I'm finding calculating drawbar pull from motor power to be quite a challenge. It's not that simple because the sums vary with weight and acceleration, not to mention that a real 80W motor is unlikely to produce 80W at all speeds, or that the transmission has losses, or that the wheels might not have good adhesion with the track. Is there a gearbox etc?

Theory tells us more power is needed to start and accelerate the train than to cruise at a steady speed, and pulling a train uphill also takes more power. In full-size practice, trains are sized so that the locomotive is powerful enough to restart the train if it stalls on the steepest section of the route. Or a second locomotive is kept ready at steep parts to temporarily double head the train. (This is an interesting problem in railway economics; locomotives are hideously expensive and it doesn't pay to have them hanging around on the off-chance they might be needed, nor is it a good idea to run trains light if that can be avoided. Is it cheaper to replace double-heading with a tunnel?)

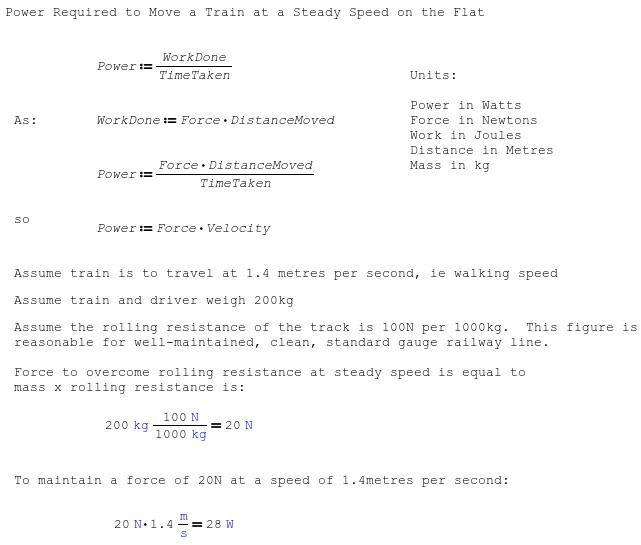

Complications abound. However, it's relatively easy to calculate the power needed to maintain a train at a given speed on level track. Tables are available giving the Rolling Resistance of various surfaces. Note that the calculation is optimistic – it does not allow for stiff bearings, grinding on bends, sticky brakes or any other practical embuggerances that occur on a real railway.

Here goes: the calculation was done in Smath Studio for which I am indebted to Mr Duncan Webster of this parish. All mistakes are mine.

The sums show an 80W motor can be expected to be well capable of keeping a 200kg train in motion at walking pace on flat track; actually it has power available to either go faster, or to pull a heavier load. Starting is a different matter.

A second easy calculation would show how much power would be needed to pull 200kg at 1.4m/s up a given incline. It's relatively straightforward to calculate how fast an 80W winch would lift 200kg up a lift-shaft. Too difficult for me is to calculate how much weight an 80W locomotive could move from a standing stop. Even with full information about the locomotive; torque, wheel diameter, motor efficiency across the full speed range, transmission efficiency, and adhesion etc, the maths are too much for me. Perhaps a clever chap will have a go?

Reading about locomotive development in Victorian times, it seems that getting the optimum balance between weight and power in loco design was difficult. Over the years many different approaches were tried, with experiment often showing the theory was insufficient. Many good ideas didn't work well in practice. I don't know how modern locomotives are sized. Probably based on mathematical analysis much tuned by a couple of centuries worth of much studied experimentation.

Rough and ready methods aren't to be disparaged. Another way of getting a feel for what an 80W motor might be capable of, is to compare it with your good self. The average fit man can deliver about 200W continually, much more in bursts – professional footballers peak at about 1.5kW. Even unfit chaps should manage 200W in short bursts which is a benchmark. Don't over do it – an ambulance would be needed if I had to produce 200W for more than 5 minutes!

Dave

Ron Laden.

) but definitely prefers my own built driving trolley than the huge, heavy trolleys most clubs have.

) but definitely prefers my own built driving trolley than the huge, heavy trolleys most clubs have.