed. Nope!

Torque is the measure of a motors ability to apply a turning force. It is usually highest when the motor is stalled, and drops to almost nothing at full speed. Power is the rate at which the motor can do work over time. Normally the power output of a motor peaks somewhere between zero and max rpm.

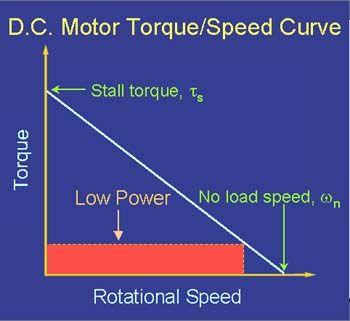

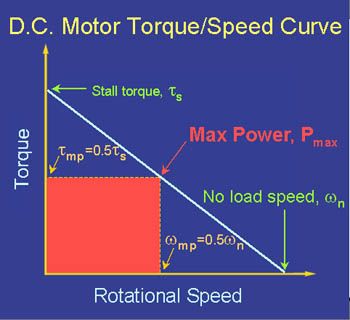

These graphs are from 'Understanding D.C. Motor Characteristics' – worth a read if you're interested in theory. The graphs simplify the relationships by showing them as a straight line. A real motor's characteristics would be a curve of roughly the same shape. The shape of the curve might indicate one motor to be more suitable for an application than another but that's grown-up design.

Note High Torque occurs at Low Speed, and that power output in this condition is Low. As the excess input power has to go somewhere it appears as heat. A motor stalled for too long is likely to burn-out.

Next graph shows that both torque and power output are also Low at maximum speed, putting a limit on the maximum speed to which the shunter can be pushed.

So, ideally, an electric motor should be operated somewhere in the middle, where torque and speed combine to produce maximum power. Where necessary a gearbox is used to ensure this happy condition.

The good news is that:

- Four motors of the same make and size will have similar characteristics that, on average, will allow them to work together well. This is very different to fitting four different motors and hoping for the best. It's important that the motors match as a set, which yours do.

- In practice, only enough torque is needed to start the loaded shunter. Once moving, the motors will tend to move towards the sweet spot where they deliver maximum power/efficiency. (Quite likely this will be near your intended cruising speed because you calculated how to convert motor speed to axle speed)

- As the shunter isn't a race car, the motors you have available should comfortably support its intended purpose.

My only worry would be if the shunter was operated like a real shunter, that is continually start/stopping heavy loads in a marshalling yard. In that case the design would need beefing up, for example with gearing down and fan cooling the motors.

Bottom line, it should work as you have it.

Dave

Edited By SillyOldDuffer on 23/05/2018 10:42:18

Ron Laden.