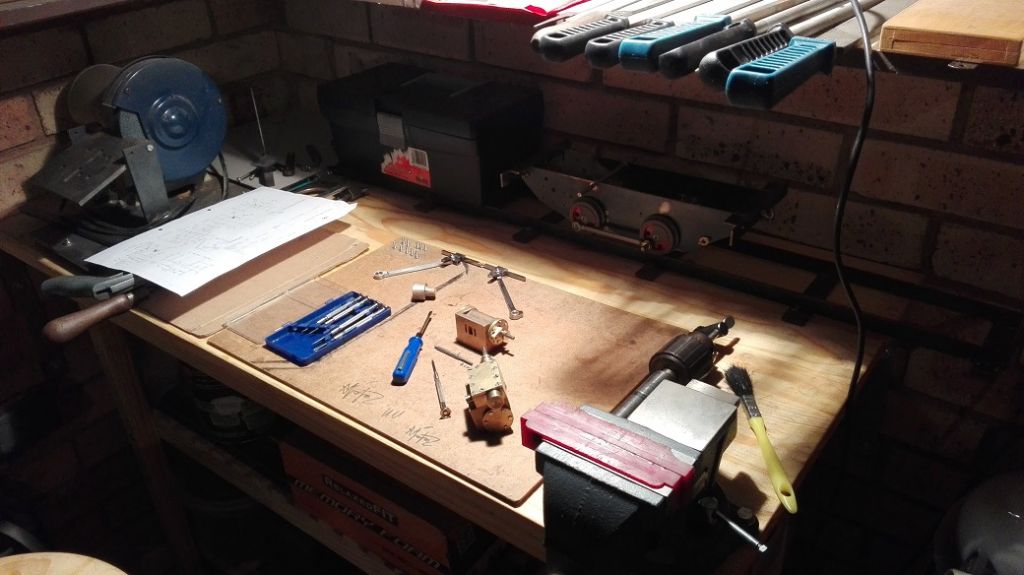

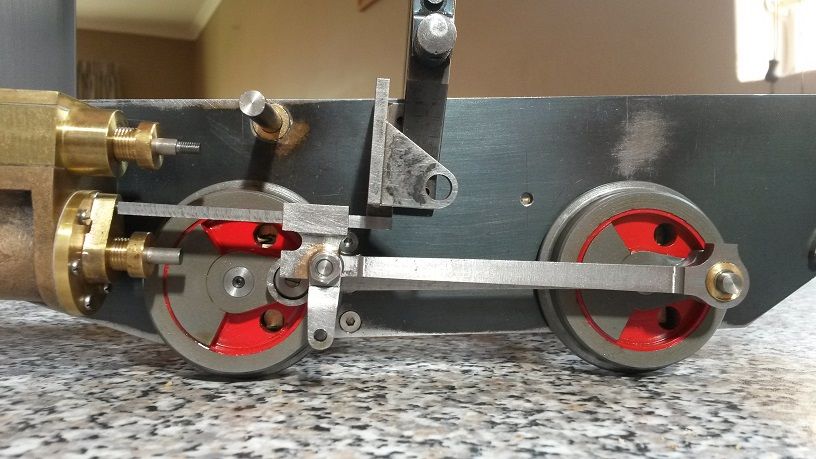

I have set aside the gear link frames for now, to work on something new to keep the interest flowing.

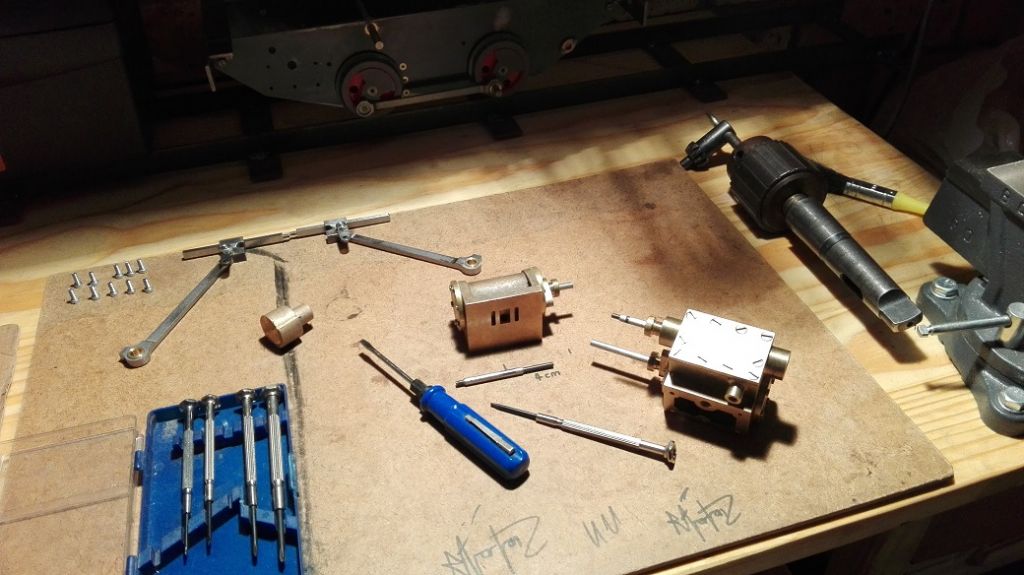

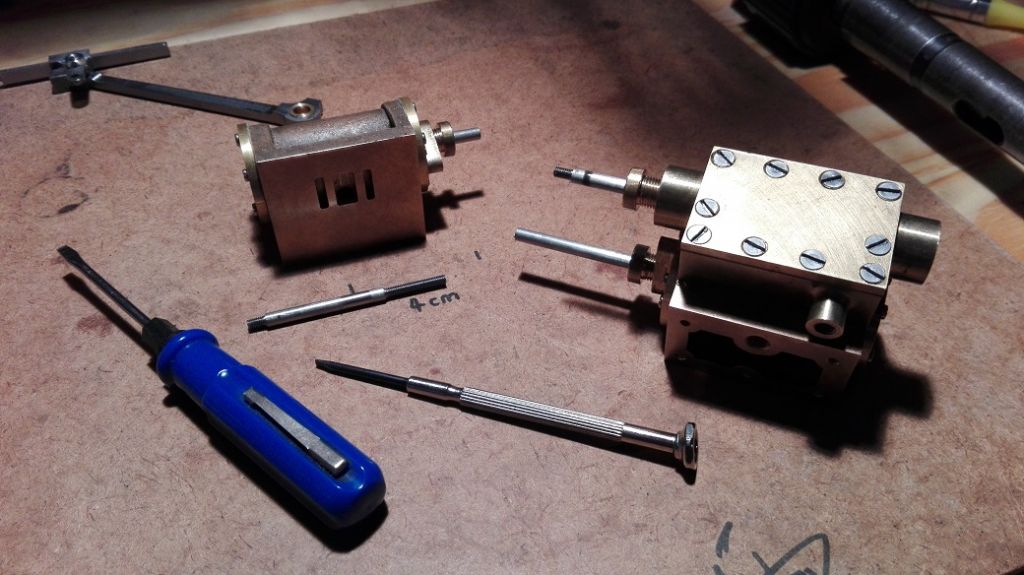

I have started on the combination levers.

The levers are going to be machined from one piece, together and then split into separate levers and the final profiles then filed.

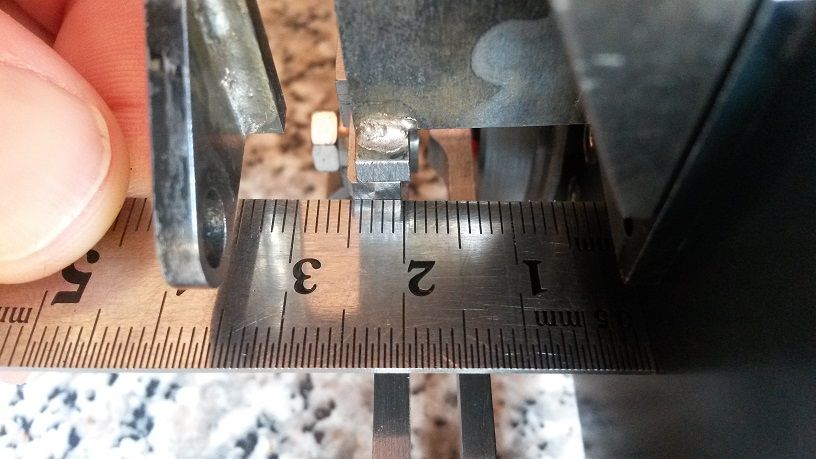

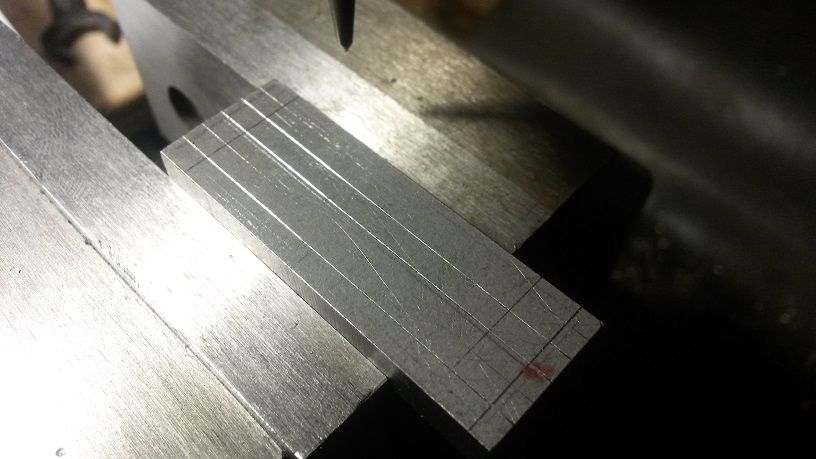

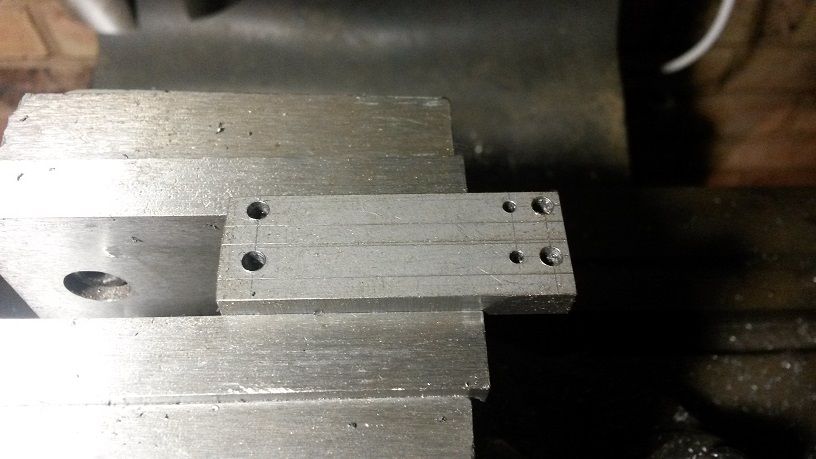

I first marked off the relevant sizes and hole positions with a scriber in the collet chuck.

The 2 and 3mm holes were then drilled and reamed.

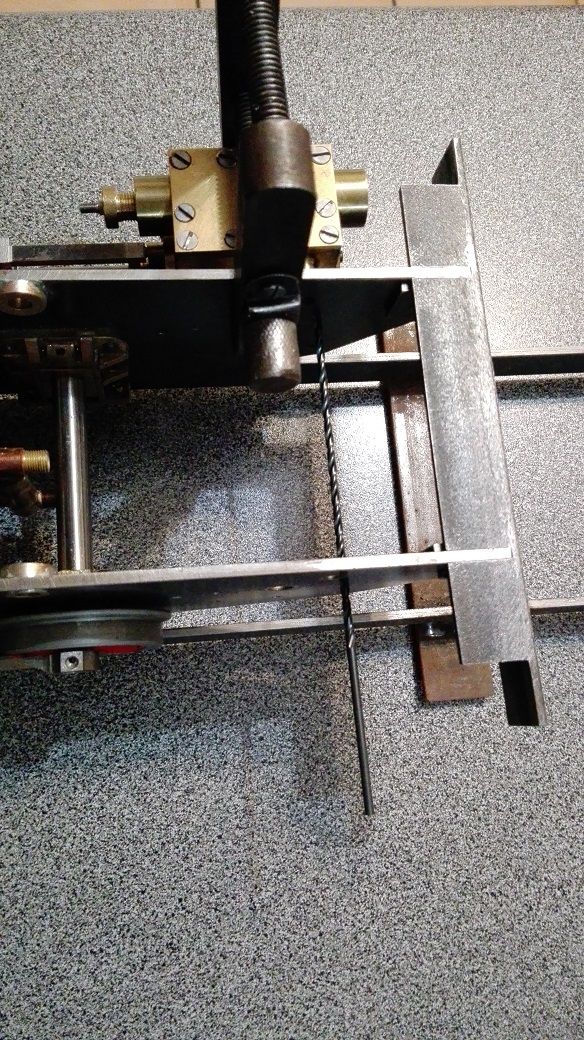

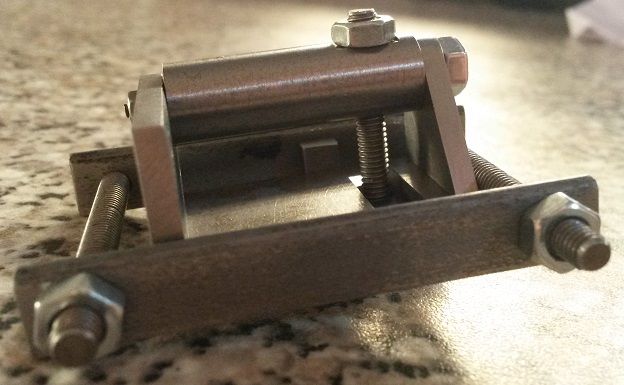

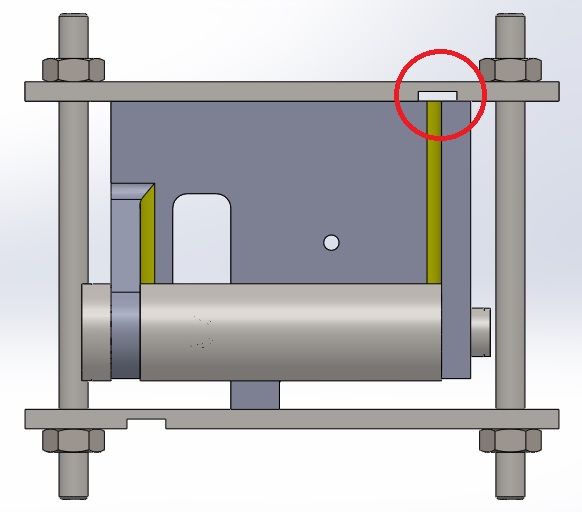

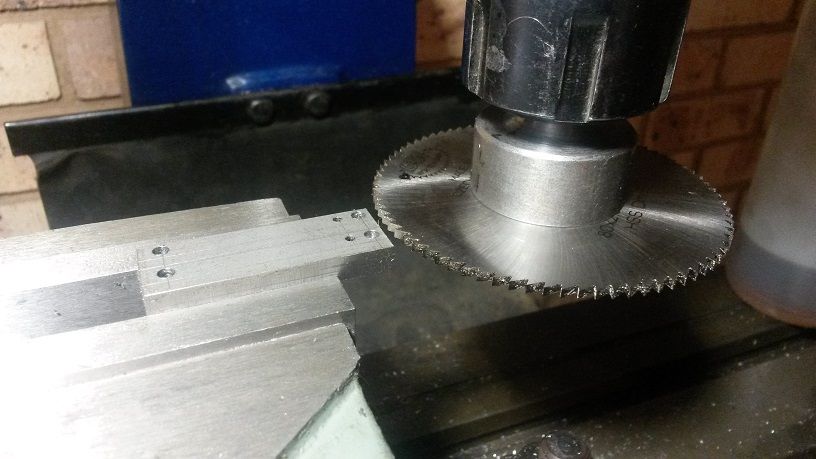

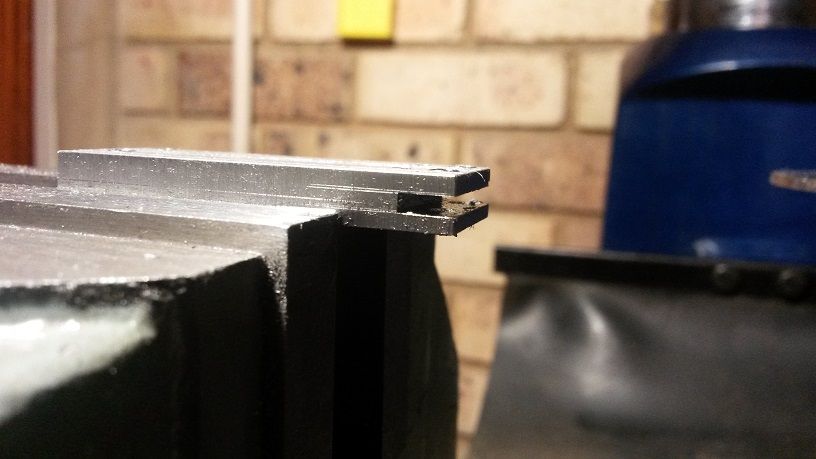

A slit was then cut using a slitting saw.

The saw was used at the lowest speed on the mill (80 rpm), with a cutting fluid of paraffin and oil, judiciously applied. The embryo lever was fed onto the saw in the direction of the rotation (climb milling) carefully.

The slit was cut to 6 mm deep on the first cut and then to the final depth of 11 mm on the second cut.

Cutting the slot took about 2 hours but the result is perfect.

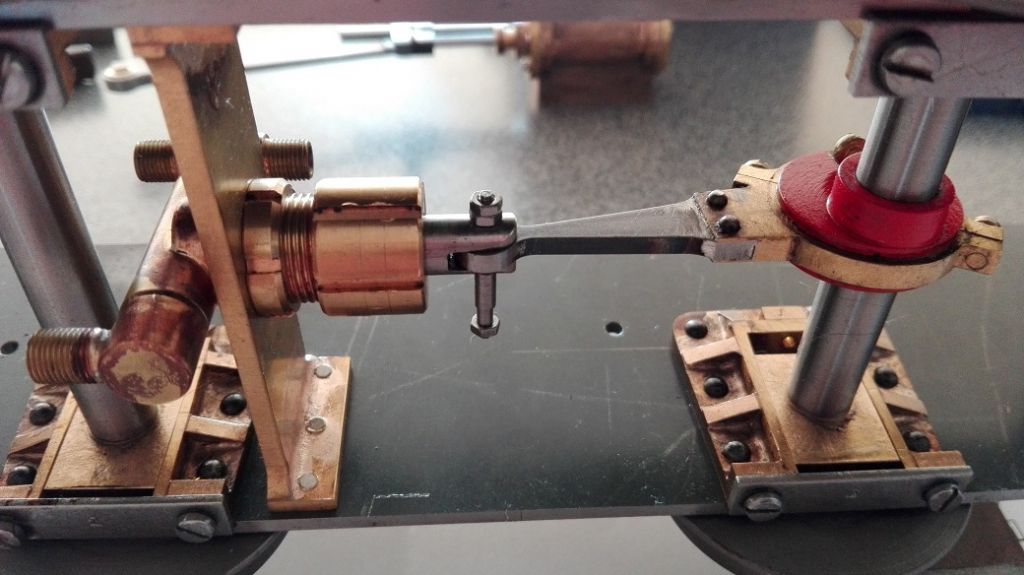

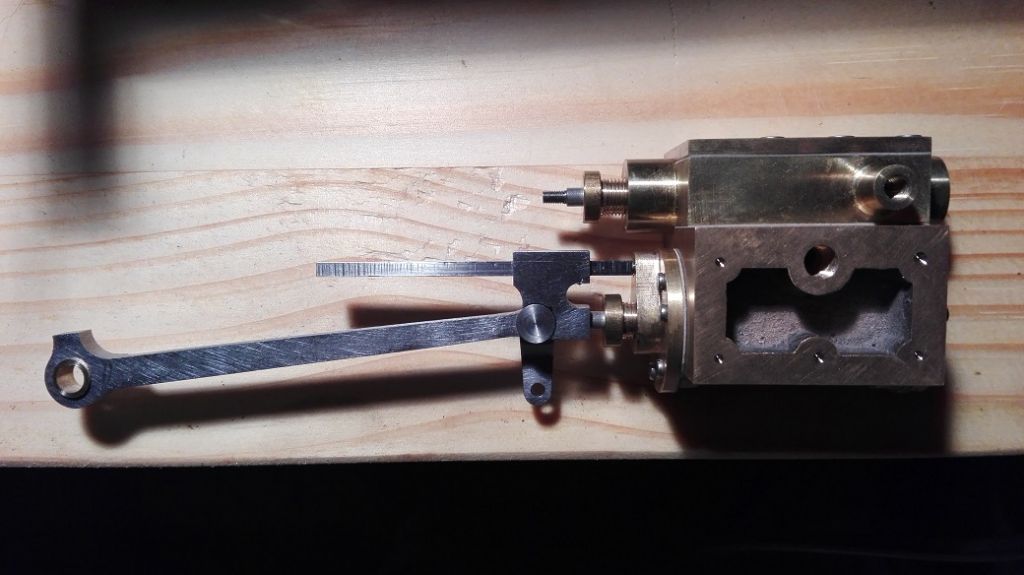

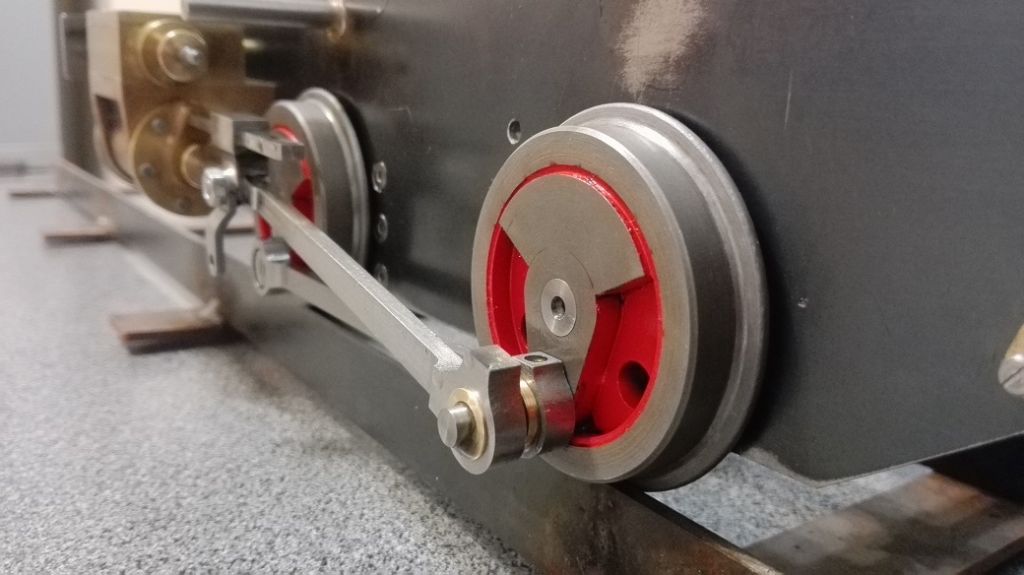

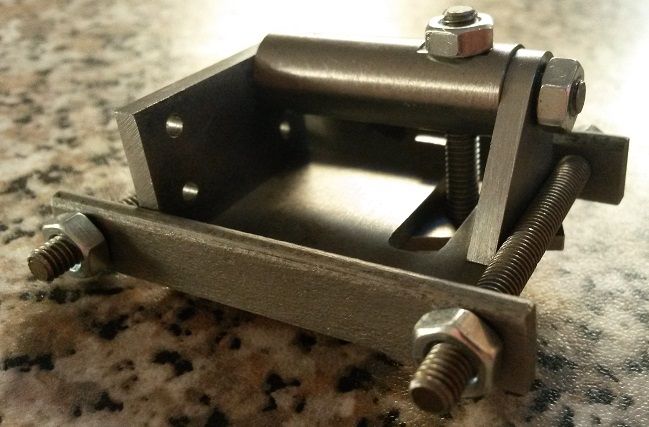

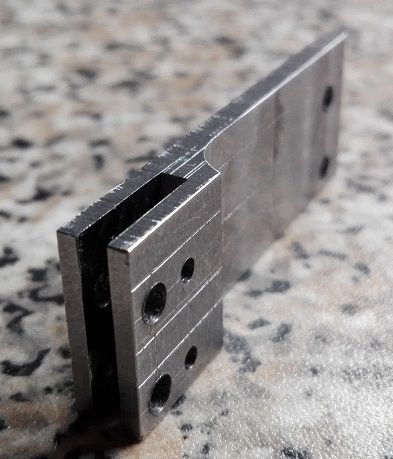

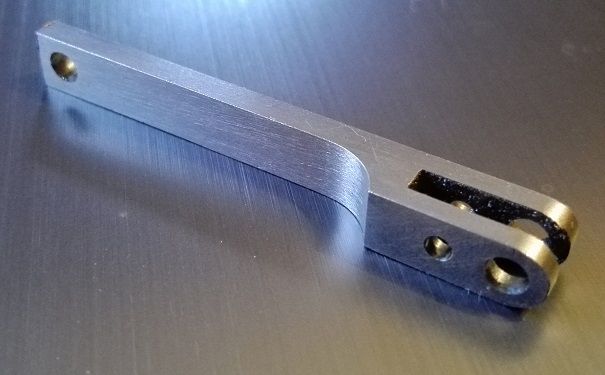

Here is a photo after the first cut

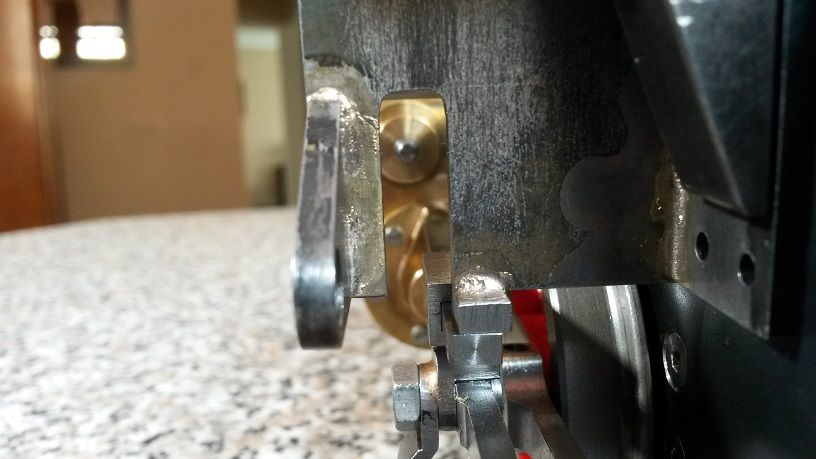

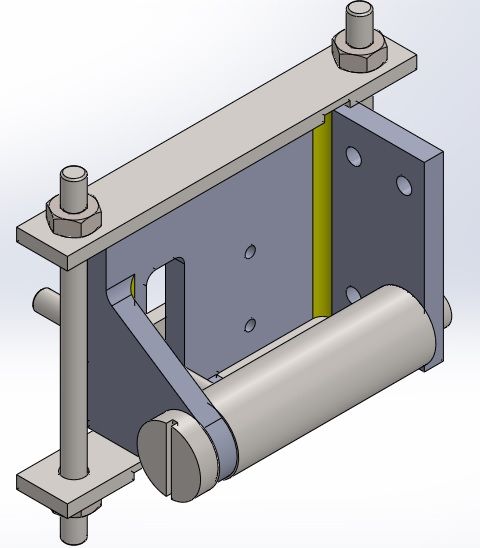

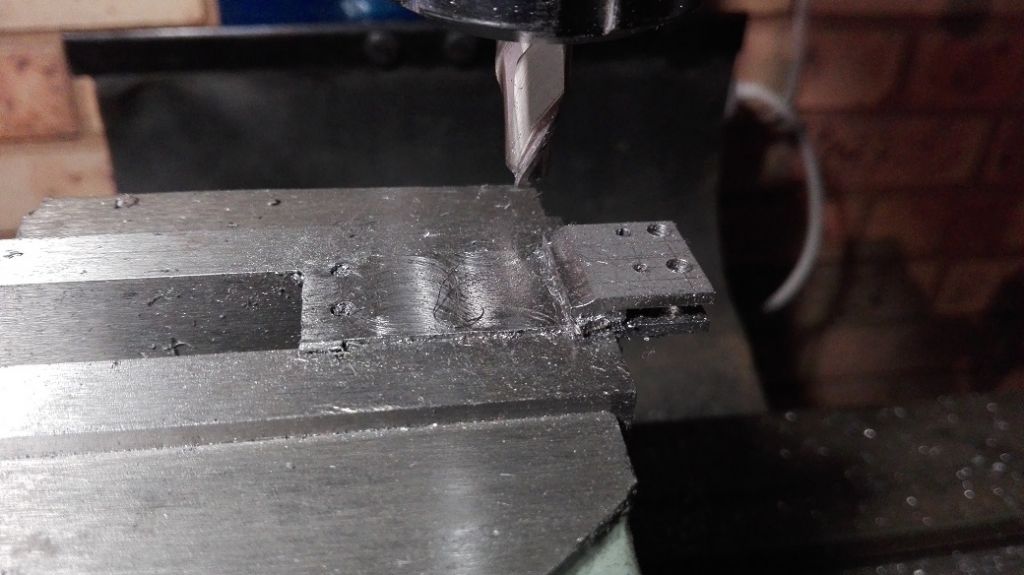

The bulk of the lower portion of the embryo lever was then milled away to the final thickness and the radius milled using a ball end mill.

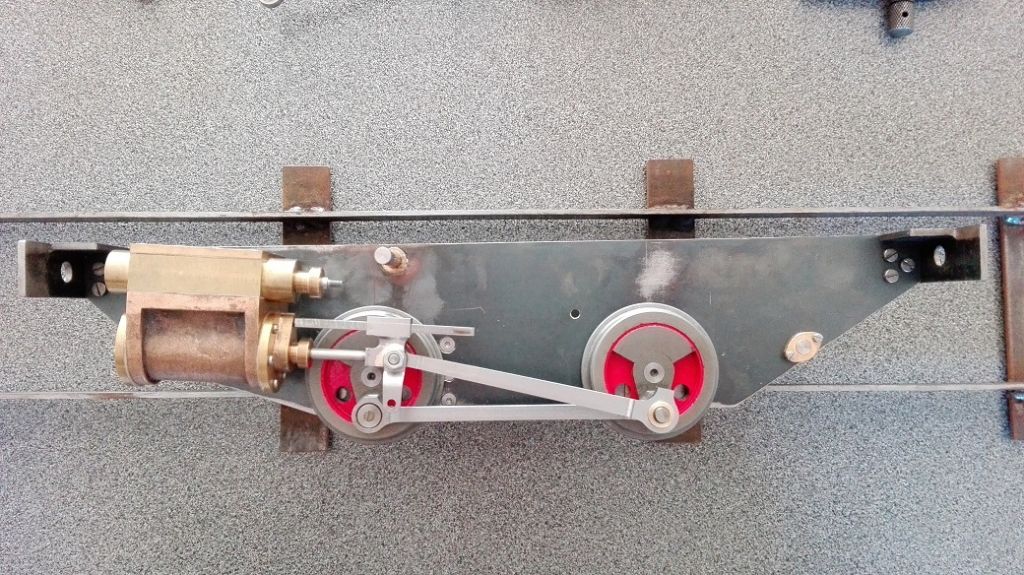

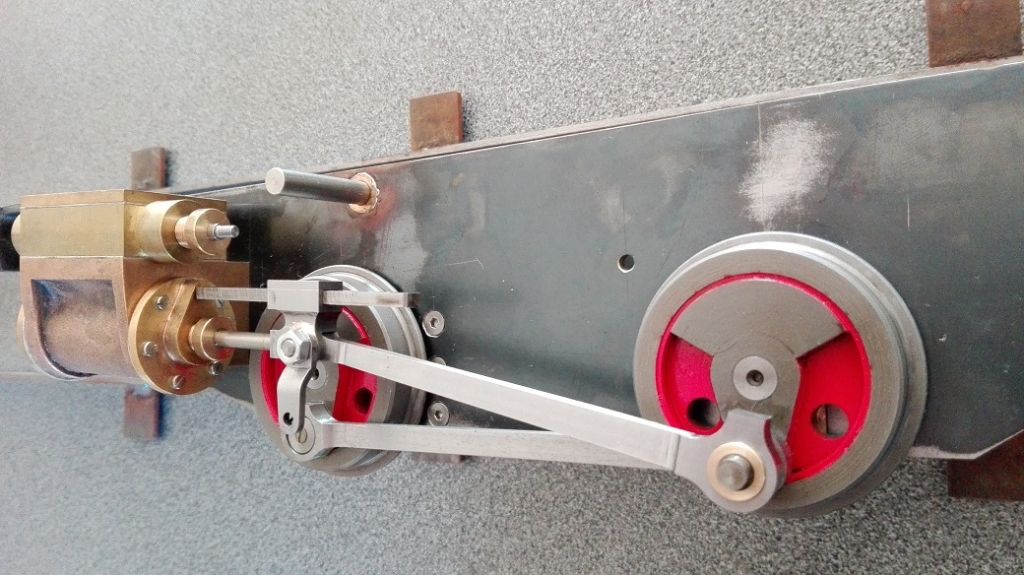

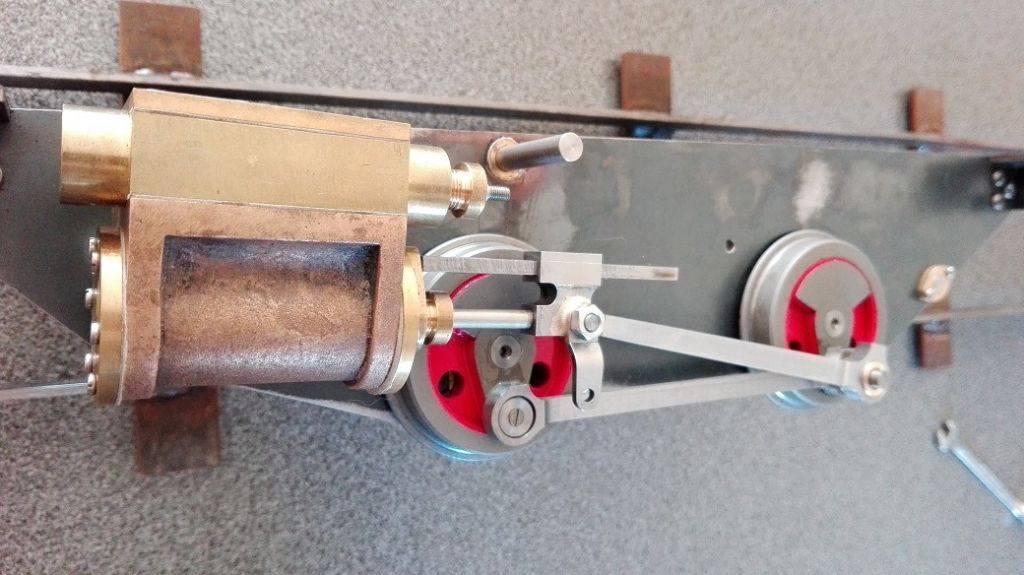

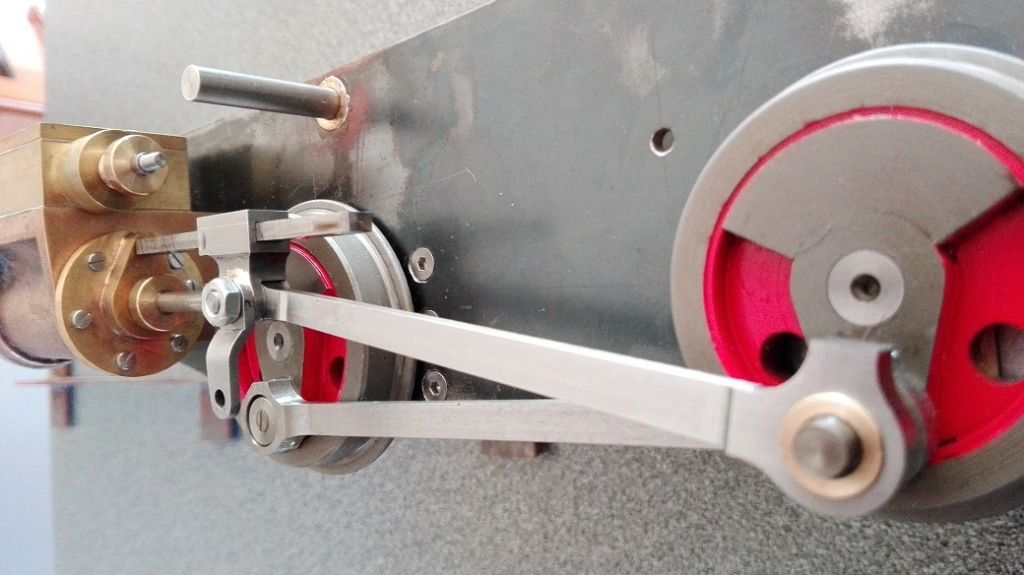

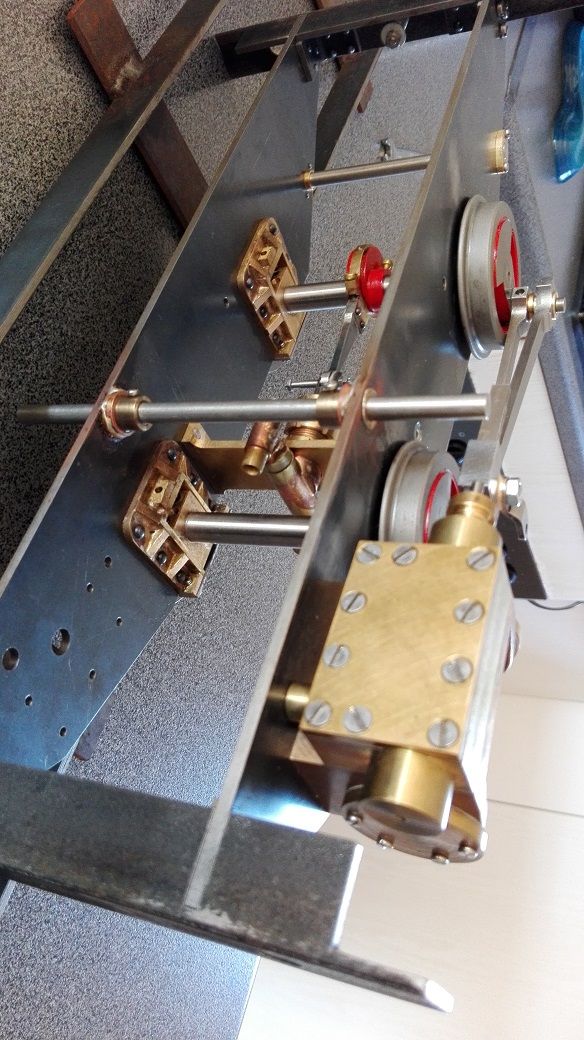

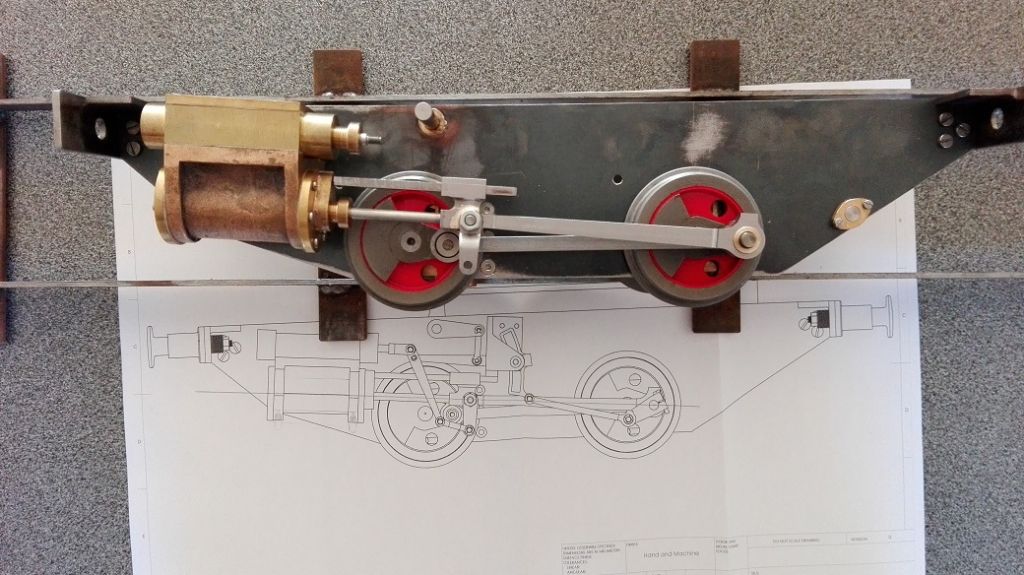

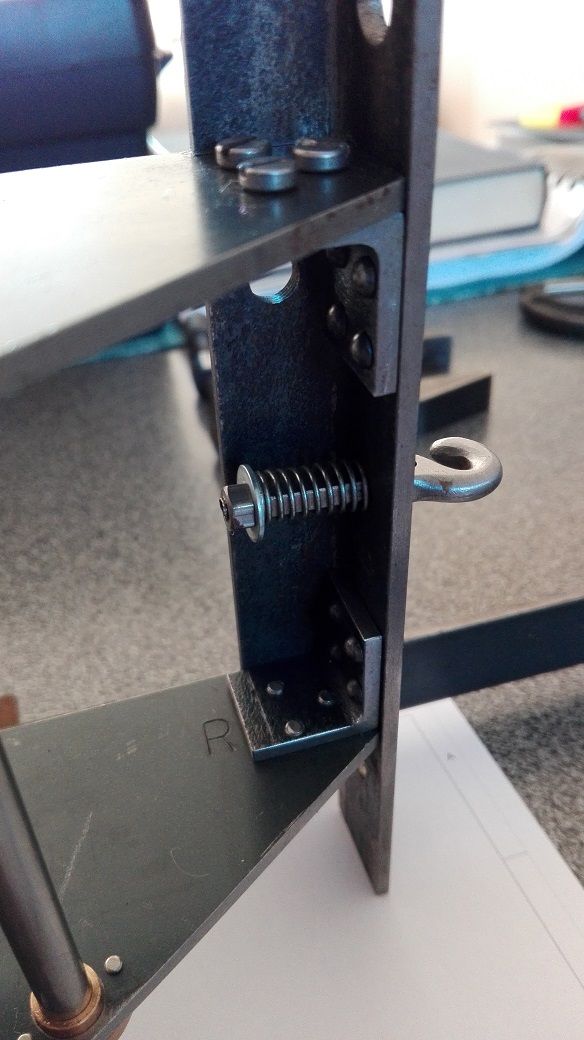

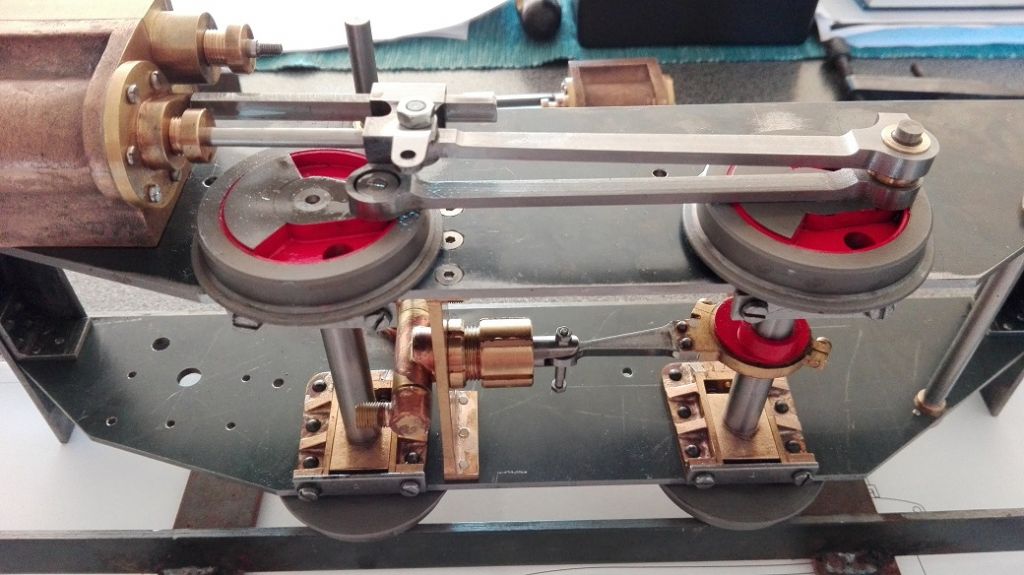

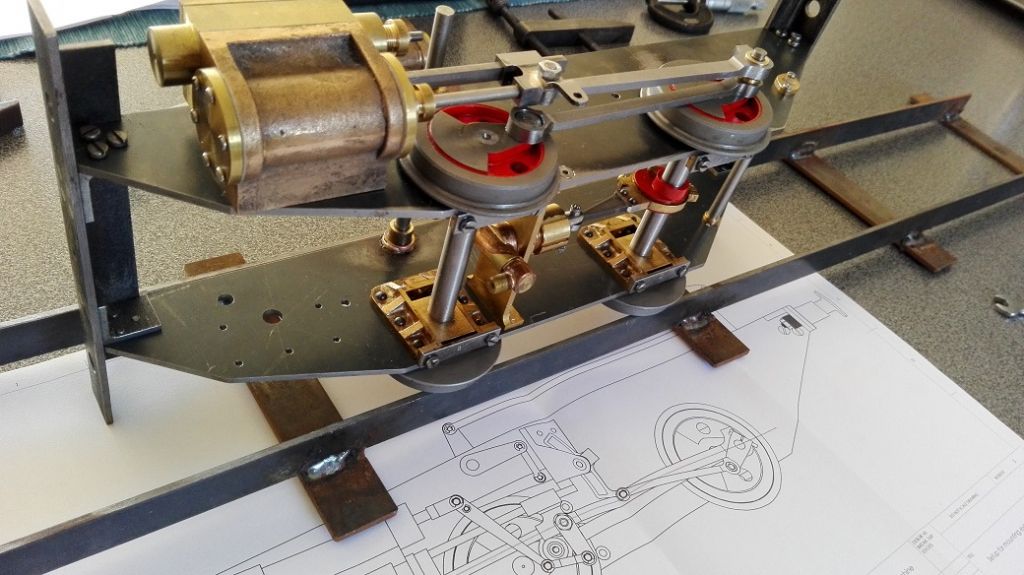

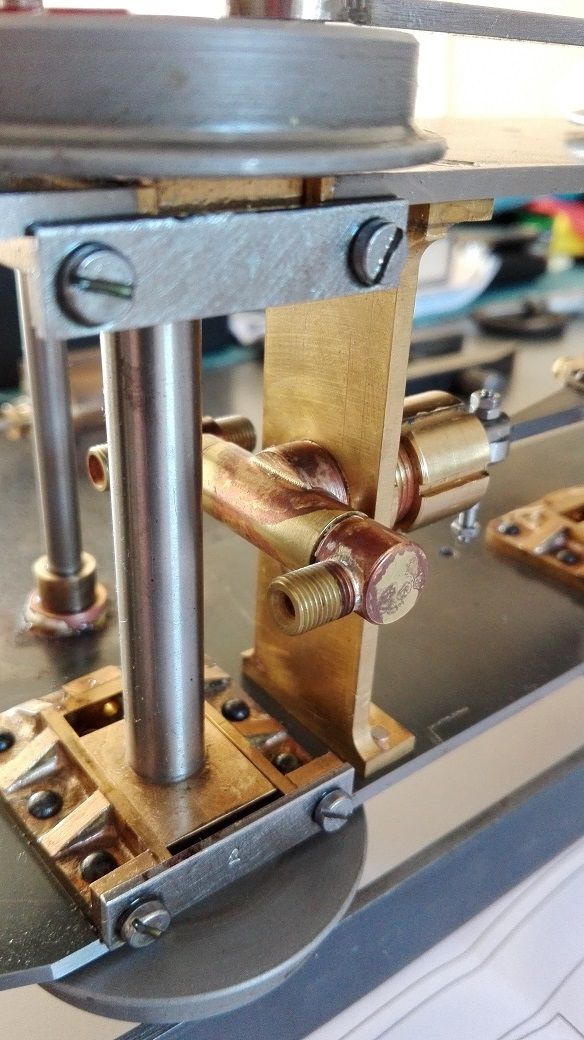

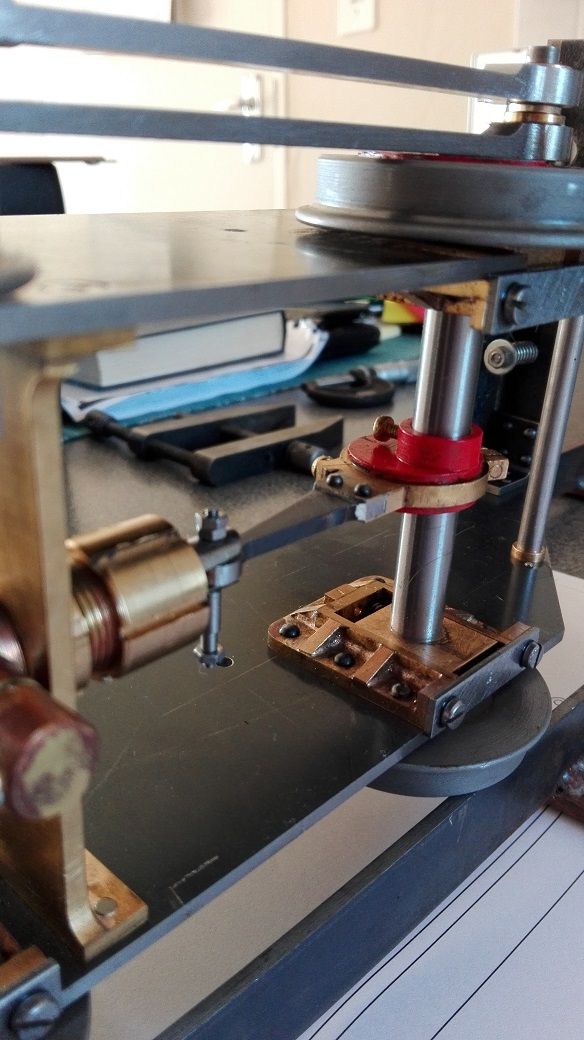

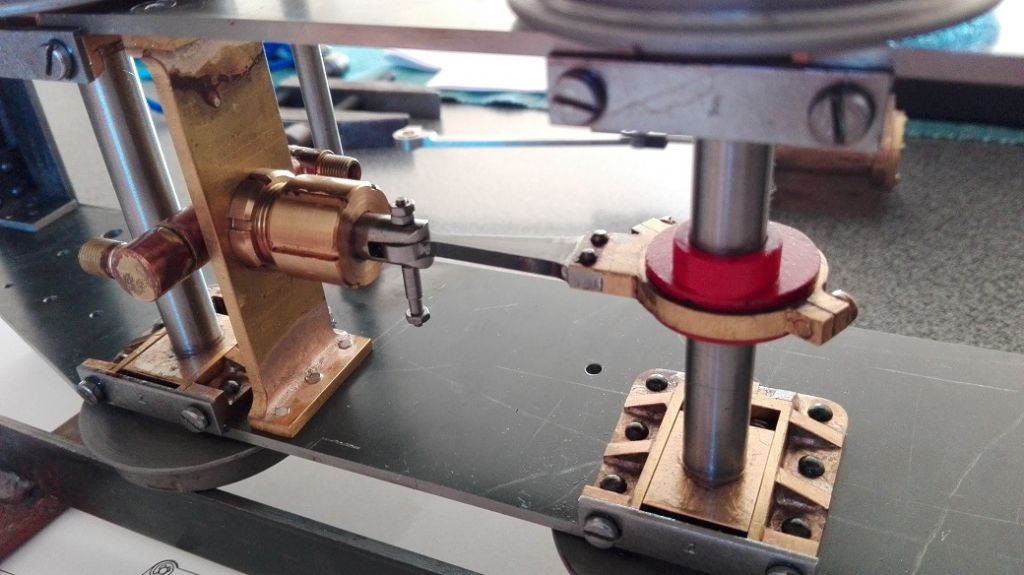

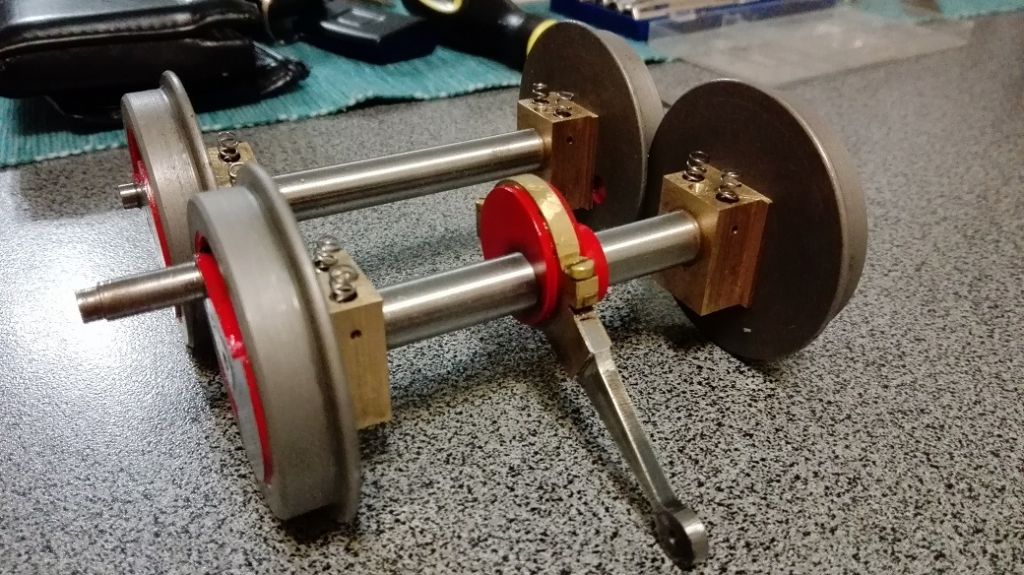

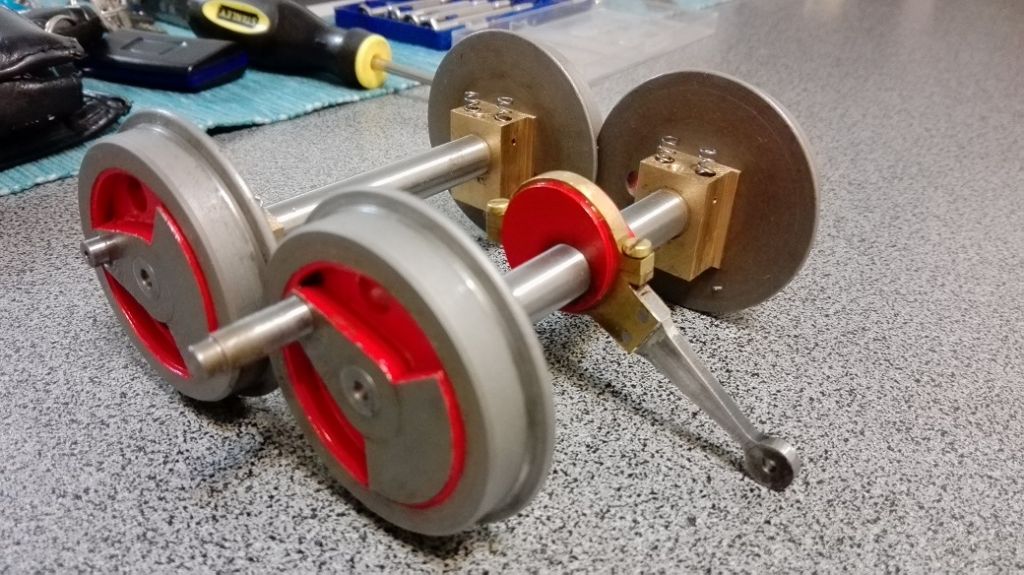

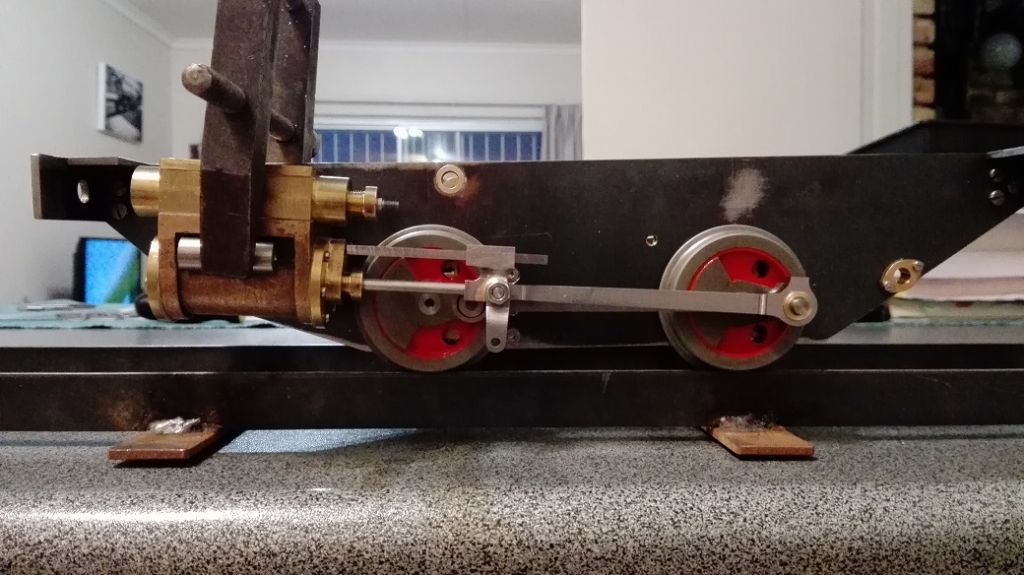

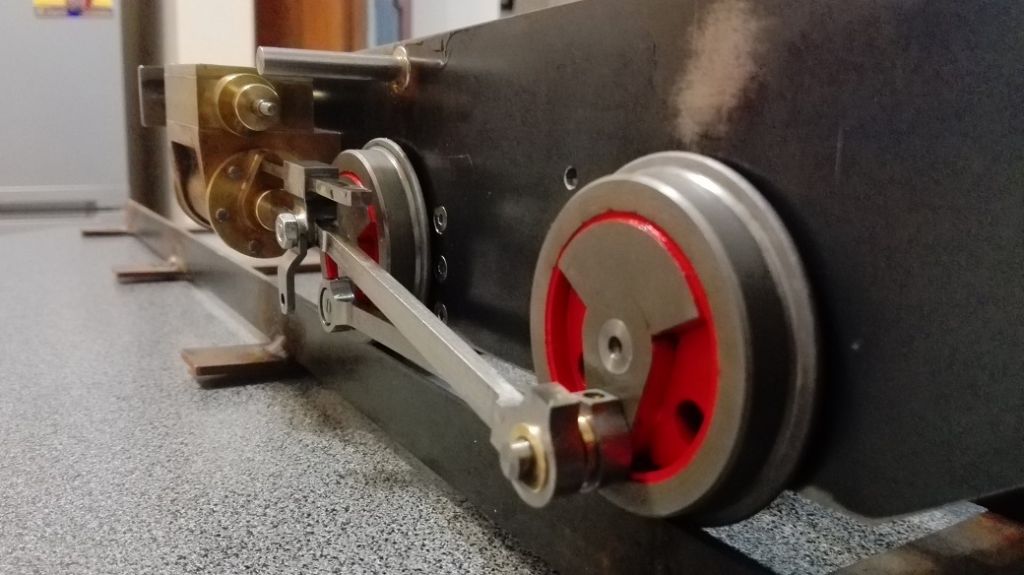

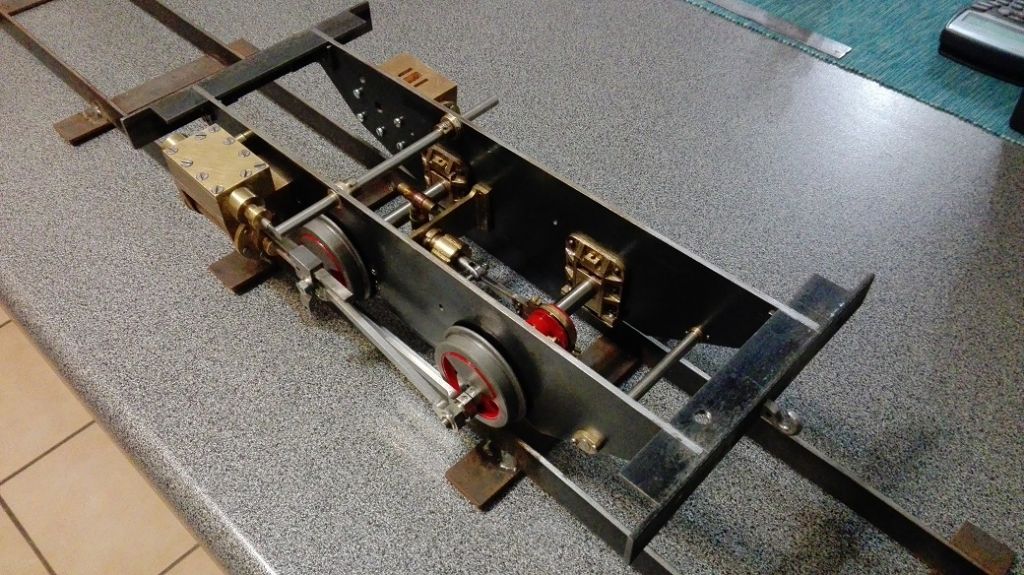

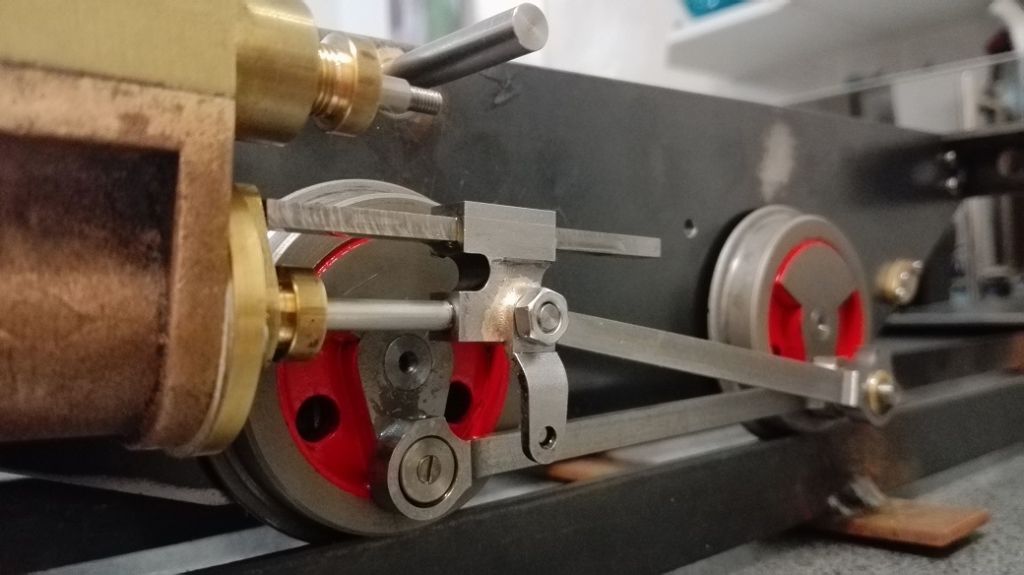

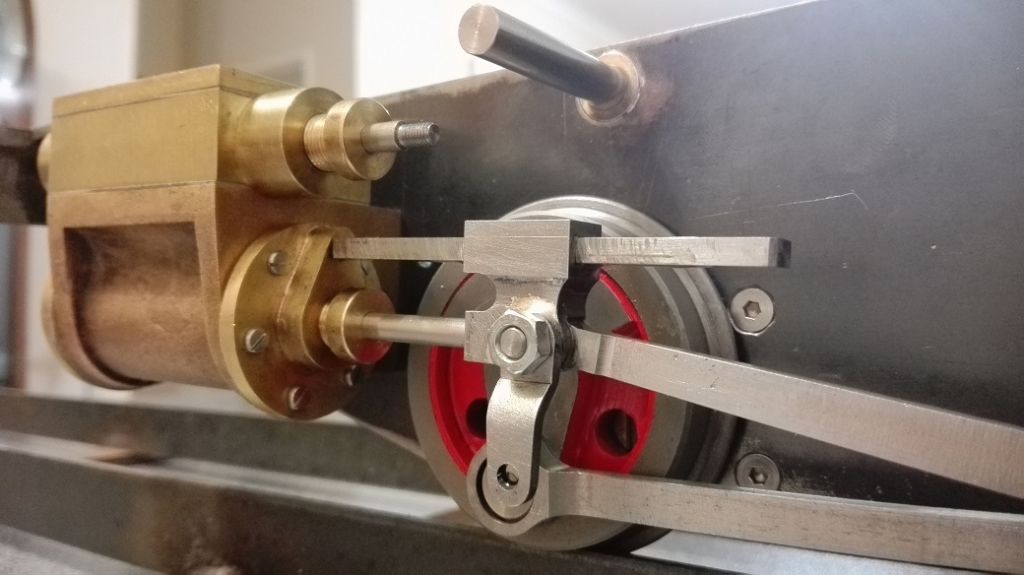

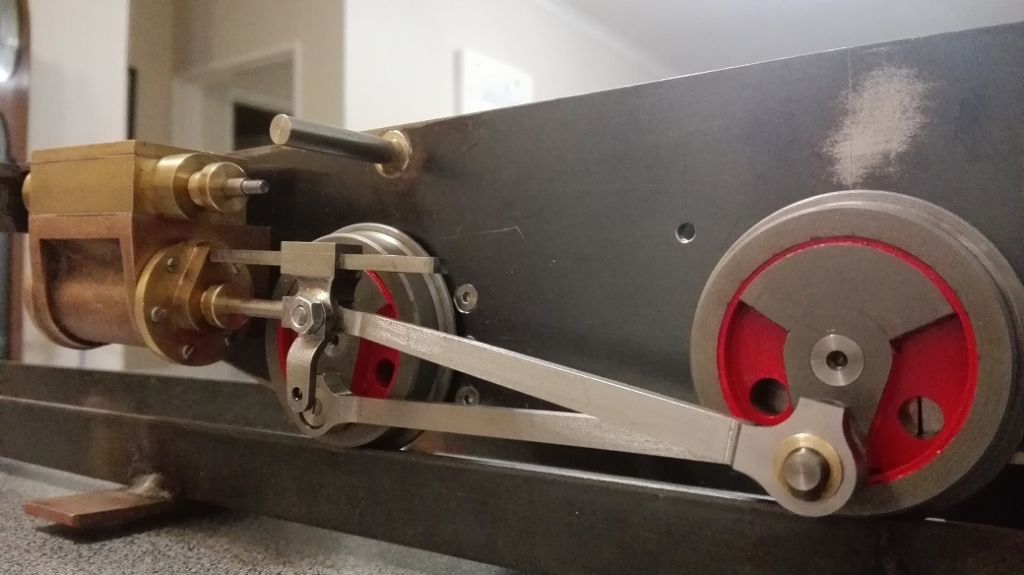

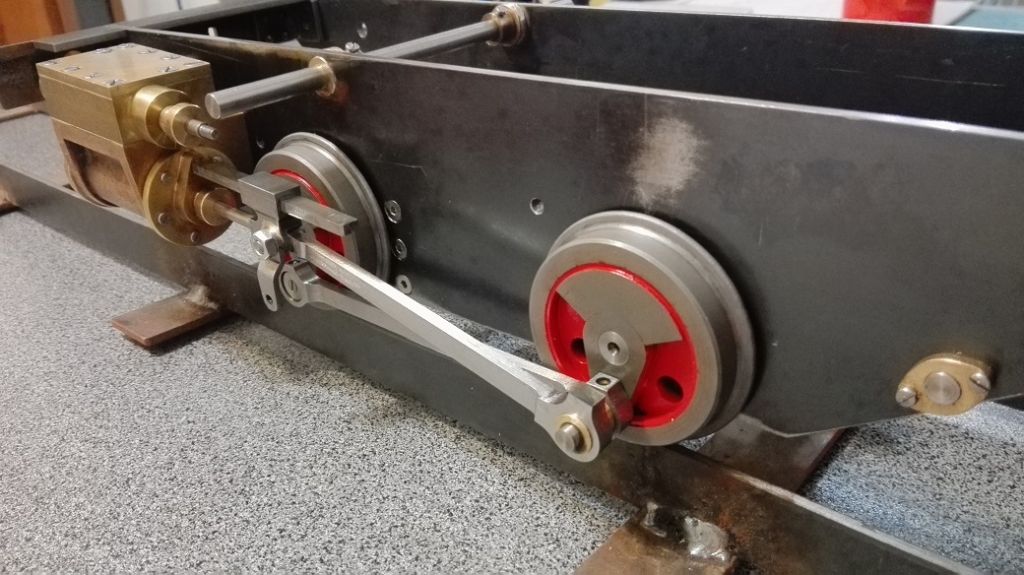

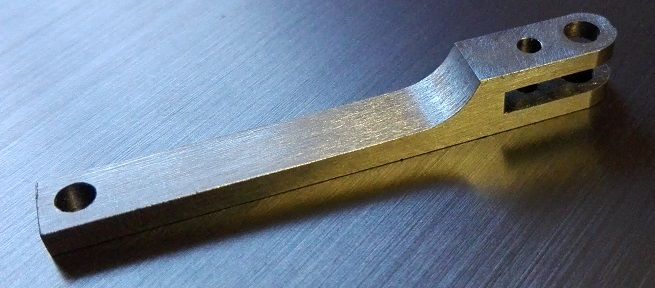

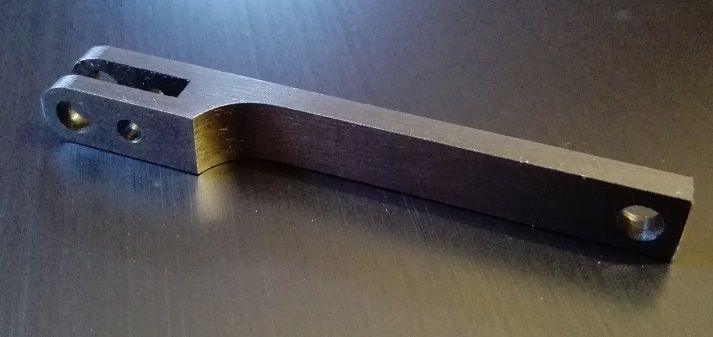

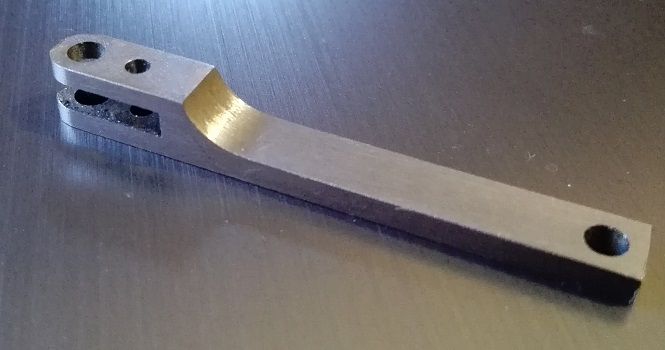

Here are some pics after the milling procedures.

Now I need to cut the individual levers out, draw file the milling marks away and finally file the profile of the combination lever. I will be making filing buttons for the ends out of hardened silver steel.

(All of the milling procedures were performed with the material in the same position in the vice. So I had to place the material in the vice ensuring that there was clearance for all of the operations.)

Edited By Ryan Norton on 13/11/2016 10:39:52

Edited By Ryan Norton on 13/11/2016 10:42:32

Phil H1.