OK, progress of some sort, albeit perhaps a bit of a cop out. I discovered by accident, amid the day's searching for VFD connection info, an extension cable and mount for the control panel on the inverter – £12 delivered on ebay. With that mounted on a small tv lever arm which I have, and the inverter further away on the wall in a wall box, that's almost me sorted for the time being.

I'm struggling to find the emergency stop parameter, tho P58 ('Multi function input,' SP1), option 5 does say 'Emergency stop'; P12 ('Stopping modes' ) option 3 has 'Emergency brake' (alongside Inertial stop, Deceleration stop and Brake stop options); and finally, p50 (Multi function input 1 X1 binding post' ) seems to have option 19, 'Emergency stop' ('seems', as the layout is confusing and p51-55 appear to occupy the same space as 50).

So I'm confused as to which is the parameter I need to set – I'm assuming the Estop button is wired as per any external stop button?

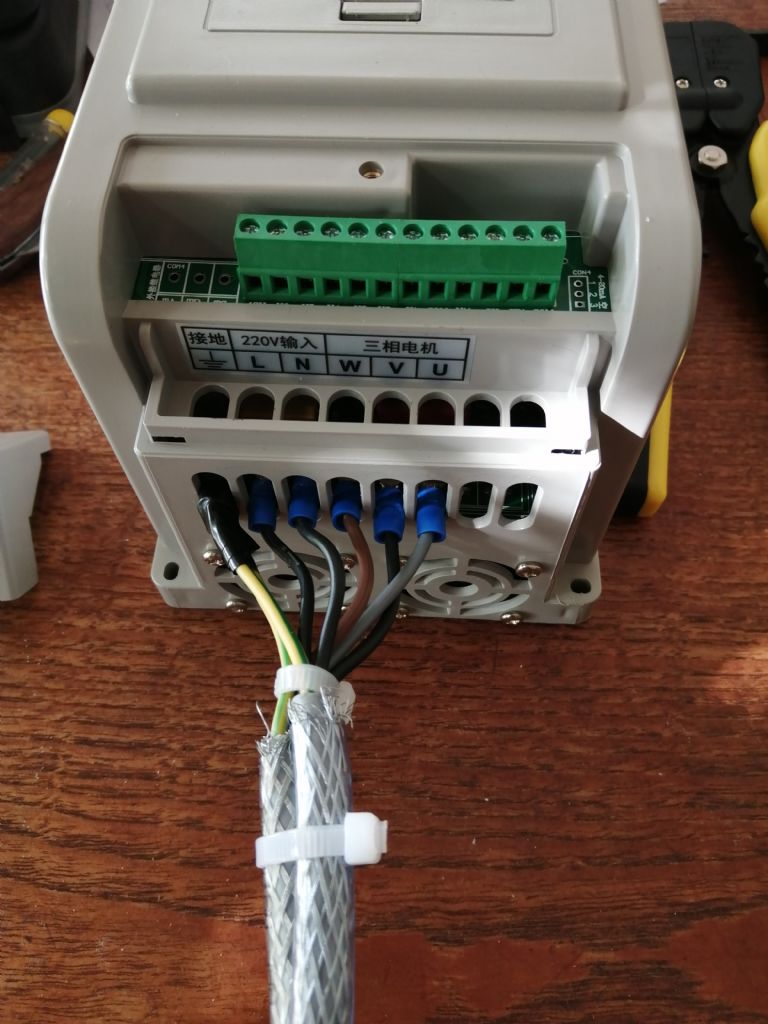

Finally, reading around the net on metal enclosures for VFDs I read that the metal enclosure needs to be earthed – any suggestions as to which earth cable from the VFD connects to the box?

Apologies for so many very basic questions.

Edited By Chris152 on 25/08/2023 22:07:15

noel shelley.