What sort of issues could crop up with this combination? Corrosion? I am well aware that brass will wear more quickly than bronze but relatively speaking how long will it take for this to have a negative impact on the performance of the locomotive?

Hi Ryan; jumping over Fizzy's toes (as the question was directed at him)

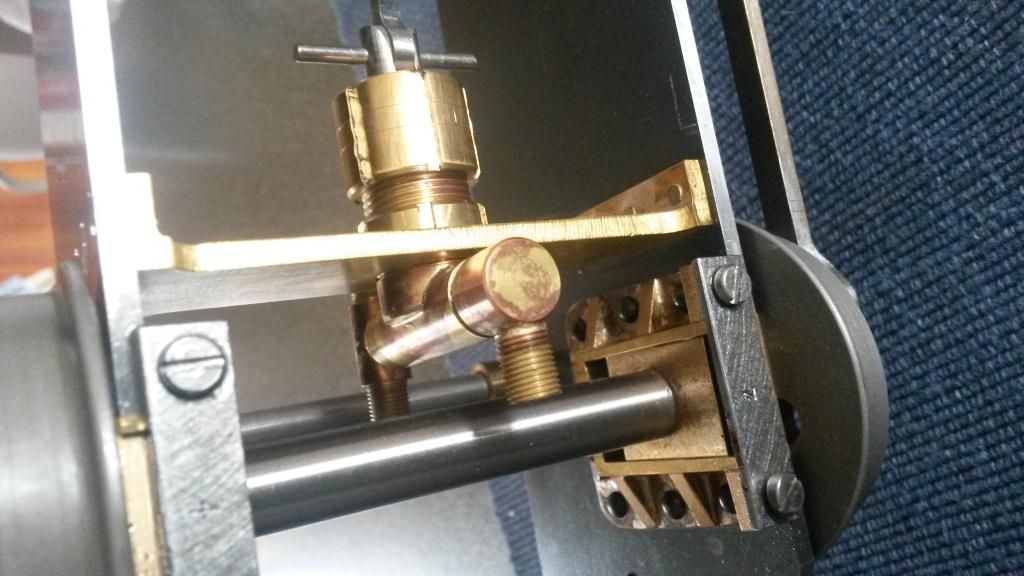

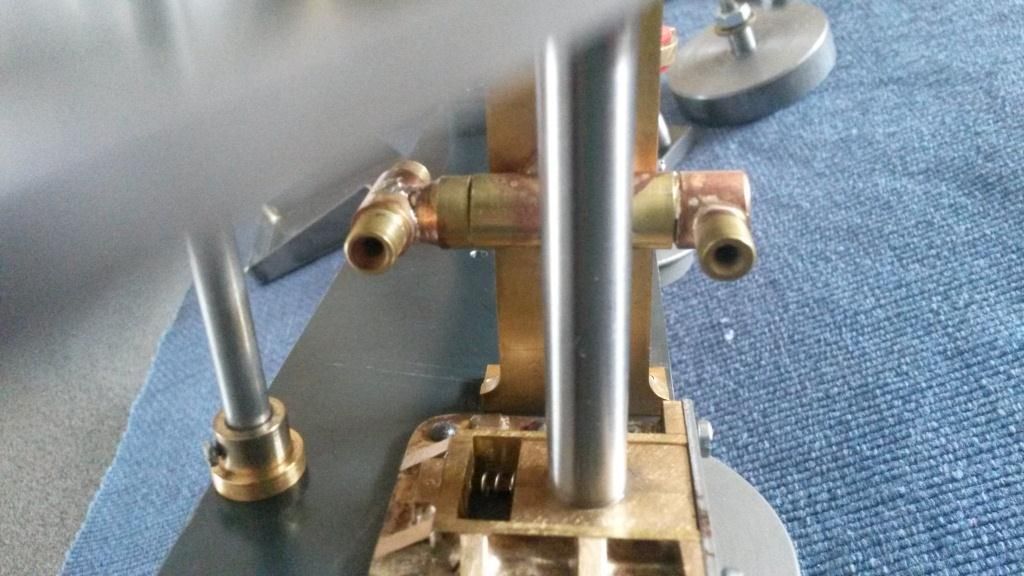

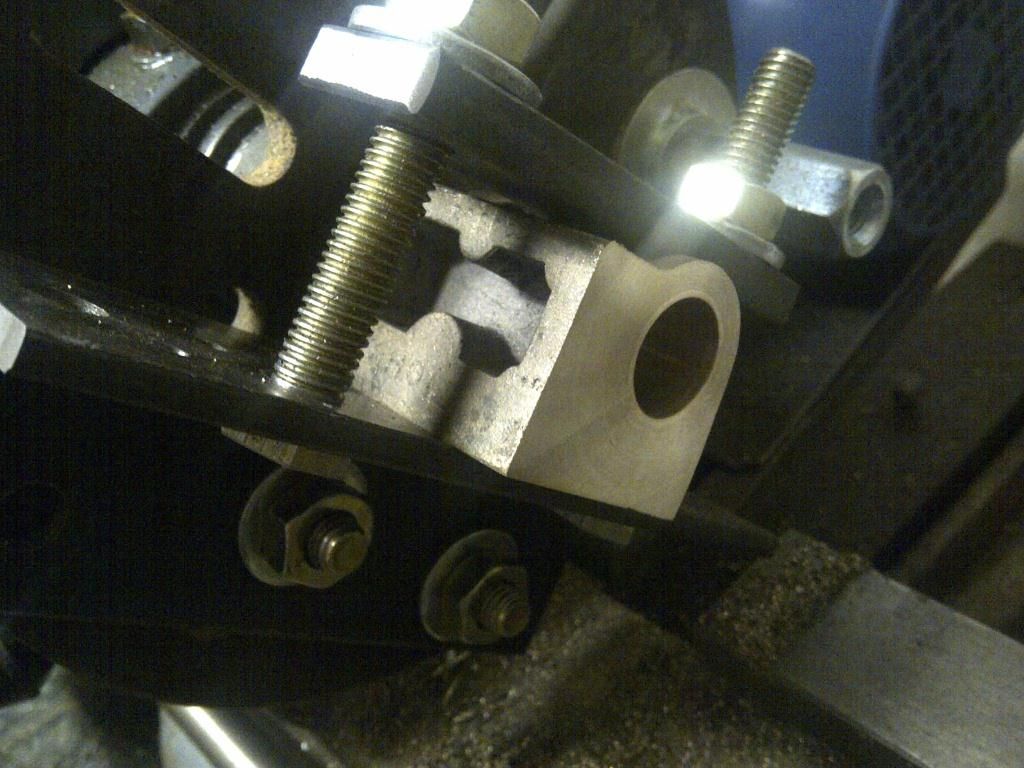

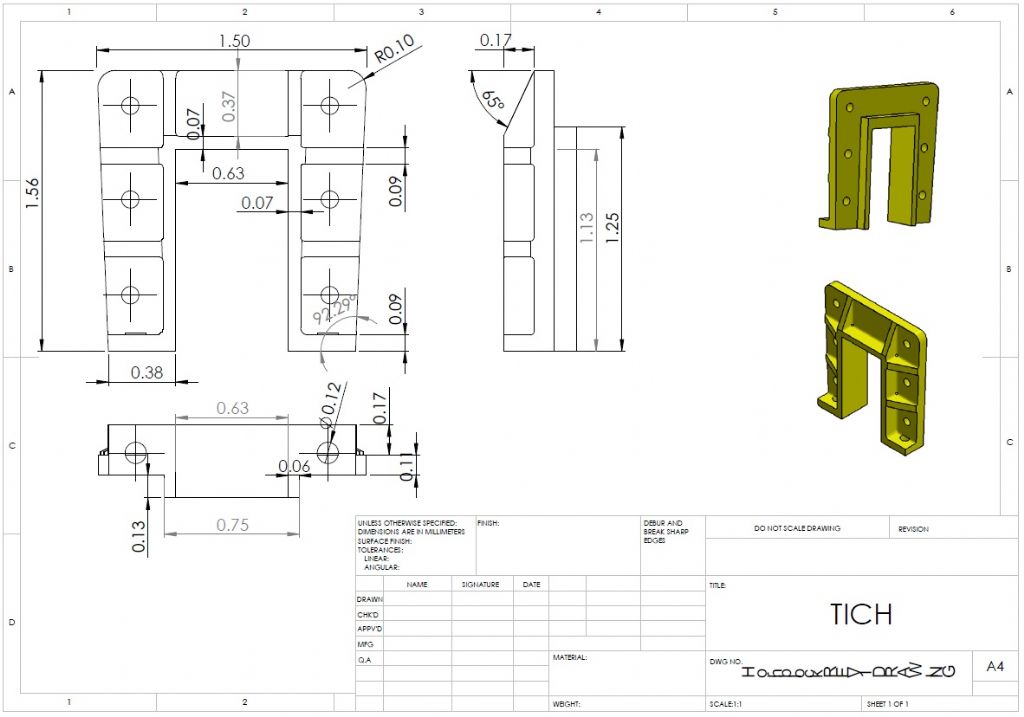

I had a look at my little large boilered slip eccentric Tich when putting her away for the winter; axle boxes (hot pressed brass, from Reeves decades ago) are fine; rod bushings are ok, the worst is the slip eccentrics where they join into the cross-frame swinging link (whatever it's called)

I would not worry about it. My little Tich runs like you would not believe, despite wearing in. I think it'll outlast me – especially as, with the Wesh Coal I use, the tubes, grate, etc plugs up and I need to stop and clean the fire out after a few laps.

My Tich (or, maybe all Tiches) are not a run-all-day locomotive, which suits me fine – run for a bit, natter with the natives, clean the locomotive (lift it up by front buffer, shake, put it back on rails) and then run again.

What you may want to do is to ensure that you lubricate the axle boxes in the horns; generally I over-oil, but better that than under-oiling.

Another JohnS.

Phil H1.