I thought I'd start a separate thread specific to modifications to my SainSmart 3018 Prover V2. I welcome comments, but I wish I could reserve multiple first messages and edit them retrospectively so I can keep a post per upgrade and edit as I do it/learn from the experience to keep it all in one place. never mind!

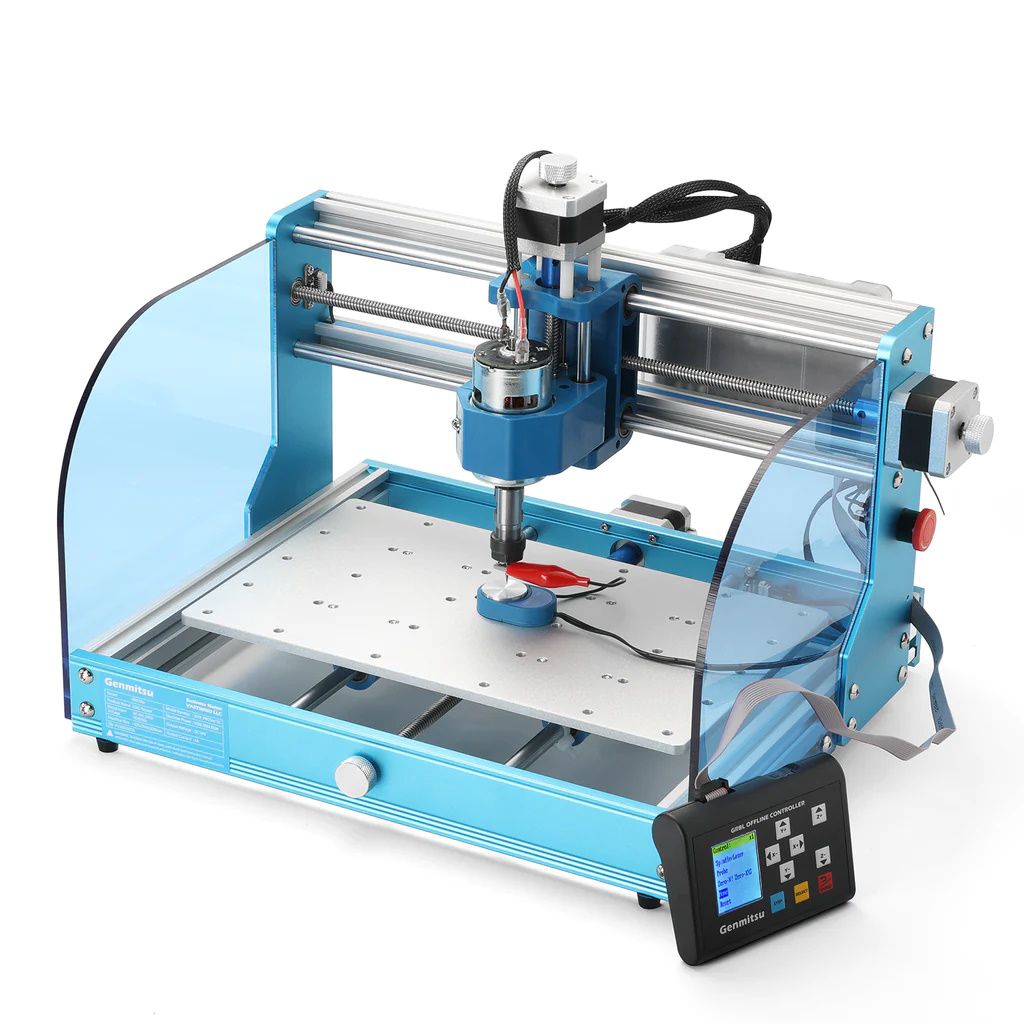

Anyway, my machine is a prebuilt 3018 style CNC router. You just have to bolt the gantry and connect up a few wires – all the hard work is done for you.

Upgrades Proposed:

- A 3d touch probe

- The X axis gantry bearings

- The spindle motor

- The Z axis (the whole assembly)

- A laser cutter/engraver with air assist

- Possibly moving the Y bearings and rails

1) A 3d touch probe so I can physically scan objects and/or engrave/laser/mill curved surfaces and zero stock/centre find etc. Using the machine as a scanner was the primary reason for buying it.

2) The X axis gantry runs on two round bars, and it flexes a lot, it might be ok for engraving and light or steady cnc routing but the rest of machine frame is really quite solid, it can be significantly improved with a minor tweak and about £60. This invloves fitting a pair of MGN type rails directly to the existing 2020 vee channel seen behind the existing round bars – the round bars and bearings go in the parts bin. A new saddle will be designed and 3D printed, and if/when more serious work takes place, something more metallic might emerge from scraps.

3) Stock motor details are few and far between but I think its rated about about 10k, 1.5A 12v…. I'm not sure how these numbers add up but it runs at 24v 10krpm apparently, independent tests online confirm it hits about 9krmp @ 1.6A 24v no load. There are multiple "upgrades" on the manufacturers website and I happen to have a European made 20k motor that exactly matches the specification of the Chinese 20k spindle upgrade they advertise but mine has a far superior brush assembly, shorter body but higher weight, its a direct fitment.

I've tested it already and it's got significantly more welly at the same output but appears to be turning at roughly the same speed, someone has borrowed my RPM meter and I'm not sure how these PWM speed controllers really work, so its up in the air a bit. The spindle was set to the same rpm and I just assumed fitting a motor with twice the rpm would result in, double the RPM…. as I said, I'm not sure if that's how DC PWM speed control works.

4) The Z axis ….is plastic but seems solid enough, however it only has very limited travel and I can see that being more of an inconvenience than anything, the first thing I wanted to test engrave (a piece of 11mm board) couldn't be reached, I had to stack a couple and redo the clamps. The saddle that carries the Z assembly and rides on the X rails, will be no use when I change the X bearings and their layout. I will 3D print a new one and mount the spindle as close to the new X rails as physically possible, I noticed quite a distance between spindle centre and X axis centre which increases leverage and promotes twisting in the X bearings, any reduction here will further improve rigidity. I will also widen the bearing spacing, reducing my X travel, but increasing rigidity especially if/when milling!.

5)Laser…. I've always wanted one…… the PCB has 2 headers for a laser and air assist and the manufacturer does their own 5.5w concentrated spot laser with a fixed focal length (I guess that's 5.5w input power not output but I don't know, the header supports upto 2 amp)

6) Possibly moving the Y bearings and maybe even rails back to the positioning on previous version of this machine, it has less travel, but should be more stable for light milling work, I was unhappy with the saddle as it was narrower, and then I noticed the bearings and rails under the bed were quite narrow too, and then I spotted the specification change, increasing travel on all axes, I double checked a few frame dimensions and it's the same, so they must've narrowed the bearings. The controller on the V2 is a significant upgrade, featuring headers for the lasers, better drivers IIRC, a better 32bit arm GRBL controller vs the previous (presumably arduino) 8bit GRBL controller and limit switches preinstalled on all axes + 2 spare….. now 1 spare…. whoops, I don't know my own strength…

No time scale for the above. I bought the machine purely to digitise some parts that are practically impossible to measure and/or have bizare contours and stuff, I need accurate 3D models to realise another dream, to run CFD on heat transfer and fluid flow though various parts. I will probably use the machine to make balsa dummies for test fitting, if it can one day actually machine soft aluminium, I will give it a shot but I suspect I'll be paying someone else to machine the finished parts properly, as the softness of the alloy makes it quite tricky to machine without damaging.

Edited By Russ B on 02/04/2023 21:28:51

Edited By Russ B on 02/04/2023 21:35:31

Andy_G.

Andy_G.