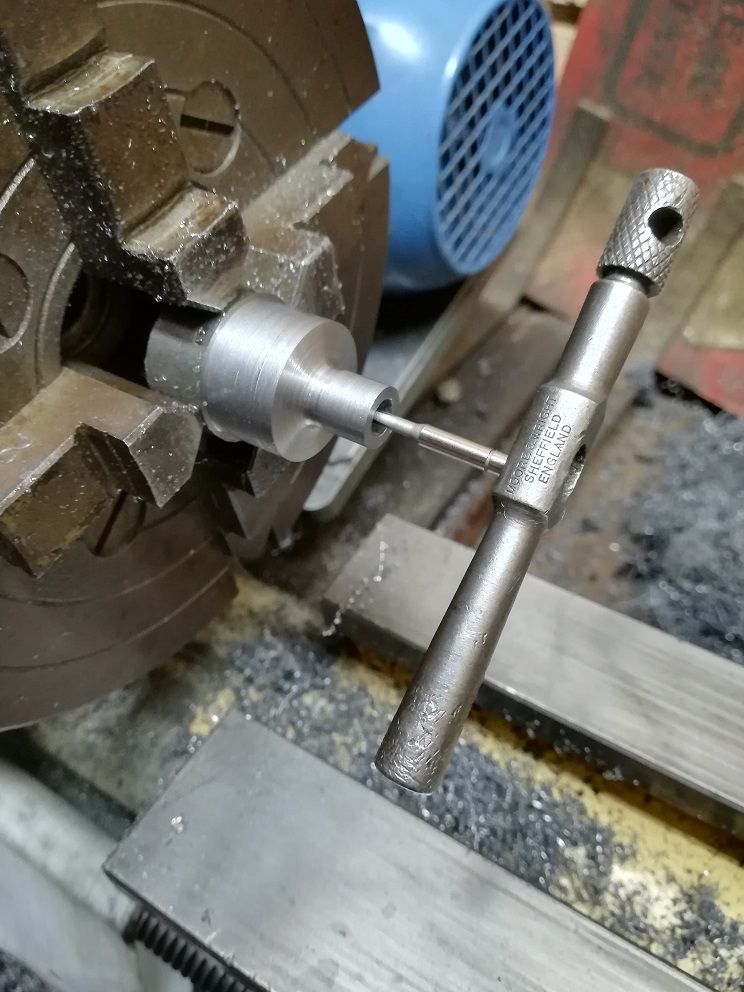

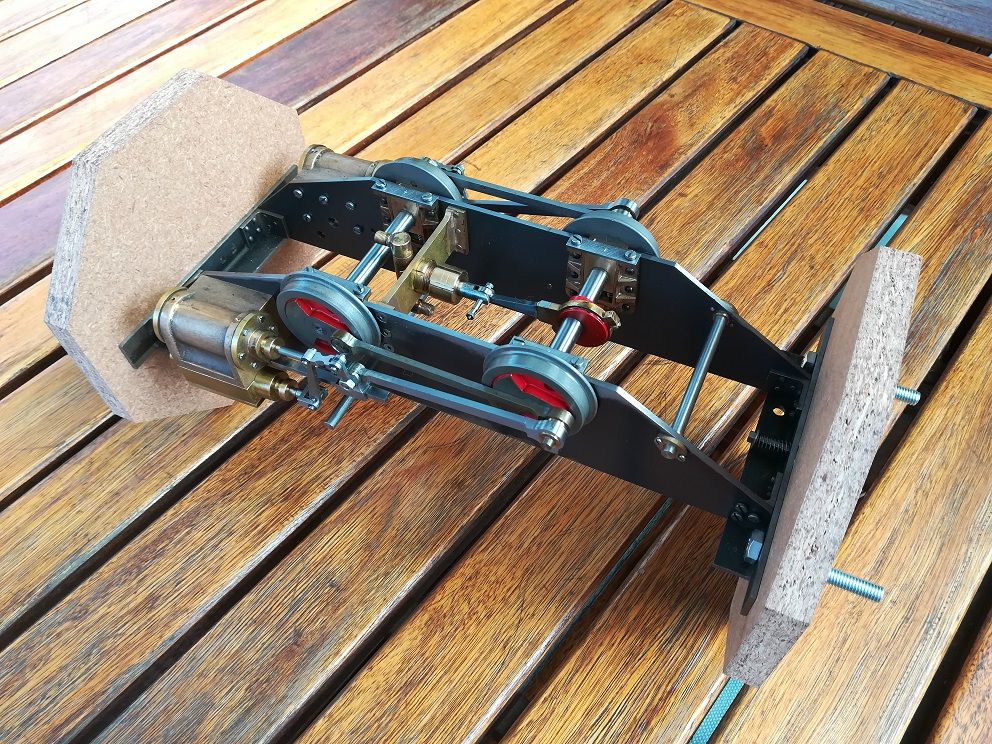

3 1/2 inch small boilered TICH

3 1/2 inch small boilered TICH

- This topic has 302 replies, 38 voices, and was last updated 16 April 2023 at 12:11 by

Phil H1.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- ML10 backgear

- Chucking Money Away!

- Boxford lathe & vertical mill VFD conversion help with start stop

- Speed camera

- Twin Engineering’s heavy mill/drill quill removal

- New member

- Amadeal AMABL210E Review – Any Requests?

- The Perpetual Demise of the Model engineer

- Colchester Chipmaster Clutch question

- Advice moving 3x machines