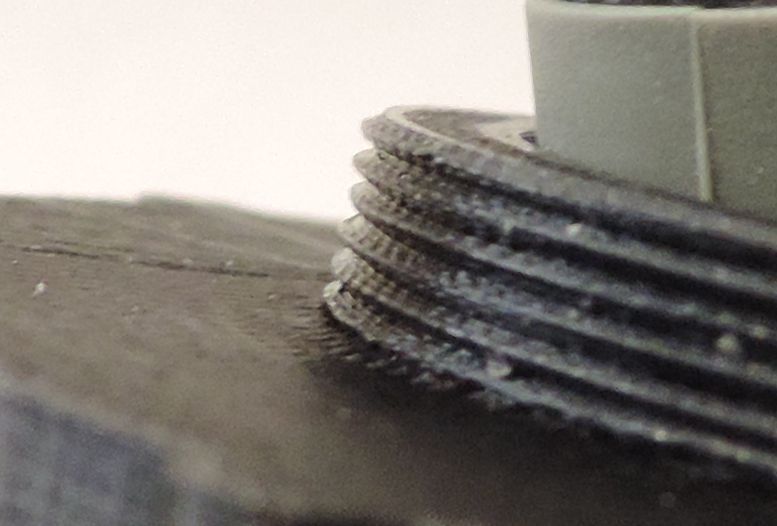

I'm now achieving consistent results printing quite fine threads for camera adaptors. I have a T-mount thread 0.7mm pitch) here that measures 41.95mm OD and spins as freely into a t-mount adaptor as a commercial metal thread.

For metric form threads this is what I am doing:

Create a cylinder at least 0.04 smaller than the core diameter.

Create an equilateral (i.e. 60 degree included angle) to represent the cross-section of the thread, side length about 1.5 times the pitch.

Position this so that its outside point (crest of the thread) is 0.02mm less than the nominal radius i.e. the thread is 0.04mm undersize.

Use the spin tool to convert the triangle to generate a clockwise spiral of the right pitch. Make sure you have the highest possible number of segments or choose 'smooth' if you can.

To create an internal thread, create an external thread as above then increase the diameter to 0.04 to 0.06mm oversize. Do not alter the pitch. Subtract this from the outside of a hole that is about 'tapping size' for the thread.

Layers of 0.1mm give me a good result with a 0.7mm pitch thread.

Notes:

Obviously the printer needs to be well set up in X and Y axes with no slop.

Print dead on diameter using an extra outer layer, then tidy up with a tap or die. This works really well with coarser threads such as M6.

If threads curl upwards (i.e. look flat on one side) try using thinner layers.

To make threads looser or tighter change the diameter in small steps, say 0.04mm, never change the pitch or the thread angle.

Rod Ashton.