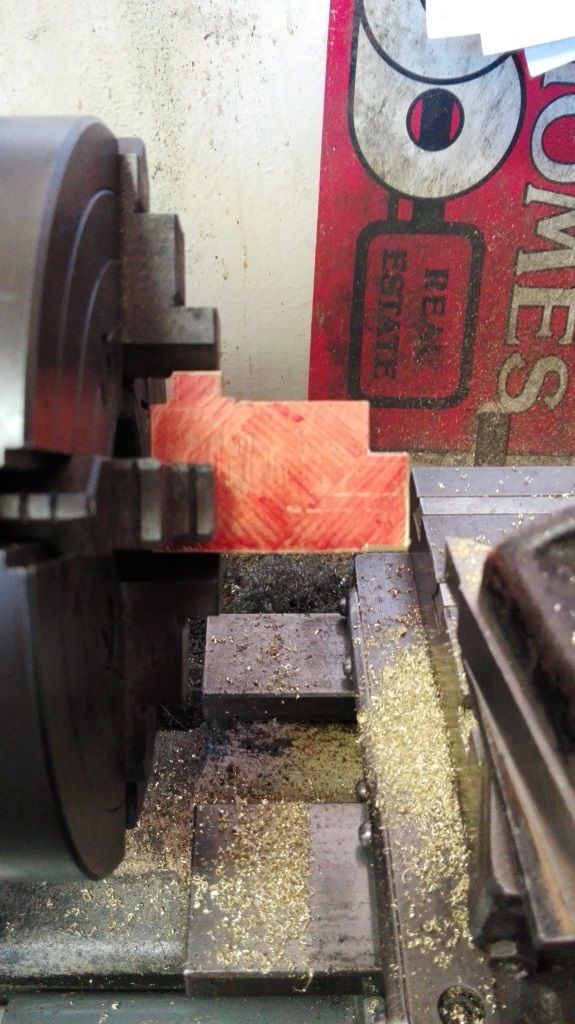

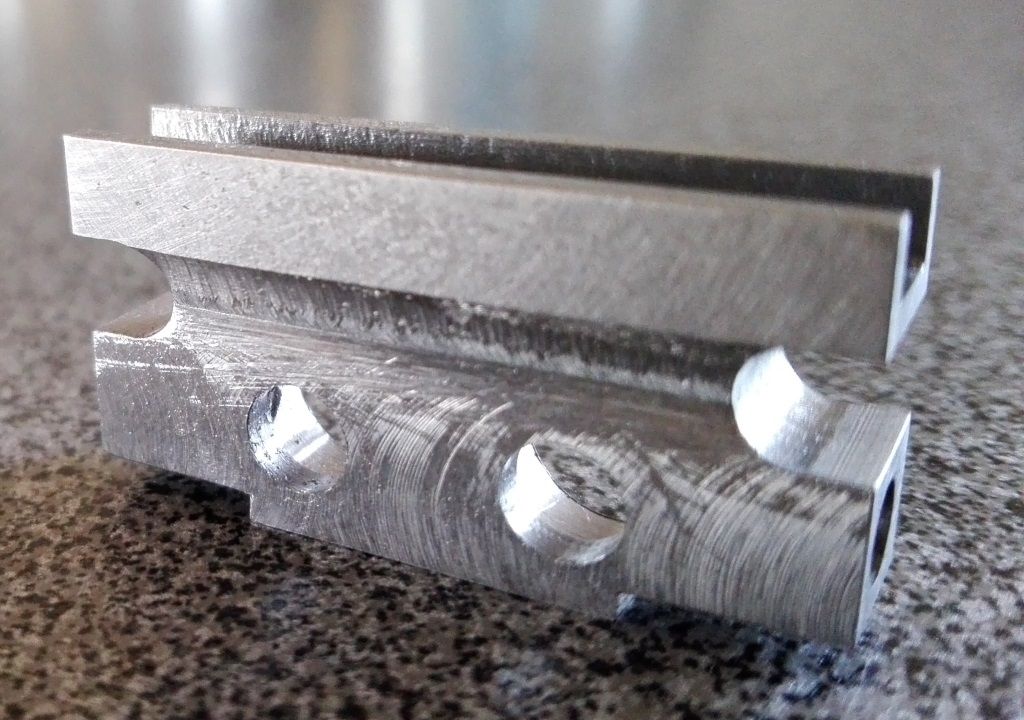

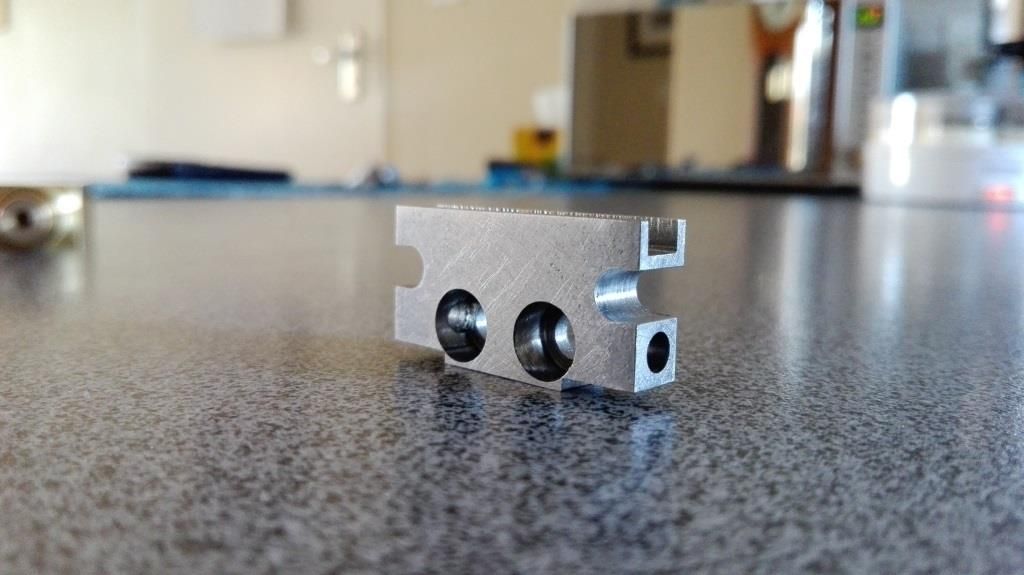

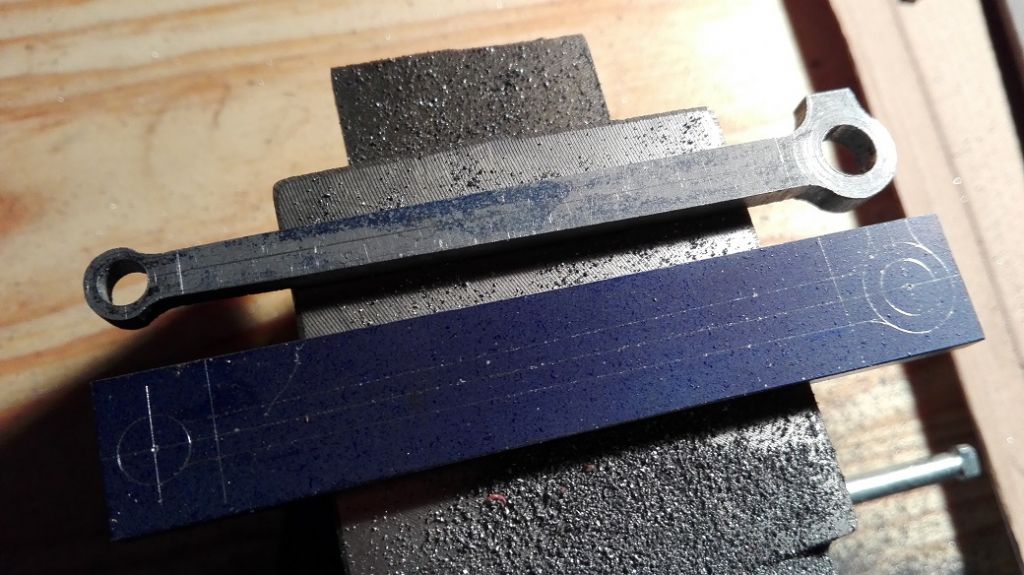

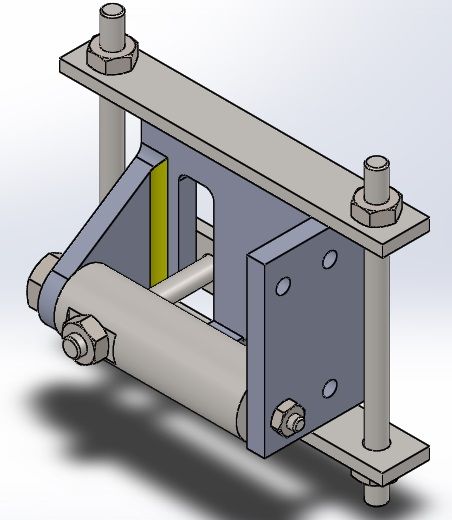

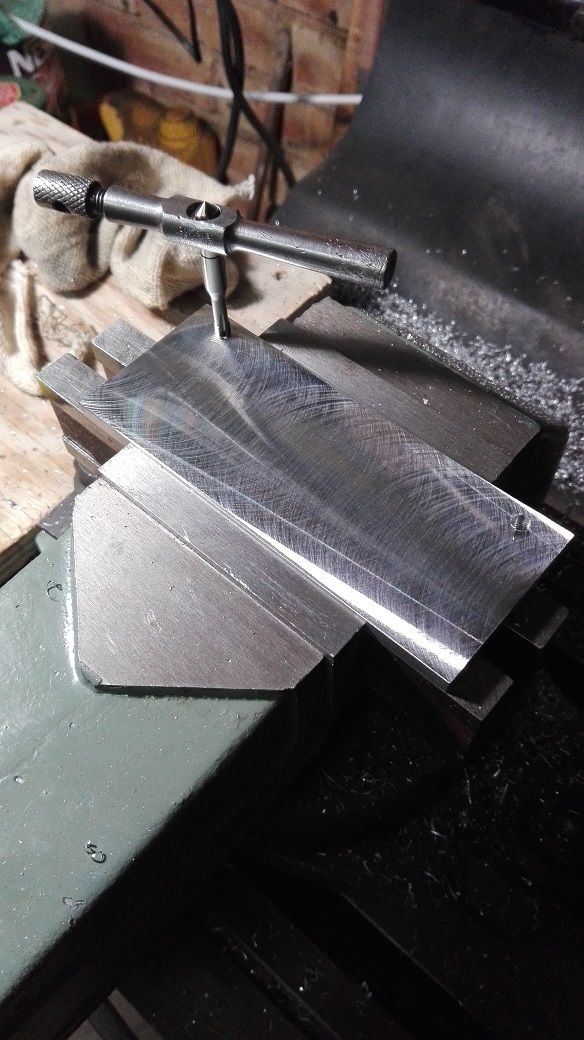

I made a jig for the milling of the side relief of the connecting rods. This consisted of an aluminium plate, squared up and drilled with two holes at the same centers of the rods. These holes were tapped M5.

Once complete, the conn. rod was screwed lightly to the jig and using a surface gauge, aligned parallel with the jigs side to allow for perpendicular milling of the relief.

The gauge was set up so that it could be moved along the length of the jig. The center line of the rod was aligned with the point of the gauge. Once I was happy with the alignment, the two cap screws were tightened and the rod was ready for milling.

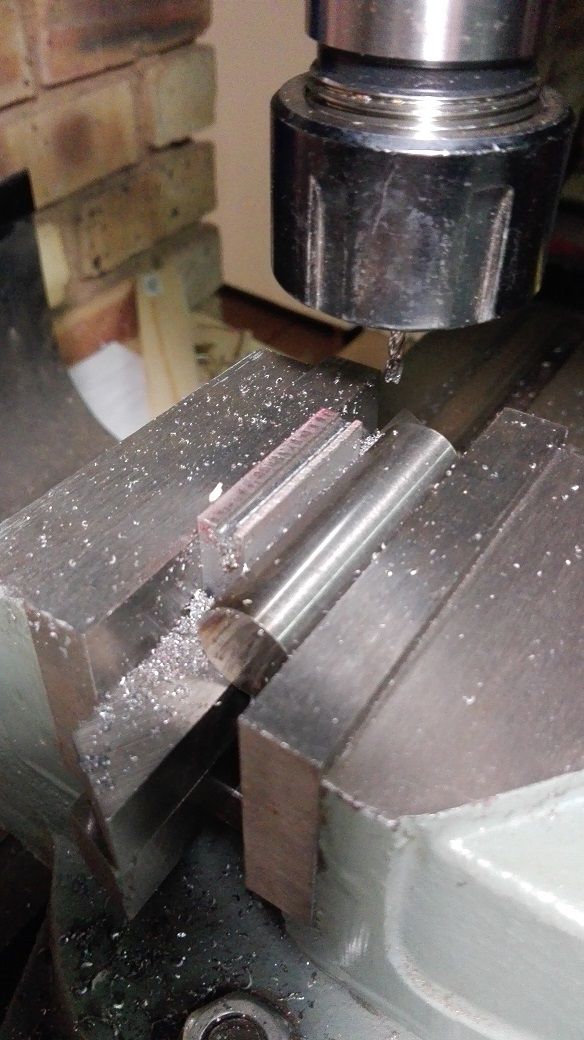

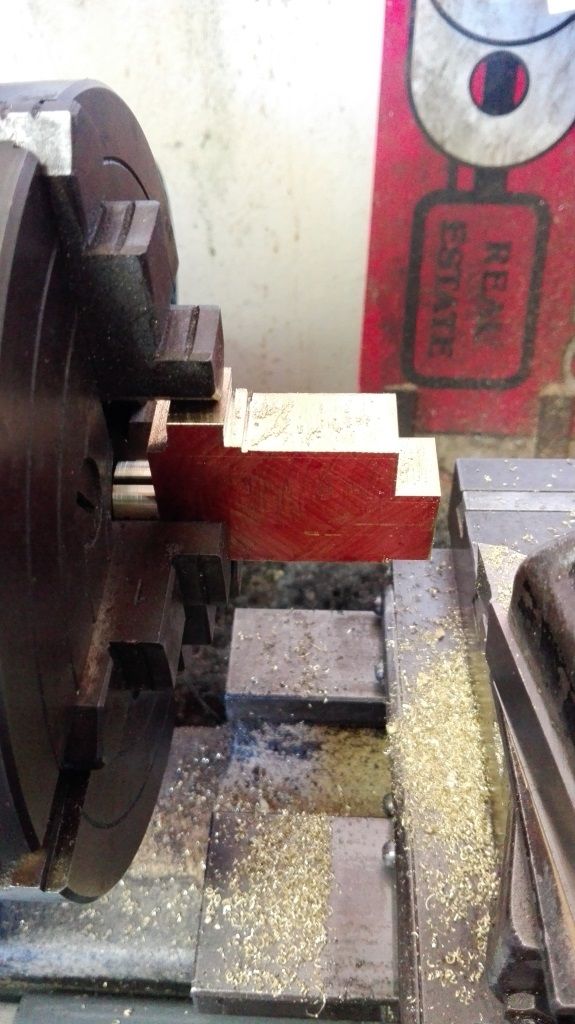

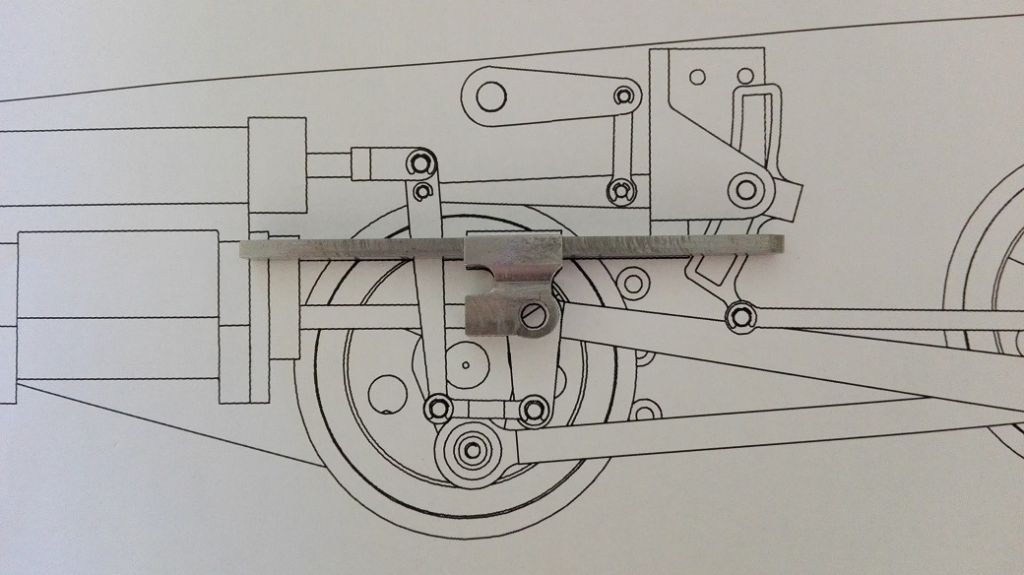

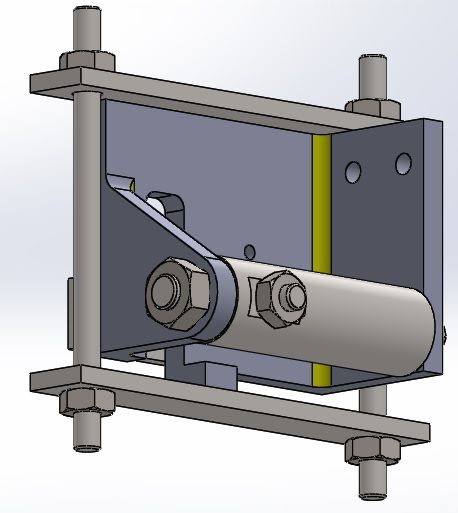

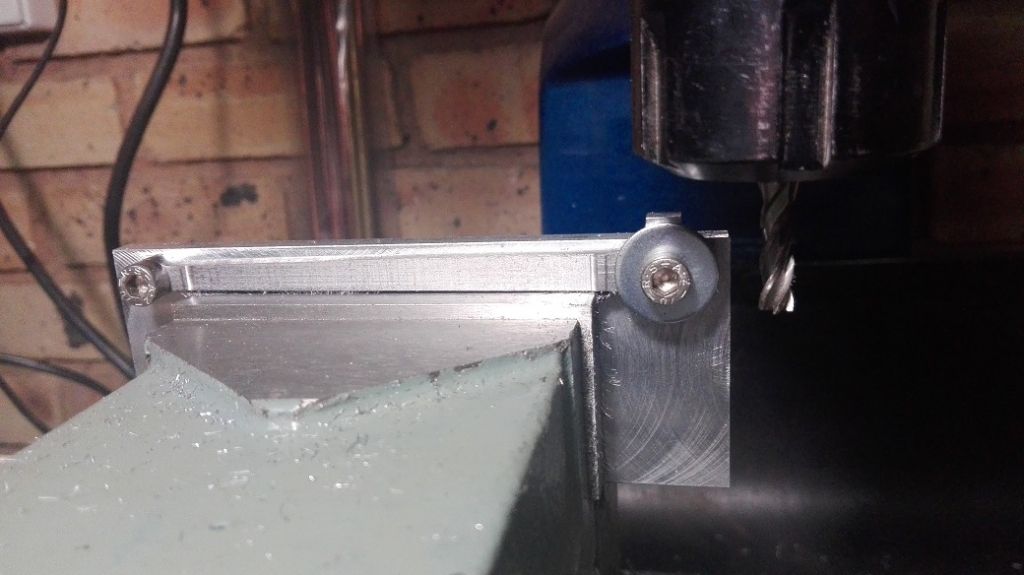

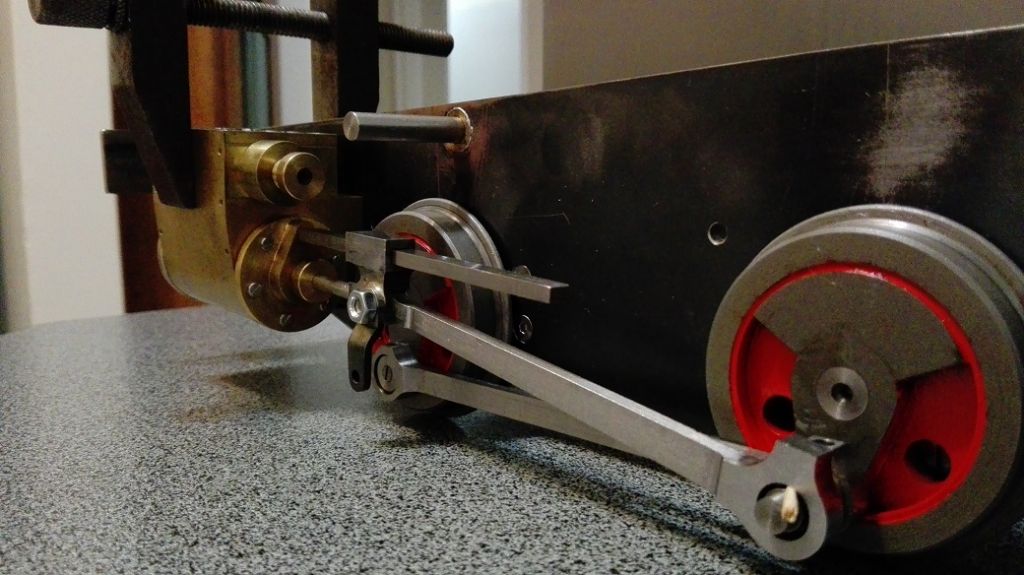

Here is the jig in the machine vice, possibly a little too low for comfort…

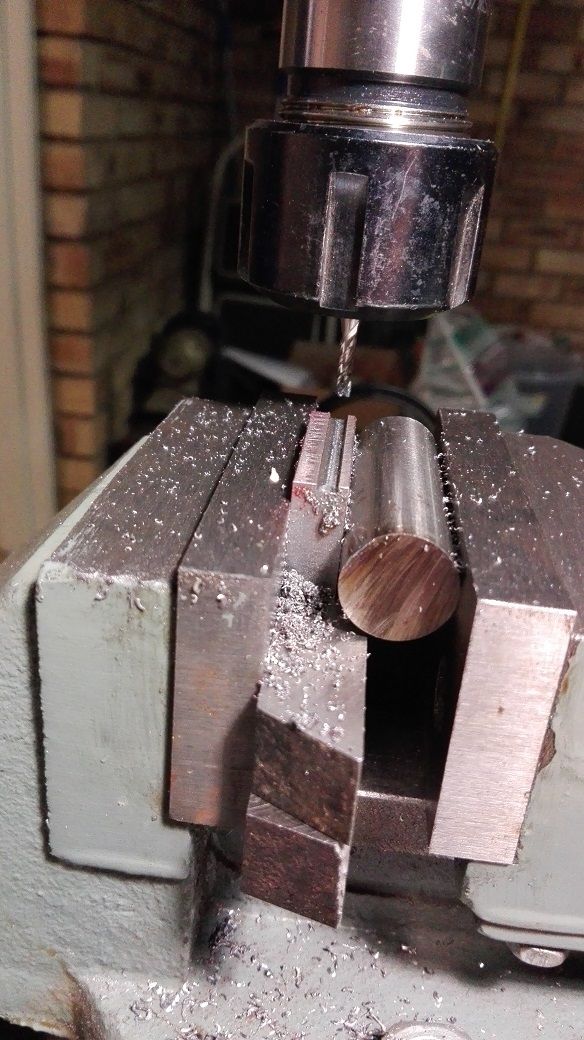

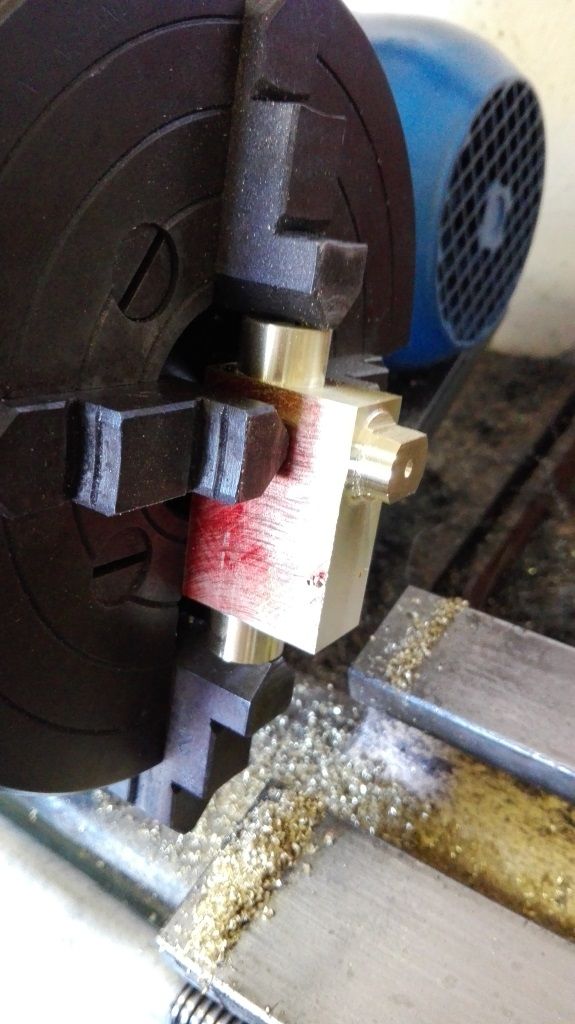

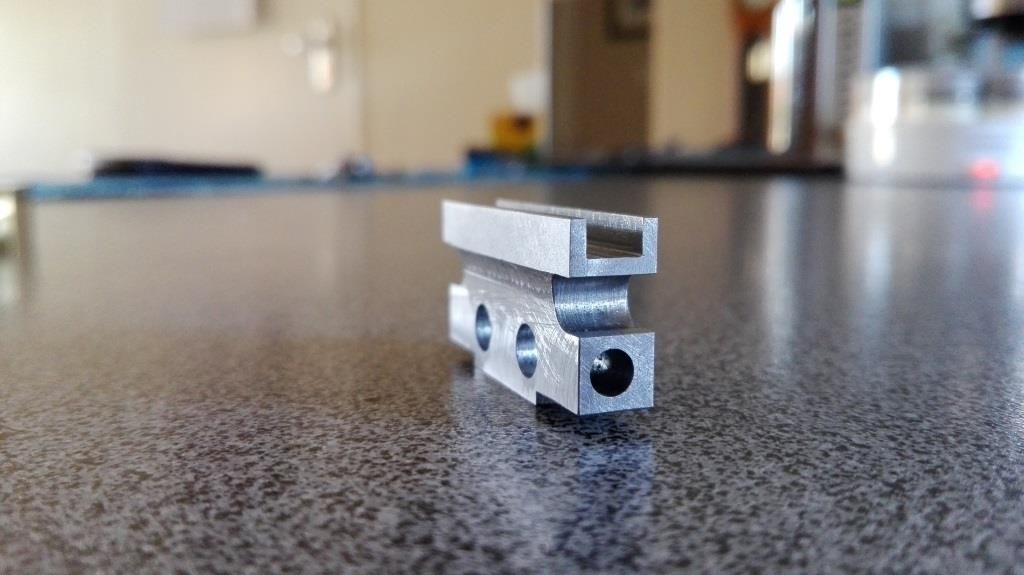

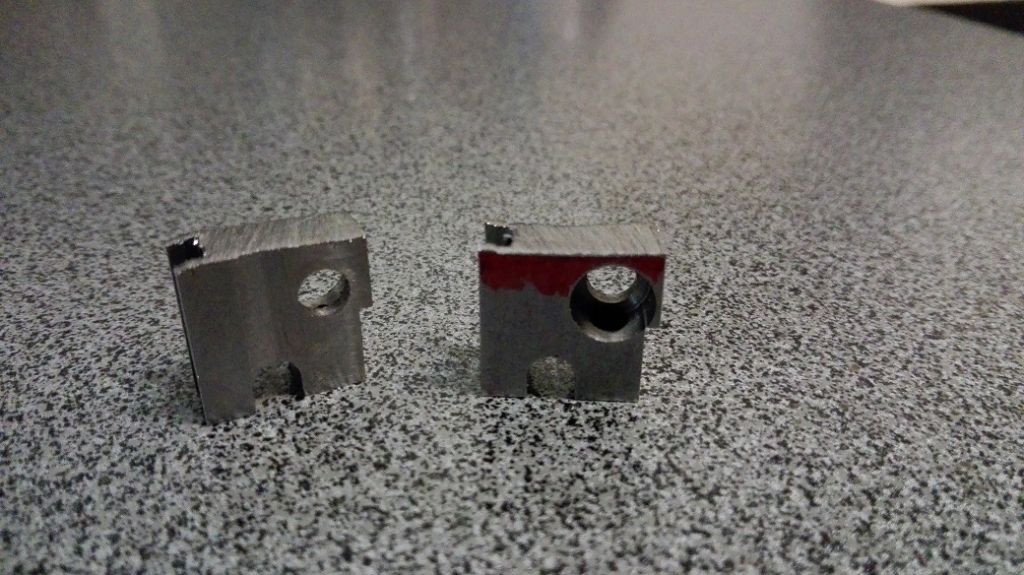

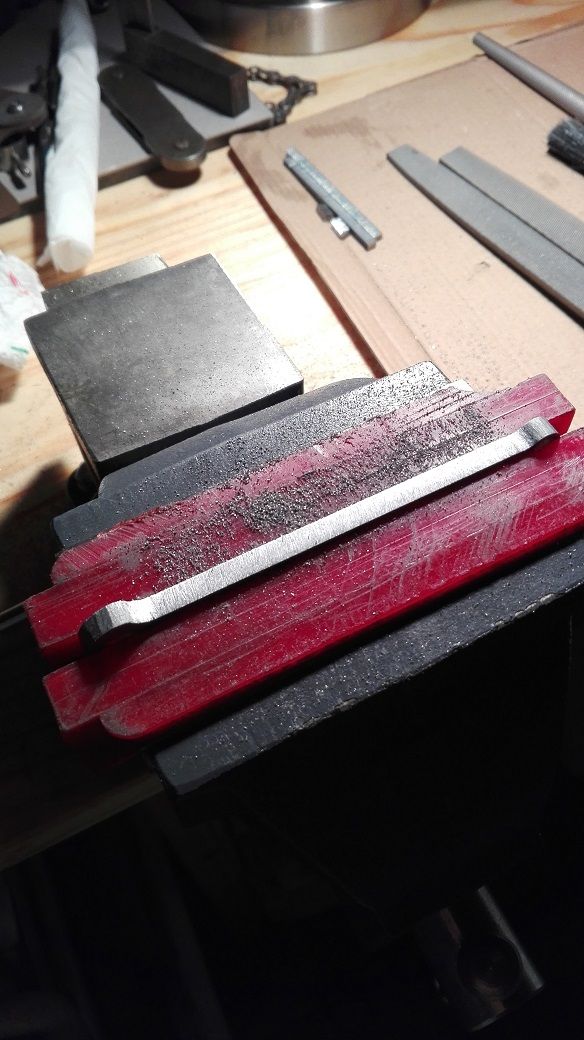

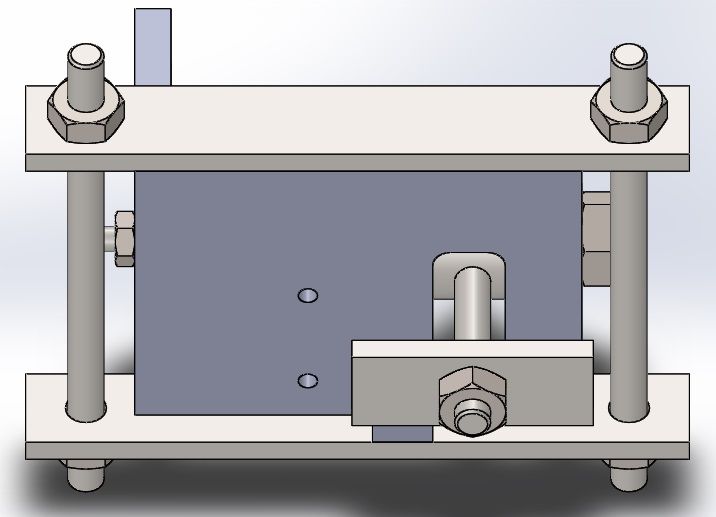

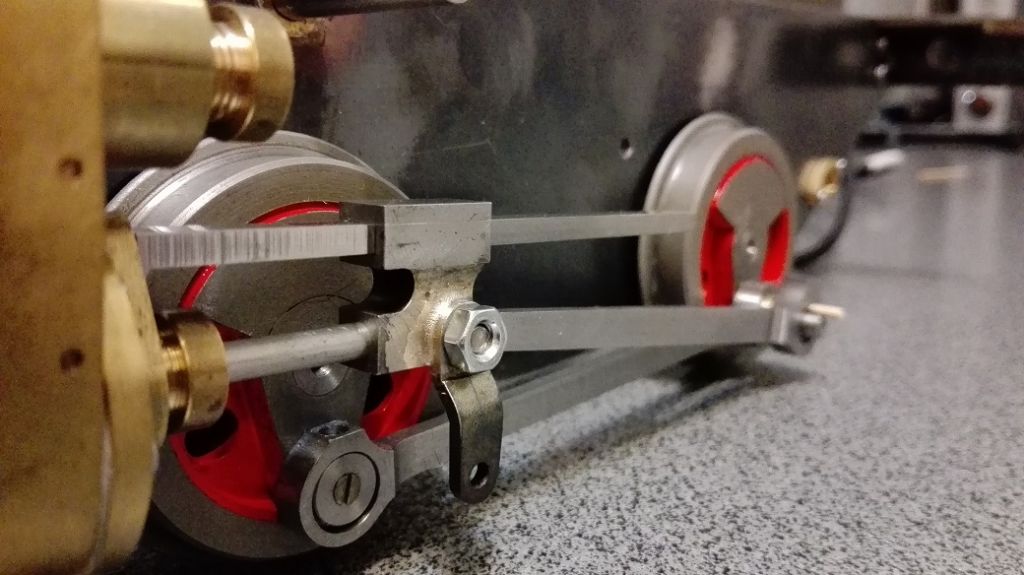

Here is the rod after the first pass with a 5mm cutter.

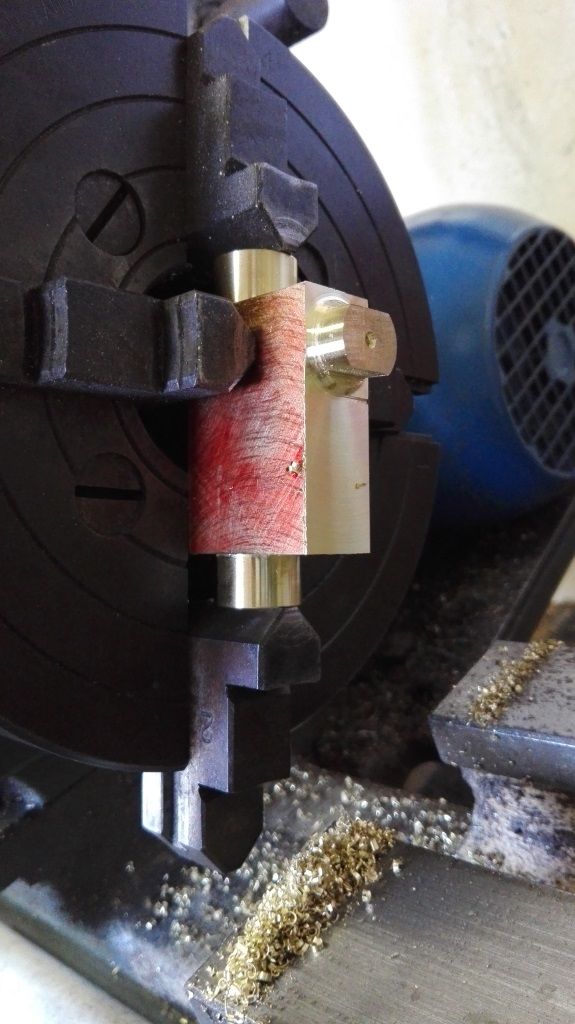

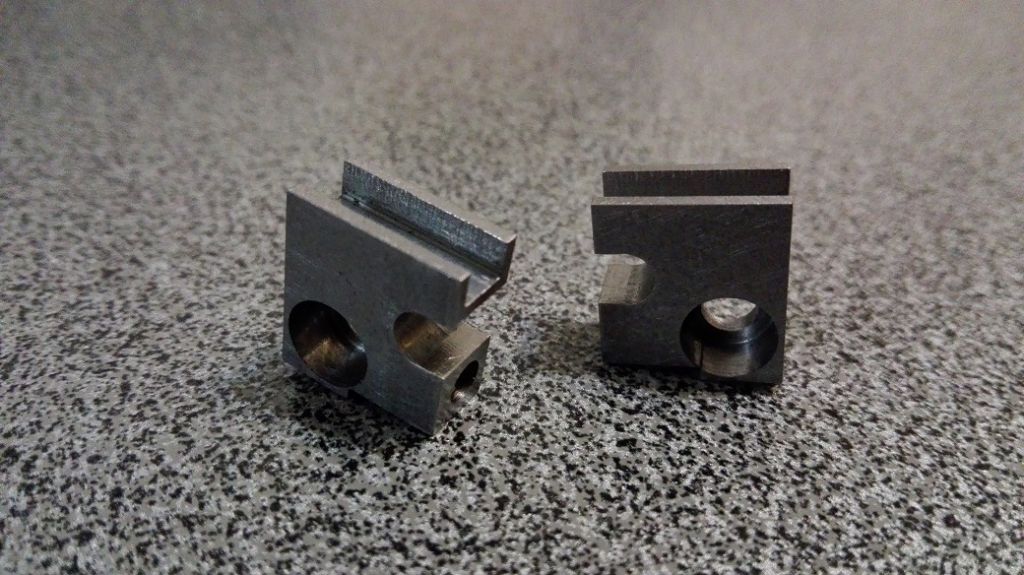

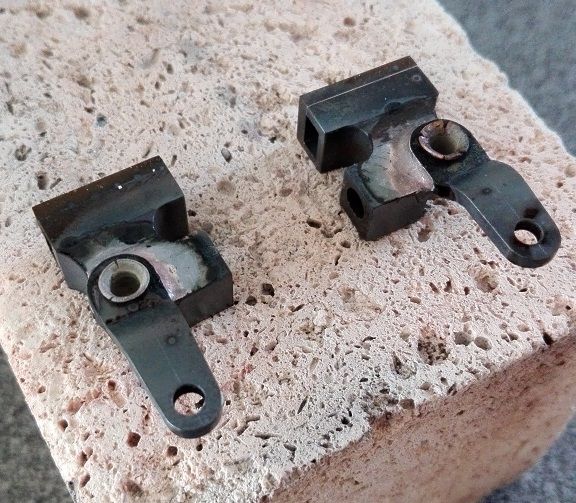

This is the finished rod after milling.

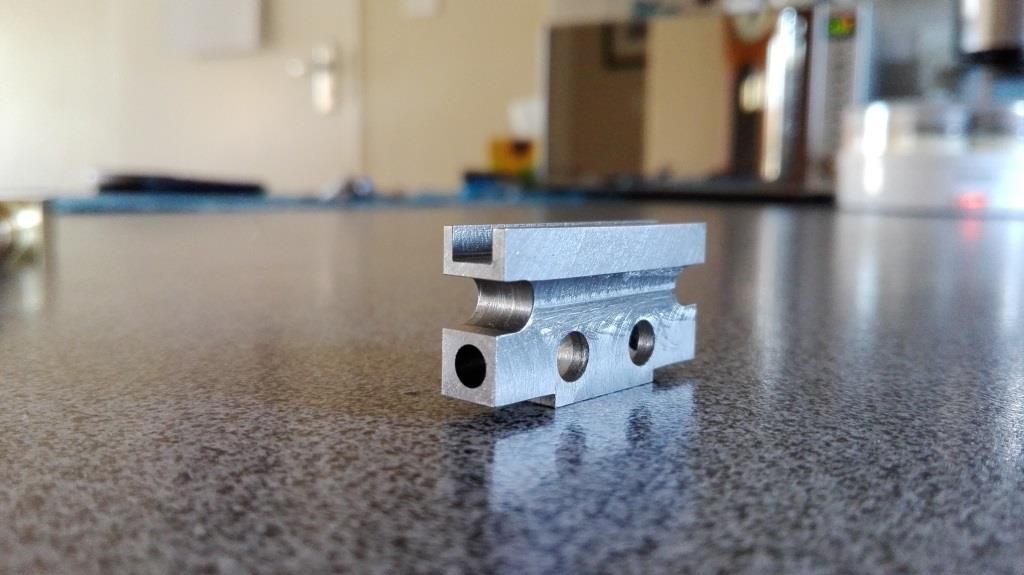

This is the other side.

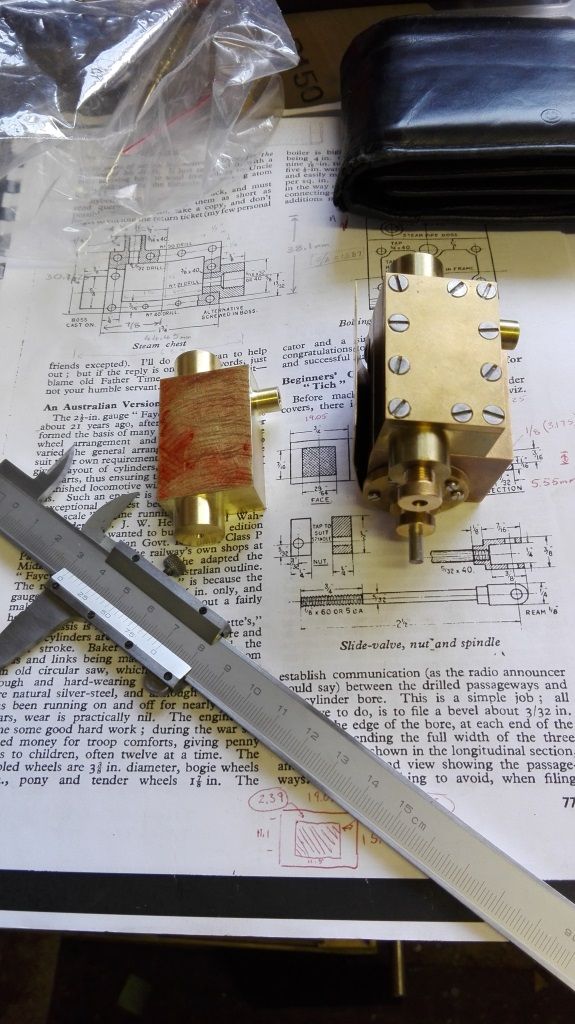

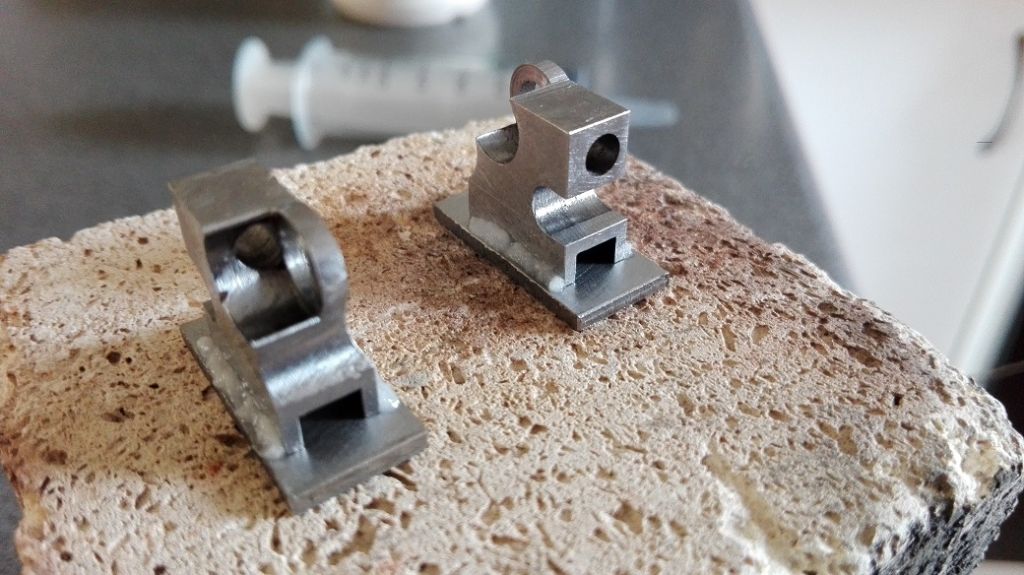

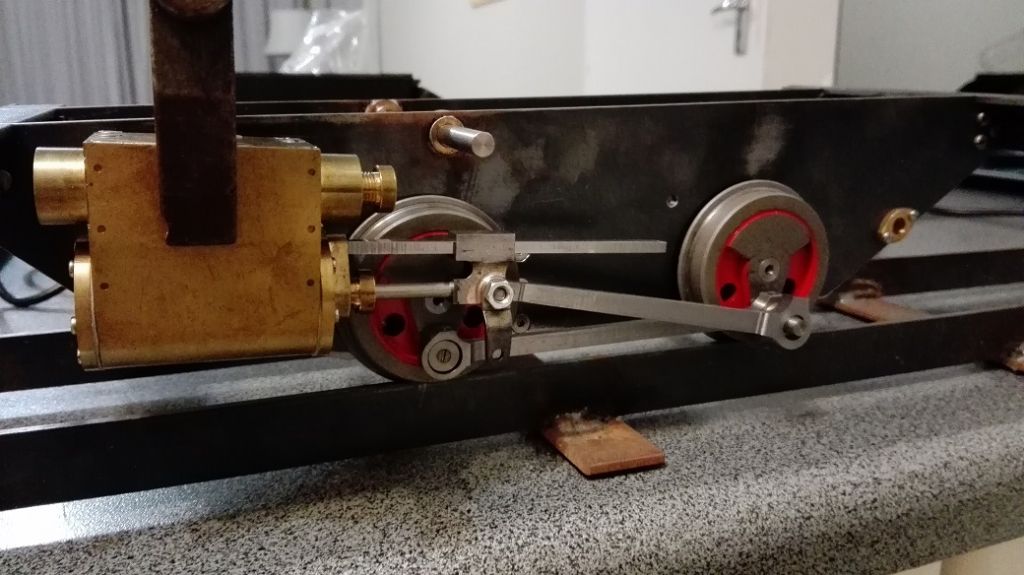

Both rods with side relief milling completed.

Phil H1.