Thanks for all the feedback and some very good advice.

I didn't want to blame the tools, so was kind of in denial about the possibility of the chuck being bad ( 4 jaw came with new machine and had been unused until recently so had assumed it would be as good as the 3 jaw).

Subsequent to MG's and other posts I had a bit of an investigation. Checking jaws 2 by 2 clamped on some silver steel showed beyond any shadow of a doubt the jaws were absolutely diabolical. Not only was the grip wobbly and insecure in the plane of the pair of jaws, but clocking the steel bar showed 20-25 thou off axis over 3 inches for one pair and the other pair could be set at almost any position you like, none of which gave a true axis.

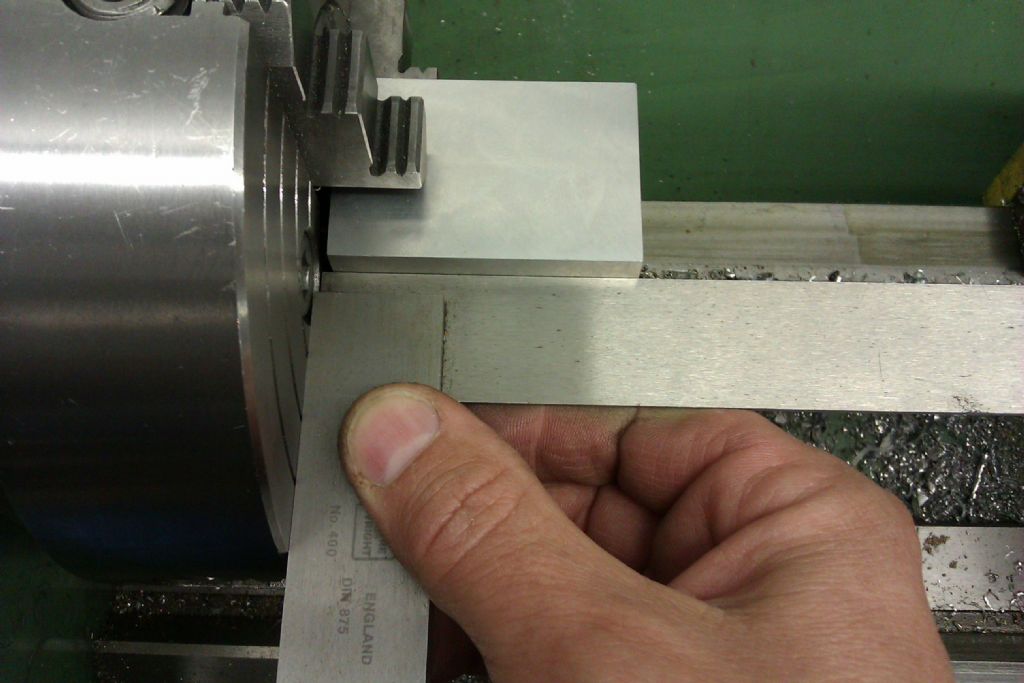

Checking against a backlit straight edge was utterly disheartening – some jaws were convex, some hollowed, others had uneven teeth (serrated jaws). A new chuck!! If you wanted to make one as bad as this it would actually be quite hard work Doh!.

Other parameters like spindle TIR checked out at half a thou and half thou wobble on the spindle plate mounting which is bit disappointing but probably OK for a CML. Slightly concerned, for as I recall there was almost undetectable run out when I unboxed the new machine 18 months ago and it has been fitted with angular contact bearings.

So replaced what is now a large heavy paperweight with the original 3 jaw that I had recently spurned for having a totally outrageous 1.5 thou TIR and an axial drift of half a thou over 6 inches. Incidentally, both chucks are from the same 'no name' manufacturer (orbiting stars brand from the logo!).

A new chuck is called for I think. I quite like the idea of attempting to re-grind but is a bit of a scary prospect, although difficult to see how any remedial action could make this specimen any worse..

At the moment all I would like to do is throw the chuck at the head of person that QA'd it. Interestingly, the gaudy check sheet that came with the chuck gives expected parameters for run out on the various planes and axis, but has no data for a chucked test bar (like the 3 Jaw has). Why is that I wonder!!!

Thanks again to all for your help.

John P.