Posted by duncan webster on 01/05/2022 00:37:47:

#2 son came round tonight. He is a bit of a CADS expert. Seems my cylinder model is all wrong, not constrained. Once I find out what that means (I have a fair idea!) I'll have another go.

I'm finding Solid Edge more sensitive to constraint problems than FreeCAD and Fusion. Partly because SE doesn't make missing constraints obvious, but mostly I suspect because the otherwise excellent Synchronous workflow doesn't encourage the user to apply them.

In 3D CAD, a constraint sets a dimension or coordinate to a fixed value, which helps the software by limiting the number of geometric solutions it has to calculate, and stops the user accidentally modifying bits of the model that should be anchored.

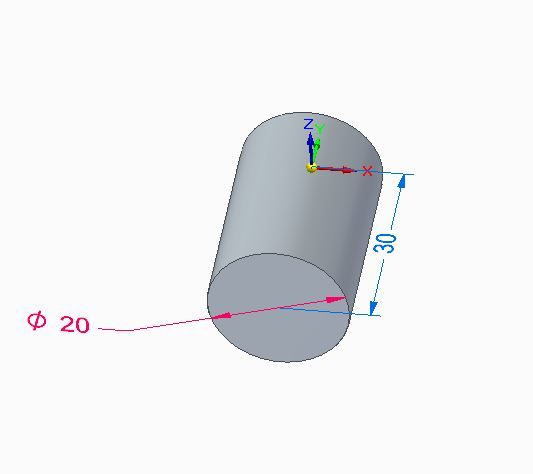

In this example, I've modelled a short rod, 20mm diameter, 30mm long. Solid Edge colour codes the dimensions:

- Blue means the dimension is unlocked, free to change, directly or indirectly. Really handy when a dimension changes automatically as the model takes shape, thoroughly confusing if it alters unexpectedly later as a side effect.

- Green means the dimension is being edited. In the example below, note the dialog box has a padlock button which can be used to lock or unlock the dimension. This is how dimensions are constrained.

- Locked dimensions cannot be moved accidentally. Solid Edge shows them in Red.

Next image shows the diameter of my rod model is constrained (20 in Red) but the length is not (30 in Blue). The model isn't fully constrained because I can alter the rod's length and also because it can move about – the rod is free to move in any direction. Again this is handy when the model is taking shape, but bad if it happens by accident.

Generally it's a good idea to lock and constrain as soon as that part of the design is confirmed. Don't go mad by prematurely locking too much though! Although constraining makes one sort of problem go away, it creates others to confuse beginners! If out of the blue an apparently straightforward operation behaves oddly, or won't work at all, it may be because an earlier constraint is non-obviously blocking it. Finding these in a big model can be tedious.

Learning FreeCAD taught me the importance of getting constraints 'just so'. At the Learner Driver stage, one is likely to create models that look OK but are internally flawed or hideously complicated. Caused by pressing buttons until something seems to work, which is liable to stack up weird or inconsistent geometries. Setting constraints tends to highlight mistakes and reduce nonsense structures. As a beginner I repeatedly crashed FreeCAD, Fusion360 and Solid Edge. Now I sort of know what I'm doing, I rarely crash any of them.

Reckon I've spent nearly 20 hours learning Solid Edge so far. As General Orde Wingate told the Chindits on their way to operate in the jungle deep behind Japanese lines: the first 30 days of a long march are the worst.

Dave

David Jupp.