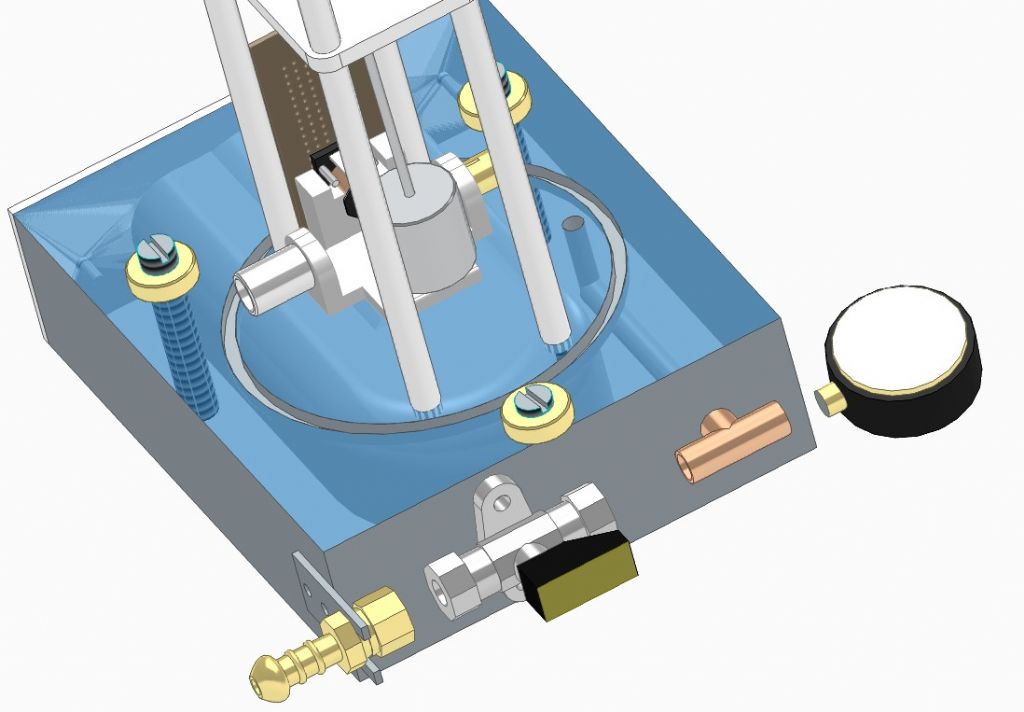

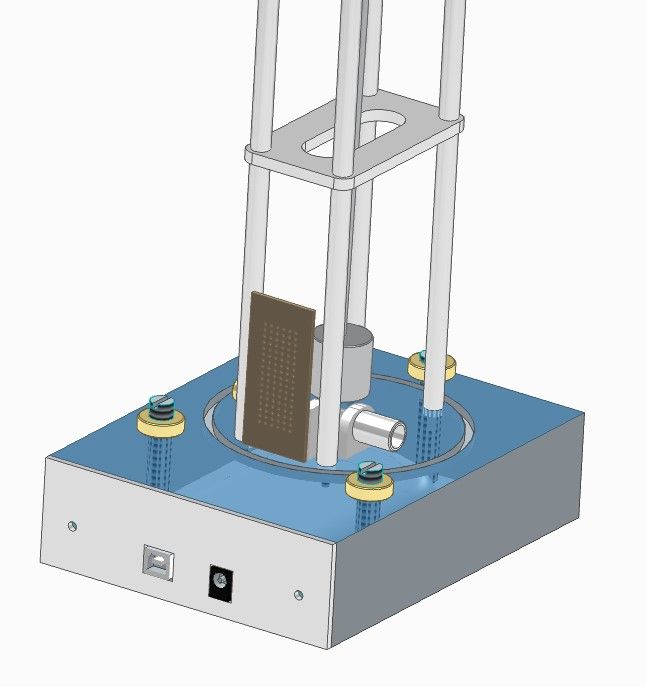

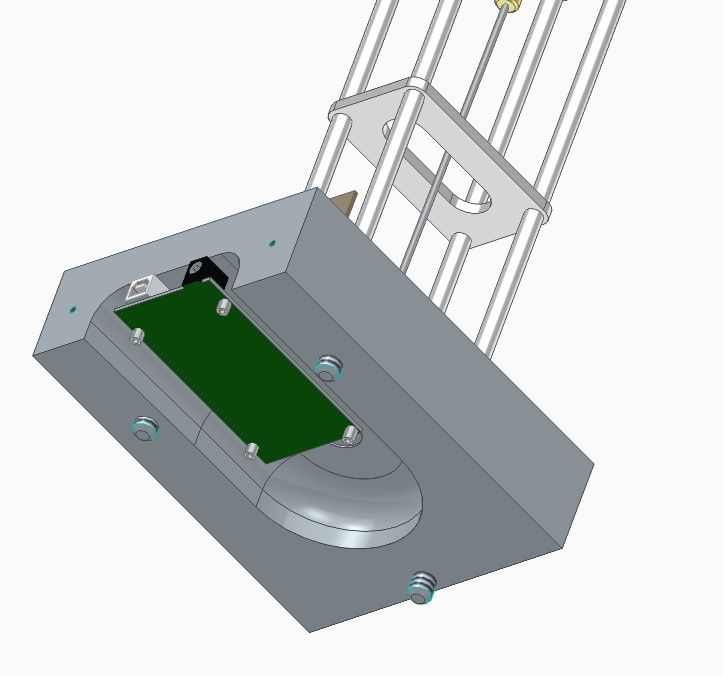

What I'm doing is a little more than a pipe run. I'm building a clock, where the pendulum swings in a vacuum. The clock base looks like this, scale, the block is140x240x48mm.

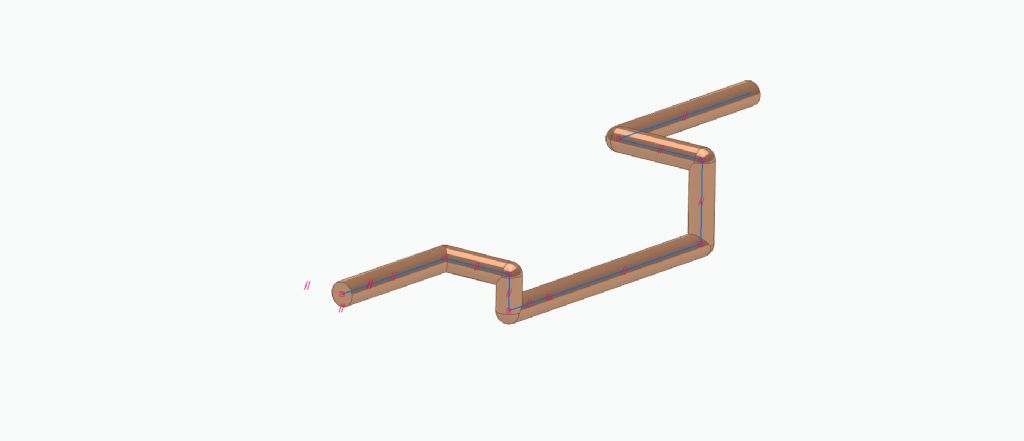

I have a vacuum pump which will connect to a bunch of 8mm plumbing attached to the block:

- Brass hose connector

- Open/Close valve

- 8mm T

- Vacuum gauge

- Screw fitting that penetrates through the block into the vacuum chamber

- 8mm copper pipe between above

- Fixings

Not much space inside the block, which also contains a microcontroller:

Needs planning, the hose and valve have to be firmly supported, the gauge visible, and the pipework routed into the vacuum chamber without getting in the way of anything else. Ideally the penetration point won't be too near the bob inside the clock because pumping out will disturb it.

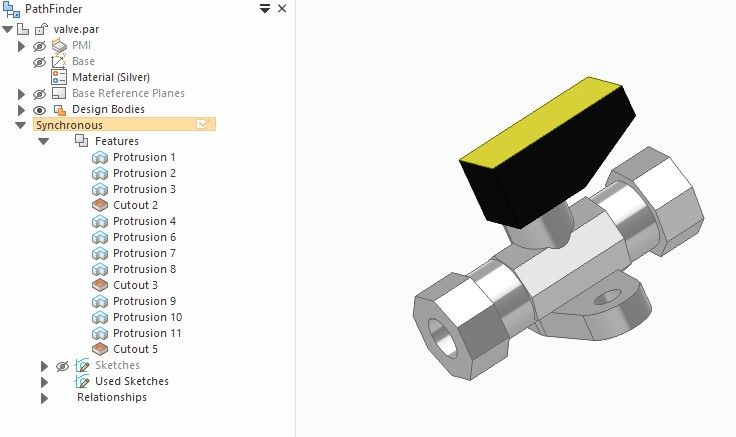

So I'm modelling the parts to see how they might be attached to the model clock assembly. I did the valve without bother, just has to be the right size and shape:

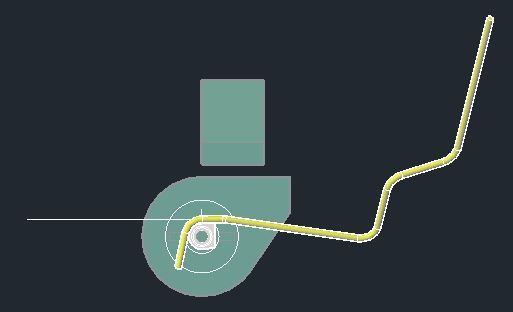

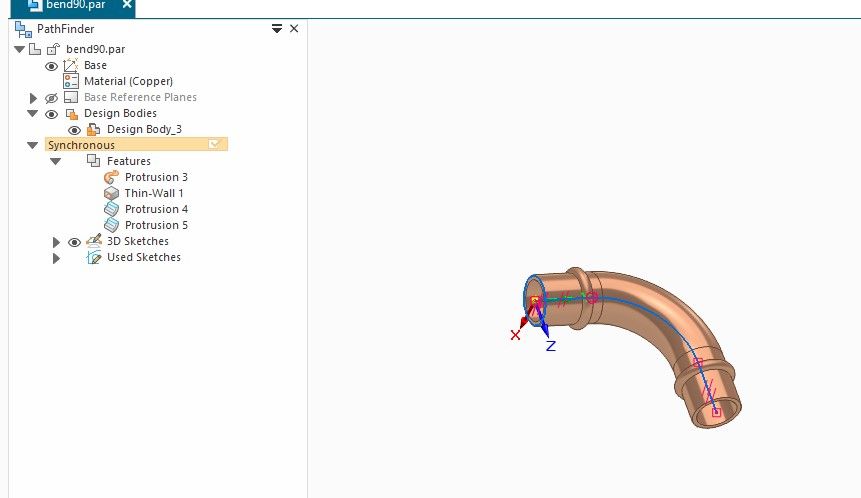

I may use up to three elbows, and it was modelling one that gave me grief yesterday:

The pipe is made by sweeping a circle along a line representing the elbow bend, and I'd forgotten how to change plane in the 3D sketcher. It's easy when you know how! The sweep creates a solid rod, which I hollow out with the 'Thin Wall' tool. This particular tool finishes with a right-click, which I'd forgotten, and also how to tell it to do a pipe open at both ends. It produces a closed tube by default.

Next I have to model the T coupler, hose fitting and gauge. Once they're available, the parts can be added to the clock assembly and interconnected with a pipe run created by the 3D sketcher.

The 8mm pipe can be modelled as a solid rod, but the other components need realistic 8mm holes because the pipe plugs into them.

I could work the plumbing out by positioning real parts around the real clock, but I've found CAD modelling is so close to real machining that it's worth modelling to be sure holes, pipes and whatnot won't accidentally interfere. For example, I can make holes and run pipes in the model with the model microcontroller fitted in the base, seeing instantly if any of them are bad news. Not a good idea to machine actual metal with delicate electronics or anything else attached!

Dave

JasonB.

JasonB.

piping comprising multiple spools with complex geometry to fit round various constraints like existing pipework and supports.

piping comprising multiple spools with complex geometry to fit round various constraints like existing pipework and supports.