I just took delivery of one of these today – a Creality Ender 3 Pro. I got it from Amazon which means I paid a bit more than the cheapest UK prices (and a lot more than the bangood ones) but you get it next day and don't have to worry about fedex dropping a bill for import,vat and admin fee six weeks later.

Anyway, I'll recount my observations here:

Packing: superb. You get literally everything you need including tools all packed in a 2-layer box with properly shaped foam inserts

Build instructions: adequate. There's a sheet and there's also a PDF on the supplied SD card & reader. It's all pictographic and there is no easy way to get it wrong.

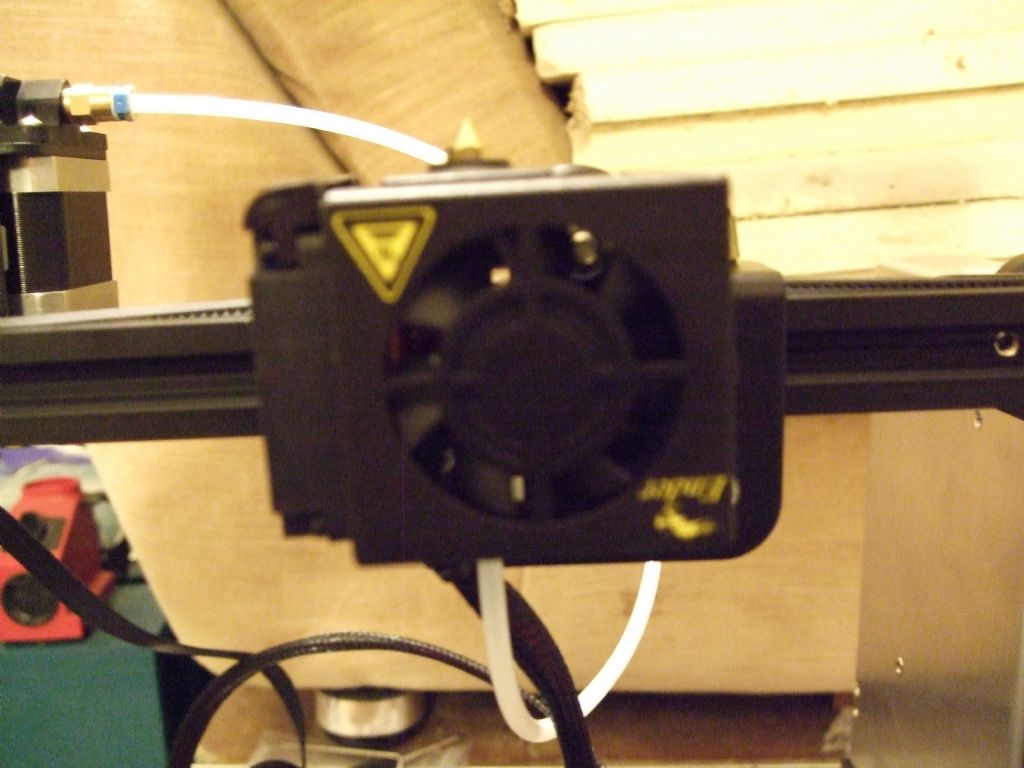

Construction: Better than expected. I put mine together loosely leaving all screws that could be tightened later just snugged up.There's only the two vertical rails, top strut and x-axis bar really plus a load of fittings. The guide wheels were well adjusted and all I had to do was get out a square to check things before tightening. Once fully assembled the frame is impressively rigid for what it is. I suspect that most people just throw it together but I am a little more picky than most and don't want to do it twice or try to dial out any mis-alignment.

Assembly: Straightforward but I did find a couple of small adjustments I had to make notably the z-axis motor mount and the cable routing. I also found that the pre-fitted cables didn't lend themselves well to following a natural route so I removed the bottom cover, cut all the zip ties, ran them out straight then routed them in nice relaxed curves to their destinations before tying them back up again. The z-axis motor simply couldn't be fitted to allow the screw to run parallel to the axis of travel so I opened up the two holes a little to allow some adjustment and made a small packing gasket from the card box that they put the filament cutter in to space it off the column, and doing this made the screw run nice and true. Not serious but looking online it seem it's an endemic problem that would take no effort for them to sort.

Operation: Well, the first time I turned it on it did – nothing. The 24v power lead had come out of the 2-pin plug due to poor soldering. I had to remove that and re-solder the lead. After that it turned straight on and worked well.

One thing I will say is that the operating instructions are sparse. There are a lot of configuration settings (that you could mostly leave alone) but they simply aren't covered in the instructions. Thankfully, the online support is huge and you'll easily find out what does what and that's what I had to do, as I literally know NOTHING about 3d printing except what I've learned in the last 10 hrs.

I printed some test prints to prove the bed levelling was good. I found that the bed plate was not truly flat but apparently that's because it was cold and they flatten out when heated. I also found that the default heat of 45 degrees for the bed and 195 for the nozzle were too low for the PLA and the tests prints were not sticking. I turned them both up 10 degrees and the alignment tests came out great so I kicked off a test print from the card.

A quick note about the software side which (like me) you might not realise:

I use sketchup but no other 3d software so I was planning to install fusion 360. Can't do that on my old PC as it needs 64 bit. Also I was going to use Cura slicer – can't do that either as the 32 bit version is very old. Creality do however bundle their own slicing software on the SD card (and it's downloadable) which does work even on older pc's so a bonus point for them there. I also discovered that you can export sketchup files to a .due format that their slicer can handle, so I'm going to try that tomorrow.

On the whole, am I pleased? Well yes I am very happy. I didn't expect it to be quite so good for a £200-ish machine. I'm going to cut my teeth by printing out some of the many parts that people have made for the printer – cable guides, tool tray, small clips etc then I have a list of other things I want to print of my on design. I can see this machine getting a lot of use. Certainly I'd recommend one to even a raw novice like me.

Pete.

Neil Wyatt.

Neil Wyatt.