Posted by Bob on 15/06/2023 23:15:32:

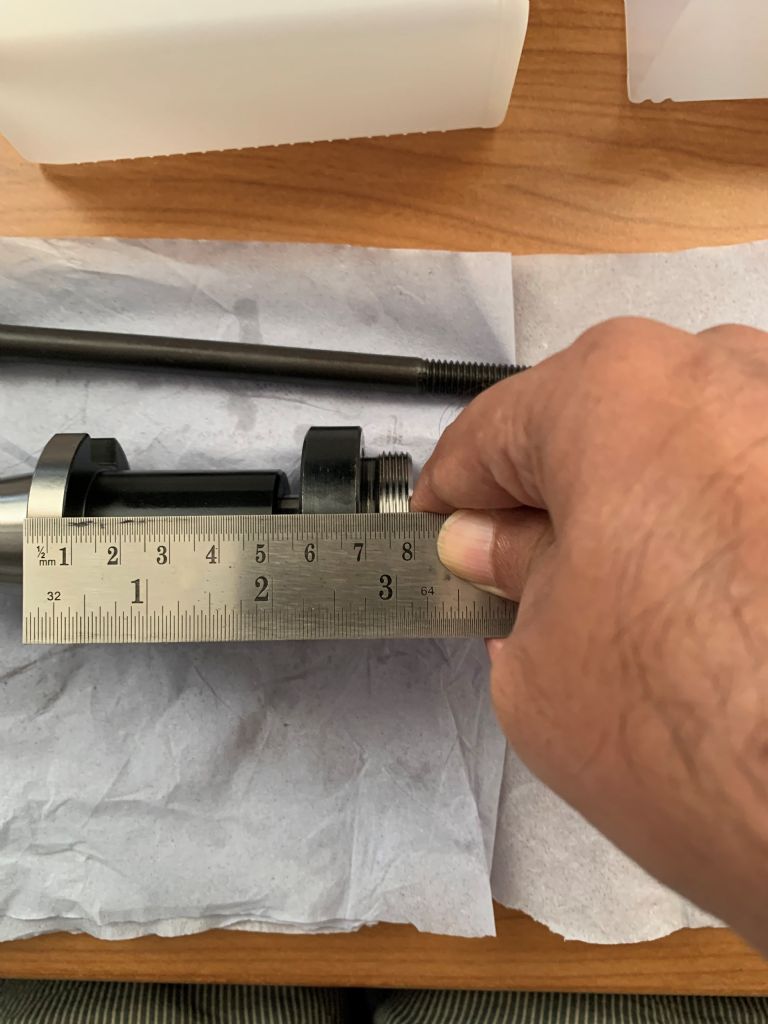

I have an adaptor but the flats that engage with the tang of the Morse taper interfer with the drawbar. I want an adaptor that is clear bored to allow 3/8 BSW draw bar to pass through and engage with the threads in the end of the Morse No. 2 boring head

Bob

Hi Bob,

I am a little confused.

A. First sentence suggests tang on Morse taper interference with drawbar. Do you mean tang of MT tooling interfering with drawbar which holds INT30 in place on your machine?

B. Your second sentence suggests needing an INT30 with through hole to enable use of 3/8” drawbar to pass through the INT30 adaptor to engage onto MT2 tooling which has 3/8”whit. female thread.

Notes:

1. All the INT30 to MT2 adaptors sold by ARC have an M12 thread to hold INT30 in place.

2. All/most MT2 tooling have 3/8” or M10 drawbar thread. The INT30 adaptor has an M12 thread. So, to the best of my knowledge (which is a little rusty):

a. As long as you have a through hole in your mill head, you can make a 3/8” drawbar/studding long enough to engage directly through the adaptor into MT2 -3/8” female tooling. Similarly, you can make and use 10mm drawbar/studding long enough to engage directly through the adaptor into MT2 – 10mm female tread tooling.

b. Some machines have a captive drawbar in the mill head, to hold INT30 tooling in place. In such cases, one needs to find out and be aware of what is the thread of the existing drawbar in the machine, and how easy/difficult it is to access or change, and do you really want to. INT30 tooling do come in different female thread configurations. This is when things become interesting, and certain changes in drawbar may need to be considered.

As it stands, I would suggest reviewing the drawbar arrangement on your mill for the existing INT30 tooling, and adaptor you have in hand, before considering a new purchase.

If I am wrong in my thinking or have misunderstood something, please accept my apologies as its been a while since I looked at this product, and I am semi-retired, leaving the younger generation headed by Ian Davidson to run daily business.

Ketan at ARC

Further note..: Chronos link suggestion made by Jason is good… especially when using new boring heads to screw directly onto INT30 arbors. However, to unscrew existing boring heads off existing MT2 arbors can be difficult, as they can friction weld (for want to phrase) over time… especially if they have been involved with interrupted cuts over a certain period of use.

Michael Gilligan.

Michael Gilligan.