Hi Guy’s

Oh dear I really have mislead you here I’m afraid – well sort of.

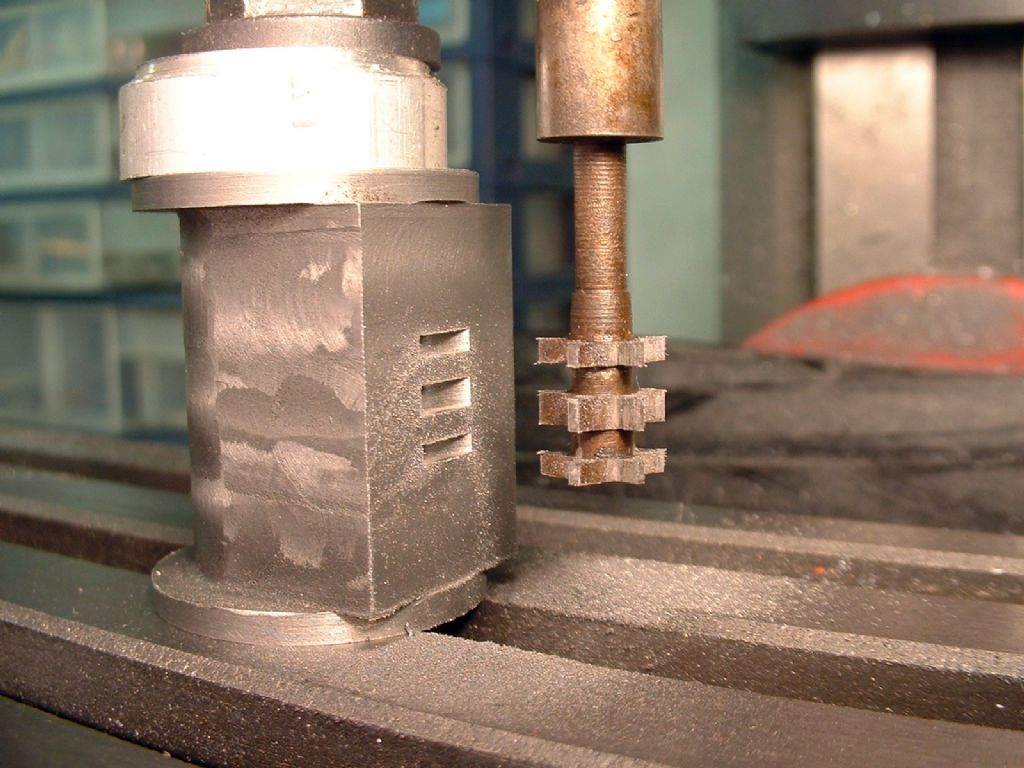

When I built my two engines and indeed the Etas too I did ream the main shaft 7mm thru with a short 2mm deep 7.5mm counterbore for 6.35 finished shafts. The inner shaft was made to suit and, as stated in the text, the whole lot was turned between centres after Loctiting. When I drew it in Cad I must have overlooked that fact and drew it as shown. I certainly didn’t realiise it conflicted with the text

However I’m certain that providing the inner shaft is made accurately before Loctiting and is a good fit in the main shaft there should be no problem with concentricity.

The easiest way around it, though not an ideal way of going about things, would be to change the design slightly and keep to reaming 6.35 through and reducing the front end to 6mm between centres making sure you remember to ream the collet 6mm and thread the spinner nut M6 too. This will be more than adequate – the Eta Mk 1 has a 6mm (as designed) front end and is running well.

Dick you really should not need to put a seal behind the front bearing to maintain crankcase pressure. The scuffing was probably due to some miniscule bit of debris that allowed the shaft to pick up. I have not experienced the problem before or since – in any engine. It is usual to allow the fuel to reach the front bearing by allowing a degree of leakage down the shaft. Though both Racers have open bearings at the front I have removed the inner seal on some front bearings to prevent ingress of dirt but allow lubrication from the rear. As far as two stroke diesel and glowmotors are concerned I have never seen a seal being used.

The drilling of holes for the transfer ports instead of radial slots should be okay but I would imagine the performance may possibly drop off a bit due to the opening being gradual. That said several designs feature this kind of porting so don’t perceive it as a great deviation. Drilling the holes at an angle towards the top of the bore however will increase the transfer period – just as in the Eta’s

Bill – Thank you for your kind words of reassurance. I do realise that despite trying my damndest mistakes will happen – it’s just not nice when you realise others are relying on you not to make any

This is fast becoming a salutory lesson. It is the first time I have had a design published and can see that far more care will be required should anything materialise in the future. All I can say – promise – is that I will take note and update the drawings as and when required.

Finally Dick could I just say that my name – Ramon – was not of my choosing, that was defintely beyond my control, but it is my name and that’s the way it’s spelt. I have had several nicknames over my years the ubiquitous ‘Tug’ being the usual but I don’t refer to it on here. That said however I’m definitely not a ‘Raymond’ either

.

Regards to all – Ramon

Edited By Ramon Wilson on 07/10/2011 12:12:09

Sub Mandrel.

.

.

I would have a recount if I were you

I would have a recount if I were you