Morning all

Jeff, thanks.

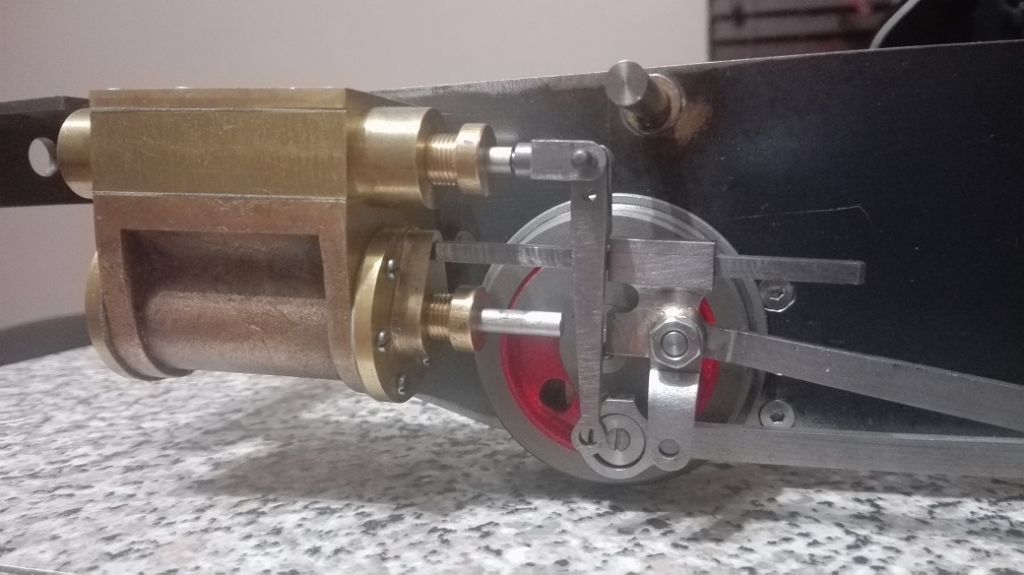

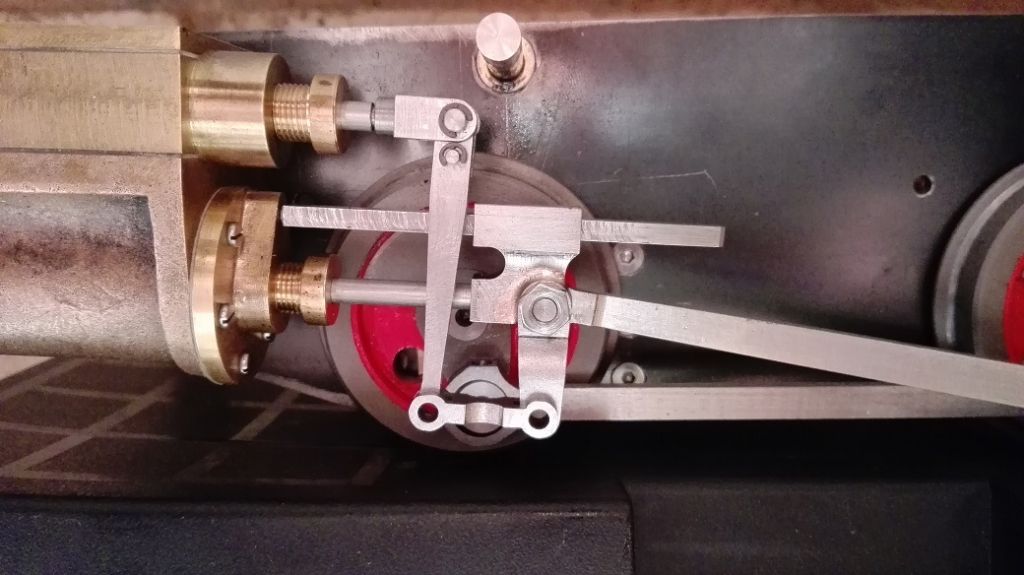

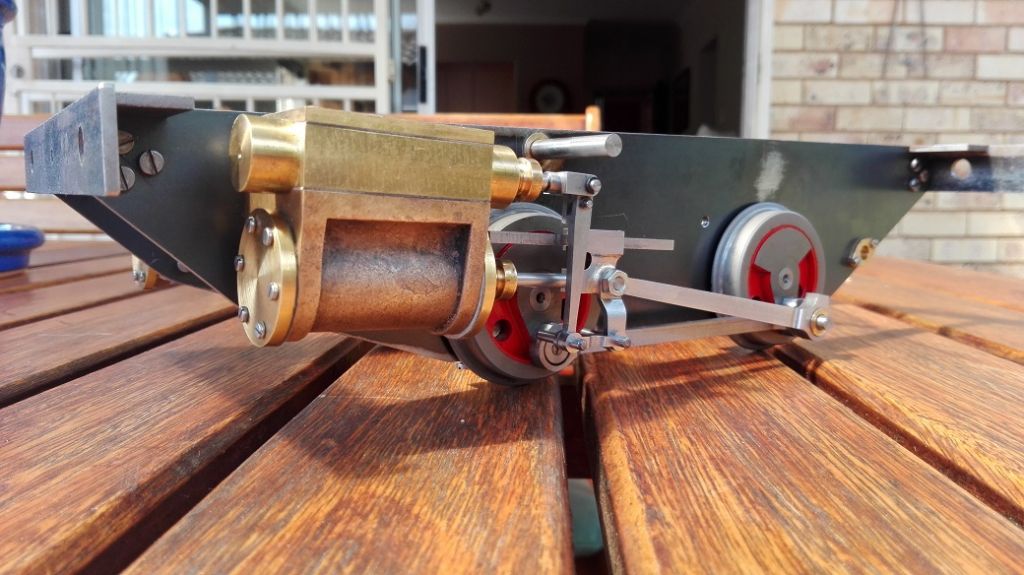

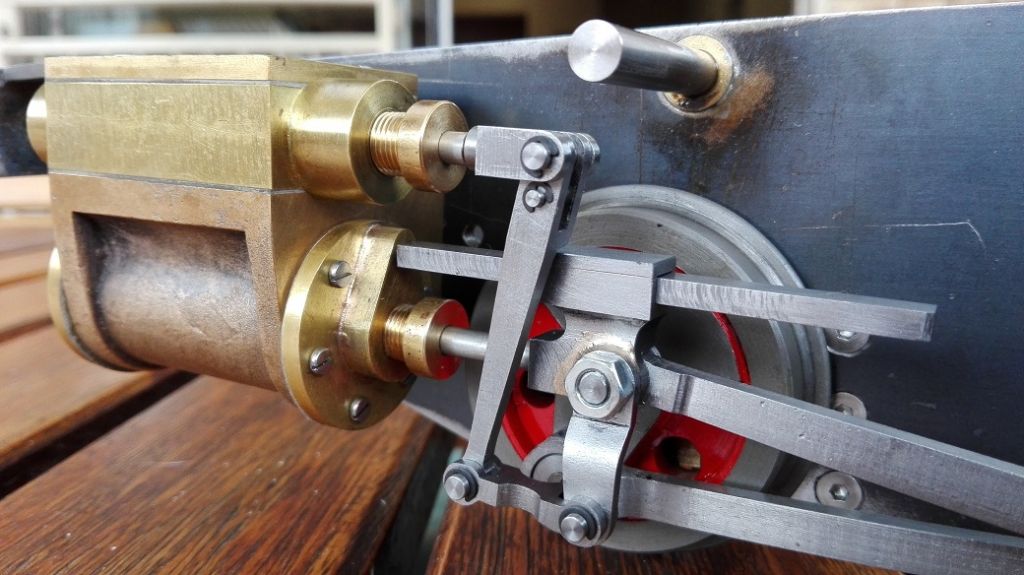

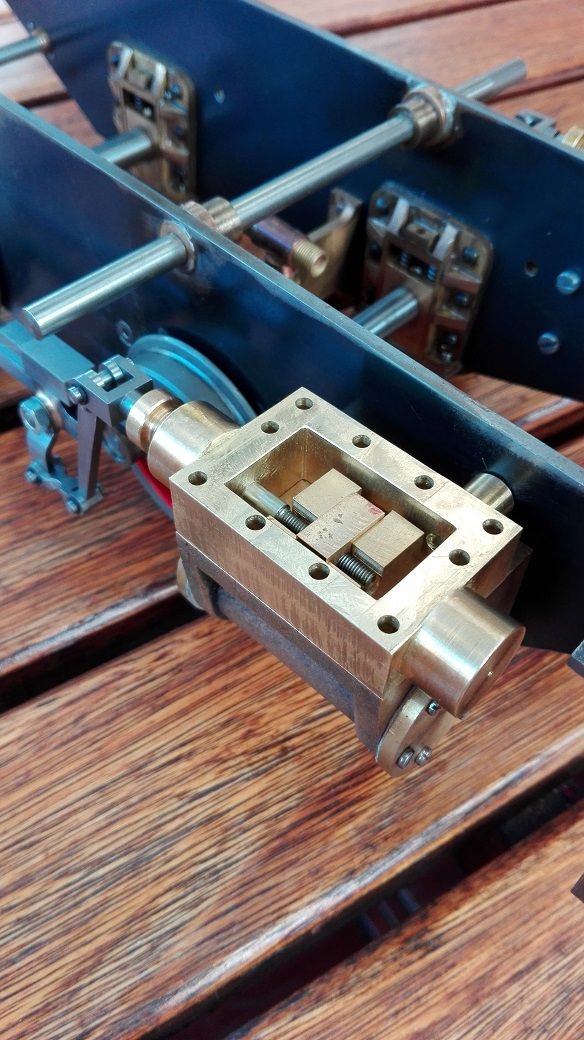

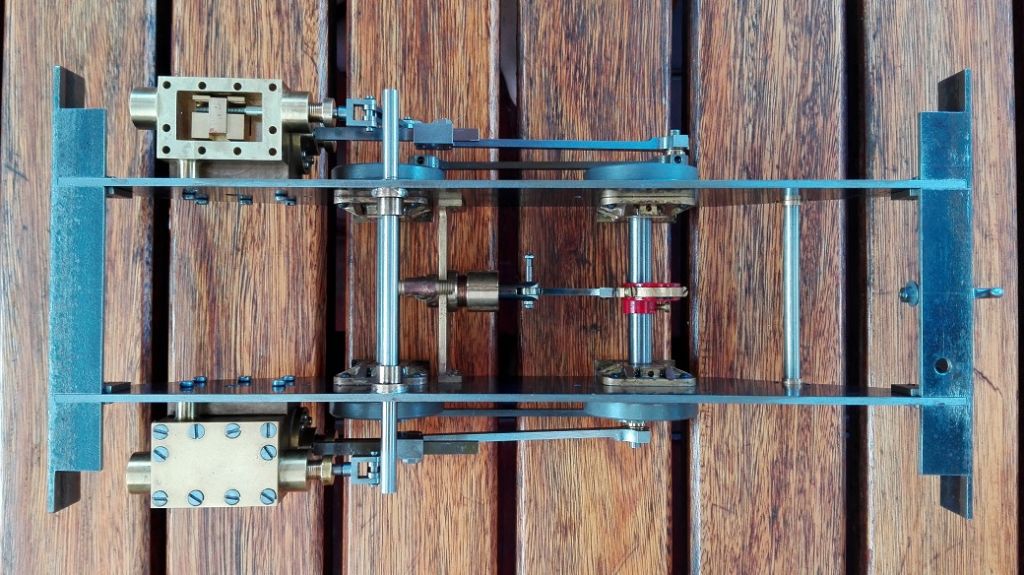

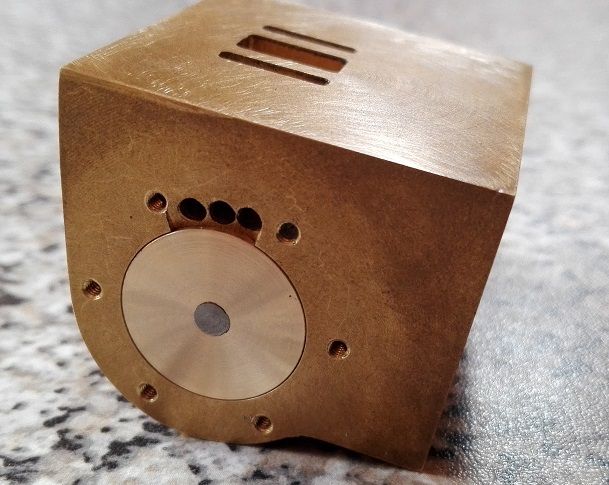

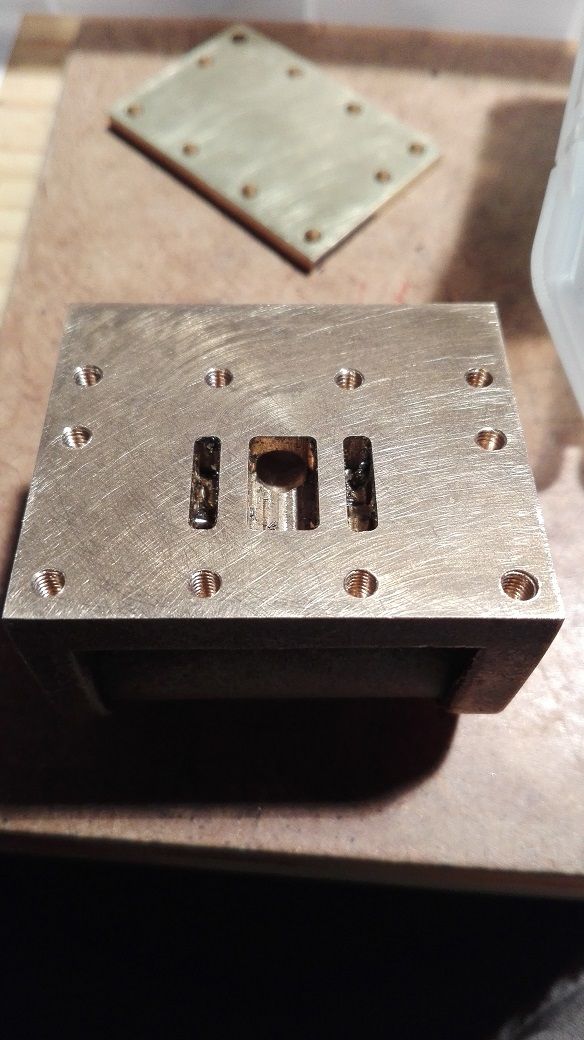

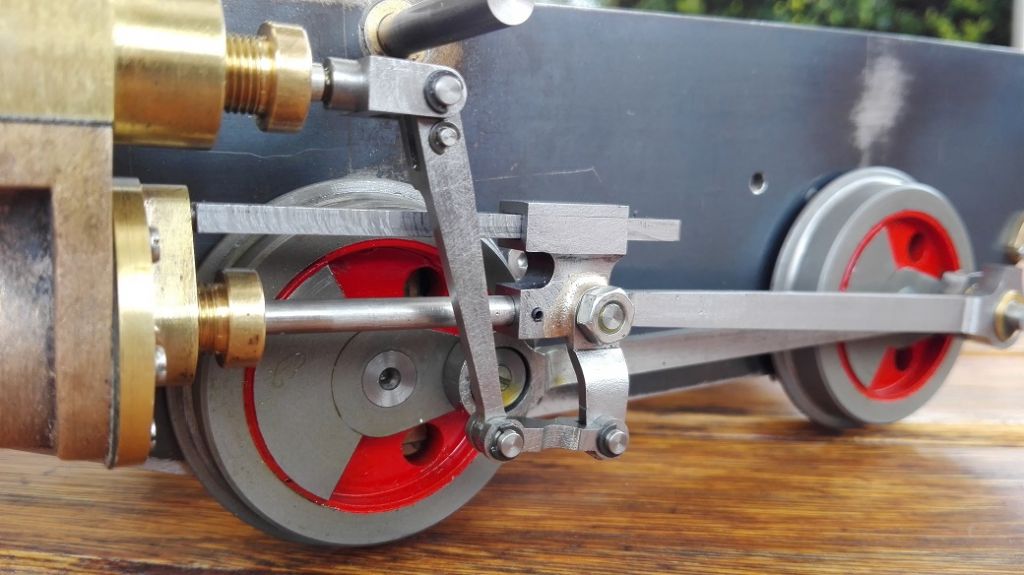

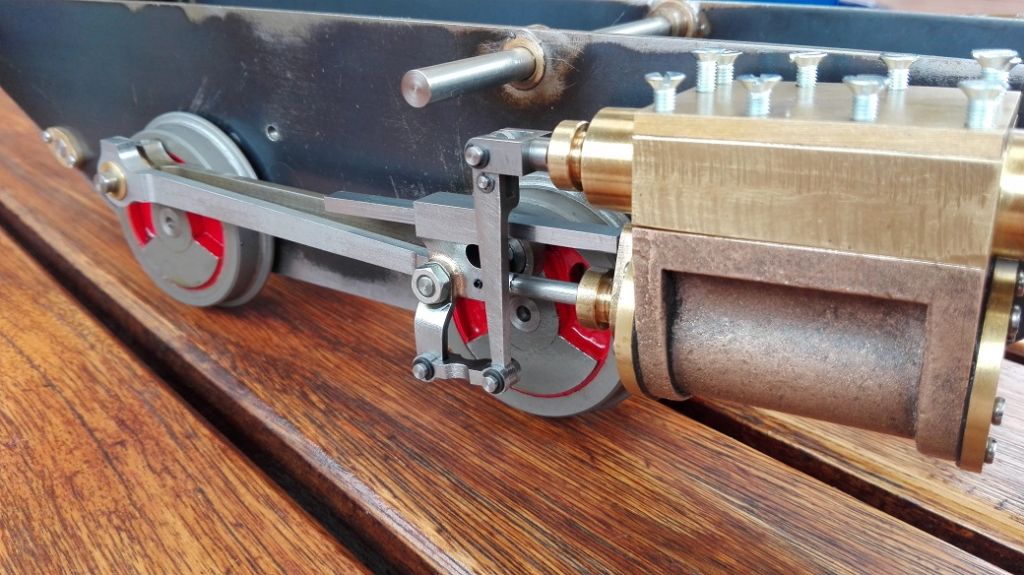

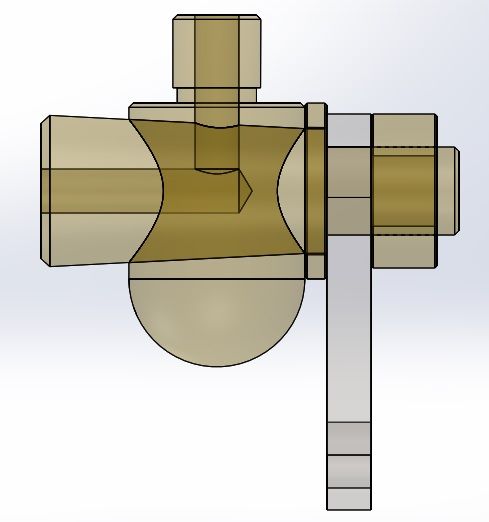

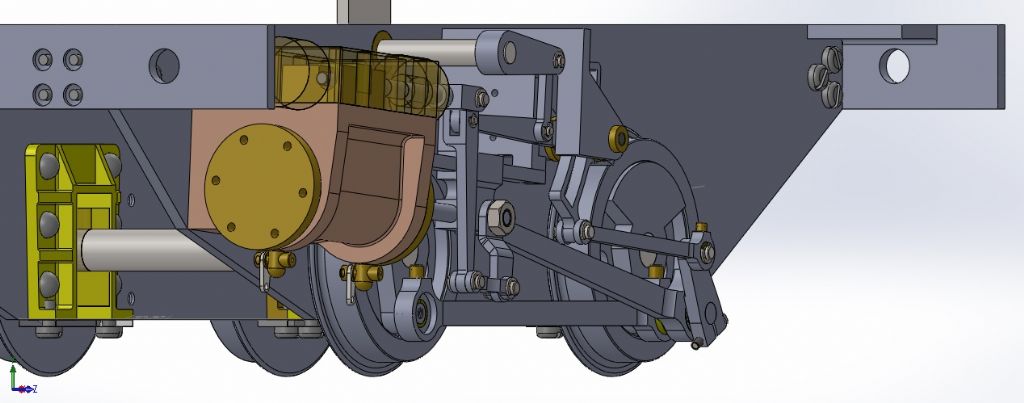

I have been busy with a few small odd jobs recently on Tich. Finally I have done the RHS steam chest. All that is required is for me to complete the steam chest cover and drill the holes into the cylinder blocks, then both sides will be at the same stage.

I also mentioned a while ago that I was not very happy with the current suspension springs that I had previously made, so with a couple of very difficult calculations and a bit of guess work,  I have made some new springs.

I have made some new springs.

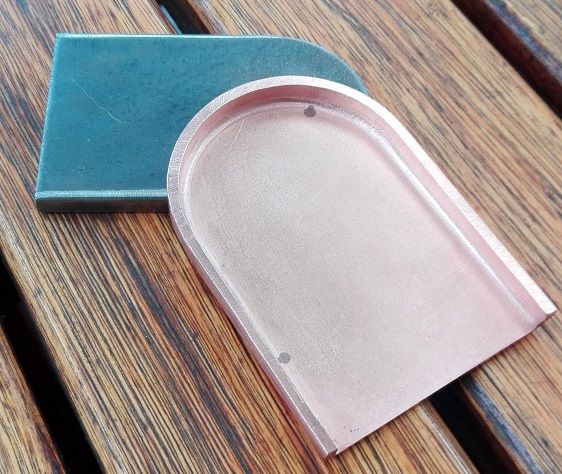

The method I had used previously was not as clean and repeatable as I would have liked and so I made some changes.

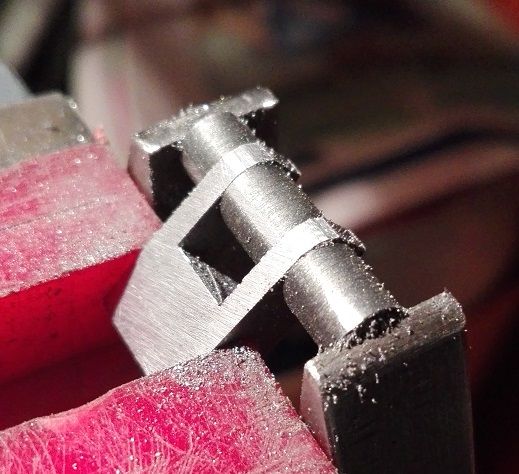

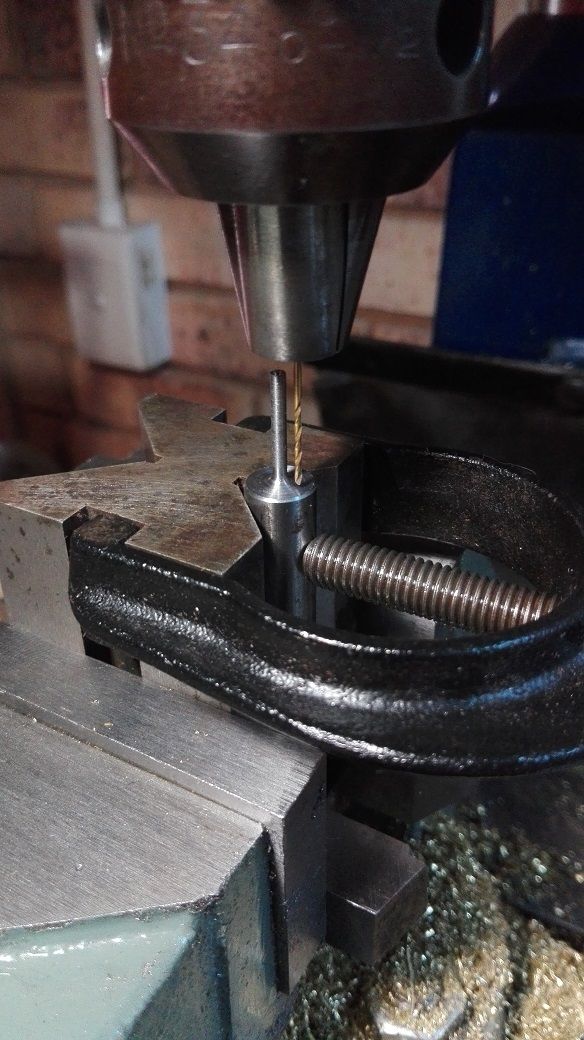

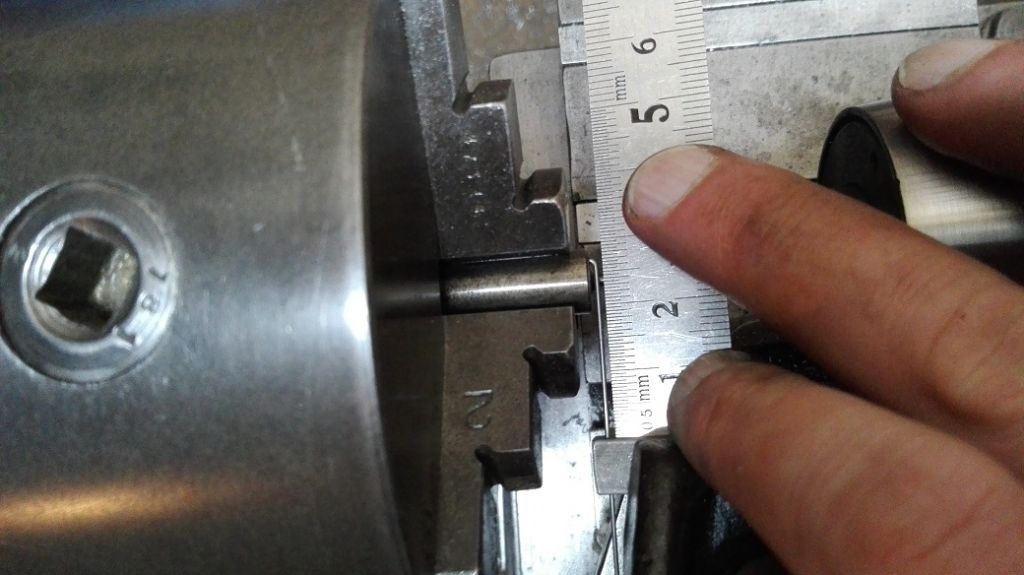

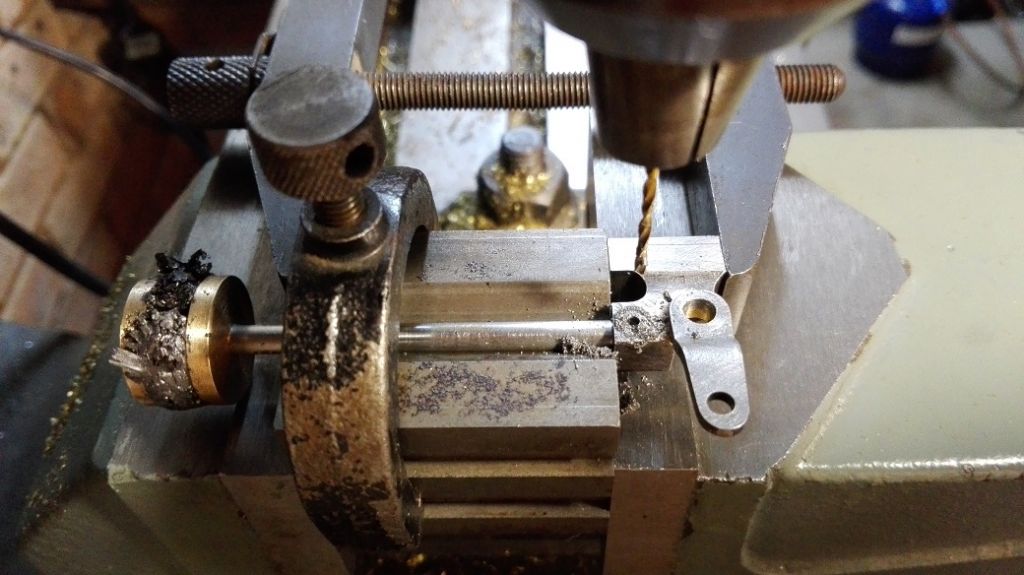

Firstly I made a 2 mm mandrel from 10 mm silver steel onto which the wire would be wound. A 1 mm hole was drilled into the 10 mm rod, parallel with the thin part of the mandrel.

This hole would allow for the wire to be kept in place when winding and would also allow for the finished spring to be slid off once finished.

The wire had a small 90 degree bend in it to go in the hole.

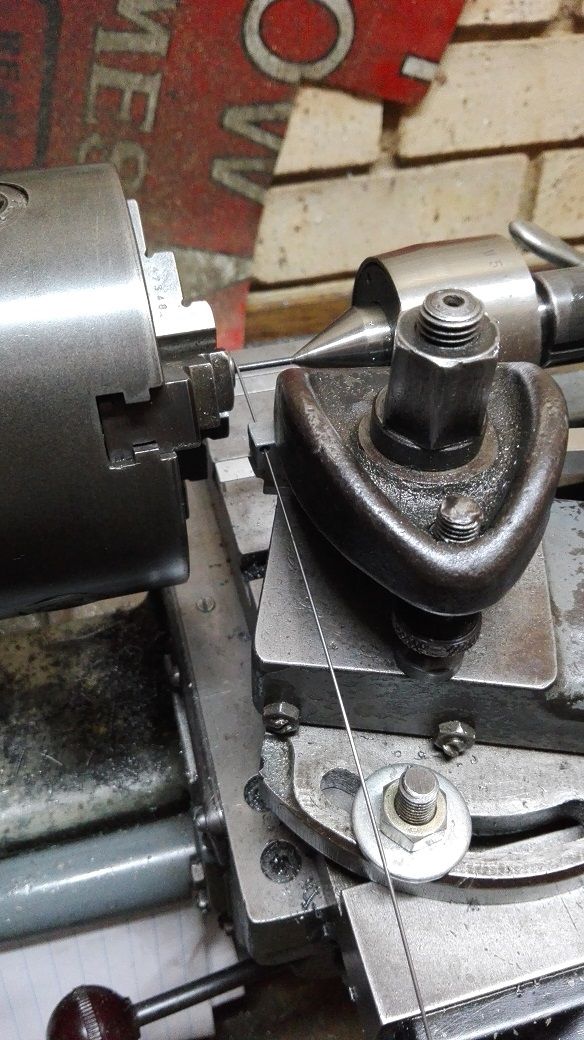

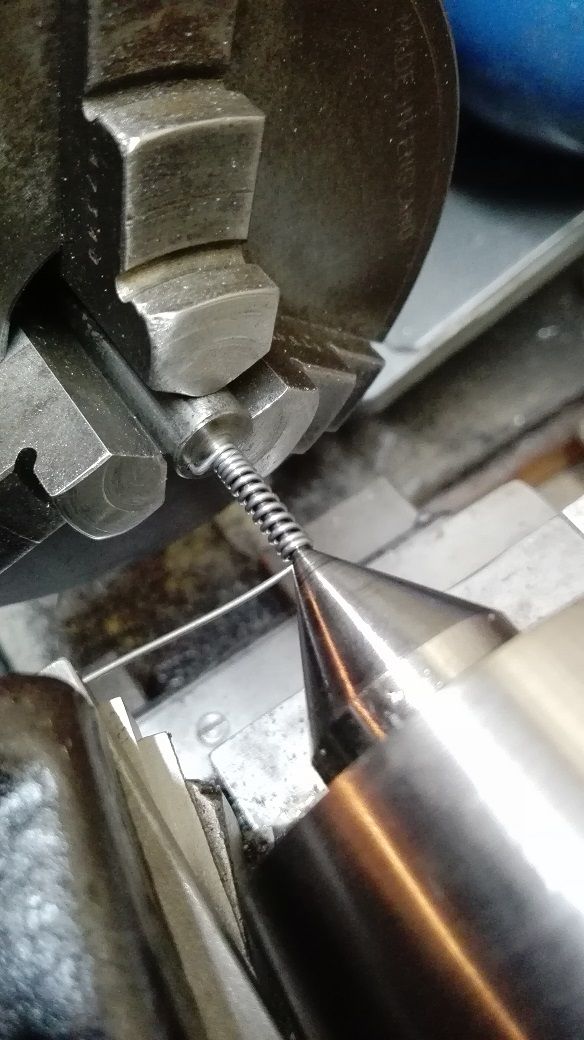

The setup is pretty standard for spring winding as far as I know. In order for the process to be repeatable I noted the settings of the top slide, cross slide and lead screw dials as well as the orientation of the chuck jaws in relation to the starting point. The screw cutting gear train for 18 TPI was set up and 0.8 mm music wire was used.

The silver steel mandrel was hardened and tempered as per standard practice for silver steel and the end was drilled for a running center to support the end.

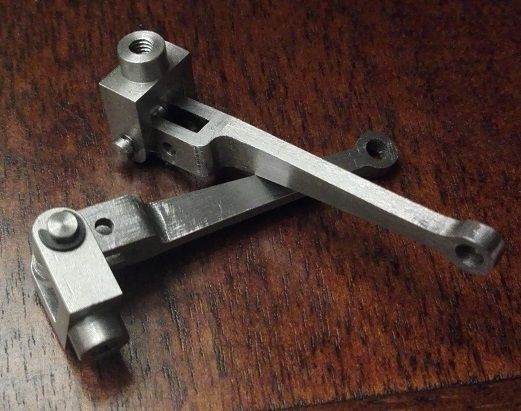

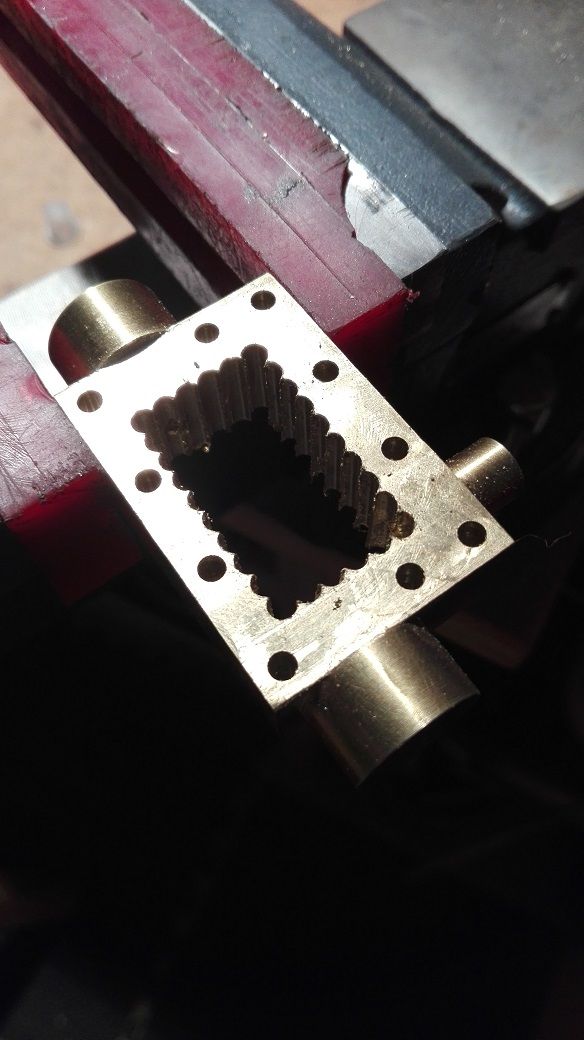

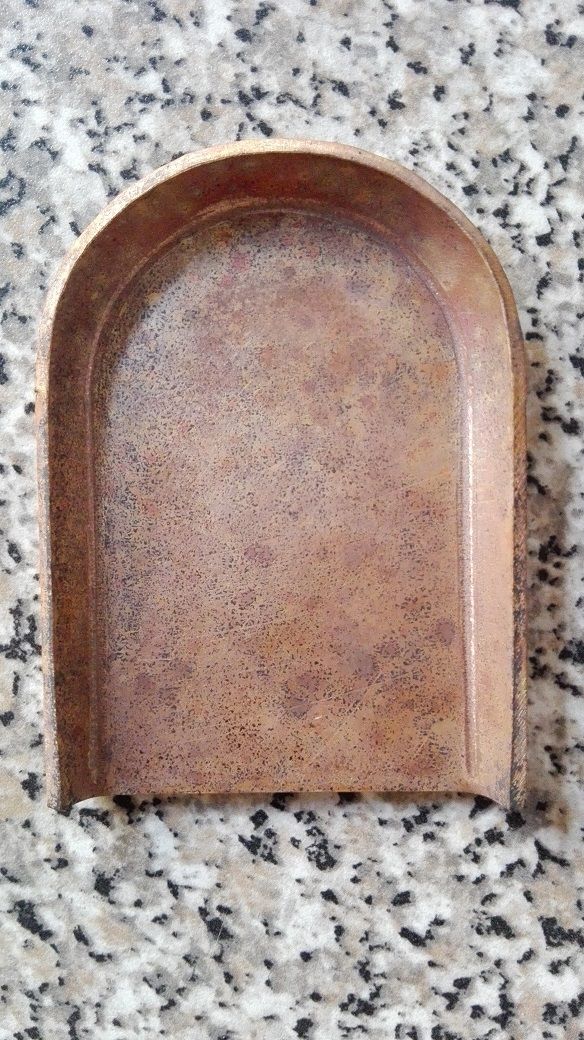

Once the springs were wound, they were ground to size with a couple of the redundant starting coils removed as well.

I then placed the completed springs into the oven at 180 degrees Celsius for 30 minutes to remove any internal stresses caused by the bending process.

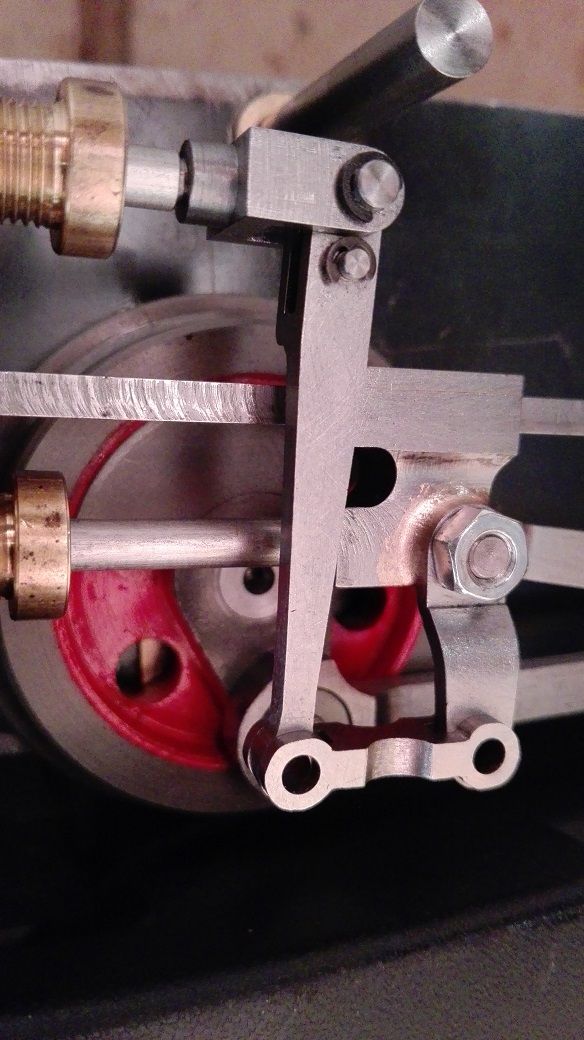

Finally here is a look at the new springs versus one of my original springs which is clearly not correct for the job.

Phil H1.

. I have taken some screen shots to show you. It seems that I have the same problem…

. I have taken some screen shots to show you. It seems that I have the same problem…